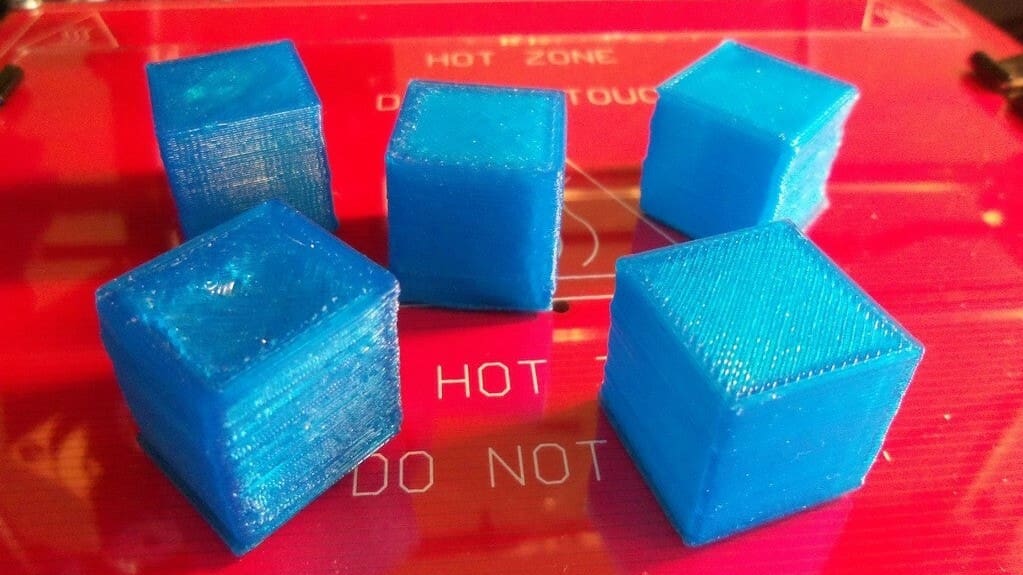

Calibration cubes are popular test prints for 3D printers. They’re simple geometric shapes – typically cubes – that help you fine-tune your 3D printer’s settings, achieving maximum precision and accuracy.

For assembly-required kits and lower-end machines, these cubes will be vital. With them, you can adjust your printer’s settings to produce precise, mechanical parts, despite the potential lack of factory tuning.

Let’s take a look at how you can use calibration cubes, along with our take on the best models you should try!

How to Use Them

There are many ways to use calibration cubes. Before we get started, however, be sure to calibrate your 3D printer’s extruder. This will ensure that any defects will be strictly mechanical and not caused by extrusion inaccuracies.

Once your extruder is calibrated, there are several things you can do with calibration cubes:

- Tune your steps/mm settings: These tell your 3D printer how much to turn each motor to complete a millimeter of travel. If you’re unfamiliar with your 3D printer’s motion system, calibration cubes will help you lock down on these settings. Our calibration guide takes you through the steps. If you understand how your printer’s motion system works, Prusa Research’s steps/mm calculator could also help you out with this.

- Tune your material settings: If your steps/mm is finely tuned, this will leave only the print material as a source of error. Bulging layers or gaps in prints are all indicators of poor extruder calibration, indicating that you should re-calibrate your extruder or adjust your flow rate. Consistently undersized prints indicate material shrinkage, so you should adjust your slicing software’s “shrinkage percent” setting; the deviation you experience divided by your desired dimension will be a good starting value.

- Fix 3D printer ringing: The sharp corners of calibration cubes will easily reveal ringing (or “ghosting”) artifacts, which can translate to poor surface finishes. Learn how to fix this problem in our ringing guide.

- Test for tolerances: Calibration cubes can be used to test for and improve your printer’s precision. This will allow for tighter clearances when 3D printing mechanical parts.

With that, you’re ready to start printing! Here’s our take on the top calibration cubes you can print today.

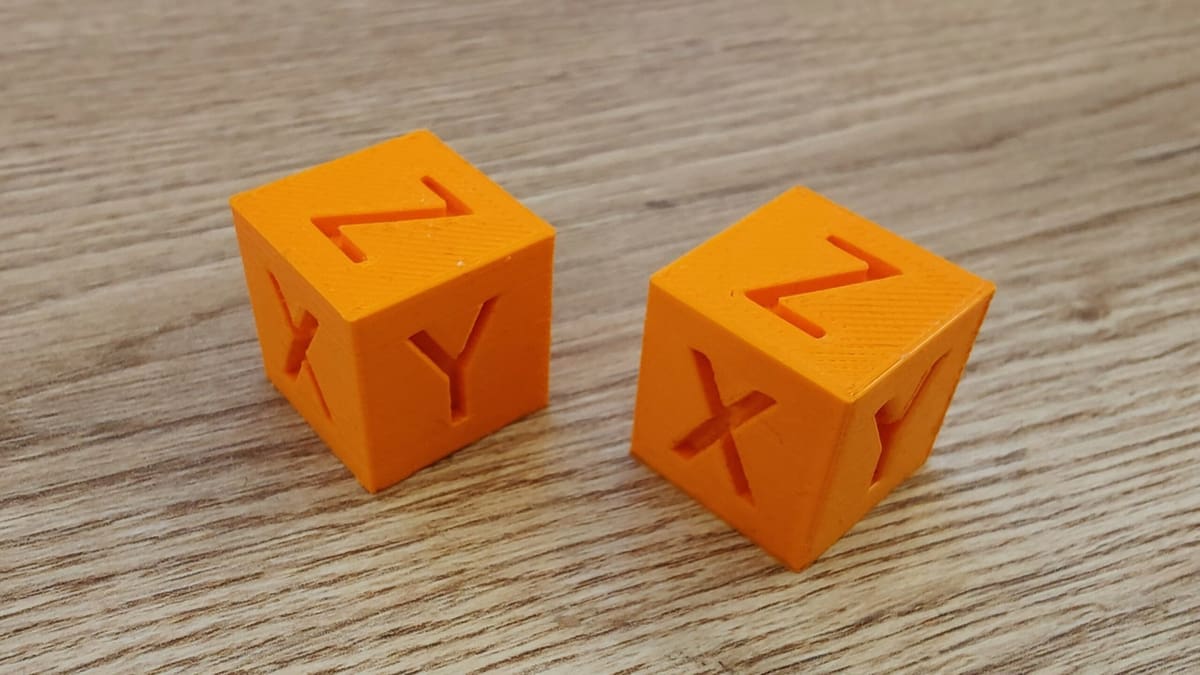

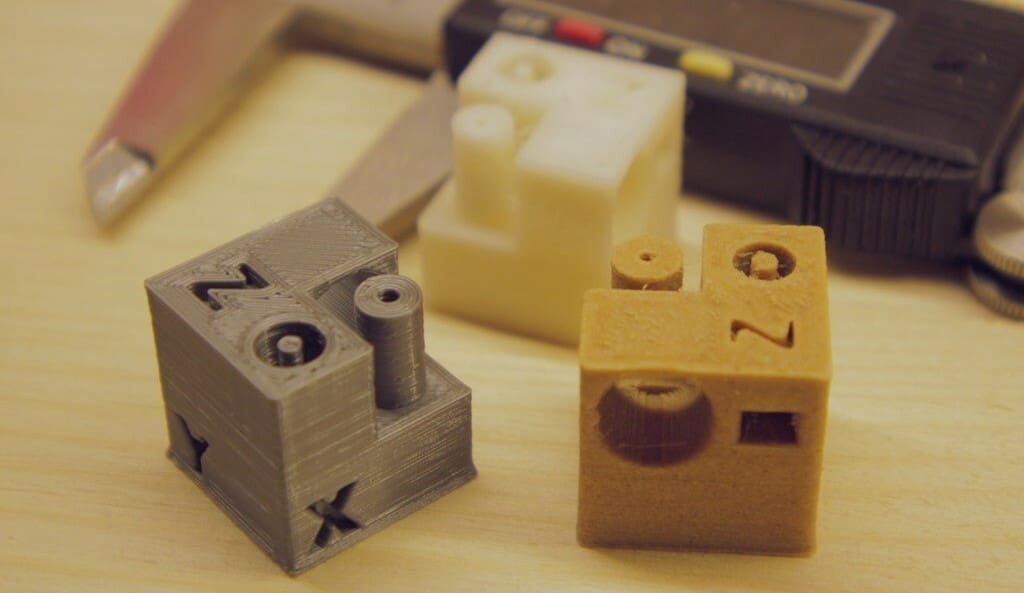

Classic

We’ll start with the basics. This is a simple 20-mm cube, with its faces labeled X, Y, and Z. It’s also the most popular cube on our list, due to its simplicity and ease of use. You should aim for the length of each side to be 20 mm and be sure to match the large letters with the axis they test. If you want to add even more usefulness to the cube, you can go for dice.

- Who designed it? iDig3Dprinting

- How printable/popular is it? This classic cube is the most popular option on our list, with well over 1,000 makes on Thingiverse. A dazzling range of printers and materials have been used for these makes.

- Where to find it? Thingiverse, MyMiniFactory, YouMagine

Dimensional Accuracy

This is an amped-up version of the classic calibration cube. It features four layers, at 25 mm, 20 mm, 15 mm, and 10 mm, with a notch at the front to indicate orientation. This is especially useful for identifying material shrinkage. If dimensions deviate by different amounts for each layer, you should correct the material shrinkage setting in your slicing software as described earlier.

- Who designed it? Make Magazine

- How printable/popular is it? This and other models have over 23,000 online downloads, and they were used in Make:’s rigorous annual printer shootouts, making this and its companion designs fierce contenders on our list.

- Where to find it? YouMagine

Flow

This handy cube has eight different models for various nozzle sizes. By measuring its wall thickness, you can calculate whether the flow rate is as indicated in the slicer or if adjustments are necessary. And don’t worry about the math too much, the creator included the equation and it’s a fairly direct one to follow.

- Who designed it? humebeam

- How printable/popular is it? The different-sized models, together, have 225 makes, and given how useful they are, we’re sure that number’s only going to keep on growing.

- Where to find it? Printables

Cali Cat

This is a calibration cube made cuter. Unlike most of the other tests on this list, the “Cali Cat” is one that you’ll enjoy keeping after you’re done calibrating. The head and the tail are different sizes, so, as with the dimensional accuracy test, you can use this cat to identify material shrinkage.

If you’re looking for different options or to create your own “Cali” menagerie, there’s a Batman Cali Cat (you read that right), a Cali Cat for dual extrusion, a Cali Mouse, a Cali Dog, a Cali Turtle, and many more!

- Who designed it? Dezign

- How printable/popular is it? The Cali Cat has more than 600 makes and over 100 remixes, and it’s been printed in materials including PETG, PLA, and ABS. Basically, it works for everything!

- Where to find it? Thingiverse

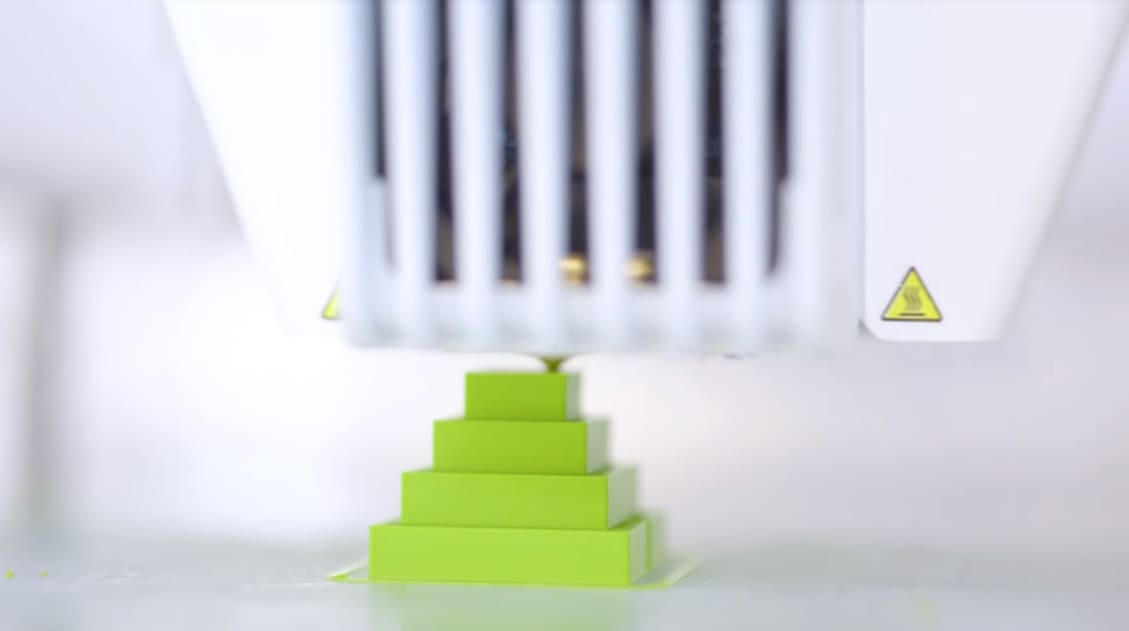

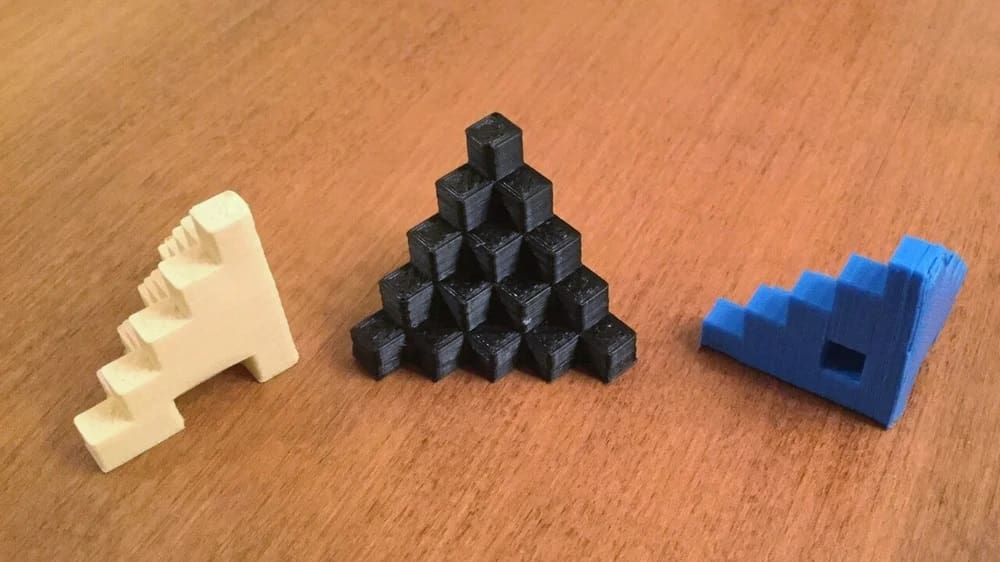

5-mm Steps

Instead of being a single cube, this stepped design features several smaller cubes stacked together. This gives you various measuring points within the overall dimensions of the print. In addition, the model has a built-in test for basic bridging, and the small steps make great indicators for print cooling.

- Who designed it? MCroucher

- How printable/popular is it? This model has an impressive 227 makes and 9 remixes on Thingiverse.

- Where to find it? Thingiverse, Cults

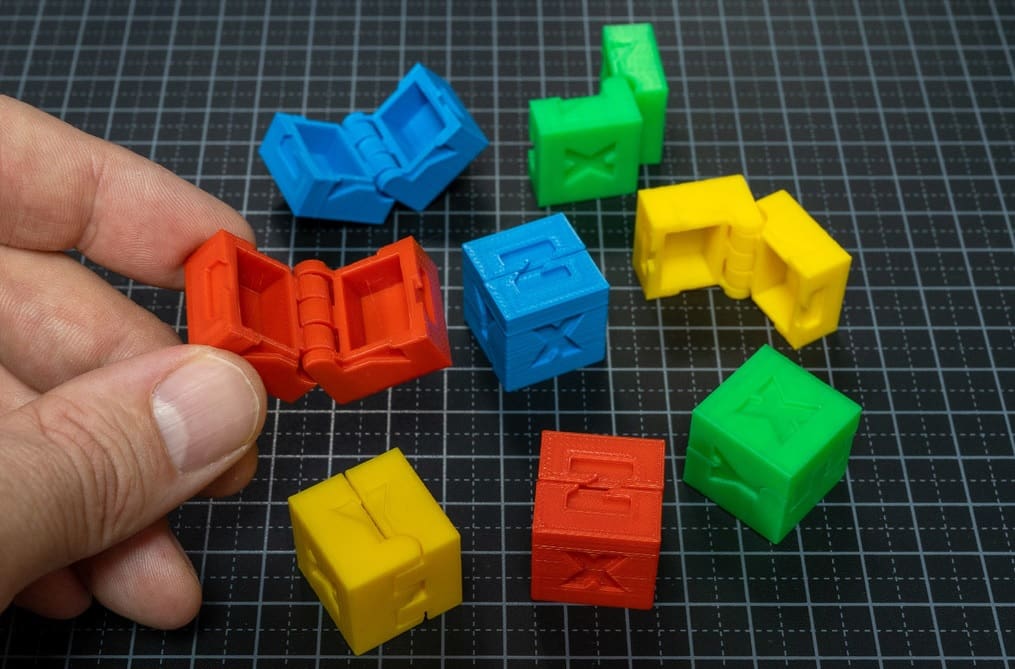

Hinged

Why not add a twist to your calibrating cube, so that you can have fun with it later? This is an especially useful cube if you’re looking to print some print-in-place models, as it will help you evaluate how the articulations work.

The designer also included tongue and teeth accessories (not for you, for the cube), which some makers have used to display their prints post-calibration.

- Who designed it? agepbiz

- How printable/popular is it? This cube has almost 200 makes combined from both sites.

- Where to find it? Thingiverse, Printables

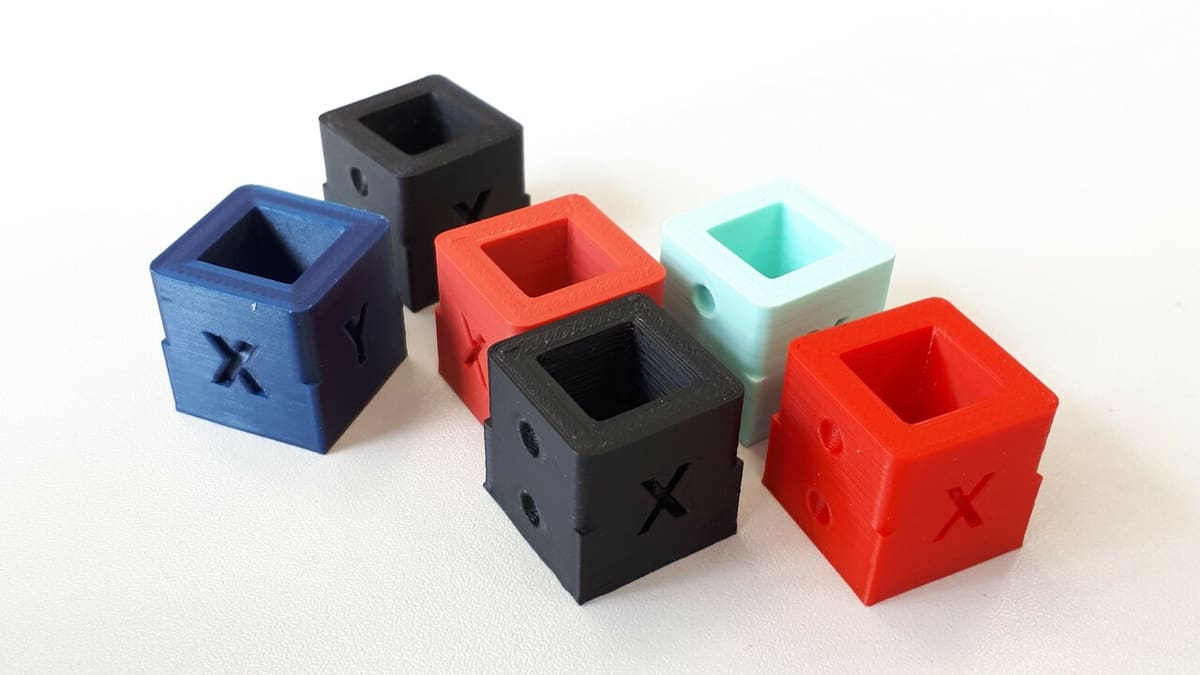

Hollow

This hollow calibration cube is a take on the classic cube that – you guessed it – is hollow. The thin, 1-mm walls make this model excellent for dialing in bridging and extrusion settings based on your prints’ surface finishes.

- Who designed it? 3D-ME

- How printable/popular is it? This cube has 135 makes and 190 remixes on Thingiverse.

- Where to find it? Thingiverse

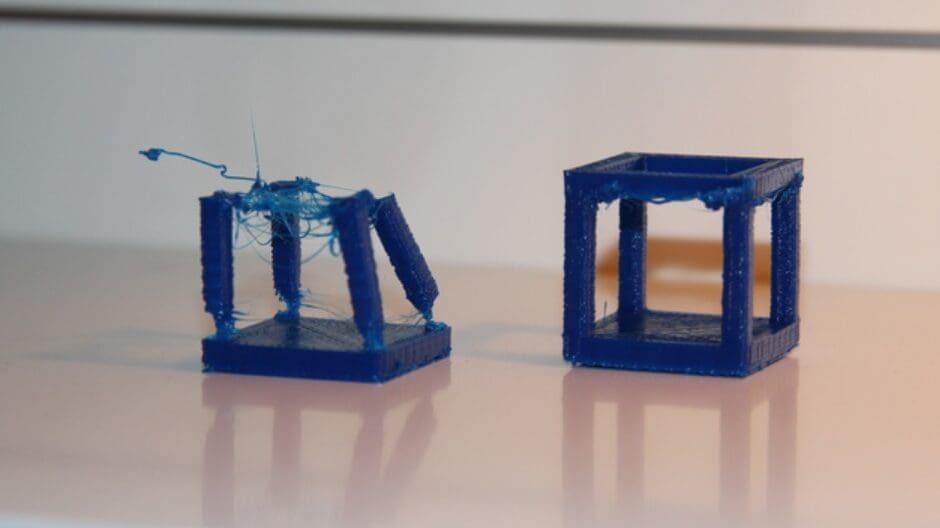

Funky Hollow

This cool cube is good for testing oozing, retraction, and bridging. As you can see from the image above, it can really help you see what you need to adjust in your printer. In addition to its clear usefulness, it doesn’t use much filament, so there’s no need to worry about the process getting expensive.

- Who designed it? orionwnix

- How printable/popular is it? This design has 28 makes and 9 remixes. One of the remixes even has a trapped sphere inside!

- Where to find it? Thingiverse

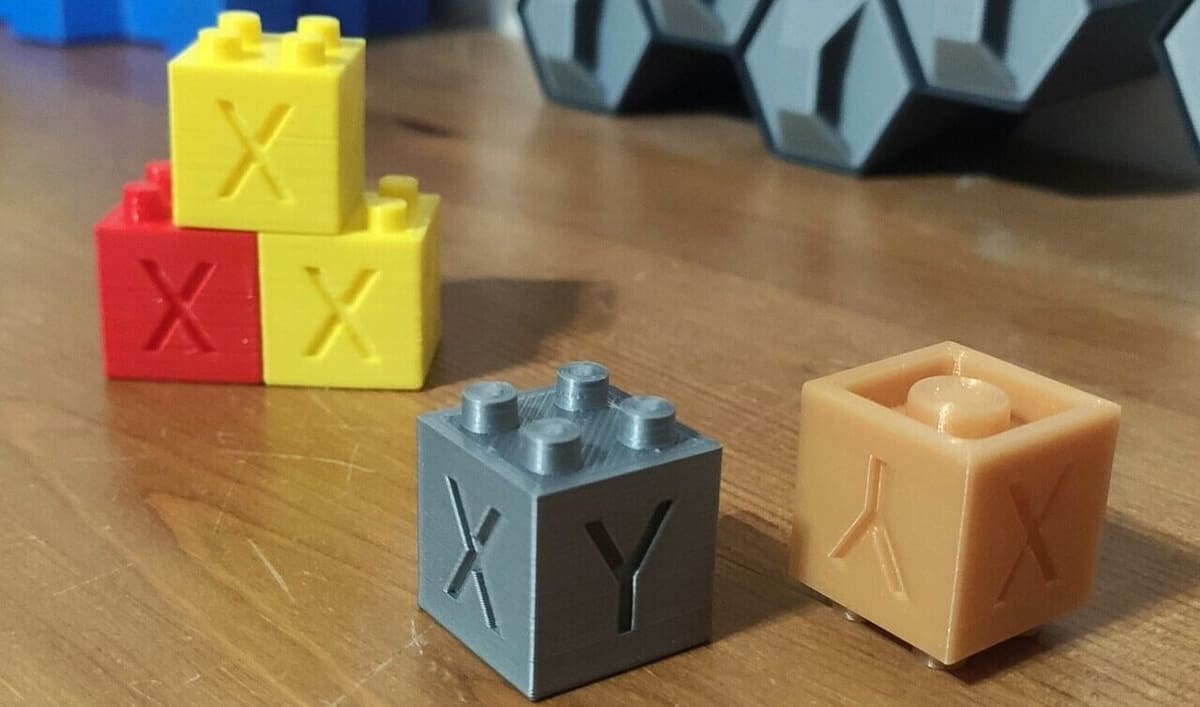

Lego

This calibration cube has Lego studs built into it, giving you something fun to do with the countless ones you’ve printed (and a way to keep them organized). Some may find this feature gimmicky, but the studs have another benefit: They can test for perpendicular printer axes, where oval (as opposed to round) studs indicate a skewed motion system.

- Who designed it? EnginEli

- How printable/popular is it? The Lego calibration cube has 5 makes and 5 remixes on Thingiverse.

- Where to find it? Thingiverse, Cults

Ghosting

We previously mentioned that calibration cubes can test for ringing. This model takes that concept and flips it on its head: It’s a ringing test that works well for calibration, too. Its cuboid shape has whole numbers for the outer dimensions (just like standard calibration cubes), but you’ll also find dimples and varying corner styles to help you diagnose motion artifacts.

- Who designed it? orcinus

- How printable/popular is it? This model has 41 makes and 2 remixes.

- Where to find it? Thingiverse

Filament

This is the Swiss Army knife of calibration cubes. It tests for dimensional accuracy, fine features, overhangs, bridges, and your axes’ orthogonality. These comprehensive features may seem extraneous to some, but they’re certainly useful to the right people.

- Who designed it? sch00f

- How printable/popular is it? The Filament Test Cube has 45 makes and 1 remix on Thingiverse.

- Where to find it? Thingiverse

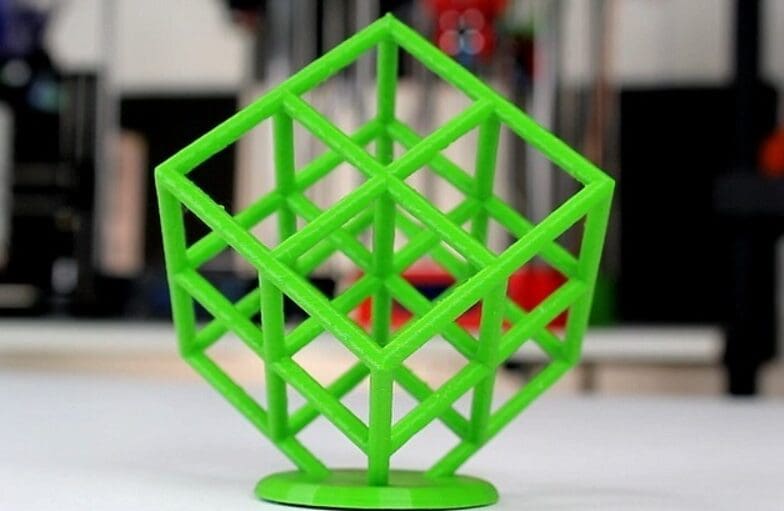

Lattice

This cube perhaps departs a bit in terms of looks from the other options on this list, but in addition to working as a décor piece, it tests for overhangs, retraction, temperatures, and cooling. There are 13 different files available, for single or dual extrusion, with and without a base, and designs that vary in complexity.

- Who designed it? Lazerlord

- How printable/popular is it? Between all of the available designs, this cube has around 135 makes and 3 remixes.

- Where to find it? Thingiverse, Printables

Helix

The Helix Test Cube is a fun twist on the classic version, featuring a helix in the center. In addition to testing dimensional accuracy, this more complex geometry lets you test stringing, bridging, ghosting, overhangs, first layer height, retraction, and top layer finish.

The dimensions are 30 x 30 x 30 mm, but it prints in less than two hours. Versions are available for both 0.6 mm and 0.8 mm nozzles. The design looks so nice that you can even use it as a material sample!

- Who designed it? Extrutim

- How printable/popular is it? This test cube impresses with around 130 makes and more than 5,500 downloads on Printables.

- Where to find it? Printables

Caliblock

Thanks to interlocking joints, this design snaps together like Legos. This way, every time you calibrate your printer, you have the chance to increase your building block collection! Caliblock is made of two halves that you glue together, and it allows you to verify overhangs, stringing, ringing, and dimensional tolerance.

While the creator mentions that printing it in PLA may be the easiest option, because of the recurring snap-fit parts (depending on intended post-printing use), opting for PETG or ABS could be better to ensure that the joints won’t snap off due to PLA’s brittleness.

- Who designed it? tempo502

- How printable/popular is it? This fun design has a total of 18 makes.

- Where to find it? Thingiverse

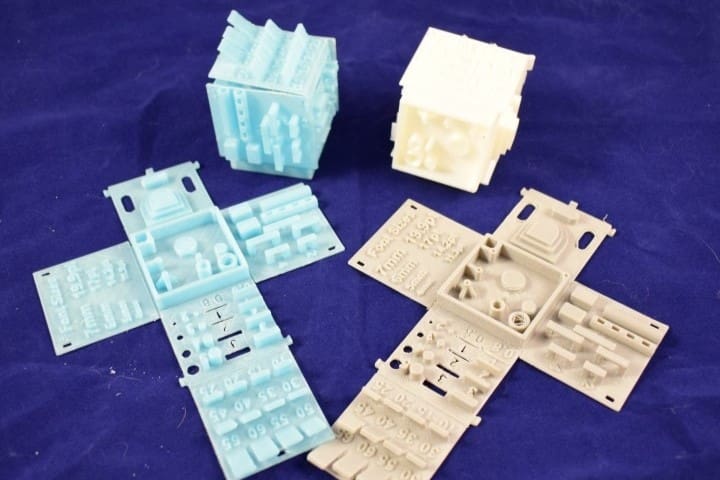

Folding Box

This complex and detailed design serves as a benchmark tool that will also help fine-tune your printer.

It’s a foldable model, so the cube is printed flat, and each side has specific features to verify how your printer performs certain parameters. The designer says to print without supports and provides solutions to some common problems in the print description.

- Who designed it? twiesner

- How printable/popular is it? This popular model has nearly 900 likes and has been downloaded over 3,900 times, with a couple of community prints shared.

- Where to find it? MyMiniFactory

License: The text of "The Best 3D Printer Calibration Cubes" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.