Building Evolution

Architecture is an ever-changing field of structural design. Since the beginning of time, a multitude of influences has resulted in extraordinary structures. Elements like climate, culture, and imagination can all factor into architecture.

Technology is also a prominent influence in architecture, including 3D printing. With its rise in popularity over the decades, 3D printing is changing how many industries manufacture and prototype products.

In the context of architecture, 3D printing presents the capability of improving and speeding up projects. Architects have already turned to it for several purposes, including to create models. 3D printing only continues to grow within the architectural field as more businesses adopt the technology.

In this article, we’ll take a look into different 3D printing technologies used in architectural projects as well as real-world examples of 3D printed architectural feats!

Methods & Techniques

There are numerous 3D printing techniques that are reshaping architecture, but here, we’ve chosen the main ones to highlight. We’ll cover architectural modeling, 3D printing interior decorations, topographic and landscape models, custom building, metal 3D printing, and 3D printing in special environments.

These methods are all unique and each uses its own tools, like architectural design software, alongside different hardware, materials, and equipment.

Modeling

Models play a fundamental and important role in architecture. They serve a range of functions from representing architectural ideas to helping eliminate design flaws. Models are further used for marketing and communicating projects.

How It Works

The process of producing a 3D printed architectural model starts with designing. For 3D models, this usually takes place with CAD (computer-aided design) or BIM (building information modeling) software.

CAD programs serve as a visualization and construction tool for architects as they design their models. BIM is similar to CAD but is more tailored to architects and engineers, easily allowing them to specify objects like walls and doors in a model.

There are many software programs geared toward architectural modeling. Some of the best and most common options include SketchUp, FreeCAD Arch, and Dynamo.

After a 3D model is designed using software, the file must be saved and converted into an STL file. Finally, the model is ready to be printed.

Benefits

3D printing has allowed architects to save time and money while creating more complex models. There’s nothing, 2D or digital, that can replace visualizing a physical model before building it.

This process is cost-effective because it drastically reduces the time spent creating the model. Compared to building a model by hand, 3D printing models can accelerate the design process with rapid prototyping: the rapid production of parts and models using CAD.

Real-World Examples

A real-world example of this method can be seen with the company WhiteClouds that 3D printed an architectural model of Brigham Young University’s campus.

Another example of 3D printed architectural modeling is the famous La Sagrada Família in Spain. Since 2001, 3D printing has been used to accelerate the repairs and maintenance of Antoni Gaudí’s basilica design.

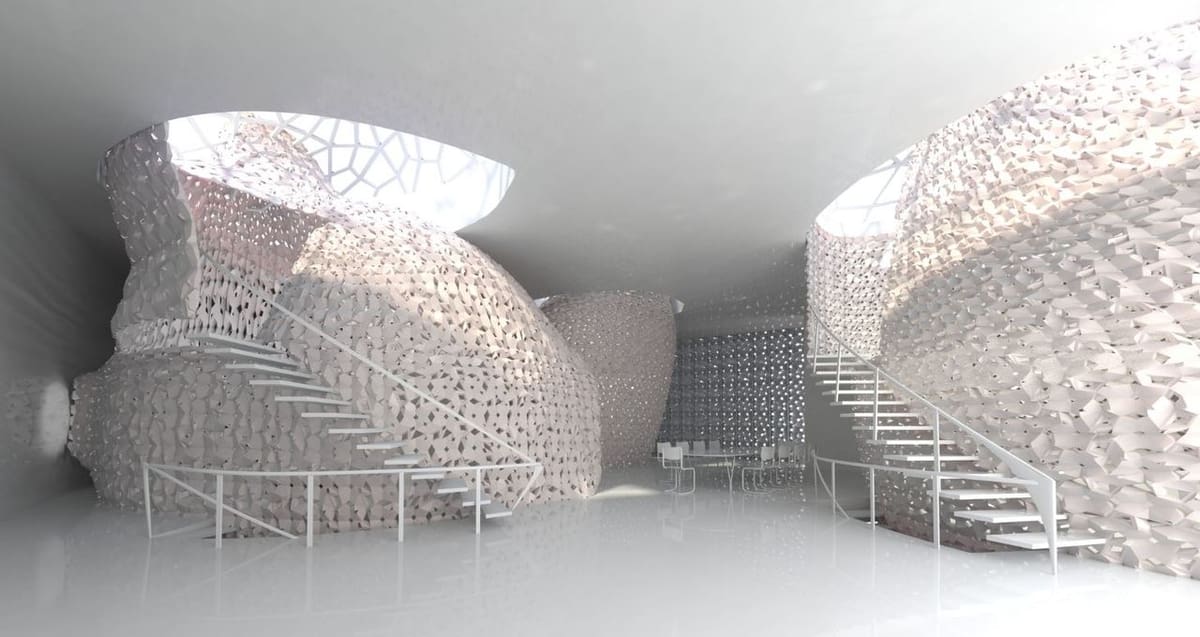

Interior Decorations

The first thing people picture in their minds when they hear “architecture” is probably the outside and structure of a building. However, interior design falls under this category as well. When it comes to interior decorations, 3D printing is definitely leaving its mark!

How It Works

The process of 3D printing interior decorations is pretty simple. Using CAD software, the designer can create a digital 3D model. Next, after customization, the model is 3D printed.

Depending on what the décor is for, 3D printing in the interior design field uses a range of technologies.

Benefits

3D printing offers several advantages in this field. With access to digital design and production, 3D printing technology provides an accurate and speedy process for designers and clients. Compared to traditional methods, 3D printing can finish something that would usually take days in just hours!

This method also gives people the opportunity to tailor anything to their liking. Before being printed, products can be revised and modified by clients. Clients can easily request changes such as color or size.

Designers can also customize a range of products, from furniture to home décor, with new and complex shapes. With such flexibility in the design process, the doors are wide open to a number of unique creations!

Real-World Examples

The company Emerging has created and printed many interior decorations such as seating structures, statues, and more. You can browse their impressive work in their portfolio.

Another example of 3D printed interior decorations is from the company, Building Bytes. Building Bytes specializes in ceramic 3D printed interior decorations that have interesting structures.

This method can also lead to sustainable production using bioplastic materials. Items that have been printed with this method include various patterns in interior parts such as tabletops.

Topographic & Landscape Models

Topographic and landscape models serve several purposes in architecture. These models can depict unique landscape features as well as elevations and shapes.

How It Works

As technology continues to grow, 3D scanning and 3D printing have presented a new method of creating topographic and landscape models. These technologies cut costs, speed up design processes, and even reduce risks for engineers.

First, 3D scanners can take extremely detailed images of their surroundings. 3D scanner technology often uses lasers, which have the ability to capture details of an entire area rather than one point at a time.

After conducting several scans, the captured images are converted to precise 3D models. At this point, 3D printers have the information they need to duplicate all data captured by the scanner into a model.

Benefits

Allowing builders and architects to visualize what needs to be done, these 3D printed models serve as good prerequisite work prior to construction. For example, by examining landscape and topographical models, architects can determine where rain will flow or what areas are best suited for certain purposes.

Real-World Examples

This technique of 3D printing is used for both personal and commercial purposes. One example of how 3D printed topographical maps are used commercially is the company WhiteClouds. WhiteClouds 3D prints topographical maps for universities, museums, national parks, and more.

More individual and non-commercial examples of 3D printed topographical models are also popular. Microscape is a company that makes non-commercial topographical models using 3D printers, while another example is this topographical map of the United States.

Custom Building

Another way 3D printing is used in the field of architecture is with custom buildings. By this, we mean, 3D printing the actual buildings, rather than using traditional manual labor to construct a structure.

How It Works

Rather than printing in metals and plastics, this method often uses materials more suited for construction like cement and sand. Additionally, due to their size, buildings are printed using large-scale machines, often with robotic arms, rather than in the conventional box-form printers.

Before printing, architects use BIM, drafting, and design software to produce a model of a prospective building. After a design is complete and it’s time to print, software is used to operate construction under human supervision.

Benefits

Automated construction with the help of 3D printing cuts production time drastically. Printing machines are fast and accurate, eliminating direct human error. Substantial buildings can potentially be printed as quickly as in 24 hours, as machines are fast and don’t get tired!

This, consequently, removes the need for most human labor, and with machines only needing to be monitored. Additionally, 3D printing saves a lot of money. At this point, the cost of construction 3D printers is significant and they aren’t commercially available. However, the material costs are minimal compared to building a traditional structure.

Real-World Examples

More recently, 3D printing has been used to print full-size houses and other buildings! There are many amazing examples, including the world’s first 3D printed apartment building in China. One floor was printed per day and 3D printing was able to cut production time and costs by more than 50%.

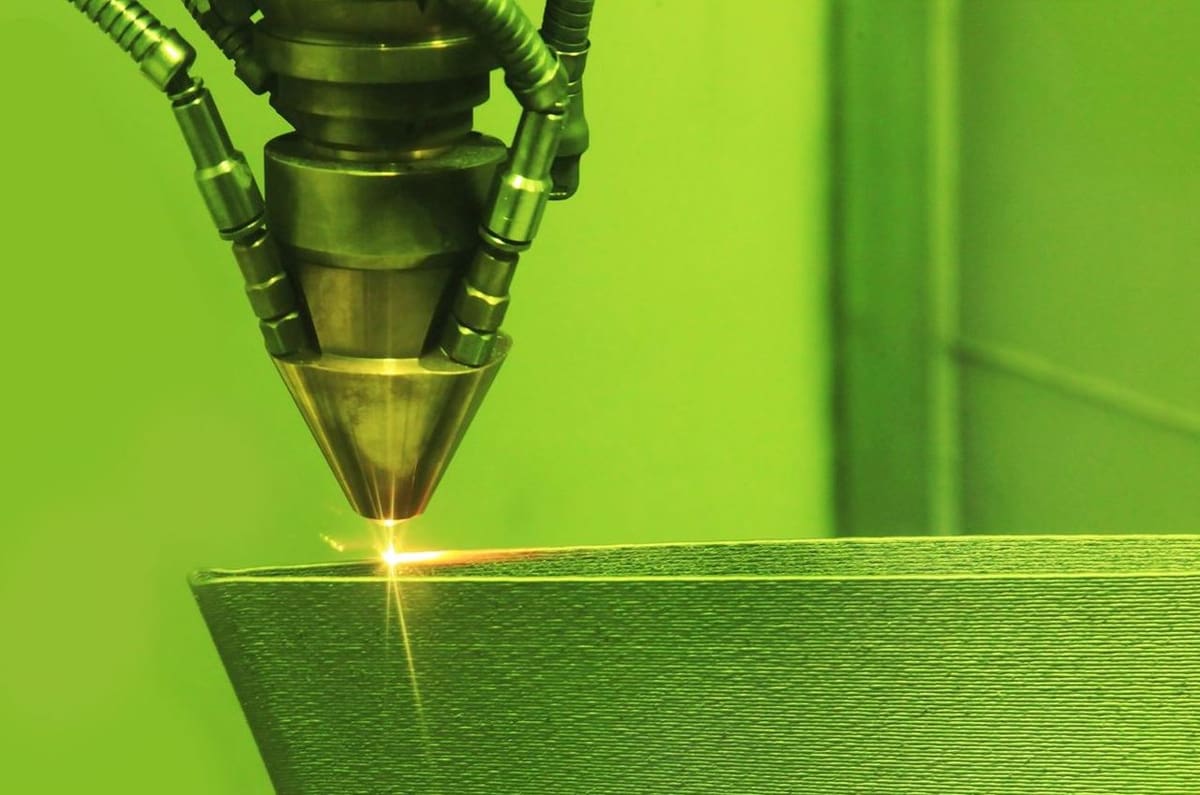

Metal 3D Printing

Printing in metal allows for creating high-strength and durable parts. These parts could be applied to architectural establishments to increase the structural integrity of a building or structure.

How It Works

For architectural purposes, larger, specialized, arm-like metal 3D printers are used. As is typical, parts and structures must be designed using CAD software.

Depending on what is required or what the final product is, several metals can be used for 3D printing. For example, titanium alloys are used to make engine parts while aluminum alloys are commonly used in industrial areas. Other metal materials include steel, copper, and cobalt-based alloys.

Benefits

Metal 3D printing, as we mentioned, allows for producing strong and durable parts that can be used in architecture projects. 3D printing allows architects to create more complex structures and gives them design freedom for large-scale infrastructure.

Real-World Examples

Currently, a robotic metal arm exists that can print stainless-steel layer-by-layer. This technology, however, is still in its infancy.

Some items architects are testing to print are steel structures for buildings. So far a 3D printed steel bridge has successfully been installed in Amsterdam. It was printed using MX3D’s metal printer.

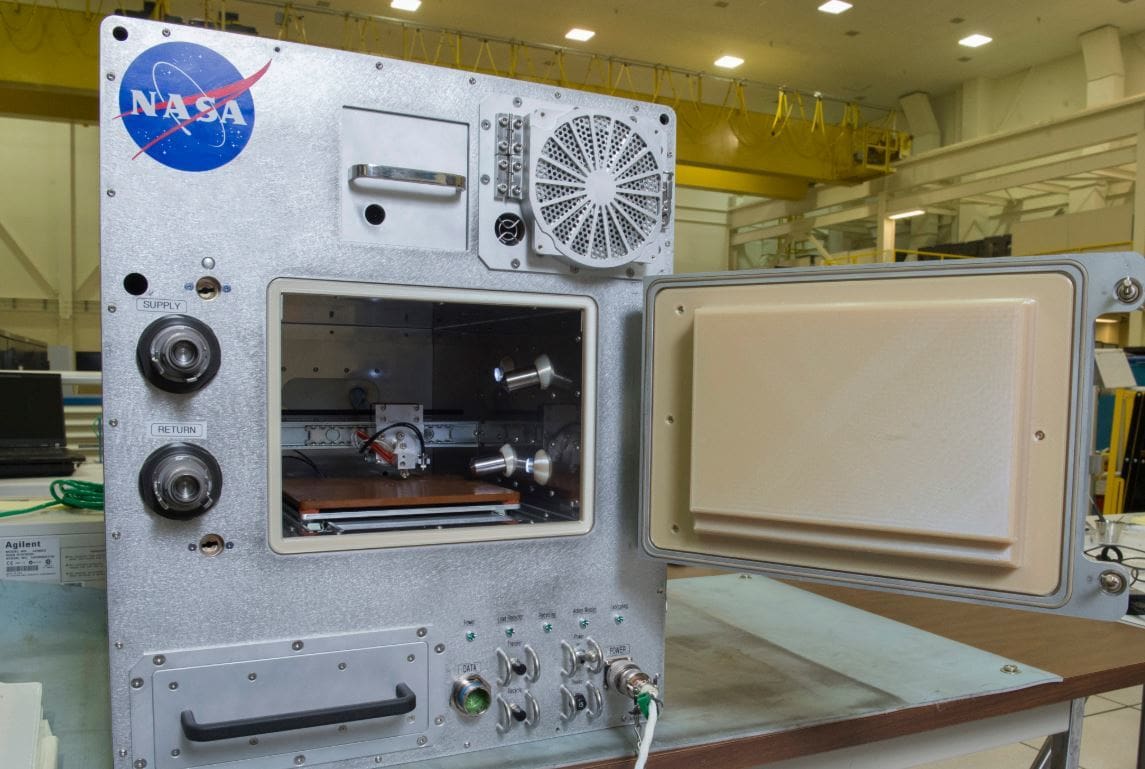

Special Environments

As 3D printing expands, people are experimenting with architectural prints in areas never before thought possible. 3D printing is making its way to remote areas, to war zones, and even to space! Because 3D printers can quickly be set up anywhere and don’t always require electricity, they can function in unique places.

How It Works

This method works in a variety of ways. The goal is to eliminate or reduce human interaction with the building environment. In turn, this decreases the risk of any environmental harm (severe heat, lack of oxygen, etc.) to the inhabitants.

You need a 3D printer with a size suitable for the task (i.e. large scale to print a building, small scale for tight spaces). This technique could be used in other ways too, such as printing different parts when none are readily available nearby.

Of course, as 3D printing architecture expands into more remote areas, printers would need to be adjusted accordingly with durable equipment and materials. To 3D print in such environments, more advanced remote printing software also needs to be developed.

Benefits

This method could significantly reduce human risk as well as human labor. You’d be able to make a variety of different objects with the materials available. This could be helpful if someone isn’t sure what exact parts they’ll need in a remote location. 3D printing would allow them to make whatever parts they want as long as they can create or find a 3D model of what needs to be printed.

Real-World Examples

In some remote areas of the world, access to required resources isn’t always possible. For example, organizations like Doctors Without Borders operate in remote areas with unreliable resource availability. Currently, with 3D printers, rather than waiting weeks for the delivery of materials, doctors can quickly print what they need and have it in a matter of hours.

Recently, soldiers and healthcare workers deployed in deserts tested out this method. A 3D printer was able to successfully print several products such as scalpels, hemostats, bandages, and even bone parts! Another project is the installation of a 3D printer on the International Space Station. Both these projects were done in collaboration with Fab AE (Fabrication in Austere Environments).

3D printing for architectural purposes is still being experimented with. So far, there have been some projects undertaken. The US Army, for instance, has experimented with printing concrete barracks. Because manual labor isn’t possible in certain environments due to unsafe conditions, a 3D printer would reduce the risk for humans.

What Software Should You Use?

As we’ve mentioned throughout the article, designing your project is the first and main step of 3D printing. Choosing the right program is important as it helps visualize a project in detail. If you’re interested in incorporating 3D printing into your architectural project, take a look at these software programs we’ve gathered!

SketchUp (Beginner)

SketchUp provides its users with a simple platform to create quick, but detailed models. Additionally, it supports BIM plug-ins that will help you meet all your needs!

- Price: From ~$120/year (also a free version and other paid professional plans)

- Ease of use: Easy to learn

- Operating systems: Windows, MacOS

- Unique features: Beginner friendly, many extensions

Archicad (Intermediate)

This program is an affordable option geared towards architects. It’s optimized BIM software that allows users to collaborate with others to work together on a project.

- Price: Contact the sales team

- Ease of use: Not too difficult to learn

- Operating systems: Windows, MacOS

- Unique features: BIM oriented, regularly updated

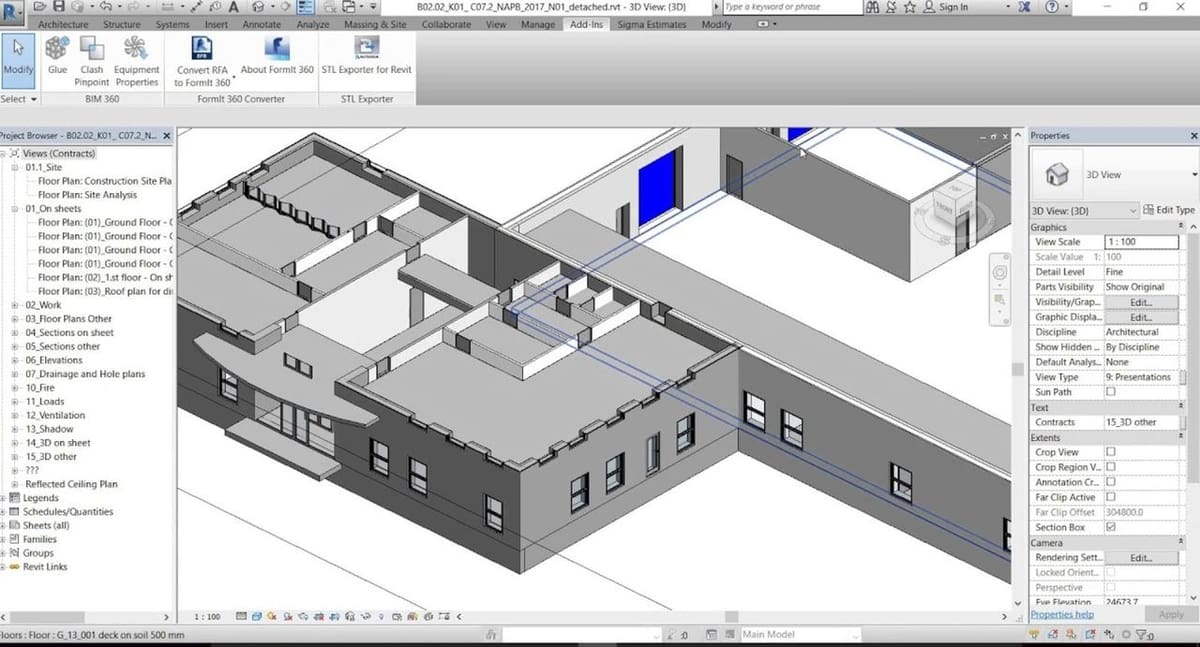

Revit (Advanced)

Revit is another software that’s aimed at architecture models and accommodates BIM. It’s also used by interior designers to map out how a room or building will be decorated.

- Price: ~$2,400/year

- Ease of use: Easy to learn the basics, difficult to learn the advanced features

- Operating system: Windows

- Unique features: Variety of features, ideal for interior design

V-Ray (Professional)

V-ray allows its users to create highly detailed and accurate models of their projects. It has several resources and extensions, though compared to other software programs, V-ray requires a higher level of expertise.

- Price: Varies depending on BIM software

- Ease of use: More difficult to learn

- Operating systems: Windows, MacOS

- Unique features: Several adjustable settings, integrated libraries

Lead image source: KMCA

License: The text of "How to Use 3D Printing in Architectural Projects" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.