Have you ever wondered if a 3D printer could be useful in your woodshop? We have, and we’ve tried it! A 3D printer can help you quickly and affordably make your own woodshop tools and accessories, such as router templates, drilling guides, construction jigs, pushblocks, and more. Much like a drill press, it makes your other tools more accurate, faster, easier, and safer to use.

A printer can also provide custom fittings for construction applications. Need a custom fixture to mount a floating acrylic photo print to a door? 3D printer. Need a clamping fixture for a job that has to be finished tomorrow? 3D printer. Want a completely one-of-a-kind set of drawer pulls that look like baby octopi? 3D printer.

Like any tool, you should consider how you will use 3D printing in your woodshop before taking the plunge and investing money in a printer. With that said, the cost of a new 3D printer has reduced significantly in recent years, and these machines are becoming more accessible. Now may be the perfect time to see how you can benefit from adding a 3D printer to your workshop.

Ready to learn more? In this article, we’ll explore different applications of 3D printing in woodworking, considerations you should keep in mind, and the best 3D printers to add to your workshop. Read on!

Applications

We’ve mentioned a few applications above, but how do these translate to actually using a 3D printer in your woodshop? Well, that will depend on your specific woodshop. We can only provide a rough guide here, but read on to see if any of the following common applications match your needs.

Tools

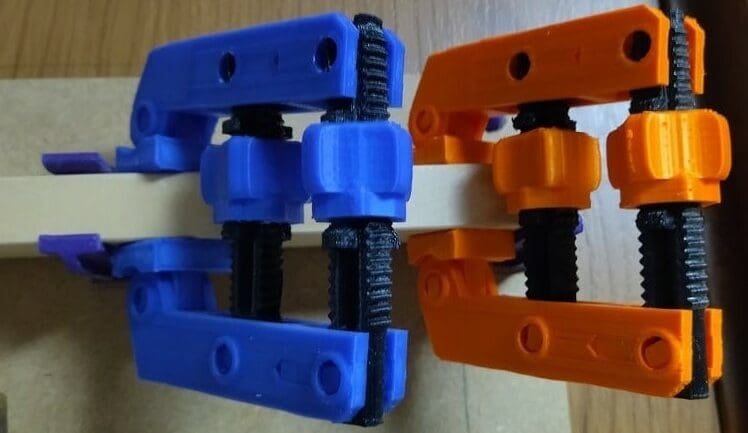

Woodworking tends to be an expensive hobby, and the tools you need aren’t always available in every area. This is where 3D printing can fill a gap. You can create a version of many necessary tools using a 3D printer, allowing you to explore if that tool is the right fit for you. For example, perhaps you aren’t sure if you need corner clamps, a framing strap, or both. You can simply print a version of each of these at home and test them out.

The tools you print might not be as high in quality as the newest Woodpeckers version, but they also won’t cost nearly as much, and you can always upgrade if you find that you really like a certain item. You also don’t have to wait for the item to ship before using it. Many people complain about how slow printers are, but a 24-hour print is still quicker than waiting 10 days for something to be delivered from overseas.

You can also customize parts of a tool that you don’t like. For example, if the handle on your jack plane too big or small for your hands, you can print a differently sized one. If it’s no good, just print another.

Jigs & Templates

This is where custom tooling comes into its own. The ability to print a custom drill guide for a tricky area or a router template that matches your specific needs is where 3D printing in a woodshop really shines. While there are many pre-designed jigs available for download, the real advantage is being able to create custom jigs and templates for your work. Of course, custom items will require doing some design work, and for this you may need to learn CAD (unless you already use it to help you design your pieces). More on this below!

Pre-fit Items & Scale Replicas

Another handy use of a 3D printer is creating a part to test fit or show a client (or significant other) before buying expensive hardwood and spending hours shaping it into a finished part. If you’re not sure if the joint will work that way and don’t have the scraps to try it out, you can print a small scale replica (dollhouse version) and see how it looks first. For small items like handles and trim pieces, you can print full-sized versions to tweak the design before committing to the build.

Finished Parts

Of course you may like the look of your prototype version better than the wooden part you intended (maybe that blue just really pops against the walnut). Or perhaps brass hinges and handles just aren’t right for that toybox design. In this case, you can also print final products. Some examples of parts that can be printed are handles, hinges, or even whole joinery systems!

The great thing about working with a 3D printer in your woodshop is that it provides limitless ways to achieve the result you want. This means there will be ways to use your 3D printer in your woodshop not mentioned here, and we challenge you to go forth and create!

Considerations

If you’ve made it this far, you might be wondering what exactly it would take to add a 3D printer to your woodshop. In the paragraphs below, we’ll go over some considerations to be mindful of.

Printer Type

Firstly, we recommend starting with a fused deposition modeling (FDM) printer. There are many types of 3D printing, but the two most common for hobbyists are FDM and resin-based. A resin printer is great for super fine detail, but without experience it can provide less accuracy to parts. Resin parts also require post-processing and tend to be slightly more brittle. You can absolutely use a resin printer in your woodshop, but it will be trickier to get the hang of than FDM.

FDM printers, on the other hand, are good at providing accurate parts. However, they typically offer less detail than resin printers. This accuracy ensures that guides and templates are as designed, that parts fit the first time, and that tools like squares or clamping aids will keep your wooden parts square and aligned during assembly or shaping.

Filament

The next thing you might ask yourself is what type of filament to use. In our experience, the majority of 3D printed woodworking parts can be made with standard PLA. You’ll only need to change filament for parts that will be subject to direct sunlight for outdoor applications or higher temperatures (e.g. in a vehicle or near an electric motor), in which case PETG would be the go-to option. This can be particularly useful when fitting out vehicle interiors, as custom brackets that suit the contours of the vehicle can make it easier to install the wooden elements of the fitout.

Once you gain more experience, the properties of different materials will become clear, and you can broaden your filament use from there. This might include using ABS to make vapor smoothed parts for a mirror finish or TPU to provide grip on a foot or as a gasket material.

Available Space

The amount of space you’ll need will come down to your specific printer. For woodworking shops, we’ve found that printers with a build area larger than 200 x 200 x 200 mm are most useful. This is due to the scale of parts needed to support woodworking.

While a 3D printer is a useful tool, they don’t like being picked up and moved around. The more you move your machine, the more you’ll have to calibrate it. Some higher-end machines are more tolerant of being moved around, but in general once your printer is on a surface, you’ll want to leave it there.

The other thing to keep in mind is that large prints can take hours or even days, so be prepared to lose the space the printer takes up. You will also need good access to the front and usually one side of the printer for maintenance, filament loading, and print removal. Lastly, they are electrical appliances, so access to an outlet is necessary.

All of this is to say, you will need a semi-dedicated area with electricity and enough space to access the critical parts of the machine, plus a little room for filament storage and tools.

Dust

It’s also a good idea to think about dust. If your printer is going to live in the same area as your cutting and sanding tools, we recommend an enclosure. These can also improve the usefulness of the printer by broadening your material choice, but mainly they’re going to keep the build plate clean. This is important as poor first layer adhesion (the plastic sticking to the print bed) is the most common cause of print failures. It’s a huge frustration for even experienced 3D printing enthusiasts. You can (and should) simply keep the build plate covered when not in use and wipe it down before each print. An enclosure just makes this job easier.

Sourcing Designs

Another thing to consider is where to find parts. There are plenty of repositories where people have shared their 3D printing designs for woodworking purposes, such as Thingiverse, Printables, and Thangs. You simply search the site to find a part that meets your needs and then download it. The file will usually come as an STL or OBJ, which you can load into your slicer and then send to your printer.

However, to really leverage your new tool, we suggest learning how to design your own parts with the help of a CAD program. We suggest starting with one of the many beginner-friendly CAD programs and then moving up to something more challenging like Onshape or Fusion 360. These more advanced programs will allow you to create complex geometry faster and more accurately than the simpler, beginner-friendly programs. Having said that, beginner CAD programs are a great choice for simple designs.

Designing your own parts allows you to match your prints to your specific application. For example, it’s unlikely that someone else has needed a clip for converting a set of finger jointed, recessed panel doors to accept acrylic art prints (or at least they probably didn’t upload their design). For this kind of thing, you’ll need to design your own part.

Cost

The last thing to think about is cost. The good news is, 3D printers are reasonably cheap when compared with other tools you might be considering. An entry-level printer will typically only set you back around $250. However, this will come with several drawbacks, including a lack of enclosure and a great deal of tinkering, such as aligning belts and lead screws, calibrating extruders, updating firmware, and potentially replacing hot ends or adding dampers or cooling shrouds to get the machine working the way you want. A higher-end printer may cost you around $1,000, but will probably print well straight out of the box. You should ask yourself if 3D printing is a hobby or a tool you want to leverage seriously. Neither answer is incorrect, and your case may fall somewhere in between.

Suggested 3D Printers

Given all that, it’s time to take a look at which 3D printers best suit the needs of a woodshop. Here are some printers to consider adding to your space.

Bambu Lab P1S

If your mantra is “buy the last tool first”, then we suggest the Bambu Lab P1S. It will work out of the box, has good support, and a competitive price tag for its advanced capabilities. This printer also has sufficient build volume for the majority of jobs you’ll encounter.

Be warned though, this printer is a tool, not a project! It exists in a closed ecosystem and is not very upgradeable. If you’re a woodworker looking to expand into 3D printing, this is a solid choice. However, if you’re a 3D printing enthusiast looking to expand into woodworking, there are potentially more interesting machines to consider.

Ender 3

If you’re more into the tinkering with the machine side of things, just about any Ender 3 or similar printer will get the job done. If you want an enclosure for the aforementioned dust issues, consider a machine like the Ender 6.

These machines will likely not give you premium results right off the bat, but with time and care you can tailor them to your needs. That is to say that upgrading the machine may become a hobby in its own right. While it will aid your woodworking, you will need to learn about the intricacies of how 3D printers work to get the best out of this machine.

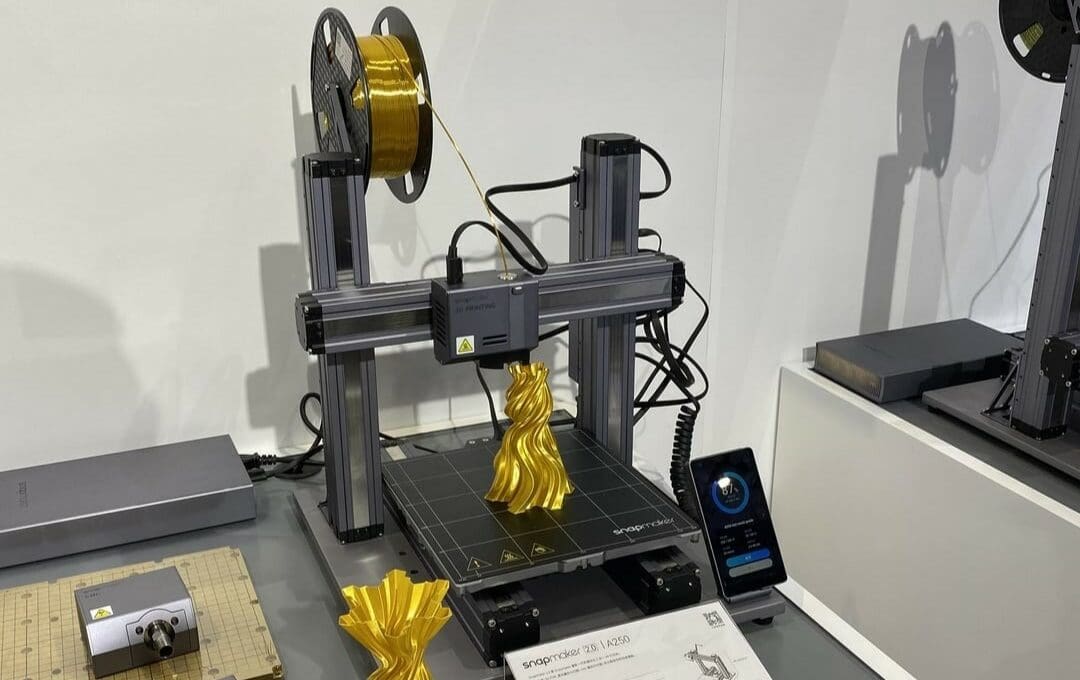

Snapmaker 2.0

If you’re also looking to dip your toes into CNC or laser engraving, you may want to consider a 3-in-1 machine, as these have interchangeable toolheads. This means they have a spindle that can be used for CNC carving and a laser tool for laser engraving and etching. Keep in mind that these machines are jacks of all trades, and won’t outperform the higher end, dedicated tools. However, if space is at a premium and you don’t require showroom ready results, this type of system is a good option for your woodshop.

If versatility is what you want, the Snapmaker 2.0 is a good choice. It’s a reliable machine with sufficient build area. Snapmaker was the first to release a 3-in-1 machine, and their 2.0 system has received positive reviews from users. It’s essentially a 3D printer with extra capabilities.

Other Options

These aren’t the only options out there. The Prusa MK4, for example, is known to be an extremely reliable machine with excellent support, as is the Flashforge Adventurer 4. If you want even more choices, check out our article on the best 3D printers.

Lastly, if you’re looking for something a bit different, you could go the full DIY route. It’s actually possible to build a printer from (mostly) wood with just a few electronic components and metal attachments.

License: The text of "Woodworking & 3D Printing: Combine Them in Your Workshop" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.