Layer smoothing is one of the most popular methods to eliminate the layer lines on 3D prints, improving their finish and look. One common way to layer smooth is using acetone, which only works on parts printed in ABS, ASA, and similar filaments.

Acetone, which most people know for its use in painting, is a solvent that can dissolve certain plastics, including ABS. Acetone smoothing can be done by applying acetone vapors or liquid to a printed part, which dissolves the many 3D printed layers. This “binding” of layers is what yields that glossy and smooth finish.

In this article, we’ll be going over acetone layer smoothing effects on ABS parts’ strength. Let’s take a closer look!

Impact on Strength

By looking at a picture of a regular 3D printed part and an acetone-smoothed piece, you might assume that the acetone-smoothed part is stronger just because it seems more solid. However, this isn’t always the case.

Vertical Strength

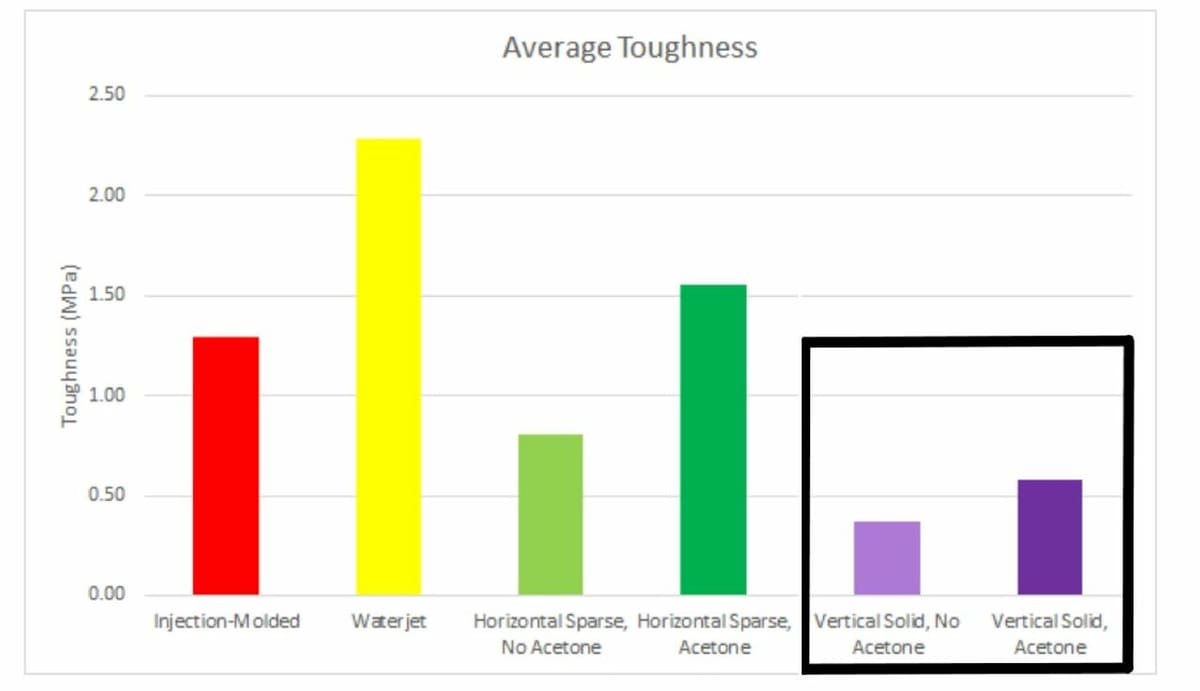

As most people might think, parts that are treated with acetone are more robust vertically because the horizontal layer lines have dissolved to bond vertically. This concept was proved by a study that measured the material toughness (MPa) of acetone-treated and untreated parts. An acetone-treated, vertically-oriented 3D printed part was found to be stronger than the one that wasn’t treated (see the bar graph above).

Horizontal Strength

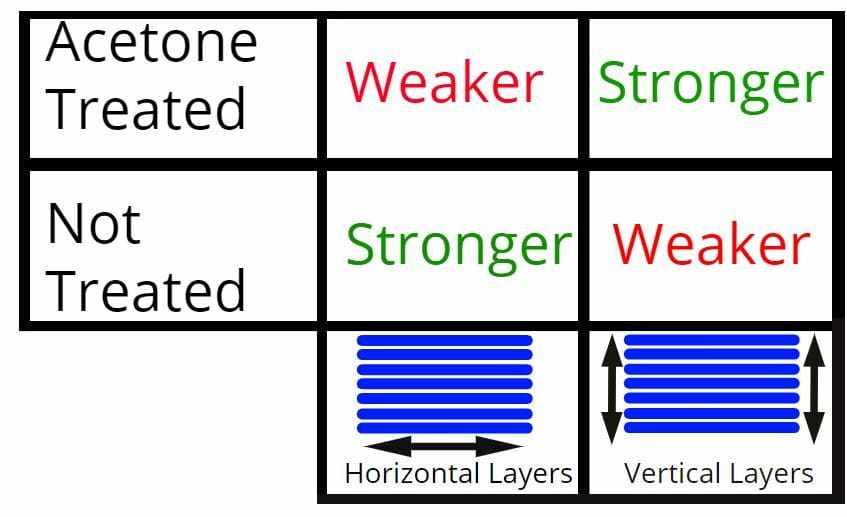

It’s false, however, to assume that acetone-treated parts are all-around stronger. A study by Michael Graham confirms the findings of the previous study – that acetone-treated parts are vertically stronger – but presents new evidence regarding their horizontal strength.

Graham’s intensive study was conducted using a machine that tests the tensile strength of acetone-treated and untreated parts both horizontally and vertically. In other words, the pieces were stress-tested when oriented horizontally as well as vertically.

When the results were recorded, you can see that acetone-treated parts were weaker than untreated parts when stress-tested horizontally (see the recreated chart above).

The data revealed that they were 9% weaker horizontally than parts not treated. Acetone-treated parts were, however, 31% stronger vertically than untreated ones.

Next Steps

Now that you know the effects of acetone, you might wonder how you can use acetone on a horizontal part without losing as much strength. We’ve got you covered!

- Adjust slicer settings: Using a high infill percentage, more shells, and other settings of this sort can help compensate.

- Larger is better: Printing a part with a larger nozzle means the layers will be bigger and stronger. Plus, a higher layer height setting in your slicer also will help because the fewer layers a part has, the stronger it is.

- Part orientation: By orienting your part differently, the original horizontal area becomes the vertical area, and it gets stronger rather than weaker. This, of course, will cause the original vertical area to get weaker.

In summary, acetone has a slightly negative impact on an ABS part, specifically its horizontal strength. As we now know, if you need a piece horizontally stronger than usual, you might want to avoid acetone smoothing. However, acetone does offer a significant increase in a treated part’s vertical strength, not to mention its visual appeal.

Lead image source: Pumping Station: One

License: The text of "Acetone & 3D Prints: Does Smoothing Affect ABS’ Strength?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.