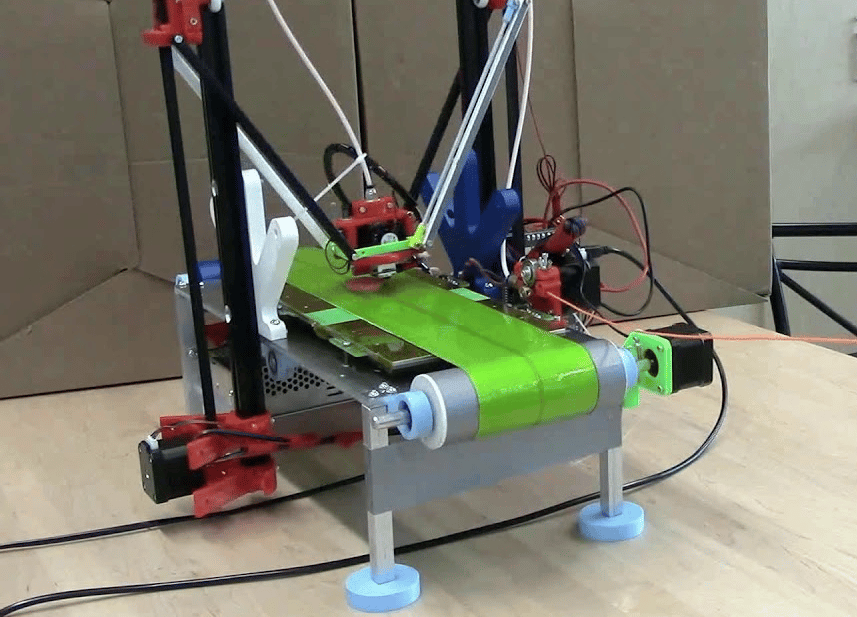

If you’ve never heard of belt 3D printers, that’s because they haven’t been around that long. The first generation came about with the Blackbelt printer in 2017.

Since then, many new companies, as well as hobbyists, are exploring the idea of a 3D printer that utilizes a belt bed. 3D printing forums and other media platforms (such as YouTube) have also helped to spread this idea.

Using a belt as a bed means you can 3D print continuously, whether to produce many regular-sized models or one, extremely long part. That’s the basic idea, anyway.

In this article, we’ll go more into how this type of printer works, how it’s different from other printing styles, and the pros and cons of using one. Then, we’ll highlight a few examples of belt 3D printers that are available for purchase, what slicer you could use, and finally, look at the future of this special 3D printing style.

How Does It Work?

Printing for an infinite amount of time sounds unbelievable, so let’s demystify some key components that make belt 3D printers unique.

Technology

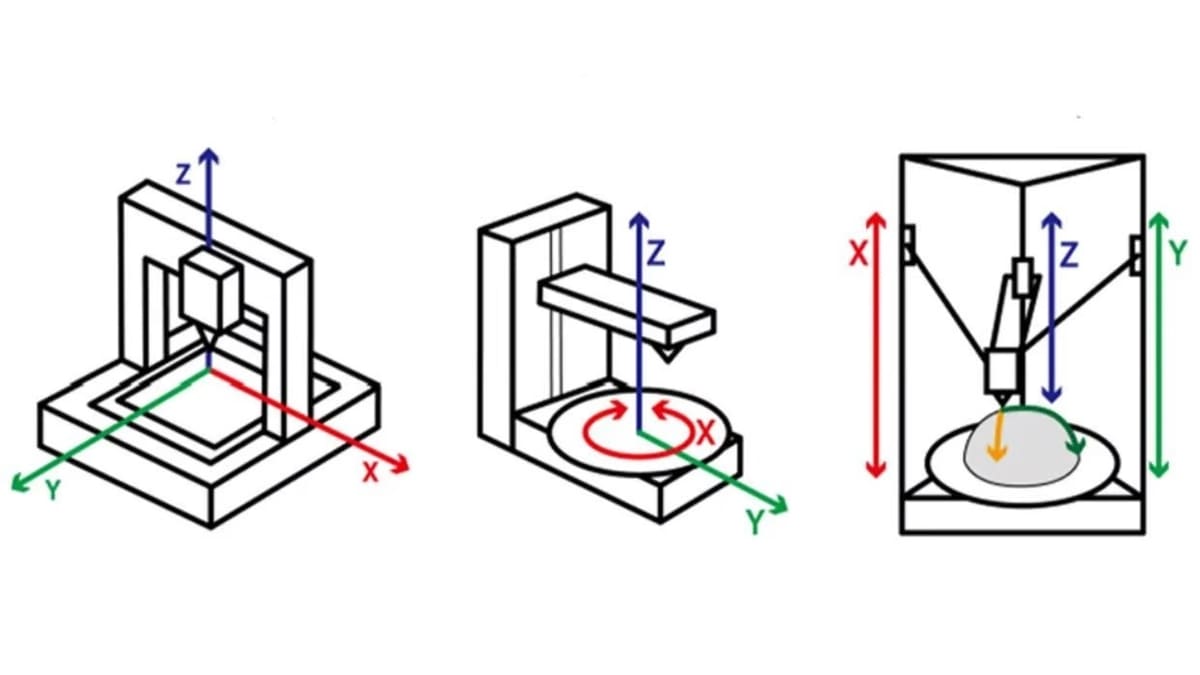

Belt 3D printers use fused deposition modeling (FDM) to print, but this isn’t your standard rectilinear, delta, or even polar printer: It’s a relatively unique technique that has no other name than “belt 3D printer”.

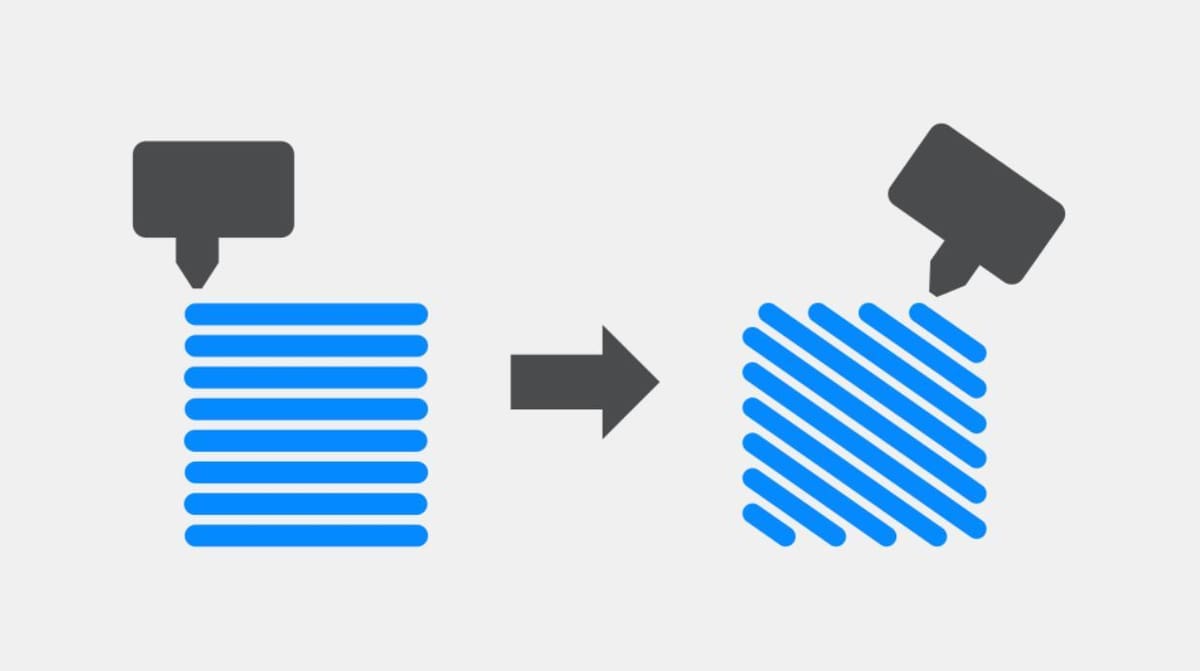

Two basic principles make the belt 3D printer possible: tilting the nozzle and replacing the bed with a belt. In theory, the former could take any existing rectilinear setup and tilt it, but what’s most common is a Cartesian-XY-head motion system with the bottom of the ‘H’ (formed by the belts) rotated down towards the bed.

Axes

Considering that the hot end is suspended from a tilted box-style frame, the axes become a little more complicated. The X-, Y-, and Z-axes must always be perpendicular to one another, but the belt printer’s frame is no longer perpendicular to the bed!

So which component do we attach the coordinate system to, the frame or the bed? Mathematically, either is fine (it’s all abstract anyway), but because belt printers are claimed to have an “infinite Z-axis”, we’ll go with the frame.

What this means is that the horizontal or XY-plane is considered to be aligned with the nozzle’s field of movement, while the belt (again, relative to the frame), moves in the both the Y and Z directions.

So, how is it possible to 3D print infinitely? Won’t prints eventually fall off the belt? Well, as long as you have some form of support, whether it’s a set of rollers at the end of the print bed or a platform at the height of the printer, you can theoretically print infinitely. The idea is to prevent gravity from pulling a long print off the belt if it goes a certain distance beyond the “end” of the bed. Check out this video of a belt 3D printer printing something longer than the bed:

Belt 3D printers also allow for mass producing smaller parts. They’re able to do this as long as a method is employed to automatically remove remove prints from the belt. (Or they may fall off naturally).

Bed Adhesion

Bed adhesion for this kind of printer can be a bit tricky, as fully-heated conveyor belt beds aren’t a thing as of now. However, painter’s tape or glue stick works well. Or, you can look for specialized PTFE-coated beds that are found on printers like the IdeaFormer IR3, which provide a nice, sticky surface for better bed adhesion.

How Does It Compare?

As you’ve probably figured out, belt 3D printers are mostly in a category of their own. Mechanically, they’re not too different from other rectilinear printers, but using them is markedly different.

Because of their unique features, belt 3D printers are especially suited for automated or semi-automated production. Technically, they also have the largest print volume capacity for a 3D printer because of the “infinite Z-axis”.

Generally speaking, a belt printer takes up a lot of space. The machine must be large enough to accommodate a belt, belt rollers, the tilted frame, and the other components associated with a belt 3D printer, like structures to support prints that are longer than the bed.

Pro & Cons

Belt 3D printers have some major benefits, but they also have some disadvantages.

Pros

- Offer “Infinite” 3D printing for mass production or very long parts

- Compatible with PLA and PETG

- Offer painless, automatic print removal

- Can support partially-heated beds

- Can maintain average print speeds

Cons

- More expensive on average

- Require additional support structures for infinite printing

- Incompatible with many materials, including ABS

- Can’t support standard heated beds

- Can’t support glass print beds

- Can’t maintain high print speeds

- Often yield lower-quality prints

- Still in development

- Little community support for purchased machines

Examples

We’ve brought together a showcase of the most popular belt 3D printers out there today.

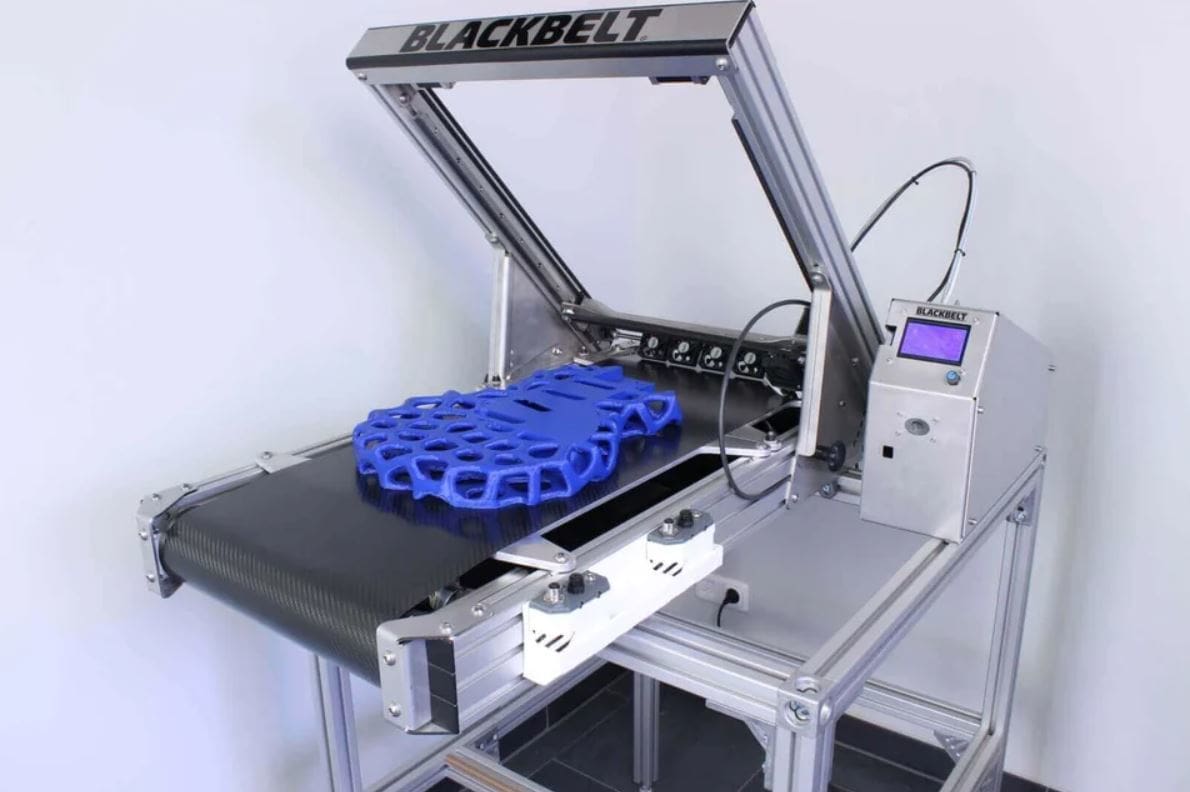

Blackbelt

Our first belt printer example is the famous Blackbelt, the pioneer of belt FDM 3D printing. It was produced by Blackbelt 3D, a Dutch company whose stated goal is to encourage innovation in 3D printing.

The Blackbelt is regarded as the best belt printer out there, but it has a price to show it too, costing over $10,000. However, some people, or more likely companies, think the price is worth it due to the Blackbelt’s many high-quality features.

For example, the Blackbelt has a large XY build area with an optional configuration to get the printer in a table setup. The electronics, such as the motherboard and power supply unit, are also located in a separate box, making the frame of the machine even larger. To accommodate smooth printhead motion for large prints, the printer comes equipped with linear rails and tons of fans.

- Purchase or DIY: Purchase

- Price: ~$12,500

- Pros: Extremely well-developed, looks great, produces high-quality prints, large print area, high printing temperatures, semi-heated bed

- Cons: Extremely expensive, heavy, large frame

IdeaFormer IR3 V2

IdeaFormer may not be as well-known in the 3D printing industry as brands like Creality. However, they specialize in belt printers, which allows them to dedicate their efforts to perfecting this niche technology. This focused approach makes them a strong contender in the belt printer market.

After the IR3 V1, the IR3 V2 had a successful Kickstarter campaign.

The second version of this printer uses linear rails for the X- and Y-axis and has a Core-XY motion system. Combining these with Klipper firmware, which is known for its sprinting capabilities, IdeaFormer claim print speeds of up to 400 mm/s with an acceleration of 20,000 mm/s2. This puts it almost on par with many modern printers that boast similar speeds.

The stock all-metal hot end comes with a special nozzle that’s customized for the 45° printing angle – which means it can’t be easily replaced. That said, two replacements are included, and when it comes to performance, it can go up to 300 °C. The printer has a heated bed (up to 90 °C) made out of PEI, which provides adequate adhesion for the first layer.

The maximum build volume is 250 mm x 250 mm x whatever length you’ve got in mind. That is, unless you want to make use of the high printing temperatures for materials like ABS and nylon, for which you’ll need an enclosure – which IdeaFormer also sell.

Among the biggest improvements over the V1, the V2 includes automatic bed leveling, which makes the overall experience more user-friendly and easy. Lastly, IdeaFormer IR3 V2 comes with the standard modern features such as a touchscreen, a filament runout sensor, and remote control over Wi-Fi with live camera feed monitoring.

- Purchase or DIY: Purchase

- Price: ~$900

- Pros: High speed printing, Core-XY motion system with linear rails, PEI belt with heated bed, touchscreen, Wi-Fi, live camera monitoring

- Cons: Included camera doesn’t come with a mount, doesn’t have a big user community

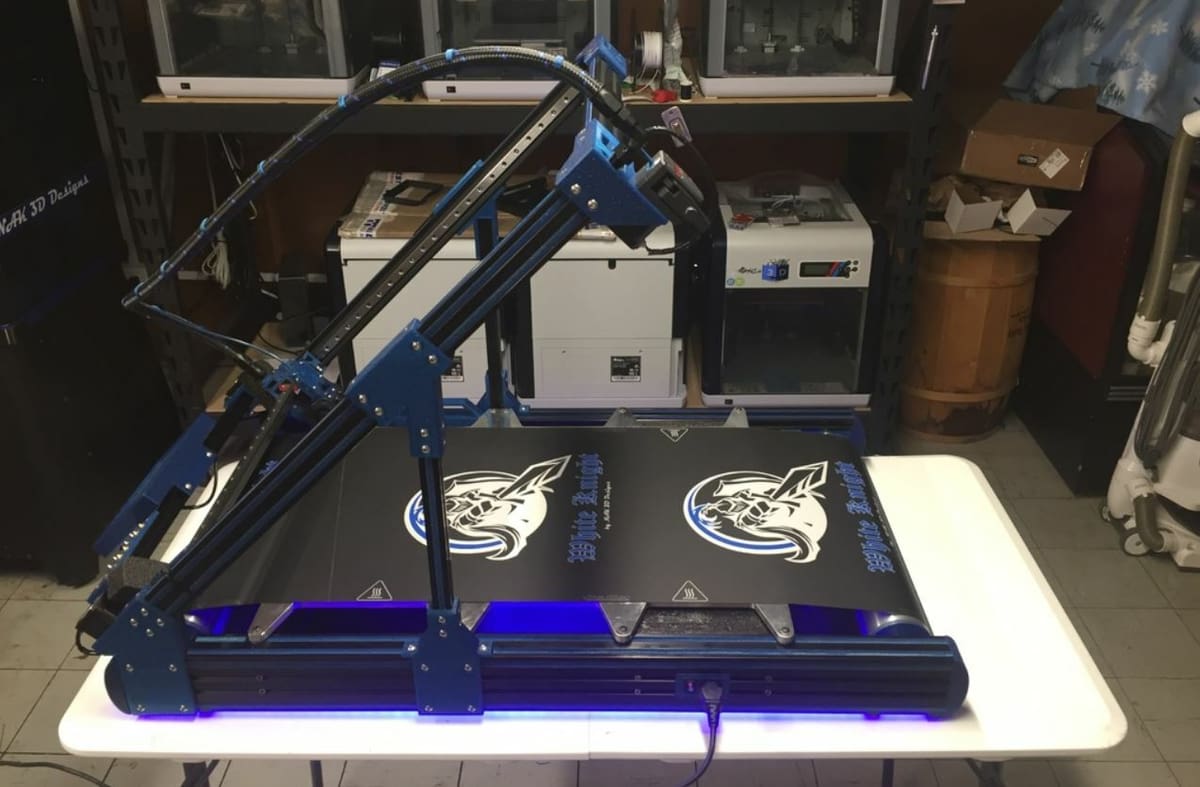

The White Knight

Next, the White Knight is an open-source belt 3D printer project developed by NAK3DDesigns, which also helped create Creality’s now discontinued 3DPrintMill (CR-30). The printer uses many 3D printed parts and other hardware, which reduces its cost (about $2,000) while still giving you a very large and sturdy frame among other features.

As a DIY project, you’ll have to gather all of the parts and assemble them yourself. While this won’t be a walk through the park, there’s a large community behind the project that can assist in your build process.

Some of the features on the White Knight include linear rails for super-smooth printhead motion, a BondTech extruder for consistent filament flow, and a high-temperature hot end. Sadly, it’s known to be pretty difficult to level the bed, which also isn’t heated. With no bed temperature capabilities, you’ll likely be restricted to printing only PLA filament.

- Purchase or DIY: DIY

- Price: ~$2,000

- Pros: Very developed with a lot of community support, sturdy frame, large print width and height

- Cons: No heated bed, minimal bed leveling options, expensive

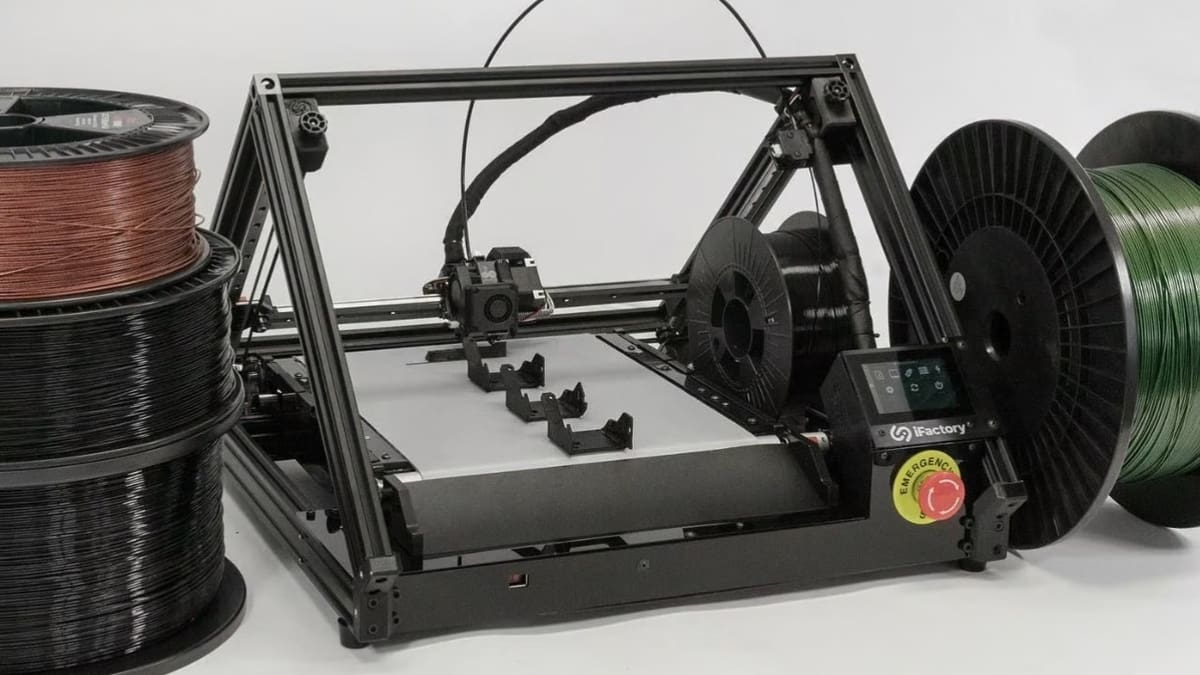

iFactory One Pro

Shortly after Creality launched their 3DPrintMill Kickstarter campaign, a small start-up company also caught the eye of many interested in lower-cost belt 3D printers: iFactory 3D. The iFactory One also launched on Kickstarter, but after its official release, iFactory3D replaced it with the iFactory One Pro, a version with upgraded specs and more features.

The iFactory One Pro costs around $4,800 and is loaded with some very unique features, such as its onboard camera that monitors your printer and ensures your prints are running smoothly with AI-enabled failure detection software. The printer has a high-temperature, dual-gears, and direct extrusion E3D Hemera printhead, which should provide reliable and precise extrusion. Also on the machine are linear rails, a Duet3D motherboard, a touchscreen LCD, and a Wi-Fi-enabled Raspberry Pi 4.

If you want a bit more material compatibility or want to up have a setup that includes an enclosure, iFactory has a solution. The corresponding enclosure will set you back around $500, which could well be worth it as a DIY option would be a lot more challenging. It’s also worth mentioning that you have to do a decent amount of assembly to get this printer up and running.

- Purchase or DIY: Purchase (extensive assembly required)

- Price: ~$4,800

- Pros: Powerful direct extruder, high-temperature E3D hot end, 32-bit Duet3D motherboard, touchscreen LCD, Raspberry Pi 4 for Wi-Fi connectivity, linear rails for smooth motion, AI failure detection available, large XY area

- Cons: Expensive, assembly required

Slicer Support

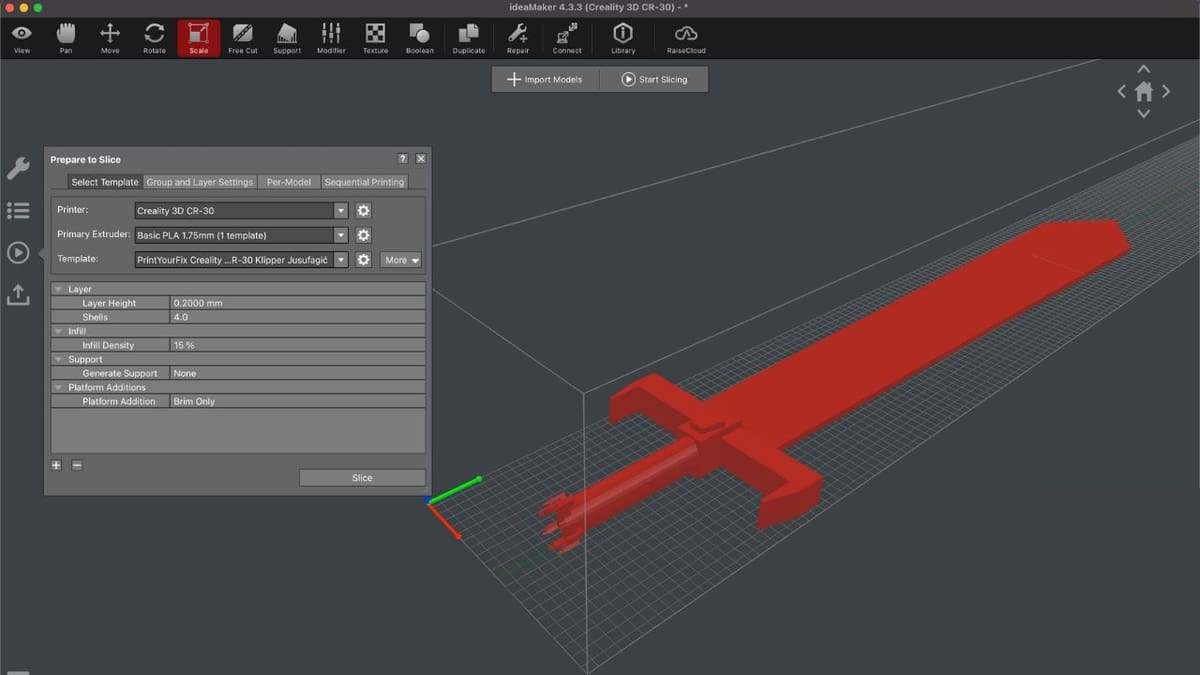

Belt 3D printers are still a relatively uncommon type of 3D printer. However, in recent years, software support has significantly improved, giving users more options than ever.

One reliable slicer is Cura, one of the best and most popular slicers available. Blackbelt has developed its own version of Cura, called Blackbelt Cura 3.6, which works not only for their printers but also for non-Blackbelt belt printers. However, it’s worth noting that this version is somewhat outdated, as the latest release of Cura is currently version 5.9.

A decent alternative to Blackbelt Cura can be ideaMaker, which now supports belt 3D printers. This slicer has been gaining traction for its features and intuitive user interface.

Another option is Kiri:Moto, a browser-based slicer that has support for belt printers along with various other types of 3D printers.

Slicer Alternative: G-Code Script

There is another option, but it’s not a slicer; it’s a G-code script that you can add to the G-code after you’ve sliced your model (in any slicer). The G-code instructions can be found on Thingiverse, where you can download the script, as well.

Looking Ahead

At this point, other printing styles are more developed and more reliable because they have a flat nozzle on a heated bed. However, we’re pretty confident that belt 3D printers will improve with time.

While there may not be many budget printers of this style, that’s likely to change. As a comparison, the first 3D printers sold for over $100,000 back in the 1980s, and now a quality 3D printer can cost around $200.

Belt 3D printing technology should stabilize and improve, especially as more companies make their own belt printers. Increased prevalence of these printers should also mean more slicer support and options in the future.

License: The text of "Belt 3D Printer: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.