Although 3D printing has been around since the 1980s, it’s still buzzing with activity. Continuous developments and innovations are making the different technologies more affordable, accessible, and expanding the horizons of their capabilities.

Traditionally, fused deposition modeling (FDM) 3D printers move in three dimensions across three different spatial axes: X, Y, and Z. However, as the technology has advanced and makers’ requirements have become more complex, some printers have introduced one or even two additional rotational axes.

3D printing with the classic X-,Y-, and Z-axes, as well as with the A and B or C rotational axes, is known as 5-axis printing. In a nutshell, the A-, B-, and C-axes provide rotational movement around the X-, Y-, and Z-axes respectively.

Not limited by planar layer orientation, this technology enables much more complex parts to be formed without the need for support material, which can increase strength and reduce print time.

In this article, we’ll be exploring what 5-axis printing is and we’ll be looking at a few 5-axis printing solutions and products!

5-Axis Explained

As mentioned, 5-axis 3D printing is one of the latest innovations in the world of additive manufacturing. It involves the addition of two extra axes of rotation to the toolhead relative to the workpiece. This enables parts with complex geometries to be made without supports, due to the fact that the toolhead can print on multiple planes instead of just on the bed.

This kind of printing allows for stronger and more complex parts to be made in a fraction of the time, since parts are strongest when the layer lines are at a 90-degree angle to the force being applied. The possibility of orienting the layer lines in any direction can enable a part to be at its maximum strength in all regions.

However, this inherent complexity also introduces difficulties with the software.

While the hardware for a 5-axis machine is complicated, it is a challenge that can be tackled with existing technology and prototyping. In contrast, the software and code that slices 3D models into G-code commands is similarly complex, but there isn’t a standardized way of approaching the problem.

Because each layer can extend throughout multiple dimensions, there are more ways of moving a toolhead to a specific location in 5-axis printing than in 3-axis printers. This means that the software has many more factors to take into account when calculating toolpaths that aren’t strictly defined, introducing significant complexity. This is a major drawback of 5-axis machines that affects the extent to which they can be commercialized.

When it comes to the slicers, many companies that make 5-axis 3D printers usually offer bespoke software for their own machines. That’s not to say that other options aren’t available, but they aren’t as popular as the likes of UltiMaker Cura, PrusaSlicer, or Bambu Studio.

Having gone over the general considerations of the hardware and software sides of 5-axis 3D printing, let’s take a look at some machines you might come across.

Machines & Mods Available

You’re probably wondering how you can get your hands on some 5-axis machines yourself. Don’t worry, we’re about to delve into three consumer and commercial machines that you can buy off the shelf, and two modifications that you can use to convert your own 3D printer into a 5-axis one.

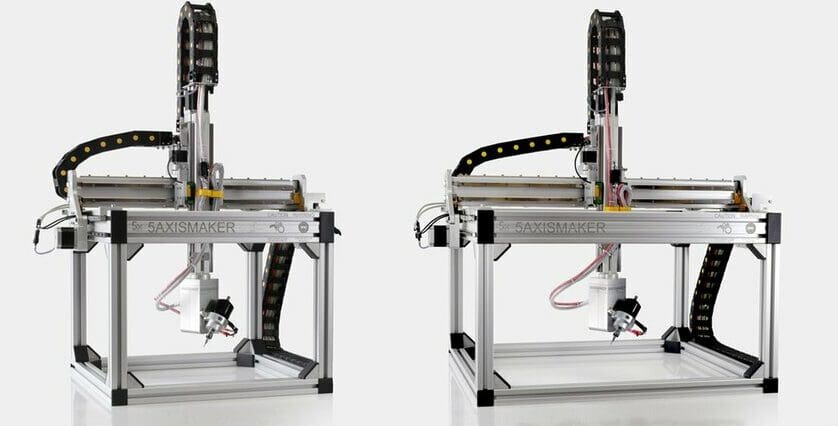

5XM by 5AxisMaker

The 5XM range by 5AxisMaker, an England-based manufacturer, is a unique line of machines that offer both 5-axis milling and 3D printing in a tight desktop footprint. Using switchable toolheads, one can change between an FDM 3D printer and a powerful milling machine in under a minute. All the machines have identical technical specifications but varying build volumes from 0.064 m3 to 1 m3.

The accompanying software, 5XCAM, offers automated generation of industrial-standard 5-axis toolpaths, alongside automatically choosing the required tools for the task. It’s powerful software that the company claims provides the simplicity of 3D printing in a CAM package.

5AxisMaker also provide a number of beginner-friendly tutorials on their website, guiding users through the use of Autodesk Fusion for milling with a 5XM machine, and of 5XCAM.

- Build volume: From 400 x 400 x 400 mm to 1,000 x 1,000 x 1,000 mm, depending on model

- Printable materials: Restricted to materials that can be printed with a Bowden extrusion setup and without a heated bed

- Company site: 5AxisMaker

5AX by VShaper

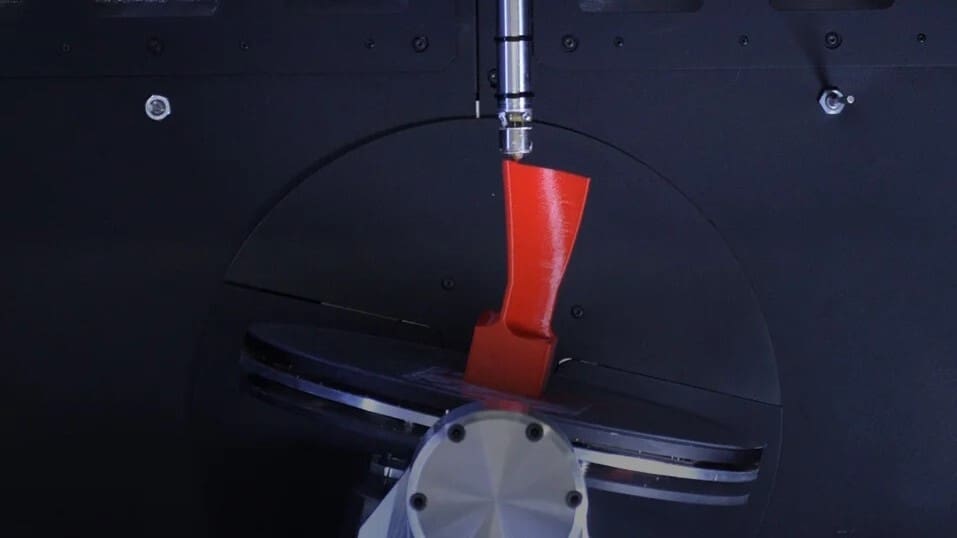

The 5AX by VShaper is a behemoth that packs an extremely wide range of features. Boasting its own integrated multi-material system, heated bed and chamber, and a probe, it’s certainly a formidable machine.

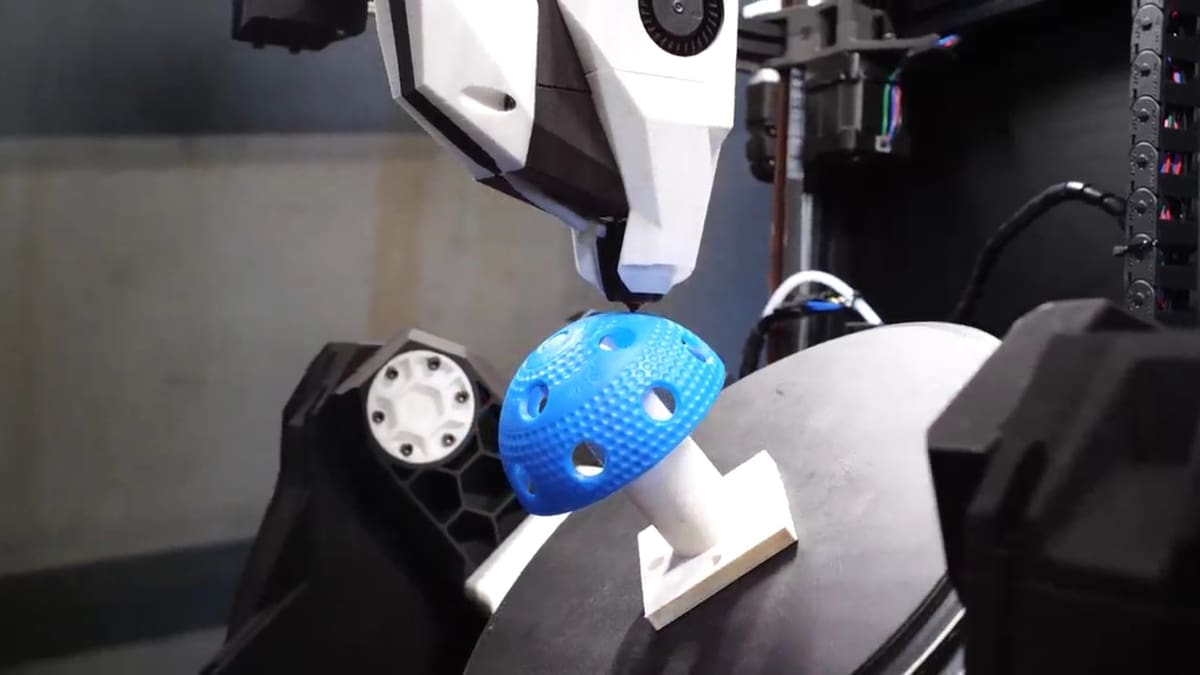

The 5AX features a rotating build-platform, which provides the additional axes, within its enclosure (rather than adding more mobility to the toolhead itself). It has its own advanced CAM software, called Soft Shaper. This software package incorporates advanced tools that let you parameterize the strength of specific parts of an object and has a wide range of easily-configurable settings.

The printer is capable of printing a range of materials at high temperatures, and has a direct extrusion setup. Through the use of its included probing tool, the 5AX is capable of updating a 3D model throughout the printing process, ensuring high quality and accuracy. What’s more, the printing toolhead can be replaced with a finishing tool that can fit milling, drilling, and burnishing bits.

MasterPrint 5X by Camozzi Machine Tools

Developed by Camozzi Machine Tools, the MasterPrint 5X is an industrial 5-axis machine that is already being used extensively across a range of fields, such as machining boat hulls and creating molds for aircraft fuselages, wings, and more.

Rather than rotating the bed, the 5X has a fully articulated nozzle that can swivel around, enabling high-quality and fast 5-axis printing or machining. It has a massive print bed that dwarves the other printers in this list, ensuring its place as an industrial option.

Ingersoll’s proprietary software encompasses various workflow steps, from programming and simulation to optimization and running diagnostics. The MasterPrint 5X has multiple configurations that enable it to be used for a wide range of functions alongside 3D printing, including milling, fiber placement, tape laying, inspection, and trimming.

- Build volume: 6,000 × 4,000 × 2,000 mm

- Printable materials: Plenty of materials due to heated nozzle of up to 500 °C, although it doesn’t include a heated bed due to its size

- Company site: Camozzi

Open5X by Freddie Hong

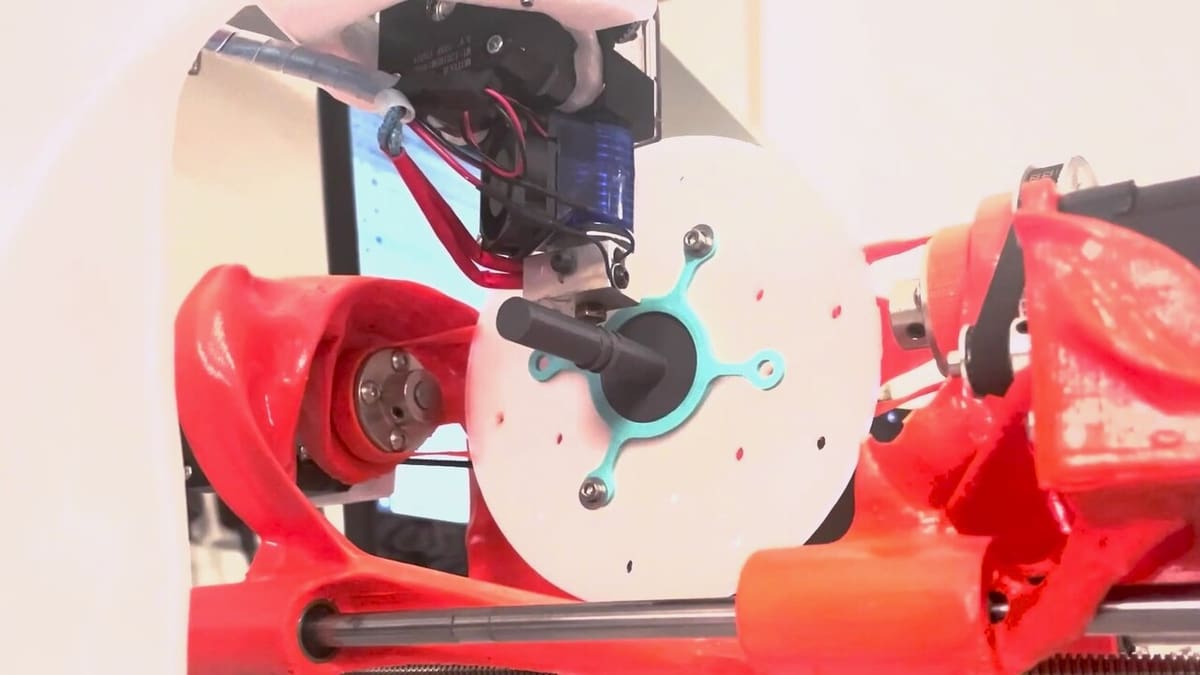

The Open5X is an accessible modification for the Prusa i3 that enables anyone to essentially convert it into a fully fledged 5-axis 3D printer. Using only 3D printed parts, the Open5X bears a strong resemblance to the RepRaps of the early 2000s, and was one of the first forays of makers into the 5-axis scene.

This modification is designed to replace the bed of a Prusa i3 printer, adding two rotational axes with the new print bed. This means that you can use any material compatible with a Prusa i3 printer, and toolhead modifications – on top of the fourth and fifth axes – could widen the range even more.

The creator, Freddie Hong from Imperial College London, currently maintains a large repository of 5-axis machine software. This is helping overcome the software bottleneck that currently exists by grouping together a number of open-source 5-Axis implementations, giving others a platform to work off of when making their own software or hardware.

The Open5X and future endeavors built off of it look to be incredibly promising.

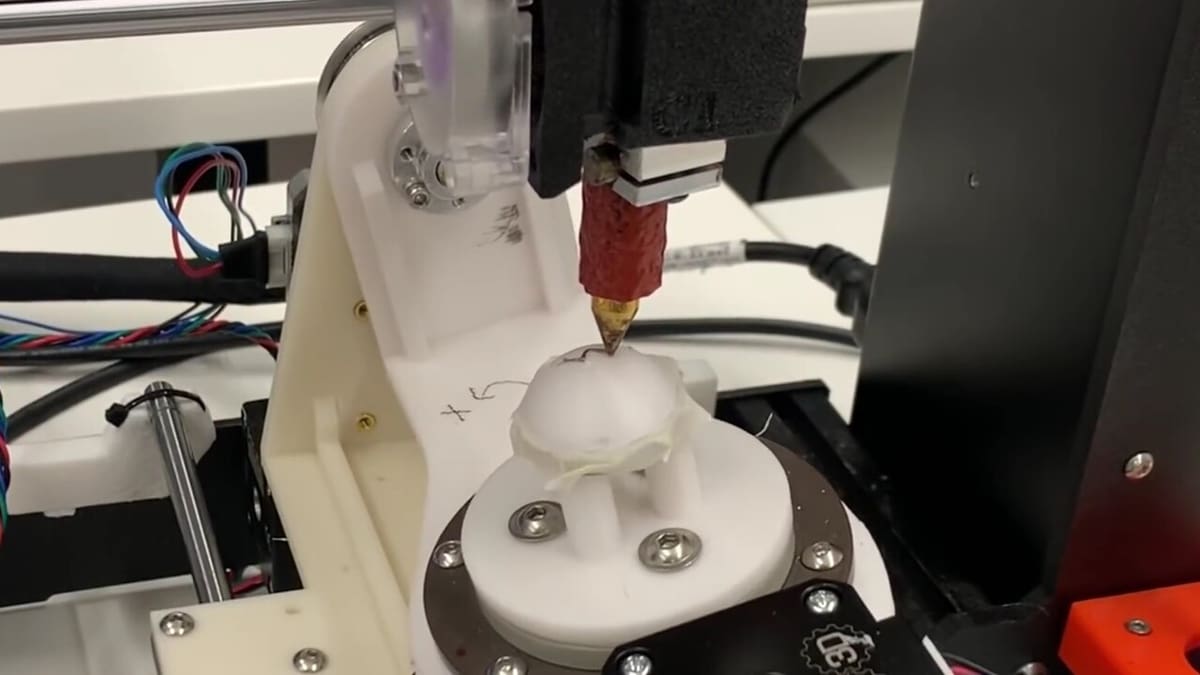

Gen5X by Ric Real

The Gen5X by Ric Real is an innovative and ground-breaking 3D printer, built entirely through generative design. This essentially means that the printer is designed using a computer system and a set of constraints. As an open-source project, the Gen5X looks to push the limits of how generative design, 3D printers, and AI can be combined.

It’s similar to the Open5X, in that the bed is the only part of the printer that moves (excluding the Z-axis), including in rotation. In terms of software, as the control board is completely up to the user’s choice, this machine should be compatible with any of the aforementioned software from Freddie Hong’s open-source repository.

The Gen5X uses an E3D V4 Titan extruder with a direct extrusion system, enabling printing in both harder and more flexible filaments such as PLA, PETG, TPU, ABS, and TPE. This printer is based off of the early self-reproducing RepRap printer project, and holds major potential with the increasing incorporation of AI to more and more fields.

What's Next?

The interest in and support for 5-axis 3D printing has skyrocketed over the past decade, and has led to an increase in popularity of the field within the maker community. This pace only seems to be growing, with more and more independent creators designing and building their own versions of such printers.

With these developments, the software bottleneck problem remains an issue that is gradually becoming more tightly defined and explored by researchers.

Some other projects in development include the 5X by Daniel Aeschbacher, a student at the IWK institute, and the HEXA delta 3D printer with 6 axes! These kinds of independent pursuits are representative of the accelerating rate of development within the field.

The future of 5-axis 3D printing looks bright!

License: The text of "5-Axis 3D Printer: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.