What Are They?

If you have a 3D printer, CNC machine, laser cutter, or almost any other similar type of machine, chances are you’re familiar with endstops. They’re those little electronic pieces at the ends axes that connect to the mainboard.

Endstops ensure that a machine, through one of various methods, keeps on object on an axis. (In the case of a 3D printer, the object could be the print head, for example.) This stops the object from derailing or jamming at the end of that axis. Endstop switches are the most common type, used especially by lower-budget machines.

However, there are other types of endstops that you can use, including optical and magnetic endstops. Different types of endstops have different strengths and weaknesses, depending on your necessary level of precision and your budget.

In this article, we’ll be discussing the three main types of endstops: endstop switches, optical endstops, and magnetic endstops (also known as Hall effect sensors). We’ll go over each type, explaining how it functions and what the differences are.

We’ll also list some criteria for each type, such as price range, precision, reliability, and more, to help you decide which one might be right for you.

Endstop Switches

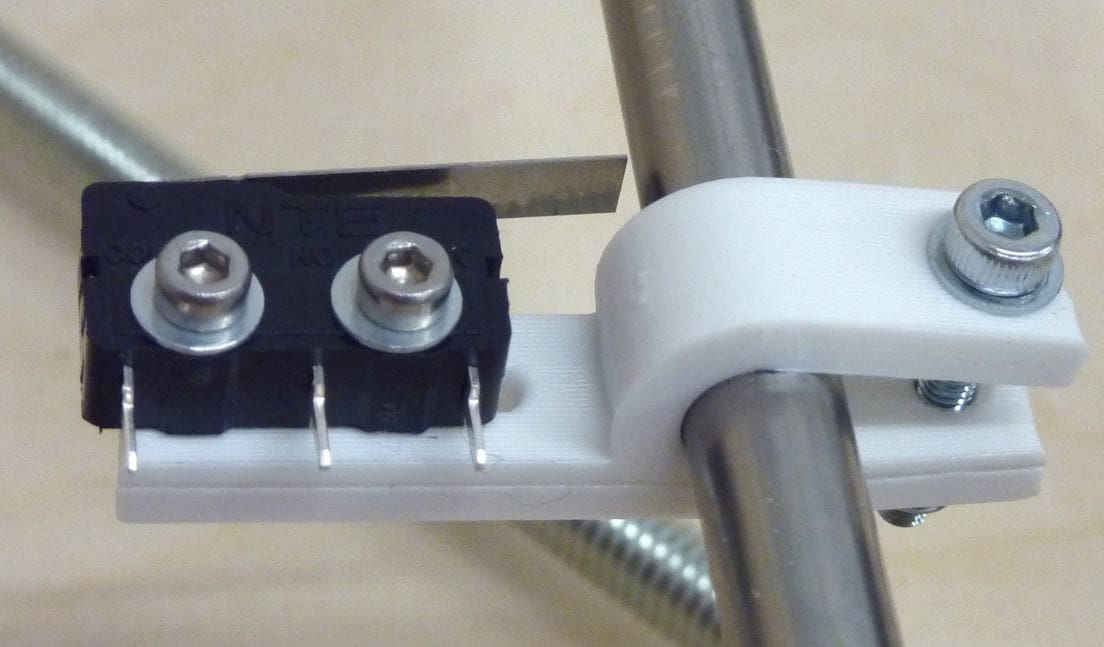

Endstop switches, also known as mechanical endstops, are contact-based manual switches (or buttons) that determine when an object is at the end of its axis path.

How They Work

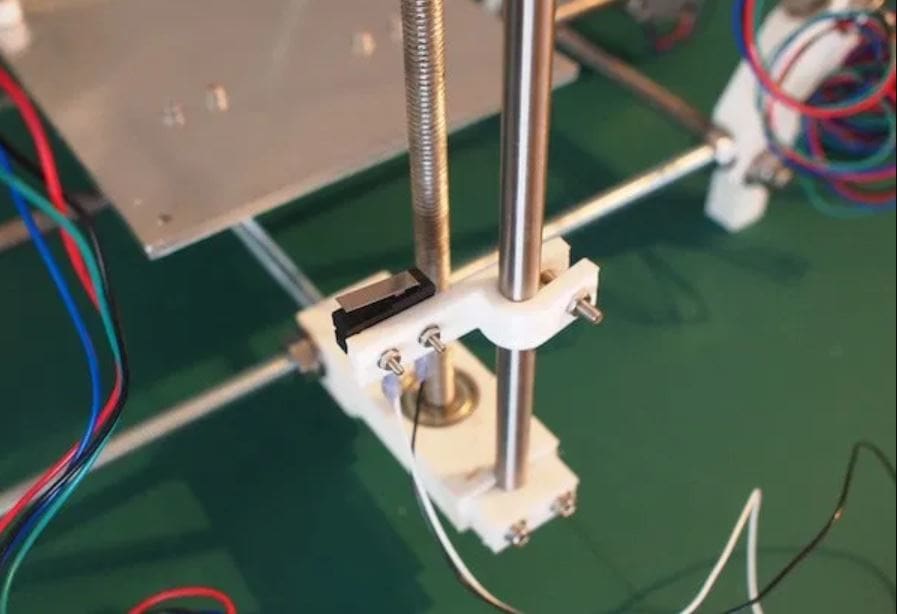

Endstop switches work using a simple touch sensor that functions as a switch. When the switch is touched by an object, it signals to the mainboard that the object is at the end of the path.

Unlike optical endstops, endstop switches are physically contacted by the object, meaning that they have to be very durable. Endstop switches are accurate, but not as precise as optical endstops. This is because they’re hit by the object in motion over and over again, which can cause them to slightly shift over time. Endstop switches therefore yield less precise results when tested for accuracy and consistency.

Cost

Endstop switches are the cheapest form of endstop and can go for as little as $1 each, though a more typical price is around $6. Even though they’re inexpensive, they’re still reliable, and most mechanical endstops can last millions of cycles without any errors.

Installation

Endstop switches are also very easy to install because they’re just a switch or button that sits on an axis path. All you have to do is attach them and adjust their home position to make sure that they work in accordance with the object in motion. For example, you might have to raise or lower a mechanical endstop on the Z-axis to ensure that the Z-axis holder never crosses underneath the print bed.

Popularity

Mechanical endstops aren’t only used for axis endstops but also as bed-leveling sensors. For example, the popular BLTouch (as well as other proximity bed-leveling sensors) is essentially a mechanical endstop mounted on a hot end carriage.

Mechanical endstops are used a lot in 3D printing, as seen on Creality, MakerBot, Ultimaker, Anycubic, and many other FDM printers. This technology is so commonly used because of its simple yet effective design.

- Price range: $1-6

- Precision: Medium

- Durability: High

- Reliability: High

- Uses: Axis endstop; bed leveling

- Pros: Very durable; reliable

- Cons: Not as precise over time as other methods

Optical Endstops

Optical endstops are a newer type of endstop, using light to determine when an object is at the end of its axis path.

How They Work

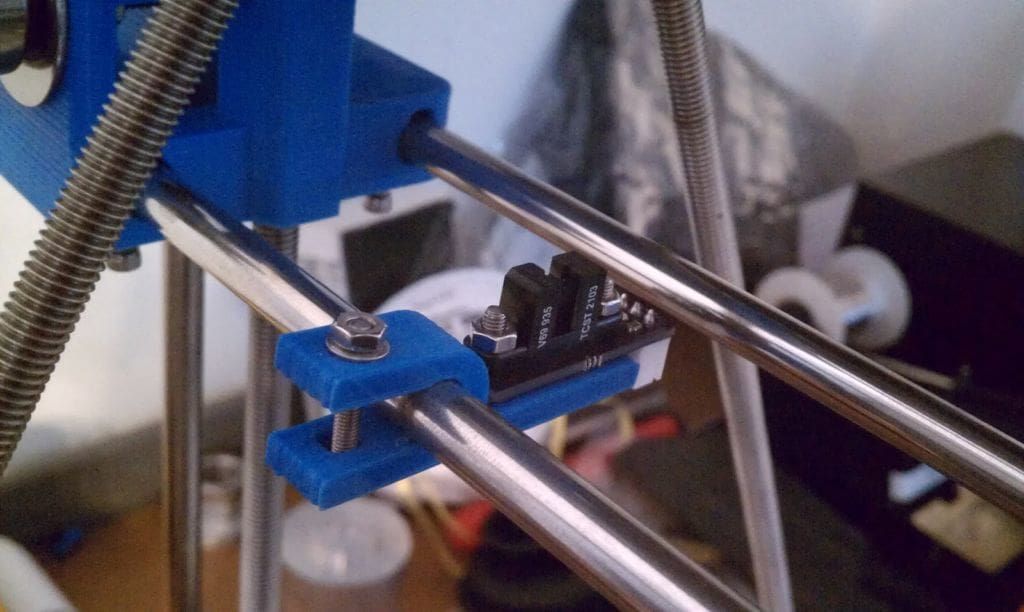

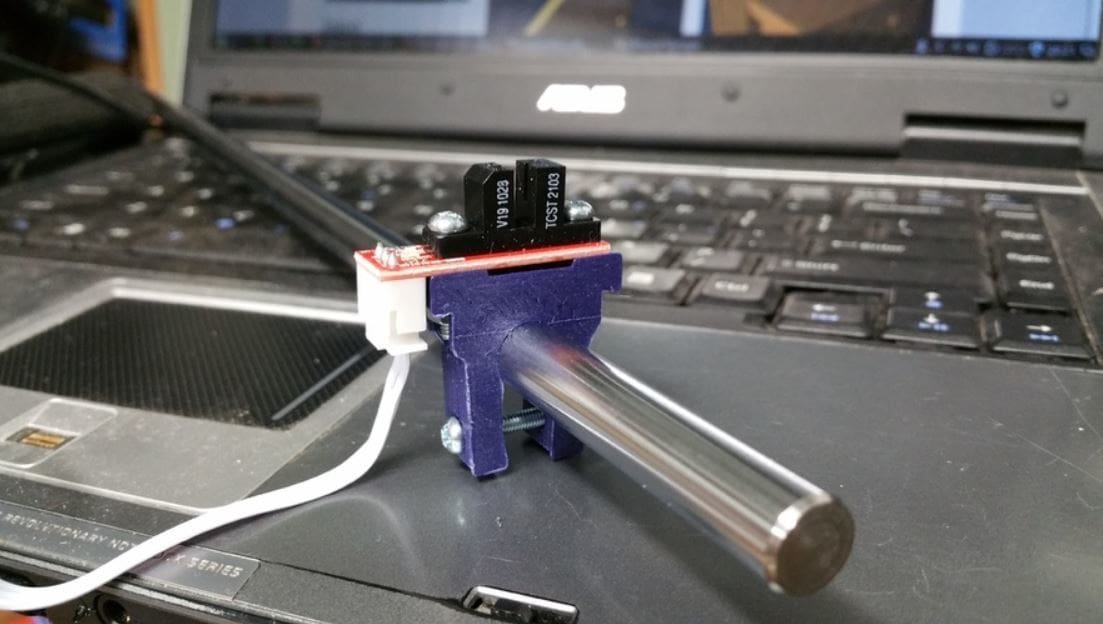

Optical endstops consist of a U-shaped device, called a photo-interrupter, with a light emitter on one arm of the U and a light sensor on the other. Optical endstops work by sensing when the light beam, cast by the light emitter, is disrupted.

The object, typically the print head on a 3D printer, uses a thin blade or flag to block the light between the emitter and the sensor. Once the sensor can no longer detect the light beam from the emitter, it signals the mainboard to stop the motion on the axis because the object has reached the end of its path. For 3D printers, this means the object has reached the end of the belt, rail, or Z-axis rod. This endstop type doesn’t require any contact between the object in motion and the endstop.

Optical endstops are very accurate, consistently stopping an object at a precise distance. However, optical endstops can run into some errors when used in areas with variable amounts of light.

For example, if a 3D printer using optical endstops is near a window, the print might fail if the sensor detects sunlight when it isn’t supposed to. Therefore, if you use this type of endstop, make sure that your printer is in a location with steady lighting or that the endstops are shielded from light fluctuations.

Optical endstops aren’t super durable, but they don’t have to be, as they’re never supposed to be hit by the object. They’re also very sensitive to movement, so it’s important to protect them from being moved or touched.

Cost

Optical endstops are inexpensive to buy, despite using some pretty advanced technology and offering a high level of precision. The average price range for this type of endstop is $2 to $6.

Installation

According to some users, optical endstops are a little more tricky to install and set up than other types of endstops. This is because you have to make sure the blade or flag on the object consistently and accurately goes between the two arms of the photo-interrupter.

Popularity

Optical endstops aren’t commonly used in 3D printers as of right now, but they are a growing technology. We presume, because of their inexpensive price and high precision, that they’ll be used more often in the near future. Many people use them to upgrade their machines, especially since they can be a fun challenge to improve machines from the stock version.

- Price range: $2-6

- Precision: Very high

- Durability: Technically low but effectively very high

- Reliability: Medium (or high, as long as ambient lighting is controlled)

- Uses: Axis endstop

- Pros: Non-contact; very precise

- Cons: Not very durable; sensitive to changes in light and position

Magnetic Endstops

Magnetic endstops, also known as Hall effect sensors, use magnetic fields to sense when an object is closing in on the endstop.

How They Work

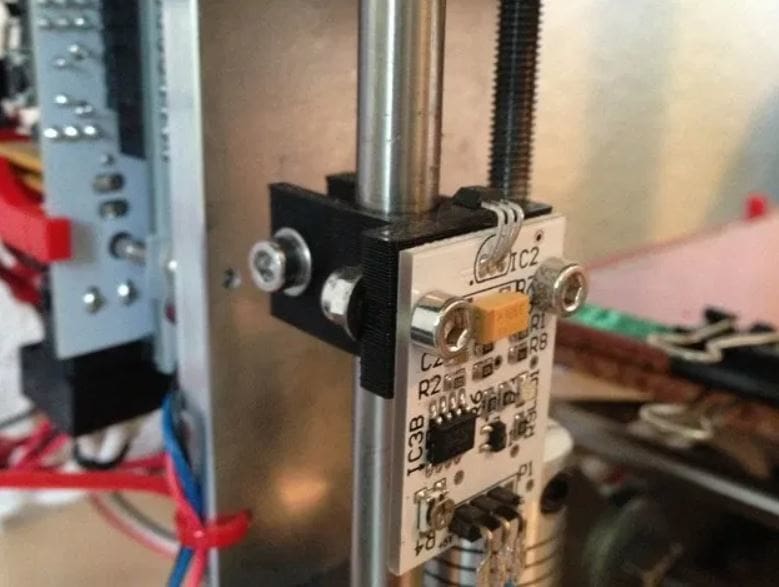

These endstops, as the name implies, use magnets to determine when an object has reached the end of its path. Magnetic endstops use two parts: a Hall effect sensor and a magnet. The Hall effect sensor is attached to the end of an axis and detects the magnetic field of the magnet, which is attached to the object in motion.

The Hall effect sensor detects the magnetic field when the object gets close to the sensor, sending a signal to the mainboard to stop the motion of the object along the axis.

This type of endstop is very precise, with an accuracy within 0.01 mm. However, you need to be sure that the printer isn’t near to anything else that emits a magnetic field, potentially interfering with the sensor. Magnetic endstops aren’t very durable, but as they’re a non-contact endstop, they aren’t made to be resistant to impacts like mechanical endstops are.

Cost

Magnetic endstops are also inexpensive, costing as little as a few dollars online. The average price for this type of endstop is around $3 to $7. However, you might have some difficulty finding these for purchase because not too many online retailers sell them.

Installation

Installing these endstops is a little difficult because you’ll have to find the right place to put the magnet on the object in motion. If you place it too far away, the Hall effect sensor might sense the magnetic field too late, causing a collision. If you place it too close, your print space will be limited because your object in motion won’t be able to pass a certain point.

Installation for this type of endstop is definitely more difficult than other types because you can’t see a magnetic field with your eyes. It might take a bit of trial and error to find a good place for the magnet.

Popularity

Relative newcomers, magnetic endstops use a technology that hasn’t yet seen a lot of development. Even though these endstops are still in the beta phase, we presume that they’ll gain popularity over time given how precise they are. As of right now, they aren’t used in any mainstream 3D printers, however, some users install them as upgraded replacement endstops on their printers.

- Price range: $3-7

- Precision: High

- Durability: Technically low but effectively very high

- Reliability: Medium (or high, as long as there are no magnets nearby)

- Uses: Axis endstop

- Pros: Non-contact; precise

- Cons: Hard to fix errors; not very durable

What's Right for You?

The three main types of endstops are all great choices for different reasons, but which one is right for you? Well, there’s no one right answer, it depends on what you’re doing.

For a high level of accuracy, you might want to go with an optical or magnetic endstop. However, fixing issues with these endstops could be difficult because they both use methods that are invisible to the eye. If you’re looking for the cheapest, simplest, and most-developed endstop, endstop switches might be your best bet.

The best endstop for you also depends on whether you want to explore new technological territory or take the safe route. There are many factors for determining which endstop to use, so the choice is yours!

Lead image source: ALBERTKHAN3D via Cults

License: The text of "3D Printer Endstop Switch vs Optical Endstop" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.