The business of 3D printing services is growing faster than ever. That’s because more and more people are looking to 3D printing for their projects. Whether an individual enthusiast, a research group, or even a production company, many aren’t keen on investing capital into sourcing 3D printing equipment and instead opt to work with a 3D printing service first.

These days, the majority of 3D printing services are based around working with professional clients. There’s certainly still a market for printing custom items for individuals, but a big part of the business is B2B.

Even if you have access to a 3D printer, sometimes using a 3D printing service is the better solution. For example, you might need a part made in a material or color you don’t have on hand and would prefer not to buy a whole spool of, so it makes much more sense to order the part instead of acquiring all the equipment and stock, which you might not need outside of a single project.

In this article, we’ll go over 10 reasons why 3D printing using a service can be beneficial over 3D printing without one.

And if you’ve already got projects you want to print and are looking for options, check out Craftcloud, our 3D printing price comparison service.

Supply Chain Management

With the improvement of 3D printing technologies over the years, the technique has matured to being able to produce both prototypes and end-use parts, especially for certain applications.

In general, developing and manufacturing a particular part can be very expensive due to the high costs associated with tooling. Because 3D printing is such an adaptable technique, manufacturing a number of different parts and their design iterations is less of an issue, making it a strong solution for evolving designs.

These days, many research groups and companies rely on 3D printing services to act as supply chains. For them, the ability to have a custom part easily created and delivered is extremely useful.

Take a look at Nyxo Studio, a design company based in Dubai. They launched a special collection of coffee tables with 3D printed bioplastic, and they achieved this by teaming up with Colossus Printers. This sort of outsourcing can save money, as 3D printing becomes cost-effective for smaller production runs.

Wide Variety of Materials

One of the most important selling points for a 3D printing service is the variety of materials (and technologies) it has to offer. With constant innovation going on in the industry, it’s often the service providers that are able to work with the newest stuff, especially the larger ventures.

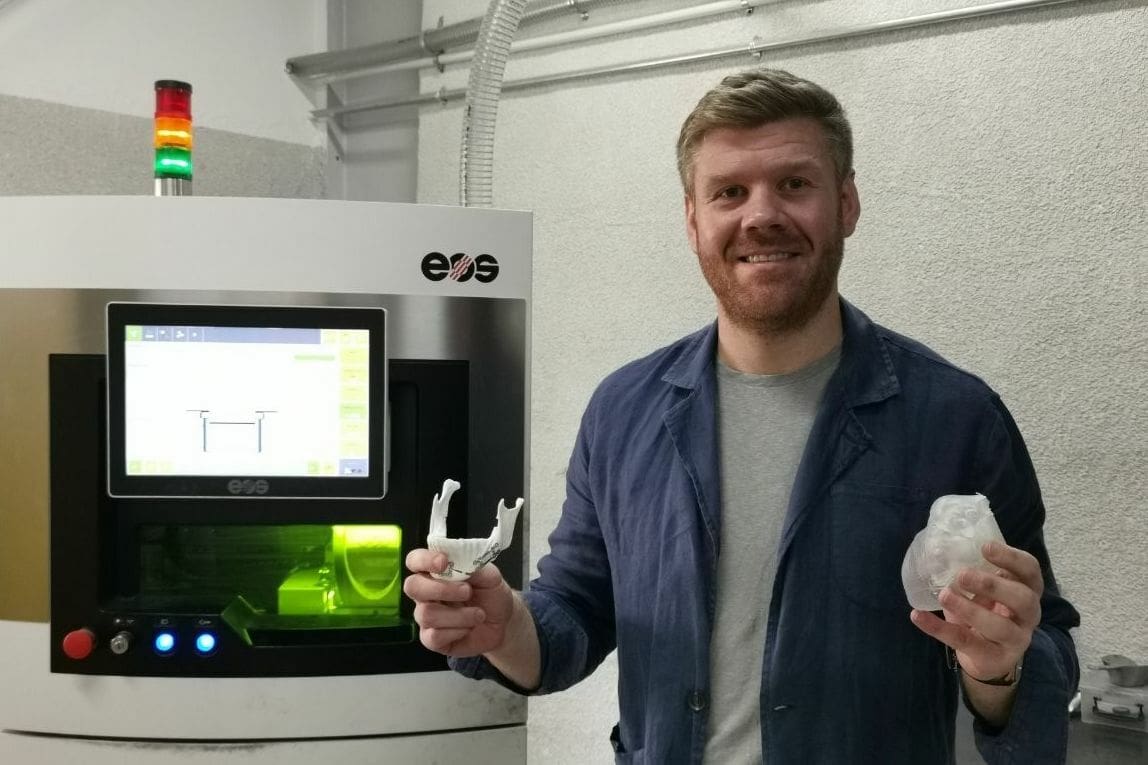

Most 3D printing services at least offer three of the most common 3D printing technologies: FDM, resin printing (including material jetting), and SLS. For FDM, some of the most common materials are PLA, ABS, and PETG, while resin printing mostly makes use of photosensitive resin. In terms of SLS, PA12 nylon powder is the most common material type. These materials have become the standard choices in the world of 3D printing services, but other options exist as well, like stainless steel and even gold.

The variety of options makes it possible for a customer to obtain the right material for their project, considering mechanical, chemical, and aesthetic properties. A rather interesting example of material meeting all the needs for a project is the 4D midsole – to fit onto some of their shoe models – developed and printed by Carbon for Adidas.

A multitude of material options isn’t useful just for professional needs. A professional 3D printing service also offers simple materials that an individual may not have access to. In this case, acquiring a specific material and using it to print a part yourself might cost more than simply ordering a single part in that specific material.

Wide Variety of Colors & Finishes

With so many materials available, 3D printing service customers are in for a treat when it comes to the variety of colors and finishes available. Creating a perfect match for a specific application has never been easier.

Colors

Filaments for FDM like PLA, ABS, and PETG usually come in a very wide range of colors. This is due to the fact that the plastic pellets from which filament is made are easily dyed.

More advanced filament blends like composite filaments and nylon are tricky to dye, hence why you don’t see them in a range of “wild” colors.

In terms of resin 3D printing, there are all sorts of colors available for resins, but generally not quite as many as there are for PLA. Technologies such as SLS operate on industrial-grade nylon powder which comes in either white, black, or somewhere in between. Again, this is due to it not being the easiest to dye.

There are also full-color 3D printers which are a perfect match for making visually appealing prototypes as well as educational models in the fields of, for example, anatomy and geography. Considering professional 3D printing equipment can be quite pricey, having the ability to gain access to otherwise inaccessible technologies via a 3D printing service is of great value for the end customer.

Finishes

Apart from color, multiple surface-finishing techniques can also be used on 3D printed parts. For starters, 3D printed parts can be processed to completely disguise the visibility of layers, making them look like they didn’t even come from a 3D printer.

But that’s only the beginning. Finishes can include sanding, smoothing, polishing, electroplating, and painting, just to name a few. Not every 3D printing material is suited for every post-processing technique, but service providers should make that clear to you during the ordering process.

Apart from the sheer variety of options, one of the greatest benefits of letting a service take over finishes is the quality and convenience. Post-processing can take a lot of time, and with professionals handling it, you can feel confident that its application will be consistent and of high quality.

Larger & More Flexible Print Sizes

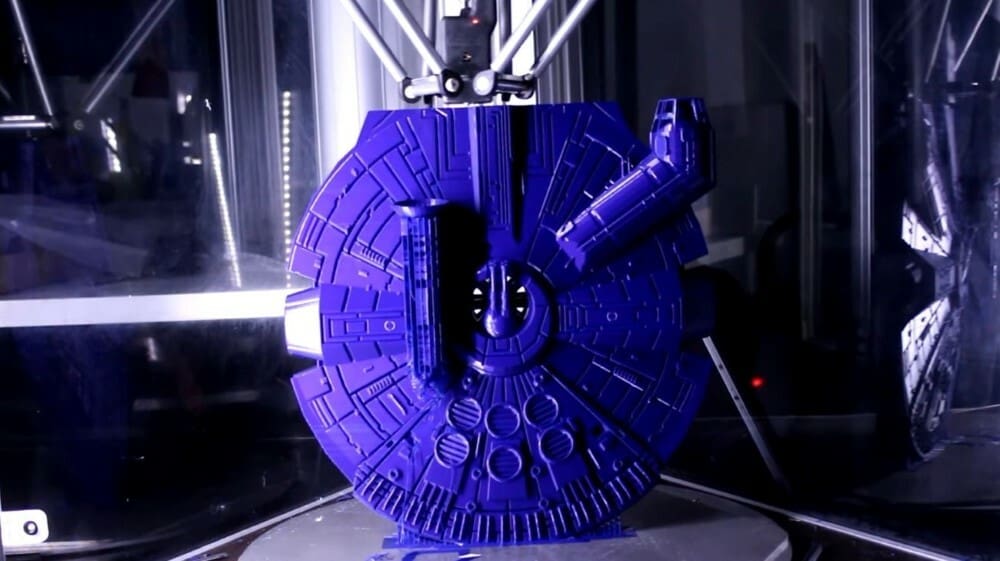

3D printing services typically operate many 3D printers in order to meet both high demand – keeping lead times acceptable – and varied requests. This leads to a number of benefits, one of which is the flexibility of print sizes.

There are times when splitting a large part into several segments simply isn’t the best solution, so a large build plate is needed. Chances are that, short of having access to a print farm, a person or group is less likely to have the necessary massive printer on hand, whereas many services do.

Professional-Quality Parts

3D printers are becoming more accurate, with even the most affordable of machines demonstrating impressive precision. Yet, many prints require that extra touch of accuracy (such as jewelry) or tight tolerances to guarantee a perfect fit (like for functional assemblies). A professional job offered by a 3D printing service can deliver parts with consistent precision and finish.

For starters, professional machines should be more reliable in terms of consistency. It’s an important factor to take into consideration when printing a large number of parts requiring consistent, tight tolerances.

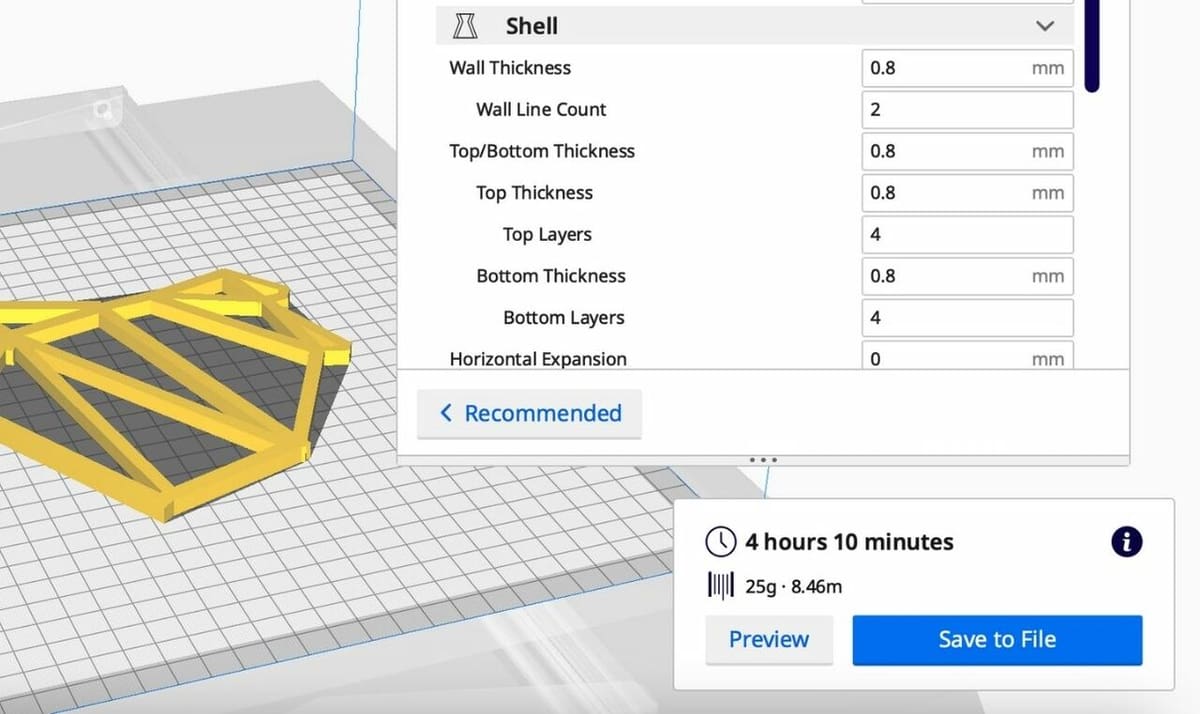

However, it’s not only the machines that contribute to the end result. People who work with 3D printing for a living make a significant contribution to the production of a professional quality part. They’ve got the knowledge and expertise to advise you on how to best prepare your model, select the most suitable material, and finally create the end part.

A good example of how professional equipment and people can make a difference is the story of how Ultimaker has helped Gerhard Schubert GmbH optimize their workflow by 3D printing custom tools for its consumer-goods packaging machines.

Another example of such a positive impact is the integration of Formlabs‘s resin 3D printers into the workflow of Isaac’s Fine Jewelry, which helps ensure that clients receive the customized jewelry they’re looking for.

Saved Money

If someone wants to have something 3D printed, there are two options: either buying the equipment and printing the parts themselves or ordering the printed parts. Regardless of whether it’s an individual or an organization, money stands to be saved by going with a 3D printing service.

In the case that in-house 3D printing is being considered for a particular venture, it actually makes sense to outsource it via a 3D printing service first. This might allow an individual or company to access 3D printing technologies while avoiding the costs of the machines, materials, and maintenance. Once you figure out if 3D printing suits the needs of your business, it might be the right time to start considering buying equipment.

In other scenarios, some businesses are able to save money in the prototyping phase by using on-demand 3D printing, before putting the final version into production via another process like injection molding.

Regardless, it can save a lot of money to outsource a project until the “tipping point” is reached, at which point the costs of purchasing the equipment become a worthy investment.

Saved Time

When you order a part through a 3D printing service provider, there’s no worrying about setting up the printer and maintaining it. It’s as simple as paying a fee and receiving your desired parts. It’s like a “key in hand” experience, with one not having to worry about all the overhead of setting up, maintaining, and operating 3D printing equipment.

And even if equipment is on hand, it may not be sufficient to print many parts in a short time. As 3D printing services typically employ large 3D print farms, large quantities of parts can be made very quickly.

Of course, lead times can be large with a service, so be sure to pick your service wisely. But the lead time of ordering a 3D print (in a standard material with a standard finish) might well be shorter than the total time it could take to set up, maintain, and operate the relevant equipment. This alone is enough of a reason for many to print with a service.

Additionally, printing times can last hours or even days, something that requires supervision that not everyone can carry out.

Scalability

Since entering mainstream media, 3D printing has been described as a slow process. Normally, this refers to 3D printing not being able to compete with conventional manufacturing methods, like injection molding, when executing large production runs.

There’s some truth to this, but it’s important to know that 3D printing can be a very efficient process under certain circumstances. Yes, it’s not the best when wanting to make very large quantities of the same parts, but it’s more than capable of pulling off low- to mid-volume production.

This is especially the case whenever custom design or iteration enters the equation. Here, conventional methods have way more overhead in terms of time and cost.

For this reason, 3D printing services in particular can provide scalable manufacturing solutions that meet the demand of even medium-scale production. In a garage or small office, low-scale production might be possible, but anything above that is hardly imaginable, and that’s exactly where the use of a 3D printing service makes perfect sense.

Expert Advice & Assistance

As mentioned before, 3D printing services work with an array of different clients. They range from individuals wanting a 3D printed cartoon figurine to some of the world’s most recognizable corporations looking to improve processes. In either case, consulting is an important factor that can help close the deal.

Experts from the additive manufacturing industry, employed by the service provider, can help clients define a smart strategy before jumping into a project. This is done by working with the client on the specific needs of their project and educating them on the options available.

Identifying the exact areas where 3D printing can be applied and discussing technical challenges and the specifics, such as which material is best for the purpose, is all part of a consultancy service. Sometimes, a good preparation based on consulting can be a money-saver as the project evolves.

While this may not be something individual customers usually need and look for, it’s surely an important benefit for big collaborations.

In-House Professional Designers

Lots of 3D printing services expect you to already have a 3D model ready to be printed. Although that approach does work, some clients need extra assistance. In a situation where a client needs a part to be developed from scratch and doesn’t have experience with 3D modeling, a service with in-house professional designers comes in handy.

Additionally, not all 3D models are perfectly suited to 3D printing as a manufacturing process. In these cases, advice (or modifications) from an additive manufacturing professional is truly useful.

An example of a service provider that offers both 3D design and 3D printing is Sculpteo. They’ve got it all under one roof, both the 3D designing and 3D printing service. This is not something that every customer will need, but it’s undoubtedly an added bonus for new customers.

License: The text of "10 Reasons to Use a 3D Printing Service" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.