We Have the Technology

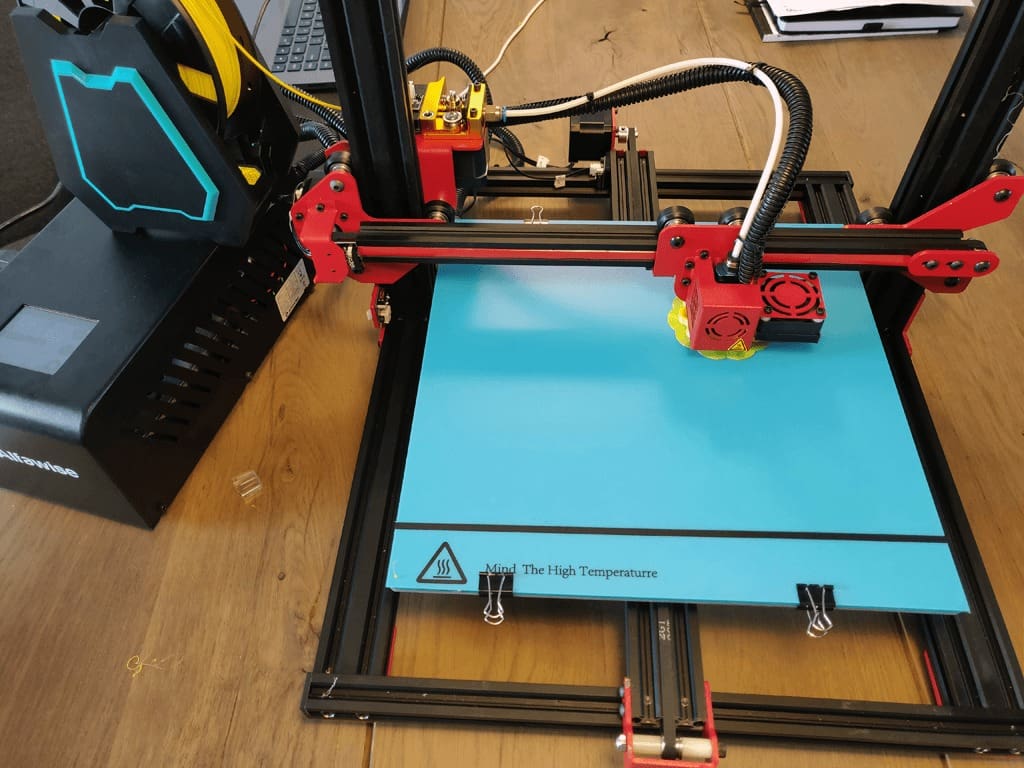

The Alfawise U20 was launched in the summer of 2018 as an upgrade to the Alfawise U10. It maintains the large build volume and emulates the success of the Creality CR-10, yet it retails for under $300.

Reflected in the low price are a few minor issues. For example, a number of hobbyists who’ve had the chance to use the U20 are unhappy with its extruder fan. Others complain about its spool holder, and the majority agree that it has terrible software, which is made worse by the regular feature-breaking firmware updates from the development team. These downfalls have left a bitter taste in the mouths of some hobbyists.

The good news is that there are Alfawise U20 upgrades and mods that can help correct some of these problems. But since the printer hasn’t been around long enough, most of the upgrades are printed parts.

Let’s take a look at what the community has to offer!

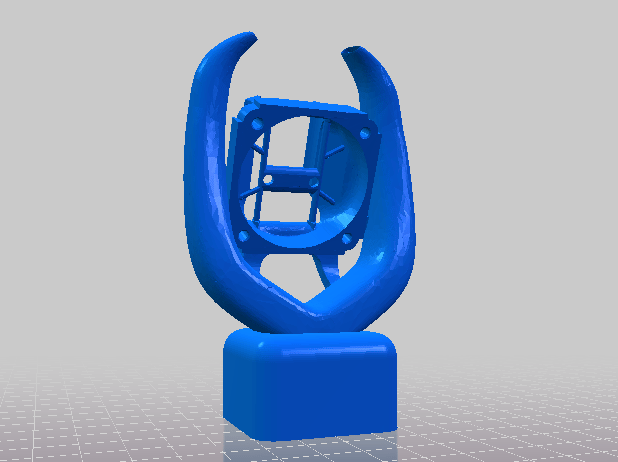

Fan Duct

The purpose of this upgrade is to better cool your extruded filament. It ensures the filament is cooled from both the left and the right side of the nozzle, improving your prints in a major way.

The standard ventilation duct that comes with the Alfawise U20 delivers insufficient air flow and doesn’t concentrate enough air around the extrusion zone. This can cause walls that are further from the fan to print poorly.

Once you print this part, you’ll need to adjust its height or rotate it until you achieve the optimal result. Just note that it should never touch the bed while printing.

Who made it? Gueuff

Where to find it? Thingiverse

A similar fan duct comes from user 3DMakerES.

Spool Holder

The default filament support for the Alfawise U20 has been called a disaster. It looks weak and can barely hold large spools, which are necessary for larger prints.

Solving the problem is this improved spool holder for the U20. It’s called the Bobine Filament Support and doesn’t require any extra parts.

This spool holder is both rigid and well-aligned to the filament input. One installs it in the top left frame of the U20, and it should comfortably hold large spools.

Who made it? Miller95

Where to find it? Thingiverse

Note that, while there are tons of other similar Alfawise U20 upgrades on Thingiverse, many of them will eat into your build space. Another spool holder that respects your space comes from 3DMakerES.

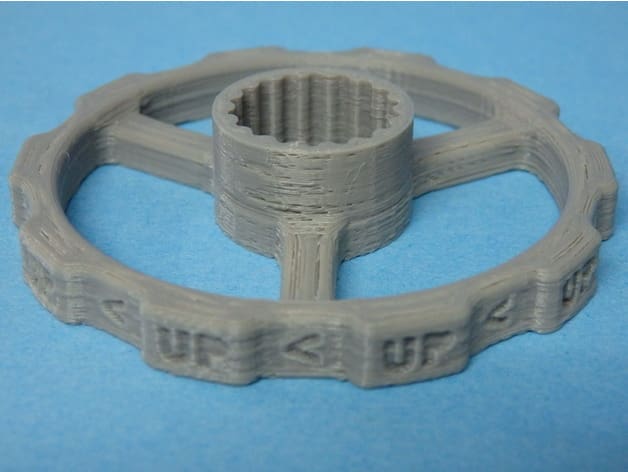

Bed Knob

The purpose of this part is to make bed adjustment a breeze. It’s a knob that attaches to the thumb screw under the print bed, making it easier to level the build surface.

Once installed, the knob is easy to turn with several fingers, instead of struggling to reach the thumb wheels under your print bed.

Who made it? boxplyer

Where to find it? Thingiverse

If, for some reason, this knob doesn’t work for you, there are other similar Alfawise U20 upgrades on Thingiverse. A popular one is this bed knob from AdryJay.

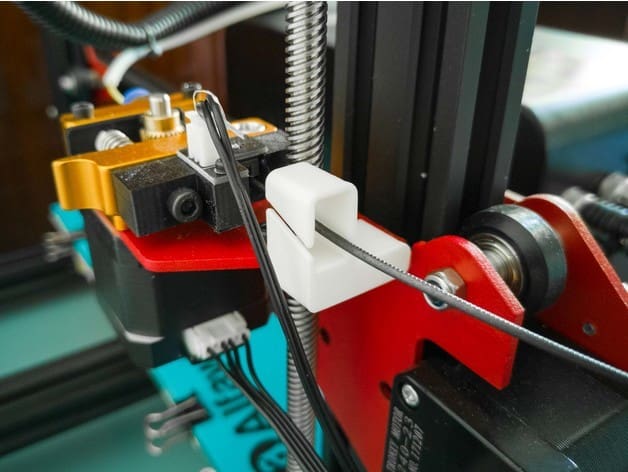

Filament Guide

Occasionally, your filament may come into contact with the Z rod while printing, and this can cause an array of problems, including a failed print. This filament guide should rectify the problem by providing extra guidance to your filament.

It’s a small part that takes only 20 minutes to print. There are other similar Alfawise U20 upgrades on Thingiverse, but you’ll find that some need screws or are too tight. This specific design will give your filament enough freedom while also ensuring it never touches the Z rod.

Who made it? AdryJay

Where to find it? Thingiverse

LiquidOnDiscord offers an alternative design but acknowledges that it’s still a work in progress.

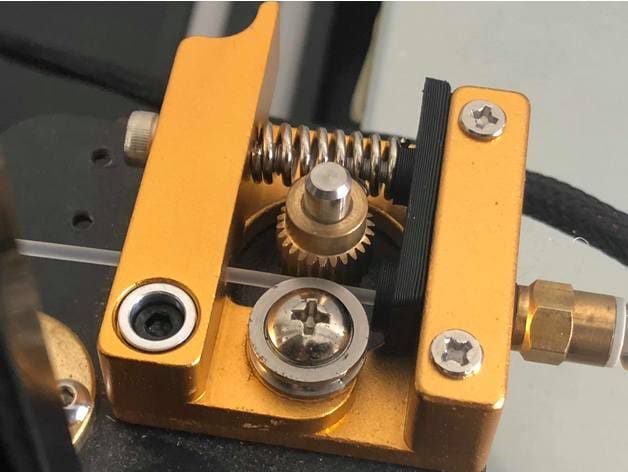

Extruder Addon for Flexibles

This addon is supposed to facilitate hassle-free printing of filaments like TPU. In fact, this is one of the almost compulsory Alfawise U20 upgrades if you want to use any kind of flexible filament.

The Alfawise U20 has a flat extruder design, making it tough to print flexibles like TPU. With this extruder design, a flexible filament will rarely push itself through, unlike other solid filaments like ABS, or PLA, and will normally bunch up, bend, or get twisted before printing is complete.

Therefore, it’s necessary to lessen the gap in the filament path, and that’s where this addon comes in. It helps close the gap between the feeding gear and the extruder casing, keeping the extruder “tighter” so that the filament can push through.

DIY3DTECH explains the phenomenon. Once you add this part to your extruder, TPU should print effortlessly.

Who made it? 3dMakernoob

Where to find it? Thingiverse