A snap fit connection (or joint) is a simple and cost-effective way to attach two plastic parts. It usually consists of a protrusion and a mating depression, generating an interlocking connection that often relies on parts that bend.

These joints are common in injection molding parts since thermoplastics offer a good compromise between flexibility and rigidity. Snap fit joints are also great for 3D printing, as they use essentially the same injection molding materials minus the associated design limitations.

In this article, we’ll talk about the most common snap fit types and cover some good practices for designing and 3D printing these features.

General Principles

Generally speaking, snap fit joints are “clicked” into place by some sort of bending. The regular plastic buckle clip on backpacks, as seen at the top of this article, is a fine example of a snap fit: The “male” clip bends inwards until it snaps back when secured by the receiving “female” clip. The joint components then return to their neutral positions.

Because of this bending motion, there’s usually a life span associated with snap fit components, with 3D printed parts usually lasting not as long as injected molded parts. Yet, if properly designed and printed, they can last for many cycles.

In terms of material, flexible materials like ABS, PETG, and nylon are better suited for snap fit mechanisms as opposed to more brittle materials like PLA and standard SLA resin. However, it is perfectly possible to use these materials, especially depending on the type of snap fit.

There are plenty of snap fit types and geometries that follow these basic principles. In the next couple of sections, we’ll go into some detail on the more common ones: cantilever and annular.

Cantilever Snap Fit

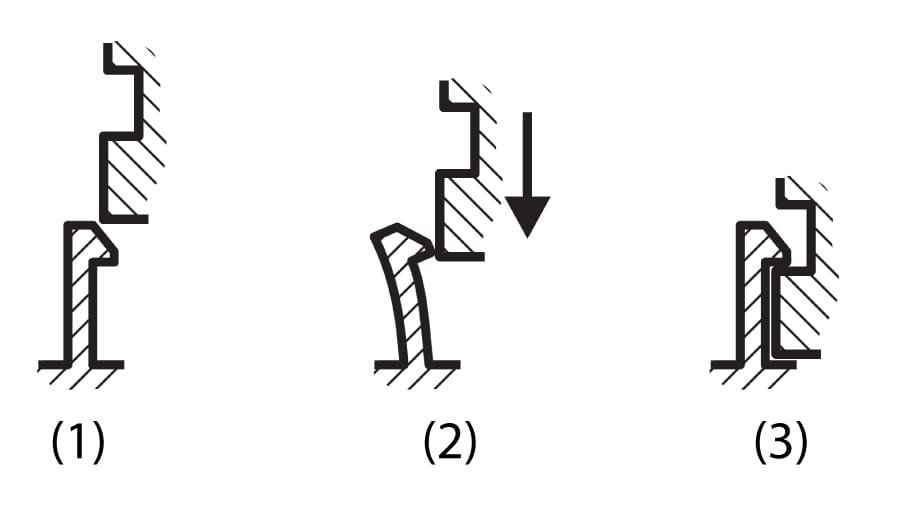

Cantilever snap fit joints can be easily identified by a cantilever or hook-like protrusion that bends itself into place. It’s one of the most versatile snap fit joints and also the easiest and most intuitive to use.

There are many geometrical variations to cantilever snap fits, ranging from the most basic straight designs to the more intricate curved or U-shaped ones. Each mechanism type has its strengths and weaknesses, and the final choice will depend on the material and final application.

Designing

A few considerations are necessary when modeling cantilever snap fit joints. The cantilever width is one of the most important, since it’s a compromise between rigidity and flexibility. Thicker beams are harder to bend but are also less prone to break.

A good design practice is to reduce the cantilever cross-section towards its tip, making it sturdier on the base and thinner along its length. Filleting the base is also a good way to increase break resistance without adding flexural strength.

3D Printing

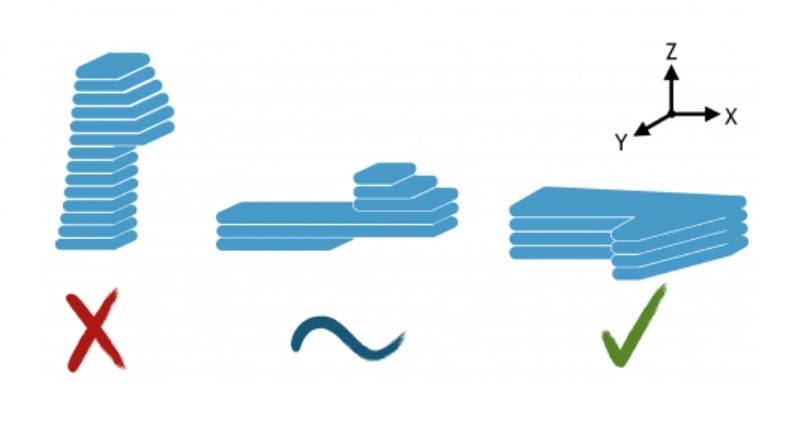

For 3D printing cantilever snap fit joints, orientation is perhaps the most influential setting. Avoid printing the cantilever in an upright orientation, as the shear forces while bending will concentrate between layers, reducing the part’s resistance significantly. (3D printed parts are strongest in the direction of their layer lines.)

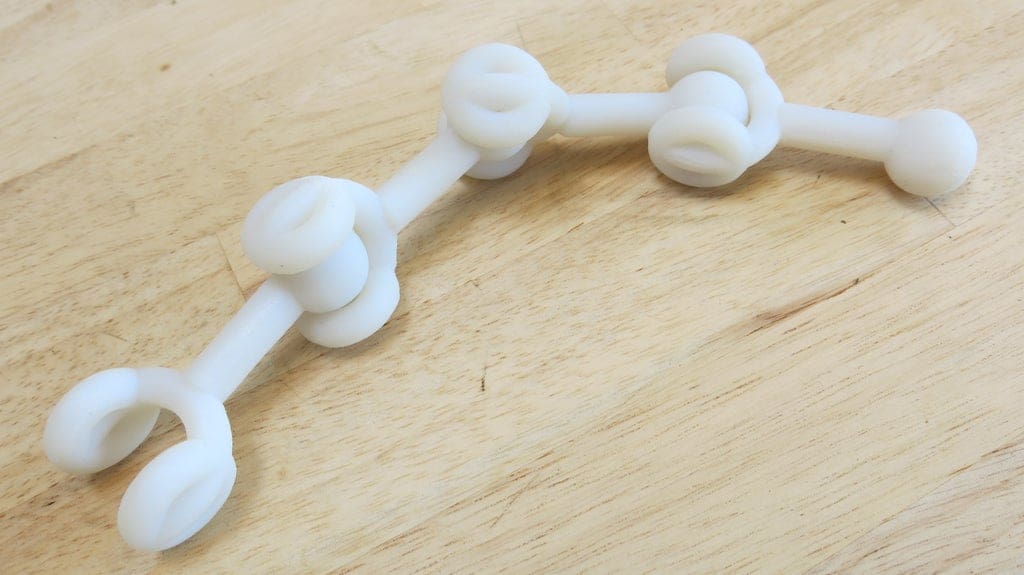

The bag clip designed by Thingiverse user MasterFX is a nice example of a 3D printed cantilever snap fit, which is even said to work with PLA. The 3D printable buckle by SingerAudio is also essentially a cantilever mechanism.

Annular Snap Fit

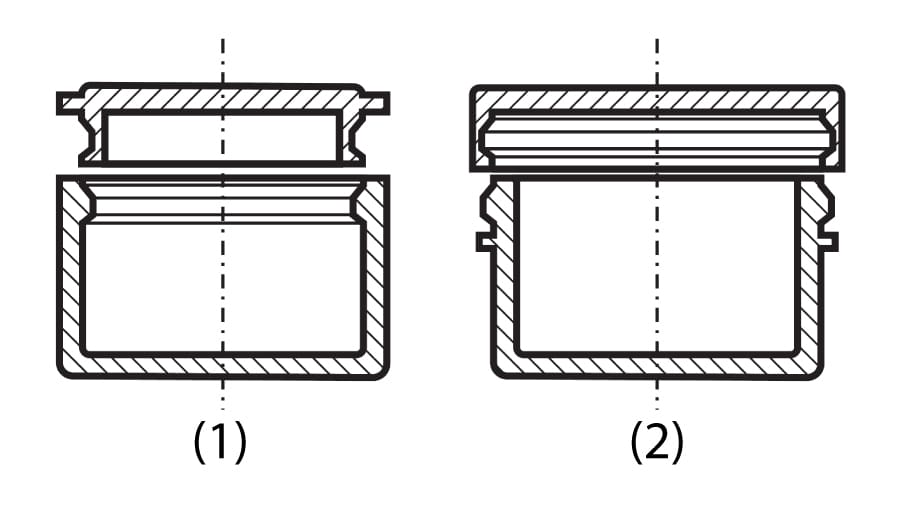

Annular snap fit joints are commonly used on pen caps and container lids. It’s a kind of joint that’s characterized by a continuous boss and a correspondent groove, sometimes around the entire perimeter of the parts.

These joints are relatively easy to add into designs and are much more durable than cantilever snap fit mechanisms, making them a perfect choice when tight connections are required. Annular snap joints can even be adapted to work as waterproof seals in lids.

Variations include articulated joints like ball-and-socket mechanisms, in which the socket is the one deflected (or bent) during insertion.

Design

Overall, annular snap fits are typically low-profile features that require less effort to design when compared to cantilevers. In addition, these joints are more easily corrected by sanding the boss and groove accordingly.

Still, the boss-groove geometry should be well considered. Deeper grooves will provide a tighter yet harder connection between parts. The bosses should also be designed with either chamfered or filleted edges to allow an easier insertion while reducing the need for support structures during print.

3D Printing

3D printing annular snap fits is considerably straightforward unless it’s an articulated joint. These movable joints can be more demanding to print and might require a trial-and-error approach.

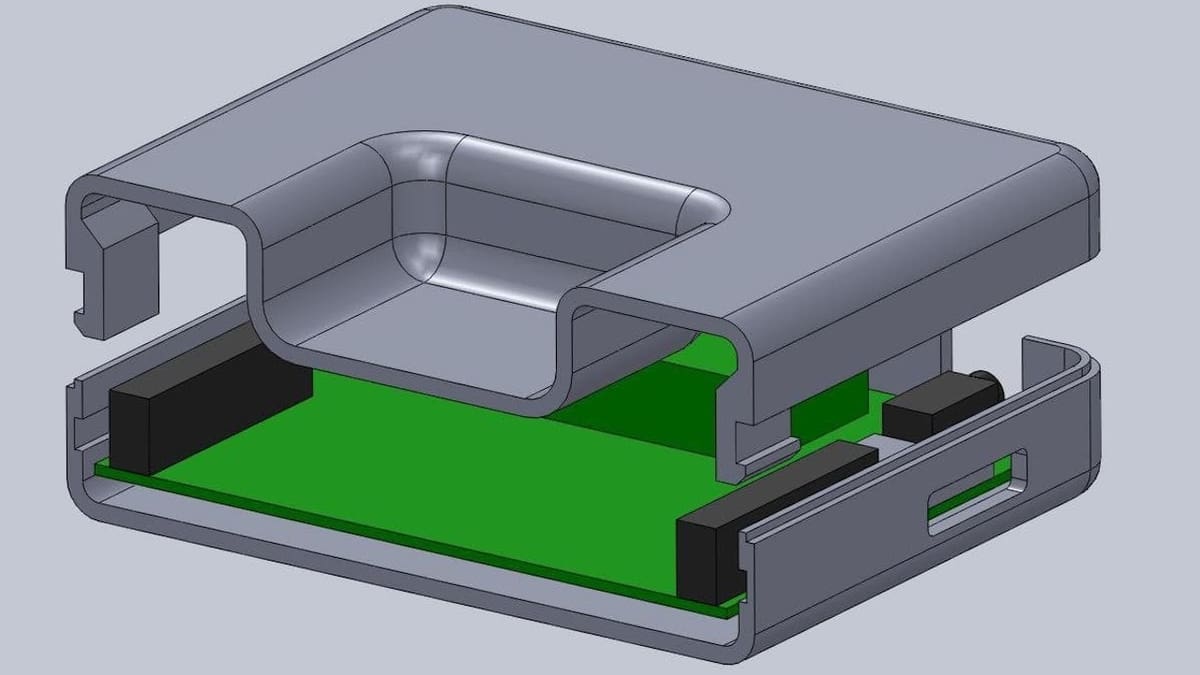

Be sure to check out the ball-and-socket designs by Cults user biglildesign for articulated joint reference and the Fusion 360 tutorial by DreamOnward for designing full perimeter annular joints in both cylindrical and squared boxes.

Start Creating!

Now it’s time to get your hands (or printer?) dirty. The cantilever and annular types are the most popular snap fit joints and should be suitable for most 3D printable designs and applications.

For more detailed information on design practices, you can start with this comprehensive guide by Bayer on how to design snap fit joints for plastics in general. This tutorial by Formlabs is also a great source of information for designing snap fit mechanisms for single-board computer cases.

License: The text of "3D Printing Snap Fit Joints: How to Design & Print Them" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.