What Is It?

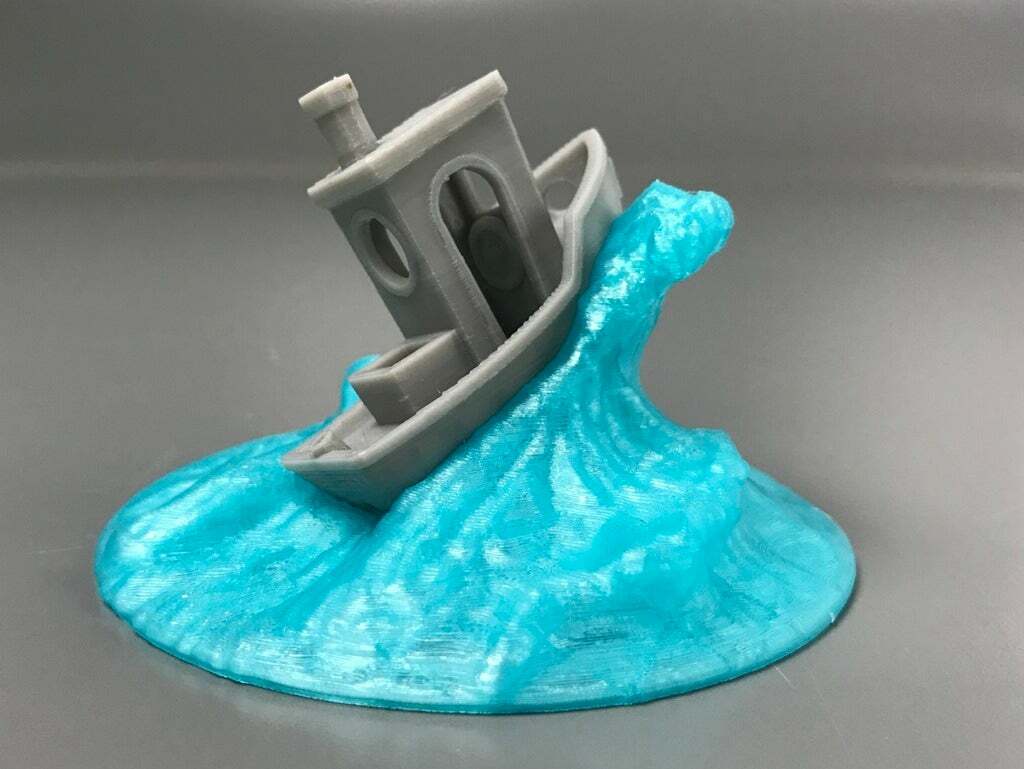

A small boat is making big waves in the world of 3D printing. Not only is the ubiquitous 3DBenchy the most downloaded STL ever, but it’s also now center stage in a race that some say will radically change 3D printer technology. A bold claim, and yet it might just be true!

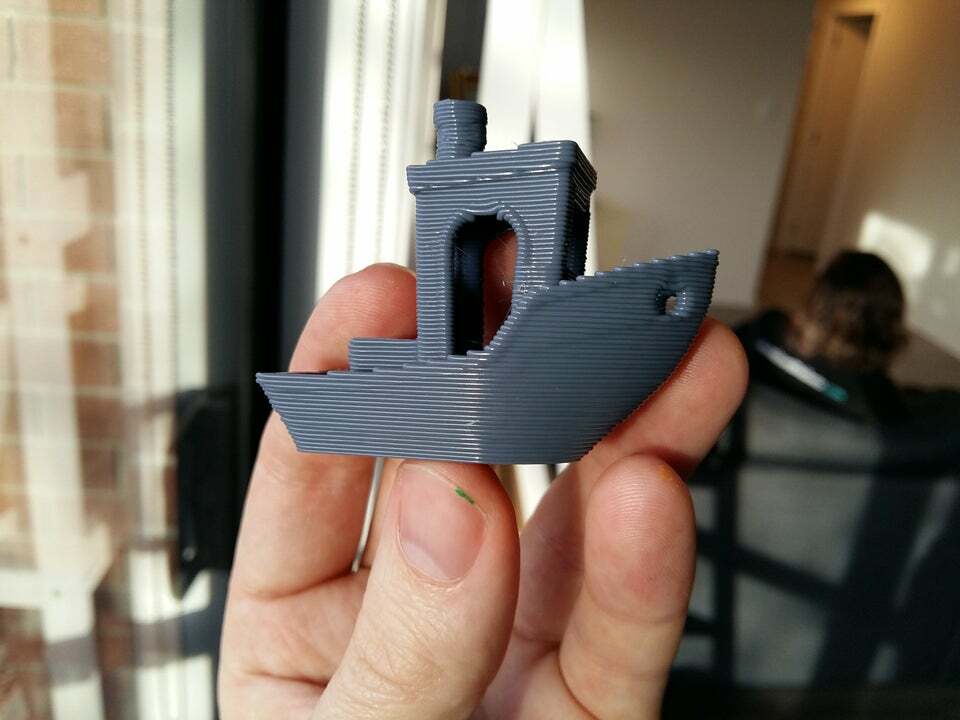

Created in 2015, the 3DBenchy challenged the technology of the day with its curves, details, and overhangs. The tiny (60-mm long) tugboat was designed to print in “well under two hours”. Today, a typical benchmark stands at around 90 minutes.

But just how much faster could a 3DBenchy be printed with the right tweaks? This question has recently inspired 3D printing enthusiasts around the world to find out! “Speed Benchys” became a popular topic on forums and clips of increasingly fast prints were posted on YouTube; the seeds of this amazing challenge were sown.

Annex Engineering was active in developing ideas to print faster and, in December 2020, with their own record standing at less than 12.5 minutes, they introduced the world to the #SpeedBoatRace challenge.

To be clear, the aim isn’t about outright speed. Annex explained that it’s all about encouraging collaboration and sharing in the 3D printing community “to find ways to reliably, cheaply, and effectively print faster without sacrificing quality.” They add that “printing as fast as you can show the weak points of your machine and then you get to address them.”

The challenge now has a vast following and the resulting exchange of ideas has seen times edge towards only four minutes! Watching a high-speed competition entry is mesmerizing.

FDM 3D printing is notoriously slow, and although we might not all expect to convert our printers to the equivalent of F1 racers, there’s sure to be a trickle-down of ideas to help everyone print better and faster.

In this article, we’ll go over all you need to know about the #SpeedBoatRace, including how to play, key participants, the main challenges, as well as lessons learned. Start your printers!

Rules

For this competition, anyone can join, from dedicated “modders” pushing the bounds of technology with custom-built super high-speed machines to those competing for “best in class” honors using stock, unmodified printers.

There’s a set of simple rules, designed to provide a consistent playing field. Check out the Discord channel for those interested in the finer points. The idea is to keep the focus on affordable and practical 3D printing that we might all benefit from in the future.

- You must use PLA, PLA+, PETG, ASA, ABS, or ABS+ (not filled, metallic, or silk filaments as these filaments typically hide defects).

- The maximum nozzle or line width size is 0.5 mm.

- The maximum layer height is 0.25 mm (you may combine infill every other layer).

- You must use 3 top and bottom layers.

- You must use 2 walls and 10% infill.

- The finished print must be dimensionally accurate (within reason) – bonus points if it looks good!

- The machine must be powered by stepper motors.

- You must record the whole print, and the print must finish. There must be a timer or clock shown in the video to verify it’s done in real-time. A phone is fine, or you can show the time before and after the print.

- You must post the video to YouTube, tagged with #SpeedBoatRace.

- You must share the print profile.

Of course, the quality of the finished print is subjective, and there are always those who are pushing at the bounds of the rules (more on that below). However, it’s all done in the spirit of good fun and faith.

Who's Playing?

The #SpeedBoatRace has engaged thousands of 3D printing enthusiasts across the world. There are many videos on YouTube showing ideas that have worked and importantly, ideas that haven’t.

Many well-known names in the online world of 3D printing have joined the fun:

- Stefan Hermann (CNC Kitchen) admitted failure (so far) in his initial mission to break the 10-minute barrier. His tests and experiments have focused on hot ends and materials as well as raised many excellent questions.

- Michael Laws (Teaching Tech) used the race as a way of testing and improving the performance of his new RatRig V-Core 3. He’s covered a wide range of printing parameters and how they were best supported in Klipper firmware. In the process, he feels that he’s doubled the speed and quality of his normal printing!

- Simon Vez (Vez3D) has posted very impressive results. Pushing at the boundaries of the race rules, he has shown what alternatives to stepper motors can achieve.

- Ora Yerta (Mirage C) has used the race to further improve the advanced, open-source HevORT 3D printers and reaffirms the conclusions reached by many about 3D printer design directions.

There’s an unofficial scoreboard including links and times of many entries. Among these, it’s great to see those who have tackled the challenge of using the stock structure and “motion control” (steppers, motherboard, and other components) of an Ender 3.

In common with all entries is a willingness to share learnings from success and failures alike. Let’s take a closer look at the main issues makers have been experiencing.

Key Challenges

It’s tempting to think about the #SpeedBoatRace only in terms of dialing up printing speeds, but this is very misleading.

A typical Ender 3, for example, may print at 55 mm/sec normally, and even manage 150+ mm/sec on occasion. In reality, the details on a Benchy are so small that the nozzle seldom has time to accelerate to such a quick speed.

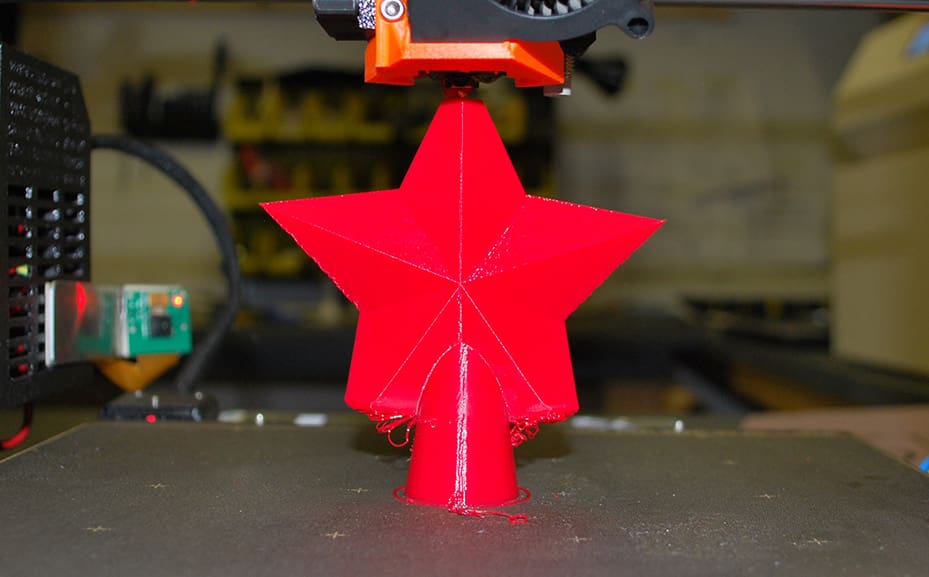

To print fast, not only is acceleration important but also melting relatively large volumes of filament quickly. All of this takes power; generates heat; imposes enormous stresses on stepper motors, heating blocks, cooling systems, and gantries; challenges the printer’s firmware; and impacts quality negatively. In short, every aspect of FDM printing is put to the test with the #SpeedBoatRace!

The challenge is to systematically look at each aspect of the whole process, including the printer’s ambient environment, slicer settings, and even the materials used.

Many who have accepted this challenge have found they can now print almost twice as fast as they used to with only minimal changes. For the speed demons, an acceptable sub-five minute Benchy is now possible. For this, you’ll need print speeds over 400 mm/s, accelerations in excess of 110,000 mm/s2, and extruding over 40 cubic millimeters of filament every second.

But how is this done? There’s no one simple answer. A number of changes need to be brought together. We’ve summarised the key considerations in the sections below.

Lessons Learned: Overview

Throughout the history of the automotive industry, innovations stemming from expensive racing development have filtered down to affordable cars. It could follow a similar course (pun intended!) with developments from the #SpeedBoatRace. The features of the fastest machines may, in some cases, seem expensive or needlessly complex, but they’ll shape the future for all 3D printers.

The following is a brief summary of only a few of the learnings from the race. We wonder which are likely to find their way into common usage!

Lessons Learned: Printer Design & Hardware

Structure

A big challenge when printing fast is handling the large forces of acceleration and inevitable vibrations. There’s no consensus yet on what is best. Historically, delta printers were deemed the fastest type of 3D printer, and there are a few speedboat entries using these (e.g. this mini delta).

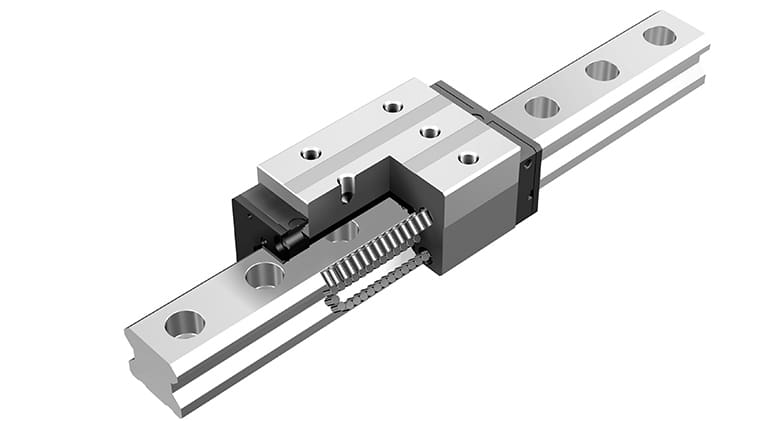

Cartesian designs, where the bed moves in the X-axis (like an Ender 3), are not ideal for top speed. Light, rigid, direct drive, CoreXY, and the relatively new CroXY designs are where the #SpeedBoatRace action is.

In common, they use linear rails for movement, with much discussion on which type of rail and even what type of lubricant is best.

Motion

Powering the very fast accelerations required has been tackled in various ways. The fastest printers are using two stepper motors per axis. The motors also tend to be larger, often running at 48 volts and frequently using 0.9° steps (rather than the standard 1.8°).

Although (strictly speaking) this is outside of the rules, the question has also been raised about alternatives to stepper motors. When 3D printers were emerging, steppers were common, low, cost, and well understood. Since then, huge advances have been made on brushless DC motors and continuous servos, and really fast times have been achieved by using these (e.g. ODrives). They’re more expensive at present but will the cost reduce enough for them to become more normal?

Flow Rate & Hot Ends

One of the biggest challenges is heating filament fast enough to keep up with the speeds required. Flow rate is key. Let’s use a concrete example: A 9-gram PLA 3DBenchy printed in 5 minutes equates to roughly 25 mm3/s on average, with much more at the peak. For reference, a typical hot end can handle only 15 mm3/s.

Upgraded hot ends get around this issue. We’ve discussed the ins and outs of these in a best hot ends article and also highlighted examples of super-fast hot ends such as the SuperVolcano.

However, the #SpeedBoatRace is also exposing the nuances of this approach. Is the measured nozzle temperature really the same as the filament temperature at high flow rates? How wide is the melting zone relative to speed? How best can we tune the heating cycle (it’s been found that normal PID tuning might not work)? Even the role and importance of heat block silicone socks becomes important (see CNC Kitchen’s brilliant tests on this).

Lessons Learned: Materials

Of course, all of the above has also highlighted the critical role of materials. Let’s take a closer look.

The race rules allow printing in “PLA, PLA+, PETG, ASA, ABS, or ABS+”. Is one better than another? Well, yes and no! Fast printing needs a filament that changes properties quickly, has a low viscosity at the printing temperature, and can cool fast too. Not all PLA or ABS filaments are the same; they vary in composition, additive, and manufacturing process, all of which change their properties and suitability for high-speed printing.

Among the fastest race entries, we find little consensus on PLA, ABS, or even favorite brands, but all lean towards those designed for high-speed printing with characteristics such as high thermal conductivity.

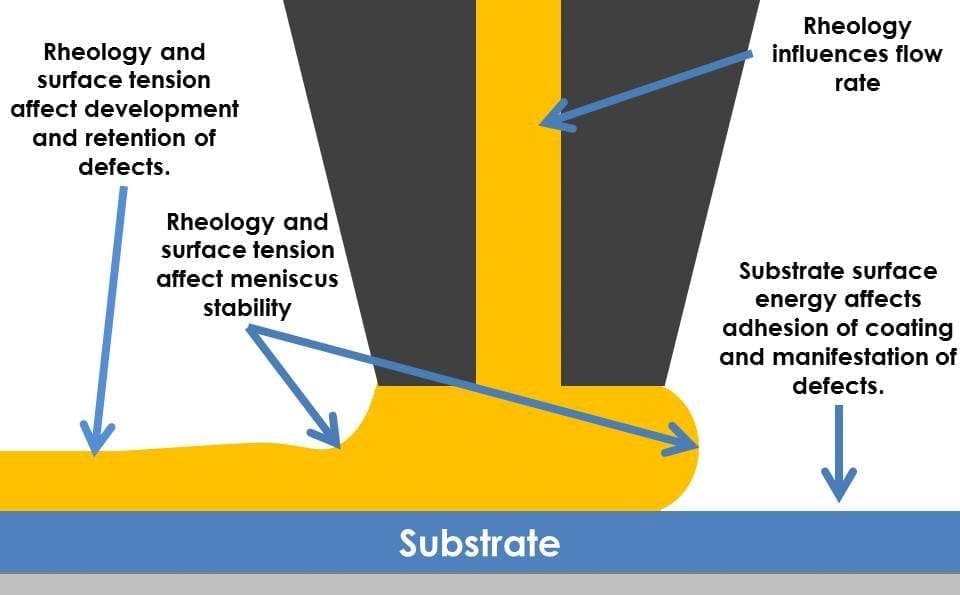

We’ve also been introduced to rheology, which is the study of the flow of matter. Watch out for this word cropping up more often as high speed and temperature extrusion is better understood.

Lessons Learned: Cooling

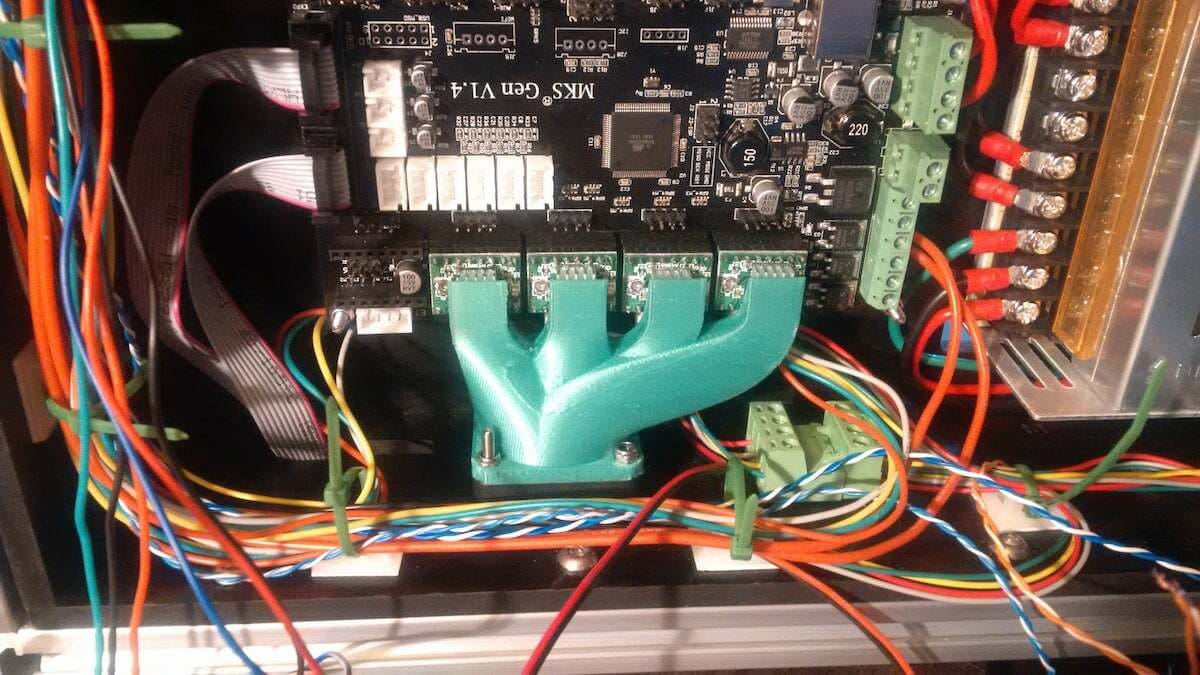

#SpeedBoatRace printing is hot work. Stepper drivers and controllers need to be specially cooled. A handful of heatsinks and a small fan that are normally found on 3D printers aren’t up to the job. Instead, those pushing the speed envelope are using more active cooling to avoid component failure.

But it’s part cooling that becomes a particular issue. Very hot, very molten, and high-speed filament needs to be cooled quickly. However, adding more and heavier cooling fans near the nozzle means extra and undesirable weight, which tends to slow printing down.

We’ve seen #SpeedBoatRace entries using compressed air jets from the side of the build plate and even manually directed additional airflow. A new idea? Not entirely, we have an article on this from a few years ago. Might it be possible that directed part cooling from fans or compressors mounted at the side of the printer has a more general future role to play?

Lessons Learned: Slicer & Firmware

Slicer Settings

The #SpeedBoatRace has been an incentive for many to delve deeper into their slicer settings. In the past, we’ve looked at simple tweaks to printer faster and optimal material slicer settings. The race has highlighted these and many more.

We all know about the speed and quality trade-off. But, experimenting with retraction settings (most fast attempts have that switched off!), making sure that Z-seam location is simply the nearest available, or subtle changes to infill and so on can make a notable difference.

Firmware

This is potentially a big and important area. All of the top speed entries use Klipper. That’s not to say that other firmware hasn’t a role to play: See our article on Klipper vs. Marlin. Two advantages that Klipper has are its “input shaping” feature and its ability to maintain tight control over the stepper motors at high speeds. The former refers to measuring and compensating for resonances and vibrations that otherwise could ruin print quality.

On forums, there’s also discussion on more “closed-loop control” of 3D printing motion as well as more active, real-time measurement of temperatures, flow rates, and so on. All of this will shine a brighter spotlight on the role of firmware.

Will the Race Change the 3D Printing World?

Expectations about the speed and quality of FDM 3D printing have already changed. Will we all be printing 3DBenchys in four minutes in the not too distant future? Probably not, but it’s easy to see a potential new normal of speeds two or three times what they are today.

The #SpeedBoatRace is bringing a focus on improved parts, designs, materials, and firmware that will steadily become more available and at a lower cost. This trickle-down effect is likely to influence all segments of the market.

In the category above low-cost or entry-level 3D printers, we’re likely to see the greatest changes. For example, 3D printing enthusiasts will be willing to pay a little more to reduce the cycle or waiting time between prints. For those with a commercial interest, a machine that can print the same quality as today in half the time is a compelling proposition.

And where might this all end? An acceptable Benchy in less than three minutes, anyone? Let’s wait and see!

License: The text of "Join the SpeedBoatRace: Push 3D Printing Speed" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.