Achieving intricate and complex prints 3D prints with fused deposition modeling (FDM) often necessitates the use of supports. These serve as auxiliary structures, providing a foundation for overhangs and bridges. Since freshly extruded filament is soft and malleable, it can easily succumb to the effects of gravity, ruining the details and integrity of your intended design.

However, the process of removing support material can also lead to damaged models, or at best, some tedious clipping and sanding. Those with dual- or multi-material printers are in luck though, as there are ways to make support removal much easier. Instead of printing supports using the same material as the model, the supports can be printed with a dedicated filament that can be dissolved or easily peeled off.

Choosing the right support material is essential for your project’s success. This guide explores various types of support materials for FDM printing, their use cases, and some filament suggestions to get you started.

PVA

Polyvinyl alcohol, or PVA, works great as a support material in 3D printing, as its water-soluble nature means supports are washed away after a soak in a bath. Diluted PVA is then safe to dispose of down the drain.

When paired with PLA, PVA demonstrates optimal performance, as it doesn’t adhere well to materials like ABS or PETG. Managing moisture is crucial, requiring storage in a moisture-free environment like a filament dry box. Additionally, PVA is heat-sensitive and should be stored at room temperature when not in use.

Printing

PVA has a recommended printing temperature range of 180 °C to 210 °C, but it can vary depending on the brand. Start at the lower end and adjust based on your printer and PVA filament brand. It adheres best to a heated bed at temperatures between 45 °C to 60 °C. For the best layer adhesion, use slower print speeds; around 20-40 mm/s is often recommended.

Removal

For effective support removal, it’s best to remove the bulk of supports by hand before soaking the part in water. The time it’ll take for the supports to fully dissolve varies, typically ranging from 4-12 hours. Warmer water will help speed things up but don’t go above 50 °C, as PLA is temperature sensitive.

Examples

As one of the more popular support materials, there are lots of PVA filaments out there. On the pricier end, GizmoDorks PVA is praised for giving reliable, quality results – as long as the printing temperature is kept low.

For a budget option, SainSmart PVA is another popular choice, although some users report that it doesn’t adhere well to all PLAs.

Summary

- Removal mechanism: Water dissolution

- Compatibility: PLA

- Settings: 180-210 °C hot end; 45-60 °C heated bed

- Price: $60-$120/kg

HIPS

High-impact polystyrene (HIPS) filament is a versatile and commonly used thermoplastic, not only as a support material. It has good impact properties and dimensional stability, all while being relatively lightweight. As a support material, HIPS is most commonly used with ABS or ASA, as the materials adhere well to each other.

Compared to PVA, it’s less susceptible to moisture adsorption. In fact, it’s not soluble in water. Instead, you’ll need d-limonene, a chemical found in many citrus fruits, to dissolve HIPS supports. HIPS is also favored over PVA due to its printing temperature being closer to that of ABS, making it easier to manage on a single extruder setup.

Printing

HIPS filament is ideally printed at a nozzle temperature of 220 °C to 250 °C. It adheres best to a heated bed, with recommended temperatures between 90 °C to 110 °C. Unlike PVA, HIPS performs well at moderate to slightly higher speeds, typically ranging from 40-60 mm/s.

Removal

This filament can dissolve in pure d-limonene, but you can also dilute it with water if you need to make a large bath. Keep in mind that d-limonene is a harsh chemical, so be sure to use a glass container and wear gloves. It can take just a few hours up to a couple of days for the supports to completely dissolve depending on the concentration of your solution and the amount of material. Removing bulky chunks of supports manually beforehand will quicken the process.

Acetone can also be used to remove HIPS, but since ABS and ASA are also partially soluble in acetone, you shouldn’t leave your parts soaking in an acetone bath. Rather, a quick dip can soften the supports enough to make them easier to remove.

Examples

The HIPS from eSun seems to be a community favorite, with many reporting a high print success rate and overall easy printing process, though the prints tend to turn out brittle. As a low-cost option, eSun’s HIPS could be a good way to dip your toes into dissolvable support materials.

Another popular HIPS choice is from Fillamentum. This filament provides great print consistency. Despite being more expensive than some other options, it could be worth it to get that perfect finish.

Summary

- Removal mechanism: Chemical dissolution

- Compatibility: ABS

- Temperature settings: 220-250 °C hot end; 90-110 °C heated bed

- Price: $20-$60/kg

BVOH

BVOH (butenediol vinyl alcohol co-polymer) filament is a versatile and dissolvable support material. Known for its reliable performance and ease of use, BVOH is a high-end option best used as an interface layer or parts with complex internal structures.

Unlike PVA, BVOH is compatible with PLA, ABS, PETG, and nylon. BVOH exhibits lower moisture absorption than PVA, making it less susceptible to nozzle clogging and other extrusion issues, but it’s still necessary to store BVOH in a dry environment.

Printing

When printing with BVOH, nozzle temperatures will typically range between 200 °C to 220 °C, but it can vary depending on the brand. BVOH performs optimally at moderate speeds, ranging from 30-50 mm/s, as it boasts naturally good layer and bed adhesion. That being said, a mild bed temperature between 40 °C to 60 °C can ensure good results.

Removal

This support filament can be removed by soaking in warm water, similar to PVA. The bulk of the material should be removed by hand to improve dissolution time, which can be anywhere from 8 to 24 hours. Frequent or continuous agitation of the water bath can help speed up dissolution.

Examples

Due to its wider compatibility, BOVH filament is becoming increasingly popular. A few reliable choices include manufacturers like Fiberlogy and Ultrafuse. Fiberlogy BVOH adheres well to a variety of materials including PLA, ABS, PETG, and even TPU, making it a very versatile option.

Ultrafuse BVOH filament was reported to work well with nylon and seems to dissolve the best in a side-by-side comparison with other soluble supports.

Summary

- Removal mechanism: Water dissolution

- Compatibility: PLA, ABS, PETG, nylon

- Temperature settings: 180-210 °C hot end; 45-60 °C heated bed

- Price: $100-$200/kg

Breakaway

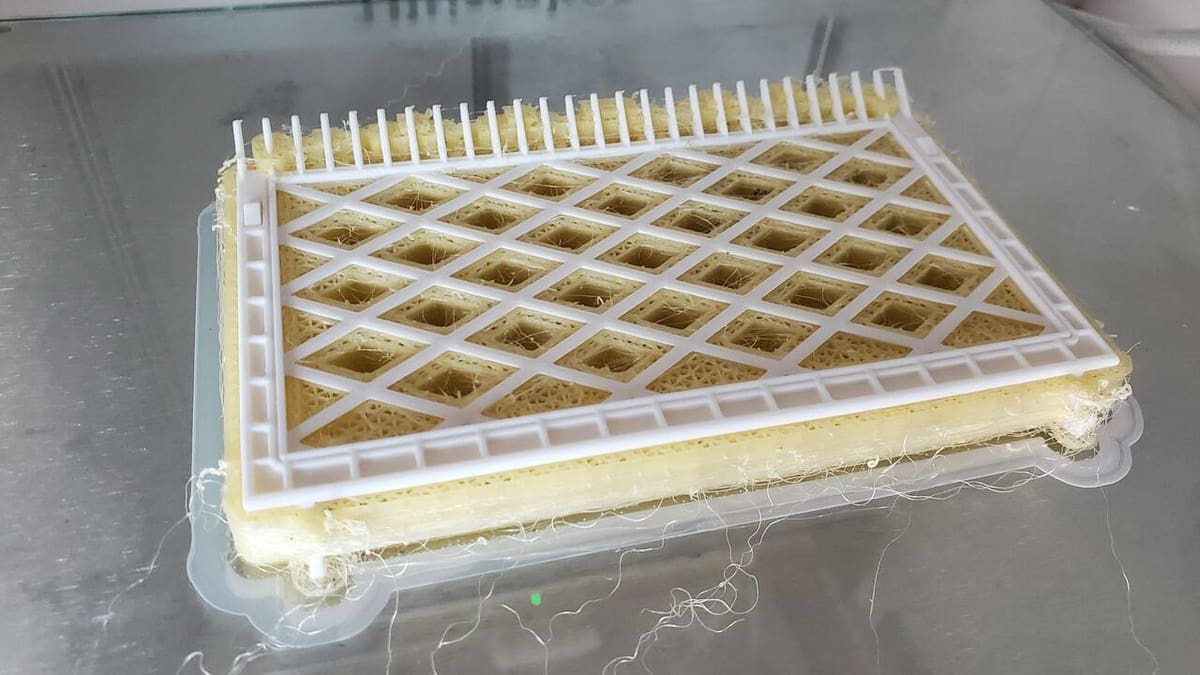

Easy breakaway support filaments are designed to simplify and expedite the post-processing phase of 3D printing without requiring any additional supplies or chemicals. These support structures can be cleanly removed without requiring much effort or leaving behind support marks due to poor interfacial adhesion. Compatibility (or rather, the lack thereof) is a key aspect of these filaments, with some brands formulating breakaway supports for specific primary filaments such as PLA, ABS, among others.

Printing

Breakaway supports typically don’t require any special printing settings, but users can opt for a brim if there are issues with bed adhesion or warpage. Temperature settings can vary depending on the formulation you’re working with, so refer to the manufacturer’s recommendation.

Removal

Breakaway filaments work similarly to normal filaments in that they require manual removal. The process, however, should go much smoother. Breakaway supports are often brittle with a weak interface to the primary printing material, not requiring much force to pull the supports off by hand. You can also choose to use pliers for removal, as the thin support structures can be prickly. Tweezers can be used to remove any remaining bits.

Examples

MatterHackers Pro Series breakaway support filament is a go-to support material for many makers out there. Known for its fast, easy, and clean mechanical breakaway, this filament is a great support material, though it can get stringy.

Polymaker PolySupport is another reliable choice formulated specifically for PLA, but it’s also compatible with PVB, PC, and TPU. Some users say that the removal of this material can damage more delicate prints, so handle with care.

Summary

- Removal mechanism: Manual removal

- Compatibility: PLA, ABS, PETG, nylon, and more

- Temperature settings: Varies by filament

- Price: $50-$75

Proprietary Blends

Proprietary blend filaments offer a unique approach to 3D printing, as manufacturers often create custom formulations tailored to specific performance requirements. These blends are designed to provide enhanced features such as improved strength, flexibility, certain aesthetic properties, and easy support removal.

The composition of proprietary blends is typically undisclosed, making it difficult to generalize their properties. However, these filaments are often engineered to be user-friendly and compatible with most 3D printers.

Printing

Always refer to the filament manufacturer for recommended printing temperatures, bed adhesion suggestions, and other key settings to optimize the printing process.

In general, if the filament is dissolvable, it’s likely hygroscopic. So, drying the filament can help solve extrusion issues.

Removal

Removal of proprietary blend support materials can be via water dissolution, chemical dissolution, or manual breakaway. In any case, be sure to read the manufacturer’s instructions thoroughly. Pay particular attention to support materials that claim to be soluble in chemical solutions, as they may require special safety precautions and disposal procedures.

Examples

There are several different proprietary blends out there, but Hydrofill from Airwolf 3D is a favorite. It dissolves in water, is compatible with many different materials, and offers a smooth printing experience. However, some users report nozzle clogging issues, so be sure to keep the filament dry.

Xioneer offers VXL in several different options that are characterized by printing temperature, including high-temperature PEEK and PC. However, you’ll need their proprietary detergent solution for dissolution.

Summary

- Removal mechanism: Water dissolution, chemical dissolution, or manual removal

- Compatibility: Nearly all

- Temperature settings: Varies by filament

- Price: $40-$100+

License: The text of "3D Printer Support Filament: The Best Options" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.