What Is Support Material?

In FDM 3D printing, support structures are necessary when the print has overhangs or features suspended in midair. They allow for successful printing of complex shapes by propping up these otherwise unsupported areas.

3D printer support material is simply the material in which these supports are printed. Different materials offer different balances between price, ease of use, and print quality, so picking the correct material for your models will make your printing experience much more enjoyable.

Let’s take a look at the options you have.

Basic: Build Material Supports

The simplest, most common support material is simply the same material your model is made of. This is because many 3D printers are still single-extruder machines capable of printing only one material at a time, making a dedicated support material impossible.

Along with being more accessible, common build materials tend to be more affordable than dedicated support materials, too. Thus, for those on a budget, build material supports may be an attractive option.

Build material supports are also guaranteed to adhere better to your model, being made of the same material. This adhesion, however, is a double-edged sword: Prints are less likely to fail, but support removal will require more effort and yield poorer surface quality. As shown above, the use of an X-Acto knife or sandpaper may be necessary to get a smooth surface on the model after support removal.

If you want to guarantee adhesion and save a little money, and you don’t mind tedious support removal and quality loss, build material supports are the way to go. And if you have a single-extruder 3D printer, this is, for better or for worse, the only option you have, anyway.

Materials as Their Own Supports

Since PLA is more brittle, if your model requires smaller support clusters which are less dense, they might be more difficult to remove compared to ABS and PETG, which are more ductile materials. Meanwhile, anecdotal evidence suggests printing PLA supports under PETG, and vice versa, has good results since the two materials don’t bond together and hence can be clipped away more easily.

Works on: Single-extruder, multi-extruder 3D printers

Pros:

- Works on single-extruder 3D printers

- Often more economical

- Material compatibility is not a concern

Cons:

- Poorer surface quality

- Support removal can be a hassle

Quick Removal: Breakaway Supports

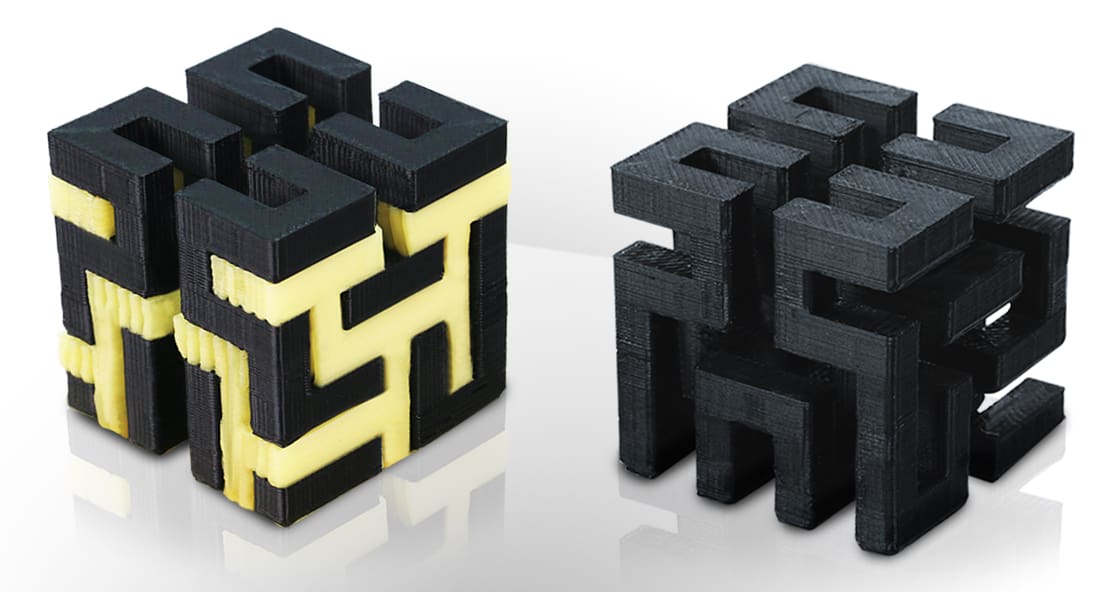

Breakaway supports work much like build material supports. But being of a different material, they are less likely to over-adhere to your prints. This means that the same support structures printed in breakaway materials will be much easier to remove and will leave behind much cleaner surfaces (pictured above).

Breakaway supports aren’t perfect, though. Material compatibility is a concern, as is often the case with multi-material 3D printing, because the support material may not adhere properly to all build materials. Availability of breakaway support materials is also poor, being the least common option on this list. Options include Matterhacker’s PRO Series Breakaway, Ultimaker’s Breakaway, and E3D’s Scaffold (also water-soluble) and Scaffold Snap (only breakaway) materials.

If you’re looking for a support material that peels off quickly and leaves a clean surface finish, a dedicated breakaway support material is for you.

Works on: Multi-extruder 3D printers

Pros:

- Quick and clean removal

Cons:

- Material compatibility is a consideration

- Poor availability

- Only works on multi-extruder 3D printers

Best Quality: Soluble Supports

Soluble support materials offer the best possible surface quality. Instead of requiring manual removal, soluble supports simply dissolve away, leaving clean, unmarred surfaces behind. This allows for dense, solid supports for optimal dimensional accuracy, as well as complex geometries into which solvents, but not pliers or X-Acto blades, can reach. Moving assemblies, such as the gyro above, often benefit from such dense supports and clean removal.

There is a price to pay, however. Aside from being literally more expensive, soluble support materials are usually more difficult to manage. The most common water-soluble material, PVA, is extremely hygroscopic, which means that it degrades with moisture. Proper filament storage is a must. Material compatibility is also a concern, as no single soluble material works well with all build materials. If PVA doesn’t work, then alternatives such as HIPS will often require nasty chemicals to dissolve, which is less than ideal. And as if that’s not enough, soluble supports may take up to hours to fully dissolve, making them a poor choice for those pressed for time.

If you’re looking for the best possible performance, regardless of filament storage, dissolving times, or even potentially harmful chemicals, soluble support materials are for you.

Works on: Multi-extruder 3D printers

Pros:

- Cleanest removal and surface finish

- Complex structures can be supported (internal structures, moving parts)

Cons:

- Material compatibility is a consideration

- Material storage can be a hassle

- Dissolving times are long

- Only works on multi-extruder 3D printers

There You Go!

There you have it! The 3D printer support materials available, along with when to use which. By picking the right material for your use case, you can improve print quality and make 3D printing much more enjoyable.

If you’re interested in diving deeper, we have full guides to 3D printing materials, support structures, and printing supports in general.

Happy printing!

Feature image source: Prusa Printers