Infinite Printing Potential

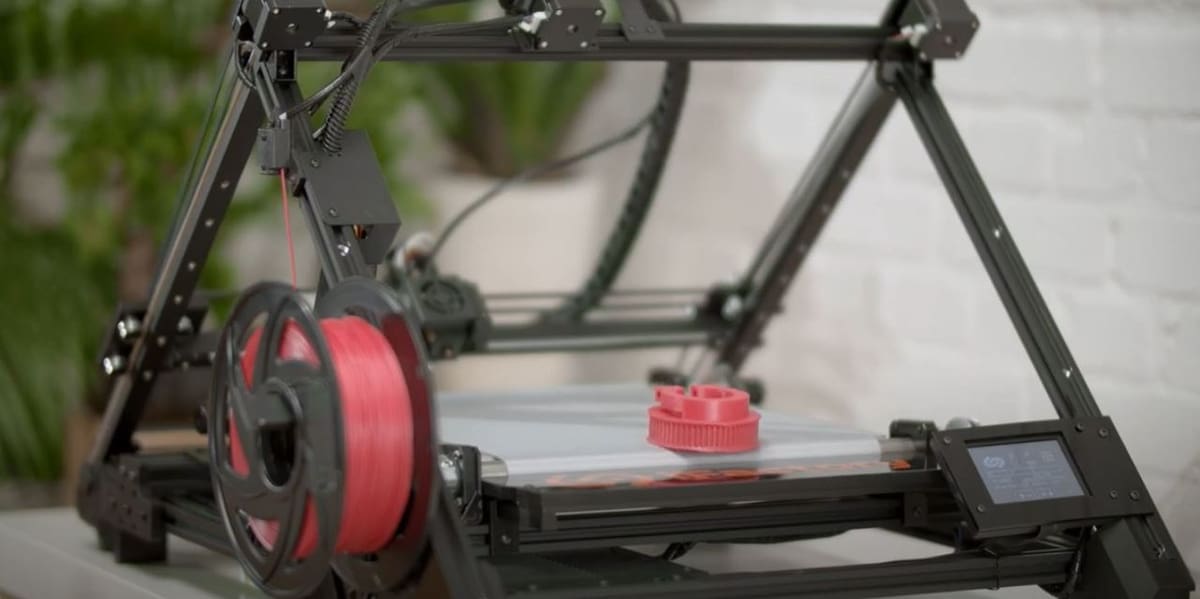

Belt printers are a special type of fused-deposition modeling (FDM) 3D printer dating back to Blackbelt 3D’s Blackbelt printer in 2017.

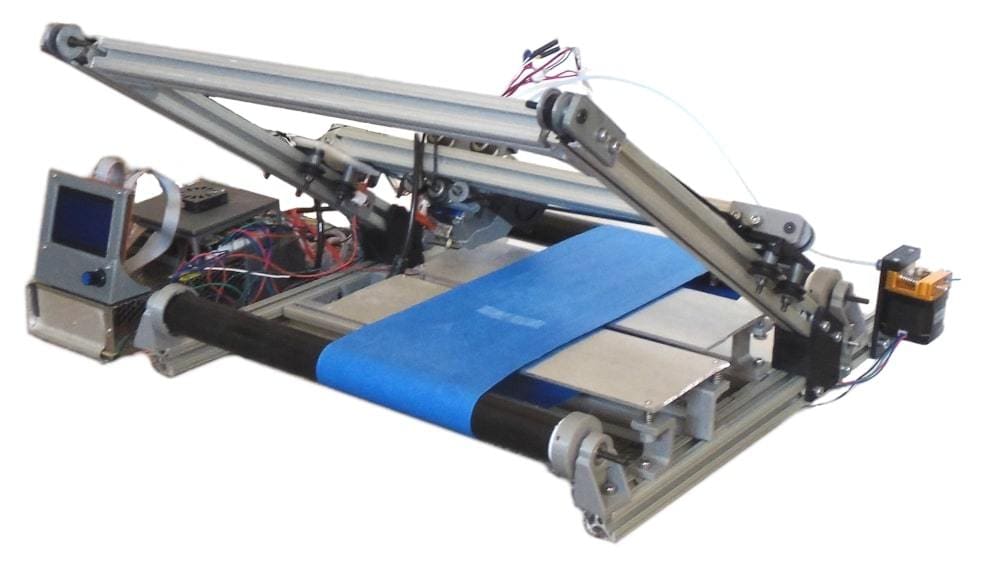

One of the most obvious differences between the majority of FDM printers and belt printers is that the latter have a conveyer belt as the bed. At the same time, as an FDM-style printer, belt printers make parts by heating filament and extruding the material layer by layer from a nozzle onto a build surface. However, belt printers usually have a 45° or similar angle for the extruder, which, along with the moving belt, allows them to print a part with an infinitely-long Z-axis.

With a unique build surface and tilted axis, belt printers have two significant capabilities that standard Cartesian FDM printers don’t have. The first is infinitely long printing, where the belt printer can print “forever” as long as the print is physically supported. The second is continuous 3D printing, where the printer can print parts repeatedly because it never runs out of build space (as parts fall off when they reach the end of the belt).

Belt vs. Standard FDM

Below are a few reasons why belt printers are unique and different from other FDM styles of printing:

- Can print infinitely long and continuously

- Slower print speed

- Can’t (or at least don’t currently) maintain a high-temperature heated bed

- Limited brands making these types of printers means fewer affordable choices

- Limited community support

- Can only have one type of build surface: a rubber belt (no glass)

- Some structures require additional supports on a belt printer

Funding

The Creality 3DPrintMill, AKA the CR-30, and the iFactory 3D iFactory printer are two new belt 3D printers, possibly the first of a newer generation of budget belt 3D printers. The CR-30 and iFactory printers were released on Kickstarter in mid-November 2020, with a one-month funding period.

Though not yet released, both printers are significantly cheaper than any existing belt machine (except perhaps the ~$750 Powerbelt3D Zero) currently on the market. (The Blackbelt costs around $11,500.) The CR-30 is expected to cost around $1,000 at the post-Kickstarter retail price. The iFactory doesn’t currently have an expected price, but the Kickstarter pledge options indicate a similar price point.

Creality set its funding goal to an extreme low of $12,000 and was 1,000% funded in one hour. At the end of the month, they were over 10,000% funded. iFactory3D also met its (more realistic) goal of around $113,000, but it took them seven days to get there. They ended their funding period with 185% funding, which is impressive for such a small company.

iFactory3D shipped a small number of printers to certain backers before Christmas 2020 and say they’ll ship the rest in March 2021, while Creality has said that they’ll begin shipping in May 2021. Of course, that’s assuming both companies stick to their word and don’t fall behind schedule.

In this article, we’ll go over each printer and compare them side by side. We’ll review each printer’s features in a few different areas and go over what type of maker each printer is suited for. Before we get into all of that, though, we’ll briefly discuss the risk involved with making a purchase or pledge for one of these printers.

A Risky Investment

Apart from being belt printers, the 3DPrintMill and the iFactory printers your average printers for another reason: They were funded on Kickstarter. While Kickstarter can be a great way to fund projects and support new technology, as it says on the website, it’s not a place to buy things.

The Promise of Kickstarter

When you fund a project on Kickstarter, it’s not an exchange of money for a product; it’s pledging money to a company (or individuals) that will only be given if the funding goal is reached. There are no rules or laws that mandate the company give you an item if it’s promised to do so on Kickstarter, and there are (at best) extremely limited refunds. For this reason, All3DP strongly encourages you to use caution when backing Kickstarter projects because there’s a pretty substantial level of risk involved. Instead, it can be safer to wait for a successful Kickstarter product to be released for (retail) sale.

So not only are these printers risky because they’re working with fairly new technology, but pledging money to get one doesn’t guarantee that you will. Also, there are reasons to be wary of both companies behind the printers.

Some Background

This isn’t Creality’s first rodeo on Kickstarter, and we’re hoping it’ll go better than the infamous CR-6 SE campaign, which was disastrous for the community’s trust. Their CR-6 SE campaign ended with many aggravated backers without any reward for their Kickstarter pledges (though their money was taken). Many people also received orders months late. And perhaps an even worst offense: Creality had shipped units to retail buyers after the Kickstarter ended before shipping to the backers.

However, Creality isn’t the only one with its name on the line for the success and fulfillment of the CR-30. Naomi Wu, a popular 3D printing enthusiast, is responsible for bringing the idea of making a belt printer to Creality in 2018. In her videos, she states her intent to follow this project to the end with transparency, trust, and care.

On the other hand, the iFactory printer campaign was started by two German 3D printing enthusiasts, who founded the company iFactory3D. This company wasn’t really known until they released their belt printer on Kickstarter, which has been in the making for two years. Since this is their big debut in the 3D printing world, it’s also being seen by some as a risky investment.

Both printers could undergo some changes before being shipped out to all their backers (if and when that happens), so all of our observations and commentary are based on current information and reviews.

Specifications

Both the Creality 3DPrintMill and the iFactory3D iFactory stand out for their low price point for belt printers. In this section, we’ll go over how each printer is unique and a summary of the technical specifications for each printer.

CR-30

Unique features:

- Solid frame (2040 aluminum extrusions for sides of the printer)

- Comes almost read-to-print

- Upgrades available through Creality

- All-metal dual drive extruder

Specs:

- Dimensions: 200 x 170 x ∞ mm

- Style: CoreXY, Bowden setup

- Max. nozzle temperature: 240 °C

- Max. bed temperature: 100 °C

- Belt material: Nylon

- Extruder: All-metal dual drive

- Bed leveling: Factory leveled; adjustable knobs

- Nozzle diameter: 0.4 mm

- Mainboard: 32 bit

- Stepper motor drivers: TMC2208

- Power supply: 24 V

- Compatible materials: PLA, PETG, TPU

- Filament diameter: 1.75 mm

- Interface options: USB, SD card (full size)

- Screen: Stock CR-10 display (standard Creality LCD screen)

- Slicer software: CrealityBelt

iFactory

Unique features:

- Integrated HD Raspberry Pi camera V1.3

- Included and integrated Raspberry Pi Model A3+

- Integrated PrinterGUARD error detection

- Remote control capabilities with cloud interface

- OctoPrint integration

Specs:

- Dimensions: 200 x 290 x ∞ mm

- Style: CoreXY, Bowden setup

- Max. nozzle temperature: 260 °C

- Max. bed temperature: 100 °C

- Belt material: Durable polymer

- Extruder: Titan-style extruder

- Bed leveling: Factory leveled; adjustable knobs

- Nozzle diameter: 0.4 mm

- Mainboard: 32 bit

- Stepper motor drivers: TMC2225

- Power supply: 24 V

- Compatible materials: PLA, ABS, PETG, PC, TPU, ASA, nylon

- Filament diameter: 1.75 mm

- Interface options: USB, SD card (full size), Raspberry Pi (with OctoPrint)

- Screen: 3.5-inch LCD touchscreen

- Slicer software: Cura iFactory3D

Basic Features

We know that the CR-30 and iFactory are both belt 3D printers and utilize a CoreXY motion system.

In terms of size, both machines have an infinite Z-axis and also the same X-axis printing space. However, the iFactory has an extra 120 mm of Y-axis print space.

Frame & Motion

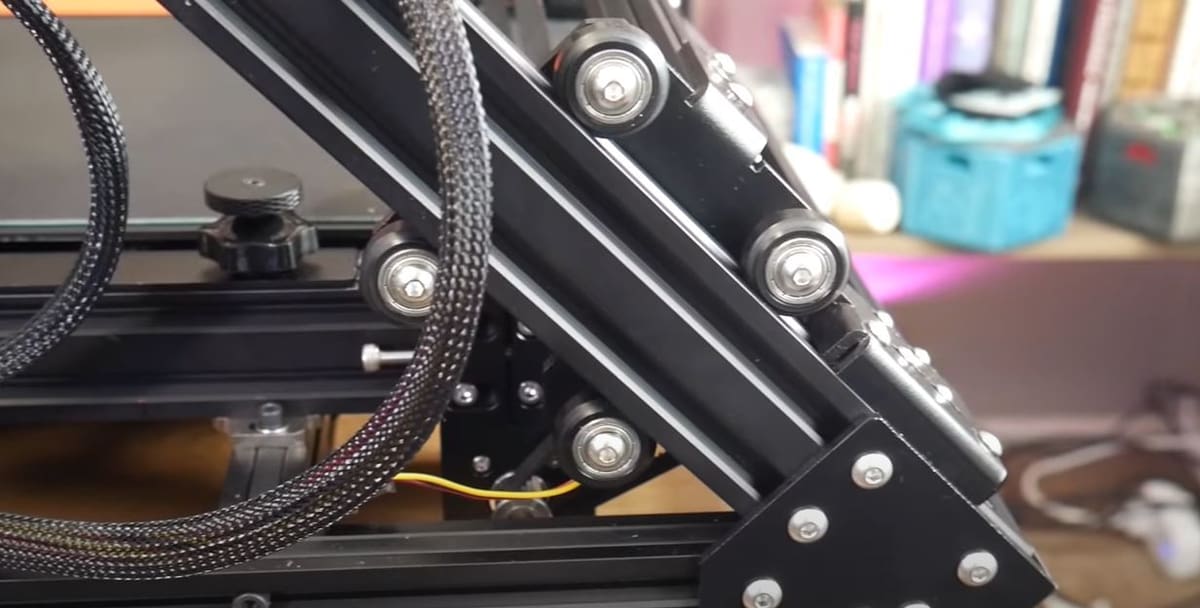

The printers’ frames are at a 45° angle, which gives them the infinite printing capability, but this angle’s sturdiness is better on the CR-30. That’s because the 3DPrintMill uses 4020 extrusions, which are about twice as thick as the iFactory’s 2020 extrusions. The overall visual structure and strength of the CR-30 make it look more like a finished product compared to the iFactory.

Both printers use roller bearing carriages for the X and Y motion. The CR-30, in typical Creality style, uses cheap plastic and rubber rollers on an aluminum V-slot extrusion. On the other hand, the iFactory, as one reviewer points out, uses steel roller bearings on non-V-slot metal rails (not to be mistaken with linear rails). This probably won’t be noticeable in printing, but the steel roller will definitely last longer than the plastic and rubber ones.

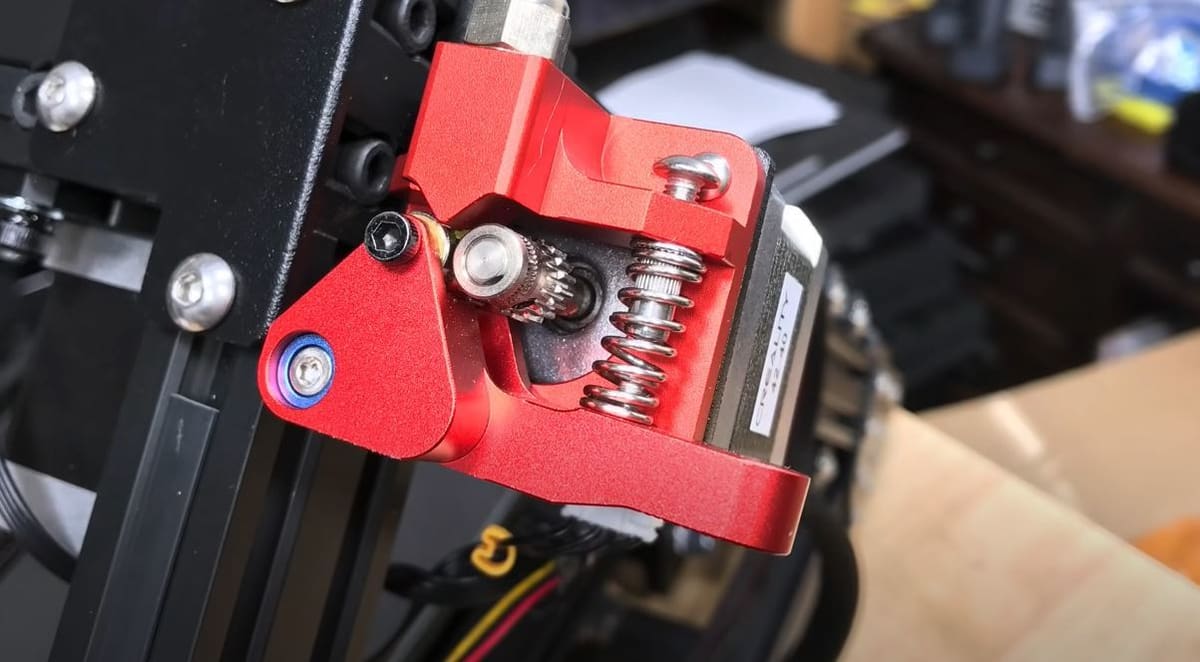

Extruder

The extruders for these belt printers are different from each other but both are impressive. The CR-30 uses an all-metal, dual-drive extruder, which is great for printing many types of filament, especially TPU. The dual-drive mechanism uses two gears on opposite sides of the filament path, which essentially hug the filament to provide more pushing pressure and tension on the filament.

On the other hand, the iFactory printer uses a Titan-style extruder with a power-increasing gear ratio (probably 3:1). According to one reviewer, the extruder isn’t a genuine E3D Titan extruder but a clone, though it still seems to work very well.

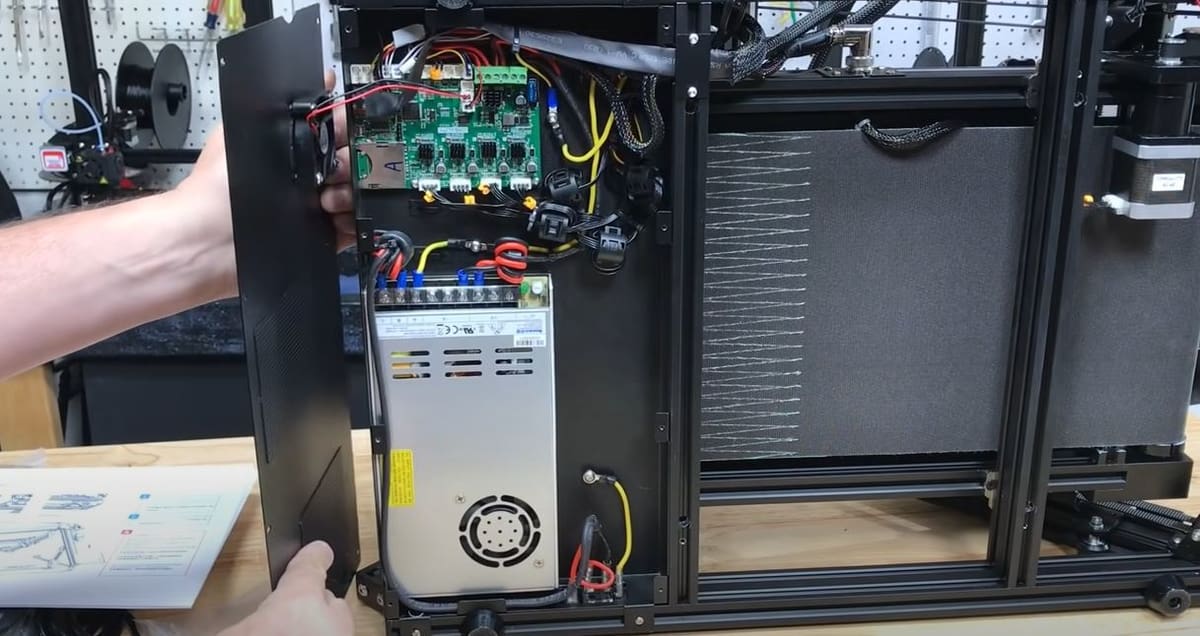

Both printers have great stepper motor drivers for quieter printing and 32-bit mainboards. That means the printers should handle larger firmware packages, which they’ll likely need in the future when more firmware becomes available.

The CR-30 and the iFactory have similarly odd bed leveling systems, each with a few adjustable knobs and an adjustable X-axis end stop that allows you to level the bed. Because of the confusing bed leveling process, both printers come factory leveled. Thankfully though, the bed only needs to be leveled in really one spot (line) because the nozzle only touches the bed at one point (think of a perpendicular set of lines but tilted at a 45° angle).

Additional Factors & Features

Although they are relatively minor, additional features can make you go from liking a machine to loving it.

To start, both printers have a filament runout sensor, which is especially important for belt printers. You don’t want to run out of filament in the middle of the longest print ever!

The iFactory sets a high bar by including a Raspberry Pi and Raspberry Pi camera. Not only are these features at no extra cost, but they’re also equipped with PrinterGuard software to detect print failures and stop your print.

The iFactory’s Raspberry Pi also allows for OctoPrint integration and thus remote printing through the OctoPrint interface. According to iFactory3D, the iFactory printer also can be remotely controlled via the cloud. However, at this time, we’re not sure if that’s separate from the remote control capabilities through OctoPrint.

Cable management isn’t really an additional feature but still carries some weight. To start, the screen placement of these printers probably shouldn’t matter, but the iFactory has its display located in front of one corner of the print bed, possibly slightly limiting print space. On the CR-30, this mistake was noticed from early versions of the printer, and now the screen is protruding outwards rather than inwards.

Wiring organization on the CR-30 seems much better than on the iFactory, with custom cuts on the bottom of the frame for wires to reach the mainboard. The iFactory’s cable management isn’t necessarily bad, as there’s a cable chain to hold the hot end wires in place. You can definitely tell that visual appeal was more of an emphasis for the Creality team, though the iFactory does have a cool color arrangement of black and orange.

Software & Support

Software for the two printers might seem like it would be different but it’s actually very similar: both printers have slicers that are altered versions of the widely-popular Ultimaker Cura software. iFactory has pre-made and adjusted PLA and PETG profiles for their printer, while Creality is still working with the community to make the best profiles.

Both company-made slicers are underdeveloped right now (minimal settings), and the only other option is Cura Blackbelt, another altered version of Cura. While there will probably be more slicers to come into play, for right now, you’ll be limited in slicing settings, modes, and capabilities.

Community Support

Another part of a quality printer is the available support. Because of Creality’s popularity in the maker community and large following, the CR-30 is likely to have a stronger and more active community than the iFactory.

Additionally, you can expect that the CR-30 will have a larger following than the iFactory, just based on the number of backers for both the machines on Kickstarter. Creality is also a more established company and has a lot of support platforms, like their large Facebook group, where users can find help for printing issues. Furthermore, Creality offers upgrades that are already compatible with the CR-30 and they plan on making more upgrades (or add-ons) specifically for the CR-30.

iFactory3D is a new company, and it’s not really known if they will continue to work with the 3D printing community, provide upgrades for their printer, or make more printers. While iFactory3D may not have the large-company benefits of Creality, they offer a personal set-up session with their engineers to help you complete their partially-assembled printer. In a review of the iFactory, a maker noted how despite the looks of it, the printer doesn’t take too long to assemble (about 3.5 hours).

Which One Is Best for You

Both printers are great and have many unique features. While you might be excited by them and want to pledge money on Kickstarter, we recommend you buy them on major platforms that can guarantee a product like Amazon or MatterHackers.

Additionally, their features can be better suited for different types of makers. The iFactory printer has many extras like a Raspberry Pi and a camera. Still, as pointed out by 3D Printing Nerd, it definitely has some room for improvement regarding the look of the printer and the frame. For this reason, the iFactory printer is probably best suited for makers looking to play around with fields other than 3D printing, such as single-board computers like the Raspberry Pi.

On the other hand, the CR-30 is another Creality-brand printer and will probably have many interchangeable parts and available upgrades (both printable and purchasable). Because of this, the CR-30 is probably the belt printer of choice for those looking to tinker with guidance from the community.

All in all, we’re hoping that both these printers live up to our expectations! And that they might be the start of a new generation of cheaper belt printers.

Lead image source: 3D Printing Nerd via YouTube

License: The text of "3DPrintMill (CR-30) vs iFactory: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.