How Does Bronze 3D Printing Work?

Need a custom bronze statue, or fancy minting your own bronze coins? If you can 3D print it, chances are you can get it in bronze. But maybe you want something to look like bronze without the cost and weight of this precious metal; there’s a 3D printing method for that, too.

Here we look at all things bronze, how to get them, and the growing role 3D printing in public art, such as the new and nearly 7-meter tall bronze “Embrace” statue in Boston.

Just like 3D printing in gold and silver, there are various methods of 3D printing that apply to bronze. When we talk about 3D printing bronze jewelry or small objects, 95% of the time, we’re talking about 3D printing the mold or model used to cast the item. But it is also possible to directly 3D print using 100% bronze, which typically involves bronze powder used in a laser powder bed fusion or binder jet 3D printer.

Far more economical, though, are the polymer filaments embedded with just enough bronze powder to make the model polish up to look like bronze and even have a nice metal-like weight.

If you need to 3D print just a few bronze parts, the best option might be a 3D printing service that will either take your digital design, print a model, make a mold, and then cast your part in bronze, or will directly 3D print in bronze — although the latter is less common.

Now, let’s take a look at some bronze 3D printing processes and services.

Great Examples of 3D Printed Bronze

When people started mixing soft copper with tin to create bronze for tools, weapons, art, and coins more than 5,000 years ago, it ushered in one of the most significant cultural transformations in human history. We’re not comparing 3D printing to the Bronze Age, but the technology does go a long way in making bronze more accessible for a wide range of applications.

But first, let’s look at one of the most iconic applications of bronze: the bronze statue. Typically, bronze statues, such as Rodin’s The Thinker, were first sculpted in clay, then covered in plaster to create a mold into which molten bronze was poured. Large statues were often cast in pieces and assembled.

Today, traditional art foundries, like Walla Walla Foundry in the US, often use 3D printed models to cast statues. Artists no longer need to sculpt a life-size model from which casts are made. The process goes directly from a computer design program to a 3D printed model.

This is the general process Walla Walla Foundry followed to construct the statue designed by artist Hank Willis Thomas called The Embrace. The 20-foot-tall bronze statue that commemorates the lives of Martin Luther King Jr. and Coretta Scott King, was unveiled in Boston in January 2023. From Thomas’ original concept as a digital file, the Walla Walla Foundry scaled up the model to the desired size and divided it into more than 600 pieces. The individual pieces were 3D printed on a Voxeljet 1000 3D printer and then dipped in ceramic to build up a mold. The model and mold assembly is then heated to burn out the model material cleanly, leaving just the cavity into which the molten bronze is poured.

Bronze, and bronze alloys, are valuable materials for a wide range of industrial applications. Metal 3D printer maker Spee3D showed that it was possible for army units to use cold spray 3D printing to be self-sufficient in the field. Among several examples, a team of the Australian military was able to print an aluminum bronze gunner’s ratchet, at a weight of 2 kg, in 60 minutes. This tool is needed to operate the Australian Light Armoured Vehicle Machine Gun, and bronze was important for its spark-resistant qualities. Using Spee3D’s printer, the item cost about $100 to make. The soldiers also printed an aluminum bronze hinge that’s an essential part for the safe operation of manual fuel pumping in 10 minutes at a cost of about $35.

3D Printing Bronze Replicas

Bronze is a valuable metal, making bronze statues and art ripe for theft. For example, after the bronze wreaths on the gates of a school in Auckland, New Zealand, honoring teachers who died in WWI were stolen in 2021, local officials thought better of installing more bronze.

Instead, they reached out to the Creative Design and Additive Manufacturing Lab at the University of Auckland. The team there set about 3D scanning similar wreaths and then digitally sculpting the digital files to make necessary adjustments using software, including SolidWorks and Meshmixer. From the digital design, the wreaths were 3D printed in sections using an EOS Formiga P110 Velocis SLS 3D printer and bonded together with epoxy. The seams were filled with automotive filler and sanded and primed. They were then painted in bronze paint, which was then oxidized. The oxidation was then cleaned off, as if the wreath had been cleaned and polished, for a more natural bronze patina look.

Casting Bronze from a 3D Printed Mold

As we mentioned above, 3D printing a model in wax or another material is how 3D printing is mainly used in making bronze objects bronze. The method, called lost-wax casting, is thousands of years old and had required an artisan to first sculpt in wax or clay. The object is then dipped or coated in a plaster-like material that dries around the object. Then the plaster is heated to melt out the wax leaving a cavity in the shape of the object. The molten bronze is poured in, and voilà, a bronze statue, coin, or tool.

Today, you can 3D print using a wax-like material, which means you design your object using computer-aided design (CAD) software – no sculpting skills required – and simply print it out or upload it to an on-demand 3D printing service. The most typical 3D printer for finely detailed wax models is vat polymerization, but wax-PLA filament is also available for FDM 3D printers.

Most of the 3D printing on-demand services, such as Craftcloud, iMateralise, and Forecast 3D, will create your bronze objects using this method.

3D Printing with Bronze Filament

If you’re a hobbyist, making a mold and pouring molten bronze might not be practical. However, there are alternative methods for printing bronze using desktop FDM printers. There are filaments on the market that can produce final parts that are almost purely bronze and others that print parts with a bronze sheen that don’t contain any metal at all. The choice of filament depends on the specific use case, as the higher the bronze content, the more expensive the filament. Here are some of our top choices of the best bronze filaments and some alternatives available on the market.

The Virtual Foundry

This company offers bronze filament for FDM 3D printers that produce bronze parts. This filament consists of 88-90% bronze powder mixed in a polymer binder. After printing with this filament, the object must be fired in a kiln to remove the polymer and fuse the bronze. Printing this filament also requires an all-metal hot end and a steel nozzle, otherwise the metal filament will wear through the printer’s components and produce poor-quality prints.

Filament from the Virtual Foundry is the only way to get a nearly pure bronze object using an FDM printer. However, this method may still not be the way to go for some makers as a kilogram of this filament costs upwards of $200, not to mention the necessity of a kiln to sinter the filament.

ColorFabb

For those who don’t have access to a kiln or a budget of $200 for a kilogram of filament, purchasing a filament with bronze filling may be a good option. ColorFabb’s offer is about 50% PLA (polylactic acid), which makes it easier to print and process.

After printing with hybrid plastic and metal filaments like ColorFabb’s, some post-processing must be done to achieve a bronze-like sheen. Colorfabb recommends sanding the part starting with lower grit sandpaper and working to a finer grit. After sanding, the part should be polished with copper polish to get the best results.

3DJake

Lastly, for those who do not require an actual bronze part, just a bronze-colored part, there is a type of filament available as well. Several companies produce plastic filament in a bronze color that is easier to print with than filaments containing bronze and which usually don’t require any post-processing to achieve a bronze-like patina.

3DJake is a European-based online shop that sells filaments, including a bronze-colored one. This filament is a specially modified PLA and is biodegradable, unlike filaments containing metal parts. Users of this filament report ease of printing and say no post-processing is required.

Alternatives

While the three picks mentioned stand out for specific reasons, there are alternatives worth considering as well.

Filaments Containing Bronze

These decorative filaments can contain up to 80% bronze and provide nearly the weight of metal as well as the cool feel you don’t get with polymers. Be careful to follow the printing instructions from the filament maker since these metal-fill products require special handling.

Get the Bronze Look

If your project doesn’t need the weight or look of real bronze and you’re really looking for the shine and metallic glow for your print, there are more bronze-colored filaments on the market that will help you make a statement with your model.

Other ways to Print Bronze

Yes, metal 3D printers can use bronze in powder form to directly 3D print bronze parts, including jewelry, coins, statues, etc., but this method is rare.

In a process called laser powder bed fusion (LPBF), also called selective laser melting (SLM), bronze powder is loaded into the vat of the 3D printer, and a laser fuses the metal powder together layer by layer to make a fully metal part. Despite the advantage of being able to directly 3D print a metal end-use part, LPBF machines are expensive, starting at around $100,000 for a base model. Plus, you’ll need several liters of bronze powder to fill the powder bed for each print run, which can accommodate several or even dozens of parts. The left-over bronze powder can be used for the next print.

As mentioned above, cold spray is a 3D printing method making use of bronze powders for part construction. Cold spray printer maker Spee3D uses an aluminum-bronze alloy for its corrosion resistance, anti-fouling, and high strength to print parts, such as housings, pumps, impellers, and bushings for maritime environments.

Although metal 3D printing using pure bronze is uncommon, there’s been new research into the application of nickel-aluminum-bronze alloys in wire arc additive manufacturing.

Bronze 3D Printing Services

If you’re excited about getting an object printed in bronze but don’t have the time and resources to make trying it yourself feasible, consider using an external company to get your object printed.

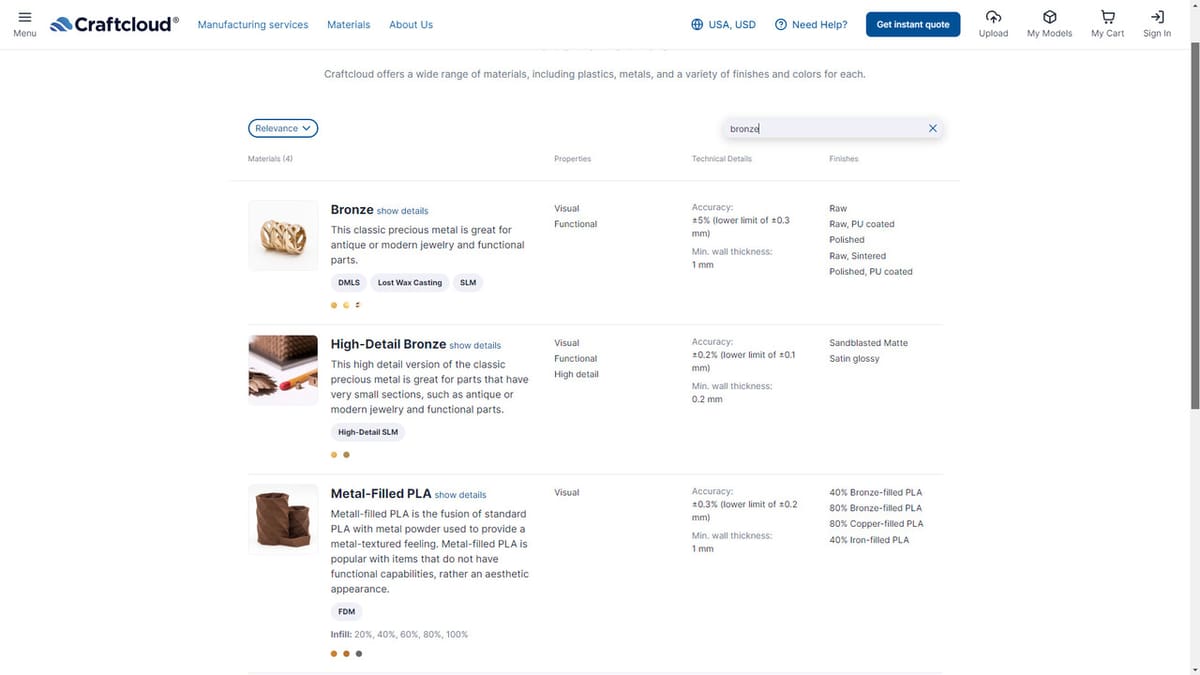

Through Craftcloud, you can easily find the best price and provider for your needs. The 3D printing marketplace offers real-time prices from vetted providers based on your designs, material choices, and location. In addition to taking the work off your hands, you can benefit from professional quality, a wide range of materials, and round-the-clock support. Craftcloud offers bronze parts made with DMLS, lost wax casting, FDM, and SLM technologies.

Other options for getting your model 3D printed in bronze include i.Materialise, Forecast 3D, and Sculpteo. Overall, these three companies primarily utilize lost wax casting to form your desired model.

License: The text of "Quick Start Guide to Bronze 3D Printing" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.