Over the last few years, many different types of build plates have been developed.

PEI sheets allow for flexibility, which eases the print’s detachment from the bed. This is a very useful feature, but when looking for the right build plate for your printer, you should take into consideration different factors that determine which will address your needs best.

Among the different build plates available, one of the most common types remains the glass bed. A few years ago, most (if not all) 3D printers came with this plate. Is it still a valid option? What are its advantages and disadvantages?

In this article, we’ll dive deeper into everything you need to know about glass beds, from their pros and cons to the best options to purchase.

Let’s discover more!

Pros & Cons

As mentioned, every build plate has its pros and cons.

Pros

Although PEI might be more convenient for its flex, glass beds feature some great benefits that make them worthy competitors. Let’s take a closer look:

- Flatness: If you’ve been 3D printing for a while, you probably started before auto-bed leveling was a common feature on 3D printers. The leveling procedure is quite tedious if you want to be sufficiently precise. Glass plates help greatly with the process because they’re usually flat and stiff due to their material composition and manufacturing process. This allows for a flat and consistent surface that will really provide you with great first layers.

- Easy cleanup: Losing a good print because it detaches from the plate is one of the worst nightmares for us makers. Keeping the bed clean is extremely important to avoid these unfortunate events. Glass beds are great because they are very easy to clean. Plus, it’s simple to see when there’s dust or grease. Textured plates are delicate and might have adverse reactions depending on the cleaning agent used. On the other hand, with glass plates, you can use a spatula to remove glue or plastic residues and easily clean with a cloth and IPA or even window cleaner.

- Durability: One of the key elements when evaluating which plate to buy is its durability. We don’t want to change our plate often just because it wears out. Glass beds are one of the most durable surfaces you can choose for your machine. While flexible plates tend to degrade after some months, glass beds can withstand years of use.

- Food safety: If you plan on printing parts that will be in contact with food, you should dive deeper into the topic of food safety. When printing such objects, you need to prepare meticulously your setup to avoid contamination. One of the most important parts of the process is cleaning your machine, and this includes the bed. Since glass beds are easy to clean, they’re a good option for food-safe prints. Additionally, they don’t present the risk of contamination with dangerous toxins, unlike many metal plates.

Cons

But all that glitters isn’t gold. As anything, glass beds have disadvantages, and it’s important to know what they are so as to make an informed decision on which plate to get.

- Cost: Until a few years ago, glass beds were one of the cheapest options for your 3D printer build plate. Now that many more types of surfaces have been developed, things have changed. PEI plates are arguably more common and they tend to be much cheaper. For instance, a Creality glass bed for the Ender 3 Max Neo costs around $30, while the magnetic build surface is around $20.

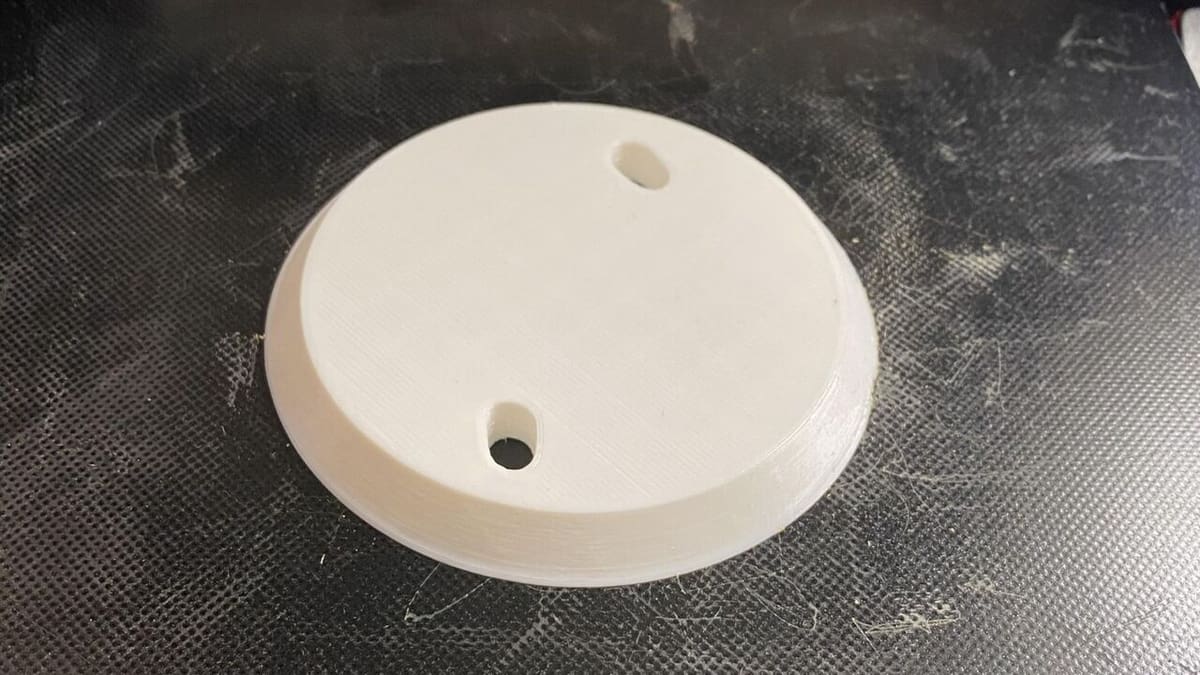

- Print removal: Glass beds can’t be twisted like you would flexible 3D printing surfaces. You’ll usually need a spatula to get the print off the plate because the part might not detach when the plate cools down, which can happen with a PEI platform. In fact, depending on the filament of choice (hello PETG), prints can stick too well to the glass bed, meaning you’ll need to pay attention when removing a part to avoid damaging the bed.

- Finish: Although many like the smooth finish of the glass beds, the cons lie in the fact that it’s the only first layer texture that you can obtain. With other types of 3D printing surfaces, you can select between a variety of options, especially since the introduction of PEO, PEY, PET, and others.

Considerations

Now that we know what the general advantages and disadvantages of glass beds are, let’s discuss a couple more things to know about them before moving to some brand suggestions.

First, it’s important to remember that when switching from one plate to another, you need to relevel your machine. If you were previously using a PEI plate and then installed a glass bed, you’ll need to perform once again the leveling procedure, including the Z offset calibration.

And when it comes to thickness, if you’re using a standardized bed, a 3- to 4-mm glass plate should be fine. This is sufficient to maintain strength and spread heat. If you opt for a very thin glass plate (for example, 1 mm), it’ll be vulnerable to cracking from the high temperatures or accidental contact with the hot end. Furthermore, thickness should increase with print bed size. For a massive print bed, you may want to consider something like 6 mm.

As mentioned, glass beds are rigid. While an advantage when talking about its longevity, the other side of the coin is the challenge when removing prints. When printing materials like PETG and TPU, glue can be helpful to avoid potentially chipping the platform. These materials tend to stick too well to the print bed and, by applying glue or hairspray, you create a thin layer that prevents the print from being directly in contact with the glass.

Glass beds are usually suggested for PLA, ABS, and nylon prints. This is due to the fact that they heat uniformly, so they should help you avoid warping with materials that are tougher to print. And glue can always be used to promote adhesion when working with engineering-grade materials.

Plus, a glass print bed should be highly heat-resistant. A plate that will crack or shatter when exposed to rapid changes in temperature won’t be ideal for 3D printing. Instead, you want something that’ll retain its original shape and structure when heated up to 100 °C and plunged into 5 °C water. Such durability is known as thermal shock resistance, and it goes a long way in ensuring that a glass plate remains usable for an extended period. If a plate can endure large temperature changes without sustaining any damage, it stands to reason that damage through 3D printing would be next to impossible. When searching for a glass print bed, keep an eye out for terms like “borosilicate” and “tempered”.

Do keep in mind that repeated heating and cooling means that even tempered glass will lose its strength eventually.

And while it’s a great choice for materials that require high bed temperatures, you need to remember that glass takes longer to heat up compared to thin flexible plates. Because of this, you should make sure to leave it heating for at least a couple of minutes before sending a print. The hotter you need the bed, as well as the thicker it is, the longer it will need to heat up.

Which to Buy

If you’re interested in buying a glass bed, we’ve got you covered. Let’s take a look at some of the options you can purchase.

3DJake

3DJake is an online shop famous among hobbyists. You can find 3D printers, 3D printing materials, and accessories from third-party brands. It also has proprietary products, such as its glass bed with a special chemical coating.

This plate is available in four sizes that match the dimensions of the most common build plates, including 220 x 220 mm. The chemical coating works similarly to a PEI plate by offering a good adhesion when heated and easy removal when cooled down.

It’s appreciated by makers, as seen from its 100 ratings, which average 4 stars.

Creality

Another really popular option is this carborundum glass plate from Creality. Although designed for Creality machines, many 3D printers share the build plate dimensions, so you should be able to find a size that fits your non-Creality hardware without much hassle. There are no less than 21 options to select from!

Many makers have already tested this plate. On 3DJake, this product features 133 ratings with a final evaluation of 4.3 stars.

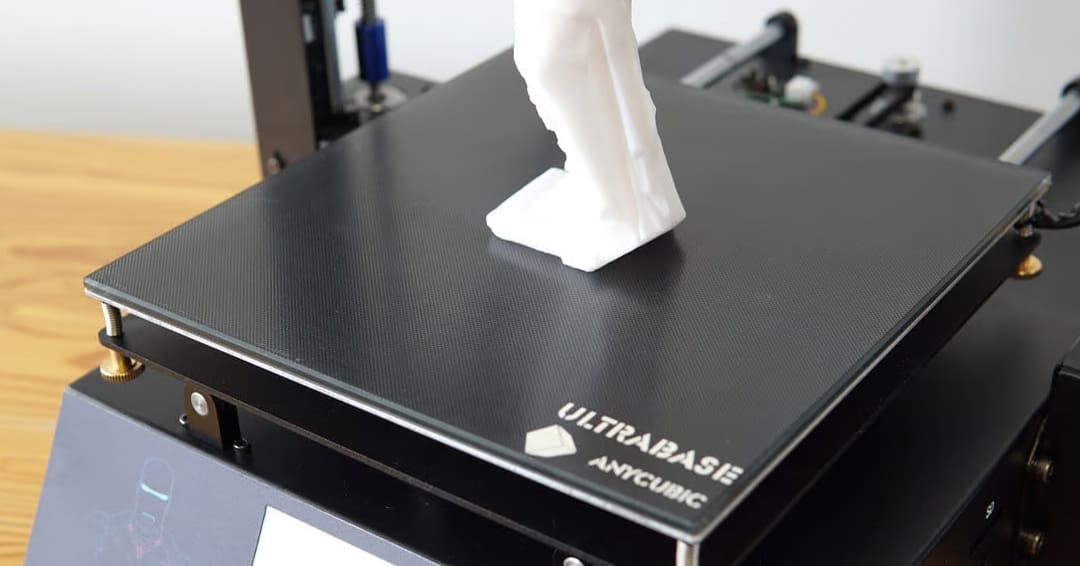

Anycubic

Anycubic’s Ultrabase is a great glass bed option. We reviewed it, should you be interested in a deeper dive. Although it isn’t provided in as many sizes as its competitors (a.k.a. Creality), there are three you can choose from.

If you’re looking for a glass bed with a slightly different finish than the super smooth one, this is a nice option. It aims to offer great adhesion when heated, as well as easy removal of the pieces when cooled down.

Although there aren’t reviews on the Anycubic official website, you can find some ratings at other online retailers, such as Amazon and 3DJake. The average rating from these two is 4.6 stars, which shows that makers are quite satisfied with it.

License: The text of "3D Printer Glass Bed: What to Consider & Which to Buy" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.