3D Printing's Not So Secret Weapon

Early 3D printers didn’t have heated beds. To encourage prints to stick to cold surfaces, materials such as painter’s tape were used to improve adhesion. It didn’t take long, however, to realize that most materials bound better to a warm print surface and that this also brought several other important advantages.

FDM printers extrude molten plastic at a temperature high enough to allow it to flow but low enough for it to cool and re-solidify in a predictable way. However, if cooling happens too quickly or the extruded filament reaches too low a temperature, it contracts too much, internal stresses build-up, and adhesion and warping issues start to occur – especially at the interface with the printing surface.

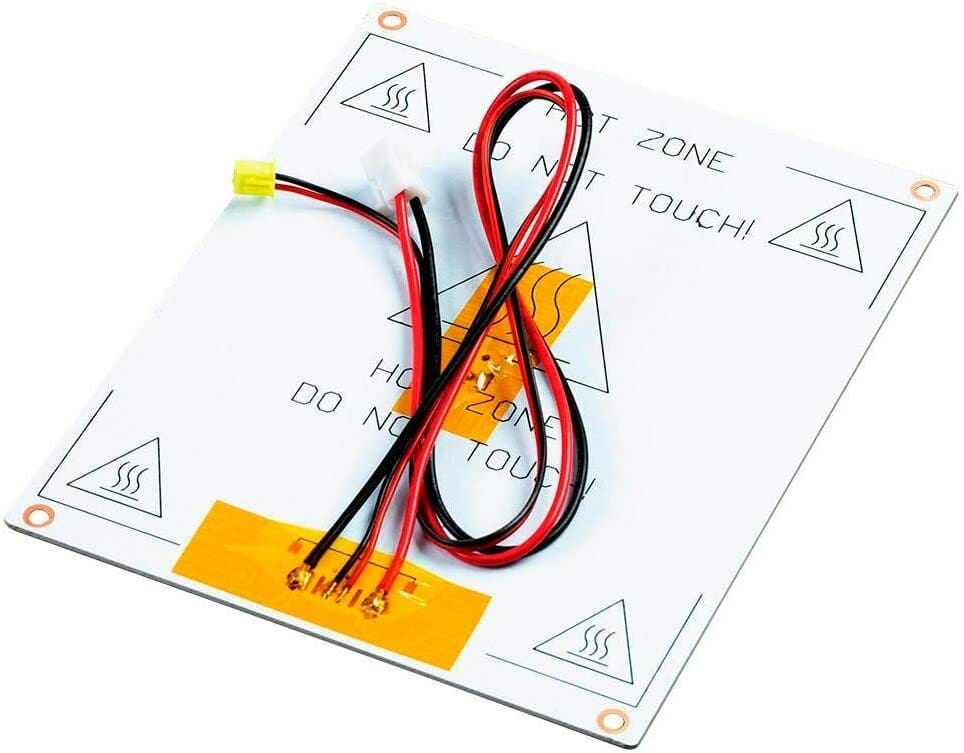

The benefits of a heated print bed mean that virtually all modern 3D printers come with these as standard, using various types of heating elements including PCB heater traces and silicon pads with resistive power elements. How this heating element is connected to the physical build plate, what plate materials are used, the power rating of the bed, and more, all have an impact on the final quality of a printed item.

We’ll examine these factors in more detail below, but first, let’s take a closer look at exactly how heated beds improve print quality.

The Most Important Benefits

Heated beds bring several related benefits. Let’s look at the most important three of these first:

- Bed adhesion: A hot build surface prevents extruded filament from cooling too much, too soon. This gives it time to adjust to tiny microscopic imperfections on the surface and stick more firmly. Exactly what constitutes “too cool” or “too fast” is dependant on the printed material and other factors, as outlined in the section below.

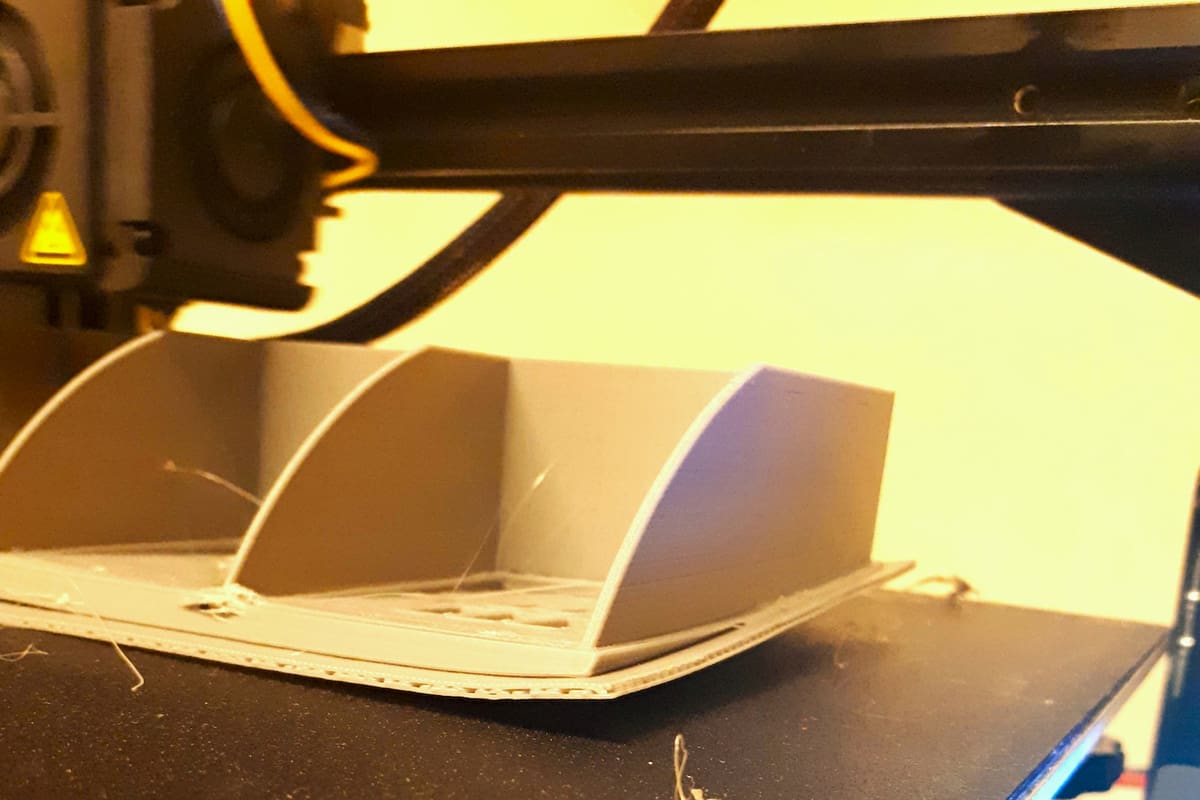

- Helps prevent warping: Internal stresses build as molten filament cools, and these are especially pronounced at corners. As additional layers of hot filament are added, the temperature difference can cause these stresses to pull inwards. In turn, if adhesion is poor, corners can become detached and curl (i.e. warp) upwards, potentially ruining a print. Heating the bed reduces the tendency for prints to warp by evening out the temperature difference as well as holding the print down with better adhesion.

- Assists print removal: When a print is finished and the heated bed cools down, it allows the lowest layers of plastic to contract a little more, become more rigid, and loosen their grip on the bed. With most materials, this helps prints to detach cleanly from the print surface.

There are additional benefits of a heated bed, too. The heat they generate is dissipated to the surrounding environment and helps keep the whole build space warm, especially if it’s enclosed. An enclosure reduces excessive cooling stresses for all layers of the print, thereby improving quality.

Different Strategies for Different Materials

In the same way that different materials extrude at different temperatures, the temperature of the heated bed also varies for best performance. There are several factors at play here.

The most commonly discussed is glass transition temperature (Tg). This is the temperature beyond which a material starts to change from a hard solid to something a little more malleable. This is different from the higher melting temperature (Tm) beyond which the material can be extruded.

Heated beds normally are set at around the glass transition temperatures to improve adhesion and reduce cooling stresses. Other factors include the temperature of the extruded material itself, the ambient temperature, differences in the materials between manufacturers, the color of material (even from the same manufacturer), and even the history of what temperature the material has been stored at.

Each material, therefore, has a range of temperatures within which the optimum lies:

- PLA has a certain degree of natural adhesion, so bed heating isn’t vital. The best results, however, are typically achieved within the range of 50 to 60 °C.

- PETG typically prints best with a heated bed between 75 and 85 °C.

- ABS is notoriously sensitive to bed and ambient temperature. Bed temperature should be in the region of 105 to 115 °C, but the ideal will vary according to the ambient temperature. Therefore, an enclosure to maintain a high and constant air temperature is key.

- TPU has a Tg despite already being rubbery. Bed temperatures are normally in the range of 45 to 60 °C.

- TPE, despite having a glass transition temperature between 60 and 120 °C, doesn’t need a heated bed, although 60 °C is commonly used.

- Nylon likes it hot, so anywhere in the range of 80 to 100 °C is recommended.

For other materials, it’s best to consult the manufacturer’s recommendations.

Getting the Most Out of It

In theory, a heated bed should warm quickly to a set temperature and then maintain it steadily and consistently. The reality, however, is somewhat different and can have a significant bearing on print quality.

- Be aware of incorrect temperature readings: The displayed temperature of your heated bed comes from a sensor (typically a thermistor). These might not be entirely accurate in the first place, and over time, they degrade and tend to read low. If you have an accurate thermal monitor, you can calibrate this and update your printer’s firmware, but more typically, a compensating change to the set temperature is made.

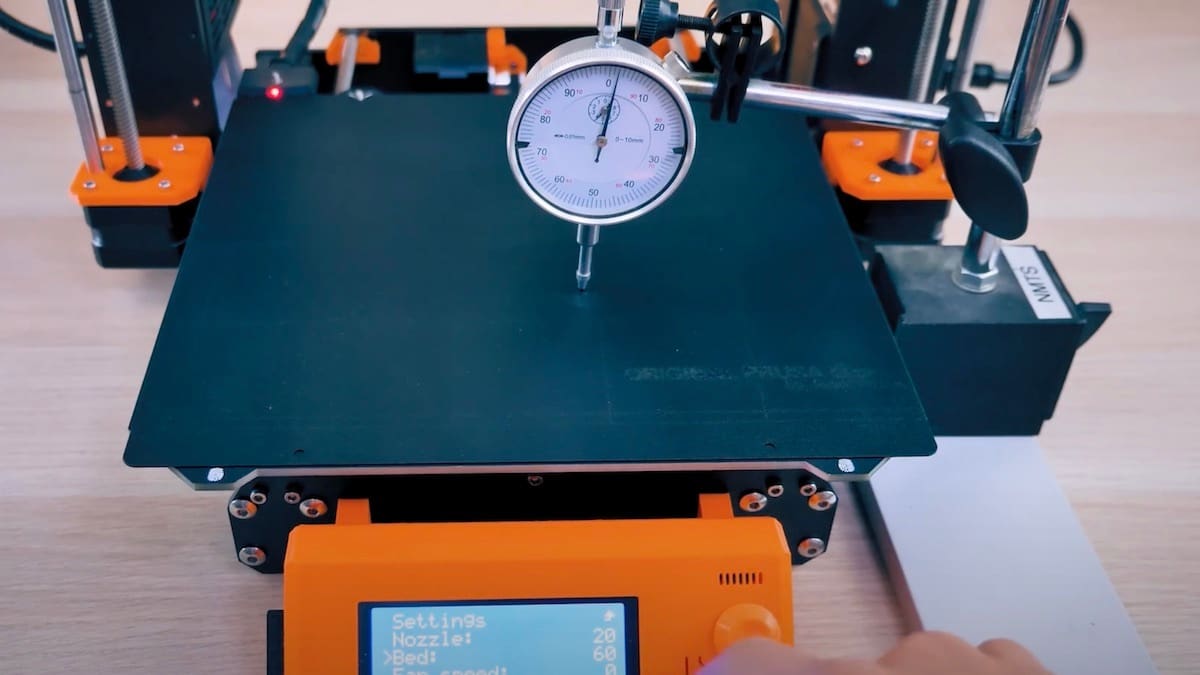

- Allow time to reach working temp: Another reason why the displayed temperature can be misleading is when “printing from cold”. The bed’s temperature sensor may read a certain degree, but this may not have been reached across the top of the entire print surface. The actual temperature will be lower than indicated, so you’ll not get the initial adherence you expect. In addition, while beds are heating, they’ll expand or contract. If you attempt to level the bed before a working temp is reached, the bed level can be out by as much as an entire layer height. (Thomas Sandader’s has a great video on this effect.) Printers vary, but typically a minimum of 10 minutes is required to reach a stable enough temperature.

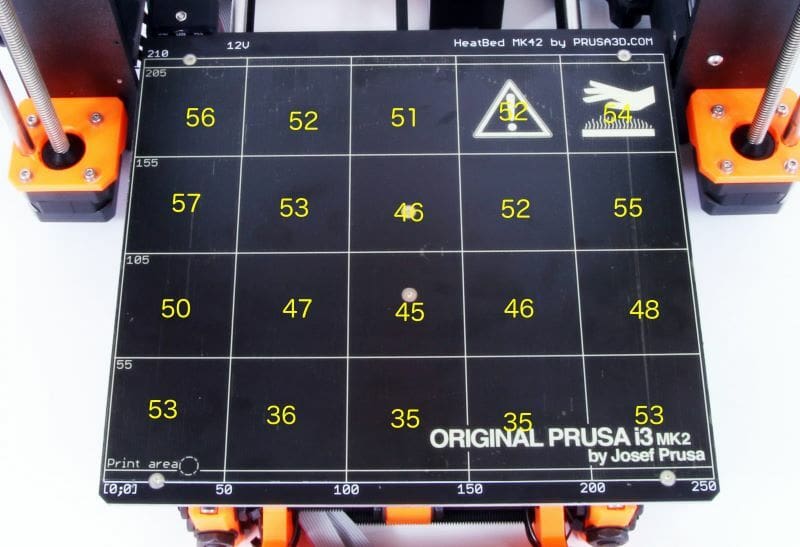

- Consider the possibility of uneven temperature distributions: A related point is that beds can heat unevenly (see images above). This effect usually evens out over time, but at high temperatures or if your bed has insufficient mass, this can continue to be an issue and cause inconsistent adhesion as well as warping. The solution is usually just to leave enough time for a consistent temperature to be reached, but for high-temperature printing, an underlying bed capable of spreading the heat more evenly is important.

- Ensure that PID tuning is accurate: This last point can make a surprising difference to prints, especially for those at higher temperatures. Bad tuning can result in temperature (and associated expansion and contraction) oscillations. This, in turn, can show up as ribbing and other surface imperfections along the Z-axis. Proper PID tuning of your bed and thermistor can fix this problem and is worth doing even on stock machines. We have an excellent article that goes into how to do this in more depth.

A final word on safety. Beyond typical 50 to 60 °C temperatures, heated beds have the potential to burn skin, so take care – especially when moving on from PLA to materials that print hotter.

Lead image source: Thomas Sanladerer via YouTube

License: The text of "3D Printer Heated Bed – The Advantages" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.