If you’ve been lucky enough never to experience the infuriating problem of filament grinding, it’s when the extruder chews away at your material. Mostly it happens when your filament gets stuck but the extruder gear doesn’t stop moving. Instead, it keeps going and strips the filament with its toothed gear.

When this happens, the filament ends up becoming so concave that the extruder gear can’t reach it anymore. You can identify filament grinding by seeing your filament chipped or stripped in one area around the extruder.

This problem is very annoying and can be challenging to fix, but don’t worry, we have some solutions. To identify the correct solution, though, you’ll need to first locate the cause, so that’s what we’ll look at in the following section.

Why Does It Happen?

Before we get into the solutions, pinpointing this problem’s causes will help you both fix it and avoid it in the future.

The direct cause of filament grinding comes from the extruder attempting to push the filament. Failing to do so, the extruder leaves a divet in the filament, as seen in the image above.

That’s not the only cause of this problem, though; a few different factors contribute to filament grinding. We’ve listed most of the known causes of filament grinding below:

- A clogged nozzle or hot end

- Under-extrusion (low hot end temperature)

- A twisted, bent, or uneven PTFE tube

- Fast print speed

- Slow print speed (heat creep)

- Too much extruder gear tension

- Fast or too much retraction

- A non-level print bed that’s too close to the nozzle

How Can You Fix It?

Now that you know some of the causes, let’s get into the solutions for filament grinding! Basically, you’ll want to counteract any of the reasons that might be causing filament grinding to happen.

Adjust Extruder Tension

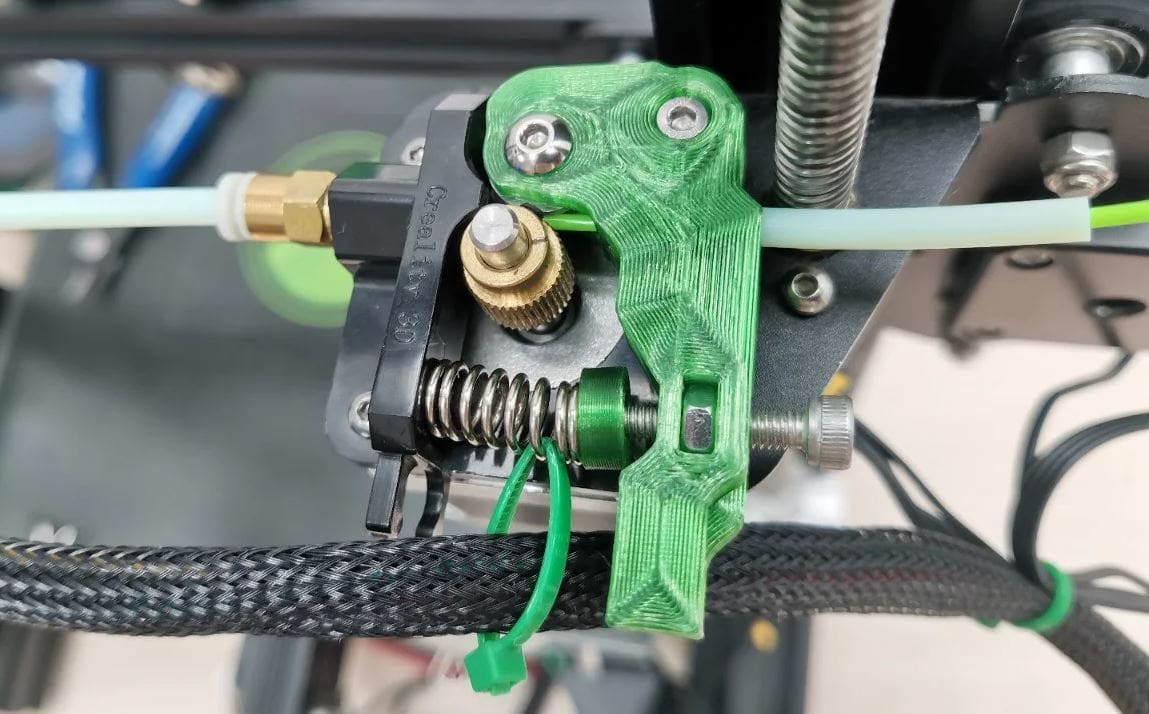

The extruder will typically have one or two screws to adjust the extruder gear’s grip on the filament (as in the picture above). If it’s too tight, there will be divots in your filament and dust around the extruder. Slightly loosening the gear will ease the grip on the filament.

Inspect the Bowden & PTFE Tube

Wear and tear in your Bowden tube or the hot end lining (both often made of PTFE) might prevent the filament from moving smoothly. Check the tubes for scratches and tears and replace them if needed. And make sure your Bowden tube is not bent or twisted!

Reduce Retraction Settings

Retracting too much filament at once, over too big a distance, can cause the extruder gear to lose its grip on the material, leading to skipping or grinding. If that’s the case, try turning down your retraction distance and retraction speed.

Change Printing Speed

Filament stripping can happen if you print too slow or too fast. Printing too slow risks creating heat creep and hot end jams; to fight this, increase your printing speed. But if you print too fast, the extruder might not be able to keep up. If that’s the case, try lowering your print speed.

Adjust Hot End Temperature

Perhaps you feel your filament isn’t extruding quickly enough. In that case, heat your hot end to the temperature you usually print at and push some filament through by hand (but not too quickly). You want the filament to extrude about as fast as you’re pushing it. If the filament isn’t melting quickly enough, raise your nozzle temperature.

Clean Your Hot End

Debris around the hot end can stop filament from moving smoothly. Use a wipe or small cloth to ensure that your hot end is clean and doesn’t have any residue on it. If the hot end is still hot, use oven or welding gloves to protect your hands. To identify and troubleshoot signs of other issues, such as wear or jams, check our guide to cleaning a 3D printer nozzle.

Level Your Print Bed

To avoid issues, such as the nozzle being too close to the bed and complicating extrusion, level your print bed. Most recent 3D printers feature an auto-bed leveling probe, while older models can be equipped with bed-leveling kits like the BLTouch. Alternatively, use a piece of paper to level your bed manually and make sure your nozzle is the same height everywhere above the bed.

Following these solutions and looking at the causes can significantly improve your chances of fixing and preventing this issue. Other factors can contribute, too, so make sure you watch out for unique or rare problems.

License: The text of "3D Printer Extruder: Grinding Filament – How to Fix It" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.