The great thing about woodworking is that there are a million ways to achieve the end result. Whether you’re a hand or power tool woodworker, 3D printing can make your work more accurate, faster, and often safer.

Of course, the best tool is the one that perfectly fits what you’re trying to do, and the main benefit of 3D printing in any workshop, including woodworking, is the ability to make that exact tool. Designing your own tools, jigs, or accessories for your other tools can really supercharge the capabilities of your workshop. Whether copying existing tools that have evolved to near perfection over hundreds of years or creating completely new tools with the geometries that additive manufacturing allows for, you’re sure to find something to use in your workshop.

Not everyone has the time to design and perfect custom tools, but fortunately, many designers who have designed custom tools have posted their designs to repositories. In this article, we share some of our favorites. These primarily focus on power tool woodworking (no router planes here), but most of the designs could be handy in a hand tool workshop as well.

If you see something you like, but your 3D printer is currently out of commission, try Craftcloud. With a wealth of material, color, and finish options, you can order prints to your specifications and have them delivered right to your doorstep.

Marking Gauge

A marking gauge is essential for laying out your work. Although they’re easy enough to make for experienced woodworkers and are somewhat cheap, finding one that you trust can be challenging, especially for a new woodworker who isn’t sure what to look for. This design, as well as several others by the same designer, will get you started with minimum fuss.

The design boasts simple one-handed operation with a tapered spring pin providing tension to lock the measurement in place instead of a thumb screw. The sole of the marking gauge has two versions: a simple square and a version with an elongated handle.

Printing the model is simple, but the tolerance on the fine taper for the locking spring pin is critical. It may take some trial and error to get it to clamp just the way you like it.

- Who designed it? agmcmll

- How printable/popular is it? This marking gauge has eight posted makes combined from both sites.

- Where to find it? Printables, Thingiverse

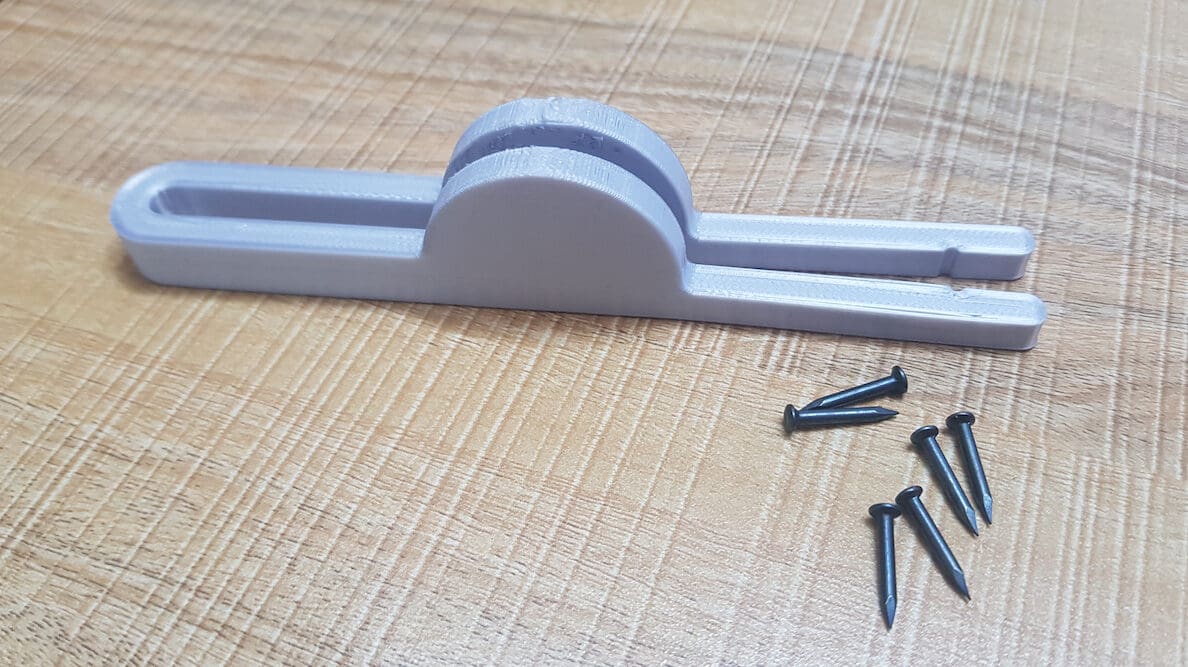

Nail Finger Protector

If you’ve ever had to work with small nails, then you know how painful it can be. To save yourself the frustration – and potential injury – while working with these nails, consider printing yourself a finger protector. This print will hold your nail straight up while you hammer it into the wood, keeping your fingers a safe distance away the entire time.

This quick print can save you a lot of time, especially if you have multiple nails that need to be hammered in. The designer created 11 different models, one for each of the most common nail sizes. They even left a chart to help you decide which file is right for you!

Sanding Block

Getting a nice finish on your wood using sandpaper can be tough with just your hands; that’s where a sanding block comes in. This tool will make sure that you’re sanding evenly across your wooden surfaces and leave them flat and smooth. Sanding blocks are great because they can take any type of sandpaper you have on hand.

This model, in particular, requires no additional hardware to keep your sandpaper in place, using printed threads instead. If this design doesn’t suit your needs, there are plenty of different sanding block models available. The best part about 3D printing a sanding block is that you can scale one to be the perfect size for whatever job you have in mind. You’ll want to make sure to use upwards of 25% infill to keep this tool from breaking during use.

- Who designed it? gumo_design

- How printable/popular is it? This is a popular design with over 14,000 downloads. In addition to the 18 makes, 3 remixes have been shared that add even more versatility.

- Where to find it? Thingiverse

Bench Dogs

Bench dogs are a necessity if you’re working on pieces with awkward shapes, as they allow you to hold your wood in place without fear of it coming loose. This specific design utilizes large wooden dowels to hold the bench dogs in place, as opposed to a fully printed version that may not hold up to the forces applied.

This method is a lot cheaper than having to purchase a new set of bench dogs and gives you a good base model to remix if you ever need a different shape or size. The designer used PETG for their prints, though you can use ABS or a CF blend for a little more strength. You might even be able to get away with using PLA for smaller projects.

- Who designed it? MeisterEdel

- How printable/popular is it? This tool has been downloaded almost 300 times combined from both sites. You can be the first to share your make!

- Where to find it? Printables, Thingiverse

Miter Box

While it’s possible to cut perfectly square by hand, it takes a fair bit of practice and patience. If you just want to knock something up quickly, you’ll want to use a miter box.

We like this version because it’s versatile with the removable V-block bottom, allowing for either square or round items to be cut. It’s strong, as the three cut lines don’t meet in the center – unlike some other miter boxes. While it’s not very big, it could easily be scaled.

Each part of the print is simple, but as with so many of the tools on this list, make sure that the first layer sticks.

- Who designed it? Mox

- How printable/popular is it? The model has no posted makes but has been downloaded around 170 times.

- Where to find it? MyMiniFactory

Speed Square

How do you check that those cuts you made with the miter box are actually square? This simple speed square will do the trick. These tools are for quickly laying out your cuts or checking square construction during assembly.

This model comes in both metric and imperial, so you can have your preference. Given that an aluminum speed square can cost anywhere between $5 and $75, a 3D printed speed square could be the way to go if you need something that might end up being sacrificed to the project.

This is a long, tall print with all the challenges that brings. Further, if you have a lot of Z wobble or your motion system isn’t calibrated, this tool may not be as accurate as you want.

- Who designed it? PPep54

- How printable/popular is it? This popular model has 12 posted makes and 1 remix.

- Where to find it? Thingiverse

Dowel Jig

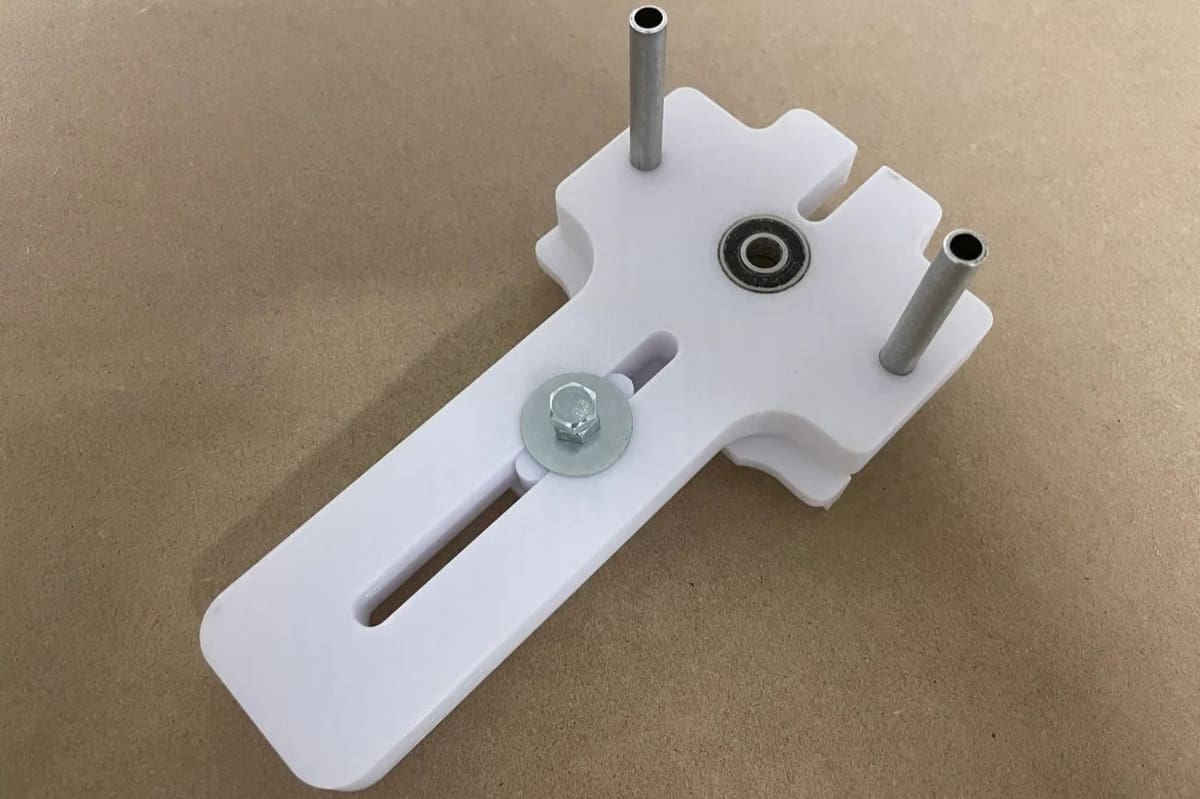

When it comes to woodworking joints, you can’t go wrong with dowels. The only issue is lining up the holes so that your project doesn’t look like a dog’s breakfast. There are a lot, possibly thousands, of dowelling jigs available – each with pros and cons.

Although we’ve tried several, we’ve found that this simple one makes dowelling a breeze. Popularized by the Men’s Craft YouTube channel, the design has been adapted by multiple people for 3D printing.

The Printables version is more true to the original, but there’s a model on Thingiverse that removes the need for additional hardware. Be aware though, the Thingiverse model has some thin pieces that are prone to breaking. The Printables version replaces the thin areas of the print with metal tubes or wooden dowels, adding complexity to the build but resulting in a much more robust tool.

The print is very straightforward but does have large flat pieces, so once again, make sure your bed adhesion is on point.

- Who designed it? Tonitwn

- How printable/popular is it? While only 2 makes have been shared so far, the model has around 230 downloads and counting.

- Where to find it? Printables

Router Lifter

If you’ve tried hand routing a rabbet or the slot for a draw bottom, you know how hard it is to keep the bit moving in a straight line – no matter how many guides you use. The solution to this is a router table with an adjustable fence. This brings up one small problem: In order to adjust the depth of your cut, you must reach under the table and press the router up against gravity while simultaneously measuring the protruding bit above the table.

Enter the router lift. The most high-end units have a scale on the mechanism that allows you to measure the change in depth as you move the bit up and down. Those units cost upwards of $600.

This 3D printed model may still need a ruler to set the height, but you can print this for less than the cost of a spool of filament. It’s designed for a 65-mm router. Before you invest in a high-end unit, give this print a try.

- Who designed it? Aldo

- How printable/popular is it? The model has been downloaded around 240 times, and there’s a posted make. The designer also posted a video tutorial to aid with assembly.

- Where to find it? Printables

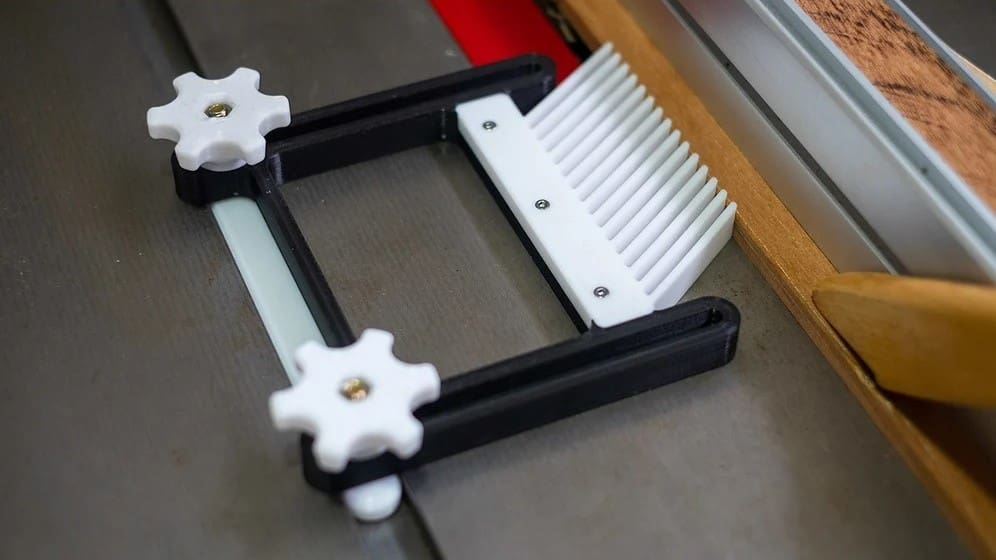

Featherboard

If you built a router table with the previous design, you may have noticed that your fingers can come scarily close to the sharp parts of the tools while they’re moving fast. This could go wrong very quickly.

To avoid hurting yourself, you might want to print out some of these featherboards. If you mount a featherboard on the fence, the featherboard can hold your workpiece against the fence and table as you slide it through, moving your fragile hands away from the sharp spinning thing while allowing excellent control of the stock. Oh, and the featherboards also prevent kickback by being raked in the direction of work.

This particular version is reversible and allows you to swap out the feathers if you break one or the work calls for lighter or stonger workholding. There is even a camlock version for situations where you really can’t afford the workpiece backing out. In terms of printing, it should be very straightforward, but the model is large and flat, so make sure your bed adhesion is dialed in.

- Who designed it? scaryPug

- How printable/popular is it? The model has 3 makes and nearly 900 downloads.

- Where to find it? Thingiverse

Dust Collection Coupling

You know that feeling you get after a big woodworking project, right in your chest as you look at your handiwork, and it gets hard to breathe? That can be fixed by using appropriate dust collection – and by wearing a mask. Yes, you need to do both. Remember, you’re only getting one set of lungs.

The only problem is, every tool you have and every shop vac or dust collector seem to have different fittings. With this design, you can easily move your suction hose from machine to machine without the need to go through spools of duct tape.

One side is fitted to your suction hose, and the other to each of your tools that have a dust port. The suction hose is held to the tool magnetically. There’s also a link to the design on Onshape. Built using variables, you can easily tweak the design to suit your tools.

While the designer indicates that they used PETG, our experience with air handling equipment tells us that a resin print might do better in this situation.

- Who designed it? fish_taco_pirate

- How printable/popular is it? The model has been downloaded around 210 times and around 80 people have liked it, although no one has posted a make yet.

- Where to find it? Printables

Drill Stop

Drilling a blind hole can be tricky. While you’re holding the drill bit square to the work and not letting it wander, you’re also trying to prevent the bit from driving too deep or through the workpiece. Many people will put tape at the appropriate depth, providing a visible indication of when the hole is deep enough. A physical stop, however, is so much easier.

Unfortunately, most commercially available drill stops either attach to the side of the drill – making them useless for anything other than the center of a flat surface – or they use a screw to clamp a piece of metal to your drill bit. This means the stop might not be square to your drill bit and may also damage the flutes.

Luckily, this design clamps to the bit by closing the center hole diameter. This ensures the stop will be the right size for your bit to fit snugly and squarely. The design is also parametric; an OpenSCAD file is included for those who want to make changes.

Printing-wise, this is very straightforward. Keep in mind that you’ll need a separate model for each drill bit diameter you want to use it with.

- Who designed it? ksuszka

- How printable/popular is it? There are 11 posted makes of this design so far.

- Where to find it? Printables

Trigger Clamp

So, you’ve cut and shaped the pieces of your creation, and it’s time to glue. (They say woodworkers can never have enough clamps, and when it comes to gluing, that certainly rings true.) But you’re short just one clamp, and it doesn’t need a ton of clamping force. It might be time to print one (or more) of these quick trigger clamps.

Clamps of this style are exceedingly useful, as you can hold an item in place with one hand while you clamp with the other. They’re not limited to woodworking either. They can also be used to hold ropes for camping, metal for metalwork (watch that temperature, though), as well as many other applications.

The multi-part design is based on the injection molded version you can buy at most hardware stores. You’ll need some springs to make the whole thing go, but you most likely have some lying around in that old Creality extruder. The Thingiverse listing has tips for print orientation and supports.

- Who designed it? Arron_mollet22

- How printable/popular is it? The model has 11 posted makes as well as a remix.

- Where to find it? Thingiverse

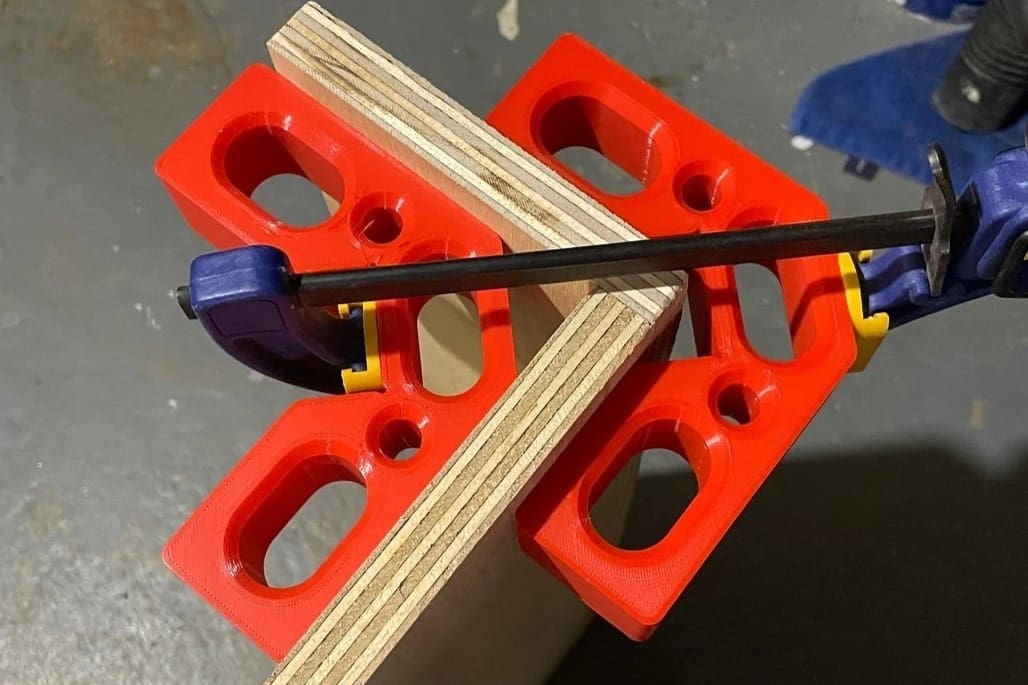

Corner Clamp

So, you’ve made the clamp but realized that you have no way to clamp your project together squarely. Well, corner clamps are usually the way to go. Simply print out the size you need – there are 32 to choose from – and away you go.

The design includes multiple locations for clamping, including flats for setting a single clamp at 45 degrees across a corner. You’ll want to use a lot of shells and some fairly high infill and adjacent settings, as the force these will experience can be quite significant.

Given lots of walls and infill for strength as well as sheer size means your machine may be running for quite some time.

- Who designed it? TheRedcoat

- How printable/popular is it? These clamping squares have 229 posted makes as well as 3 remixes.

- Where to find it? Printables

Wood Cabinet Locks

These wood locks were designed to assist in building cabinets for a garage. The locks will hold two pieces of wood at a 90-degree angle to each other to help you better visualize your project. They can even be used to keep all of your pieces in place while you mark any changes you want to make to your design before assembly.

The lock uses M8x50 countersunk screws to attach the prints together. They’re capable of holding any type of wood that’s between 15 and 20 mm in thickness. Due to the stress that these locks will need to withstand, tougher materials such as PETG or ABS are recommended.

- Who designed it? Tavo

- How printable/popular is it? Combined from both sites, over 300 people have downloaded the model so far, with more than 60 liking it.

- Where to find it? Thingiverse, Printables

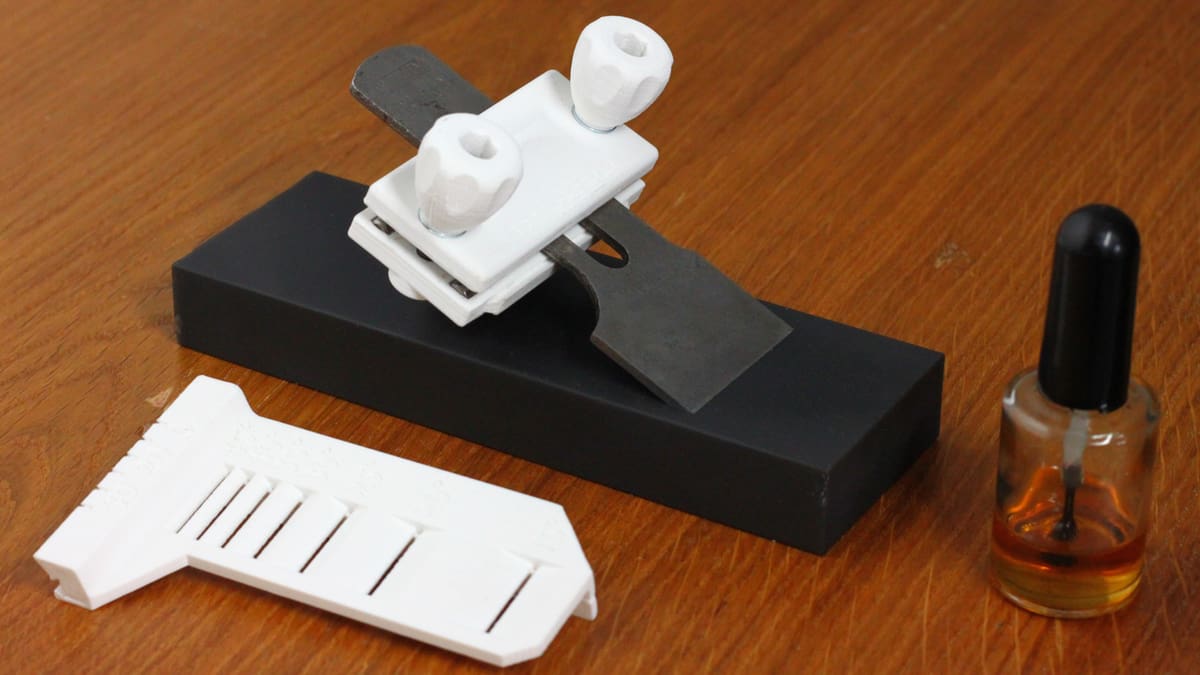

Chisel Angle Guide

Keeping your chisels sharp is important if you want them to perform consistently between your projects. The process of actually sharpening a chisel requires you to keep the blade at a constant angle to avoid changing the intended angle of the chisel blade. These types of guides usually cost quite a bit for a decent set.

This print looks to solve this issue by providing you with a modular sharpening guide. This model can take any blade up to 50 mm in width. It has a range between 15 and 45 degrees, with 5-degree notches in between so you can choose the perfect angle for any given chisel. While the print does require metal inserts for some additional strength, the designer made sure to include all of the necessary hardware in the description.

It should be noted that the model costs ~$5, yet that’s significantly less than the price tag for a purchasable option.

- Who designed it? Bricosoluce

- How printable/popular is it? This model is a rare find. It may only have around 10 downloads at the moment but the accompanying YouTube video showcases the print’s effectiveness.

- Where to find it? Cults

License: The text of "3D Printed Woodworking Tools: 15 Must-Have 3D Models" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.