Everyone familiar with 3D printing knows the difficulties of getting that first layer just right. The first layer is one of the most important components of a print because it sets the foundation for the rest of the print, so without a secure first layer, the subsequent layers could fail. There are different reasons why the first layer of a print can fail, but there are also different solutions to make it just right.

One common problem with the first layer is it not sticking to the build plate, which is the bed surface that an FDM machine prints on top of. Most people who experience this problem typically use an adhesive substance like a glue stick or hairspray or switch to a different build plate to solve the issue. Opting for adhesive substances that aren’t meant for 3D printing can cause over-adherence, and although switching your build plate can be helpful, it costs money and might not be enough to fix the problem.

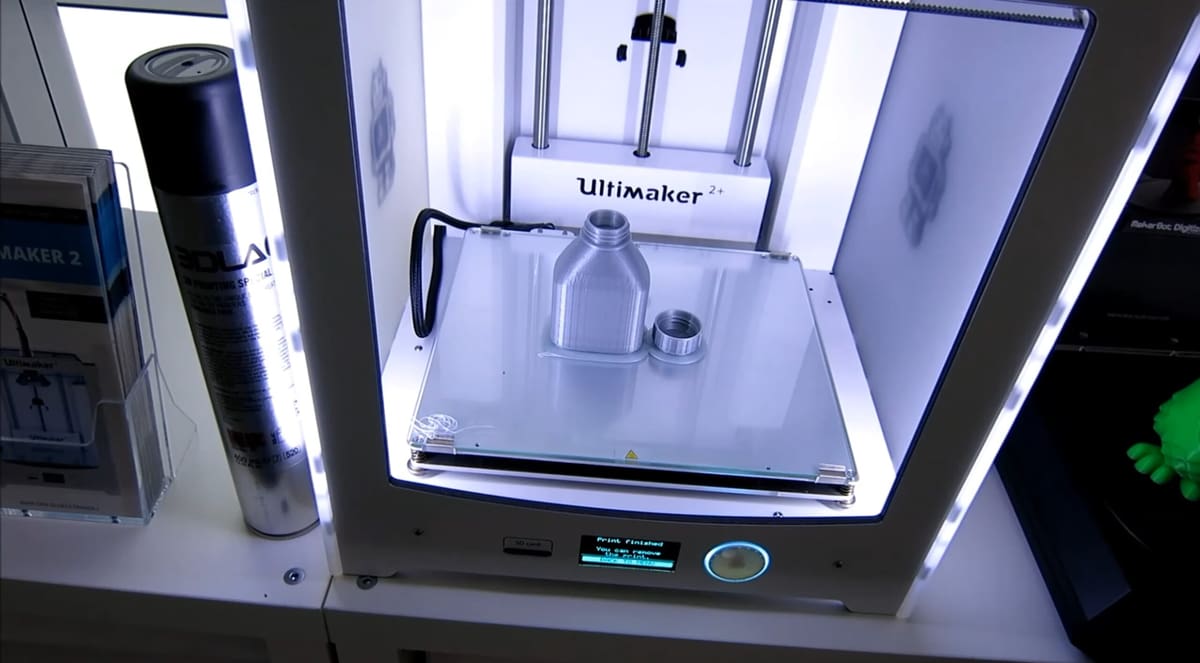

3DLac is a spray-on adherence product meant specifically for 3D printing with benefits and advantages over traditional adhesives. The company spent a long time fine-tuning adhesive formulas to provide users with the best printing experience, and the products are now available in over 30 countries.

In this article, we’ll go over the 3DLac adhesive spray, discussing its features and uses in 3D printing. We’ll also compare 3DLac to another common 3D printing adhesive product to expose its strengths and flaws. Happy printing!

Features

As you might have guessed, 3DLac doesn’t have that many “features” to discuss because it has one primary function: to make the first layer stick. So in this section, we’ll go over the 3DLac formula and the benefits it presents for 3D printing.

Adhesion

Naturally, adhesion should be the most important factor to review when looking at a 3D printing adhesive. 3DLac performs very well in this category and provides excellent adhesion to the first layer of 3D prints. This secures the first layer of the print so that it doesn’t dislodge as other layers are printed on top of it.

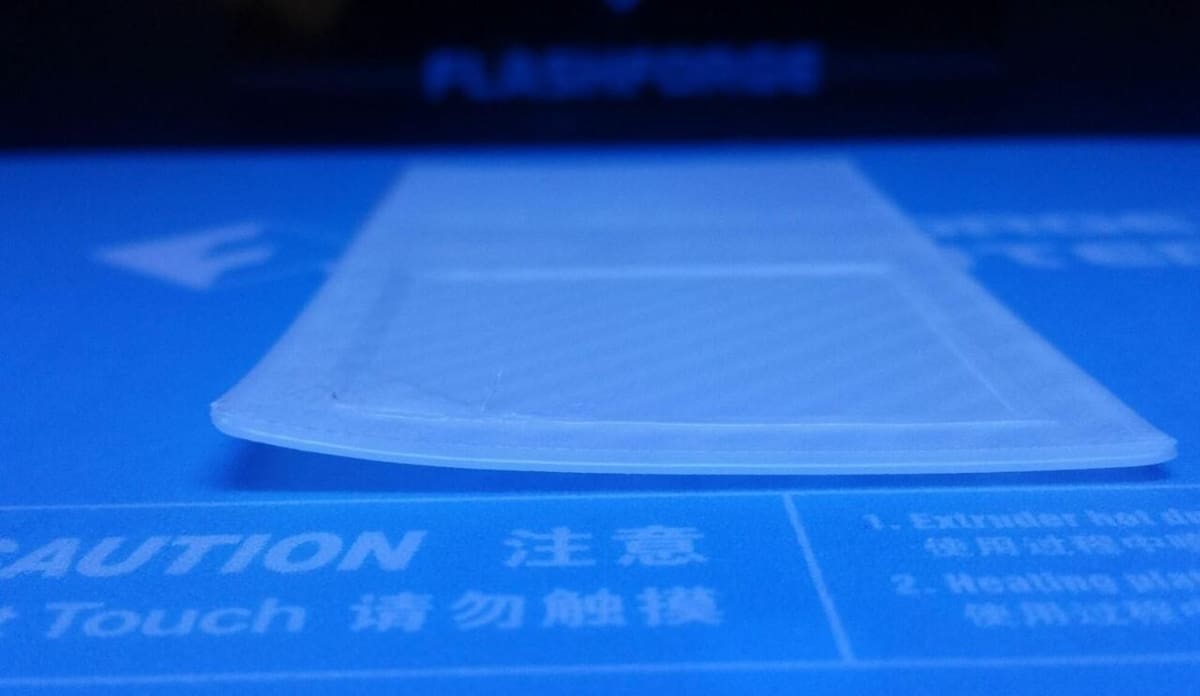

3DLac’s adherence properties also help to prevent warping. Warping occurs after the first layer and involves the upper layers of a print pulling the first layer up, effectively deforming the object. 3DLac also works with a wide range of surfaces and printing materials but is perhaps most popular for PLA.

Getting a print to stick to the build plate is only half the journey for any 3D printing adhesive because it’s important that the adhesive doesn’t over-adhere parts to the build plate. At worst, over-adhesion can lead to parts of the build plate being removed along with the print. According to their website, 3DLac’s product does a great job of not over-adhering parts, and you should be able to remove parts “with just a touch”.

Use & Application

The other useful element of 3DLac is its ease of application. Adding 3DLac to a build plate is easy, clean, and smooth.

3DLac comes as a pressurized aerosol in a spray can, similar to hairspray. This means that you can apply as much or as little of it as you want, and you should be able to clean any excess from the bed using a damp cloth, like a microfiber cloth, with water or IPA.

Another benefit of 3DLac’s adherence properties is that you aren’t left with a sticky residue or stain on the bottom of parts, something that can occur when you use a glue stick or hairspray.

Lastly, 3DLac is supposedly odorless, so you shouldn’t have a noticeable smell that makes the area around your 3D printer unbearable. However, keep in mind that this spray is flammable and can cause dizziness, drowsiness, and eye irritation, so make sure not to apply too much without proper airflow. On this note, we recommend applying the spray outside where the air is free-flowing as you won’t be in such close contact with it.

The Bottom Line

Now that you know 3DLac’s useful features, let’s see how it stacks up against the competition. We’ll use WolfBite adhesive for our comparison as it’s another popular adhesive meant for 3D printing.

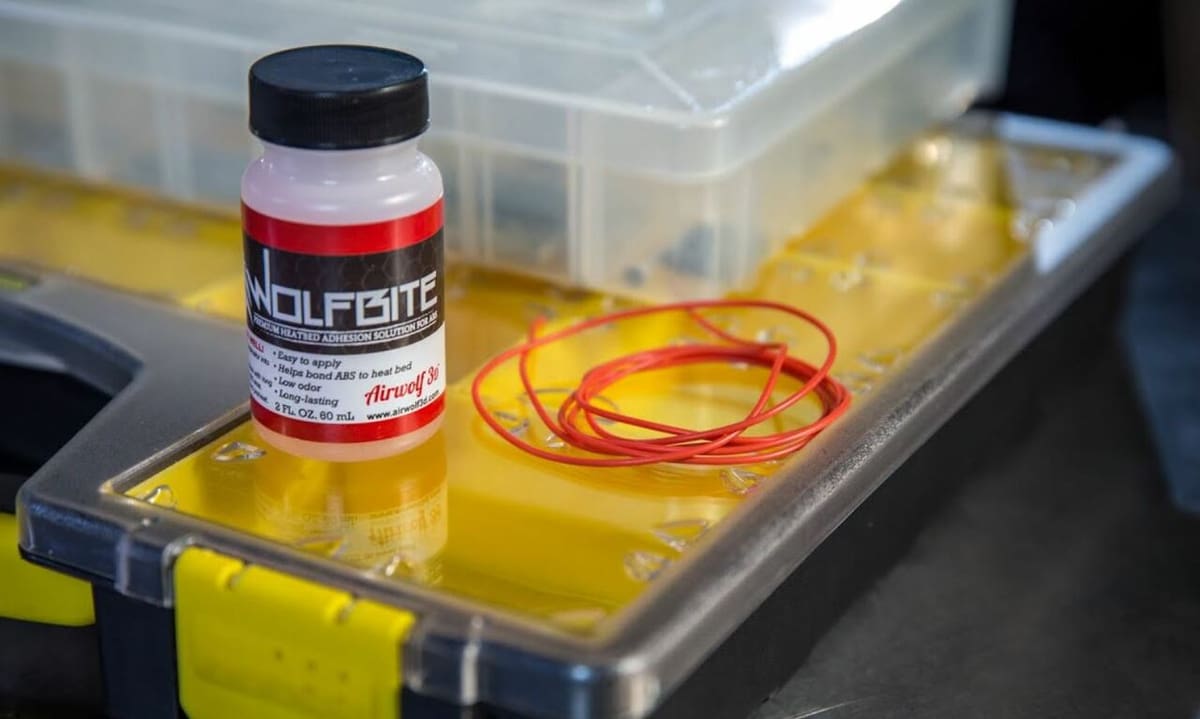

WolfBite is an adhesive liquid that can be applied to your build plate with a brush, costing around $20 per jar and made by Airwolf 3D, a manufacturer of 3D printing supplies.

Both substances provide excellent adhesion; however, traditional WolfBite is only effective for printing ABS, TPU, TPE, or PETG. On the other hand, 3DLac works on basically all materials (including PLA) other than nylon.

There’s a separate WolfBite product, WolfBite Nano, for PLA, and other versions of WolfBite for more materials. Although these options provide a wide material range, 3DLac, as an individual product, works on more materials than the standard WolfBite solution.

Another aspect to consider is that WolfBite is really only meant to work on glass surfaces, while 3DLac can also work on magnetic, PEI, flexible, and silicone build plates. This, as well as its compatibility with PLA, makes 3DLac perhaps a more compatible substance, capable of working with a wider range of printers and filaments.

Both 3DLac and WolfBite can be wiped off using a cloth and some water, but WolfBite specifically recommends not to use soap as it will cause a destructive reaction. 3DLac makes no such warnings, so you’re safe to use a cleaning substance to remove the solution.

Finally, as we’ve mentioned, 3DLac is a spray-on adhesive, which makes applying multiple layers to your build plate super easy. As a paint-on semi-liquid solution, WolfBite is also easy to apply, and it’s perhaps safer to use over the 3DLac spray. That’s because the WolfBite substance isn’t an aerosol, isn’t as flammable, and doesn’t cause irritation like 3DLac can.

Overall, both 3DLac and Airwolf 3D WolfBite are great 3D printer adhesive substances; however, they have some key differences. If you’re printing ABS, TPU, TPE, or PETG materials exclusively, or are worried about the safety of your adhesive, then WolfBite may be the more suitable option for you. However, if you’re using PLA and other materials or have a non-glass build plate, 3DLac is probably the better option.

Specifications

Although there aren’t that many technical specifications to list for 3DLac due to the nature of the product, below are those we consider more relevant:

- Size: 400 ml (around 500 sprays)

- Compatible build plates: Magnetic, PEI, flexible, silicone, glass, etc.

- Compatible materials: PLA, ABS, ASA, PETG, flexibles

- Temperature limits: 100-110 °C

- Cleaning: Cloth with water

- Hazards: Flammable aerosol in a pressurized can; can cause eye irritation, drowsiness, and dizziness

Where to Buy

It’s not always easy to have a can of 3DLac delivered as it’s a flammable aerosol. However, you can generally purchase a two-pack of 3DLac for around $20 from a variety of retailers.

License: The text of "3DLac Spray Adhesive: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.