A Change Was Needed

Big shoe brand Adidas has continuously pushed the boundaries of innovation to provide customers with more comfort, performance, and terrain responsiveness from their shoes. The shoe part that’s crucial for achieving this is called the midsole and it’s the part Adidas has chosen to 3D print using technology from American-based 3D printer maker Carbon to create what the company is calling its most advanced running shoe.

The latest iteration of the Adidas 3D printed midsole performance shoe, the 2022 4DFWD runner (which landed in stores on Sept. 1), doesn’t exactly run for you but delivers the next best thing. Its bowtie-shaped lattice midsole transforms vertical pressure into a horizontal force. This gives runners a non-stop smooth forward transition, the company says.

To make the impossible quest of creating the most technologically advanced running shoe yet a reality, Adidas says it evaluated over five million variations of the lattice structure and combined 18 years of real-world athlete performance data to identify a design that would change the game for runners around the world.

Adidas collaborated with its global innovation partner and 3D printer maker Carbon to create a precisely fine-tuned midsole, which offers what it says is a scientifically proven forward motion benefit.

THe 2022 4DFWD ($200) is Adidas’ second edition of this shoe design and features a new outsole with extra grip for a confident run in any weather condition; an all-new mesh upper construction for an extra-supportive and snug fit; and a 3D printed midsole with 23% more cushioning than before.

The Very Recent Past

Several manufacturers, including Adidas, have been interested in using 3D printing technology in their shoe designs, knowing it can produce complex shapes using different material mixtures. In fact, Adidas unveiled their first shoe prototype featuring a 3D printed midsole back in 2014. A year later, Adidas announced “Creating the New“, a 5-year strategy detailing ideas for the brand’s future, including production using 3D printers.

Two years down the line, in 2017, Adidas announced a partnership with Carbon, an innovative 3D printing company that makes its own 3D printers, to use the company’s own special technology called “Digital Light Synthesis“.

The result of this partnership was the 3D printed midsole and a whole new “Futurecraft 4D” sneaker line for Adidas, which began as a limited edition production run. Since then, Adidas has been implementing the Futurecraft 4D midsole into many different shoe lines.

Adidas was the first mainstream manufacturer to do such a thing, but as time progressed, other well-known brands like Columbia, Reebok, and New Balance, have also stepped into the field and introduced their own 3D printed shoes.

As this article is focused exclusively on Adidas, let’s further explore what the brand has been doing with 3D printing and what’s next for the German giant.

First of Its Kind: Futurecraft 4D

Adidas product engineers have been experimenting with 3D printing for at least 10 years now, and, as mentioned above, the first-ever Futurecraft prototype was shown in 2014. The prototype looked a bit futuristic, but it was nowhere near as complex and advanced as it later would become.

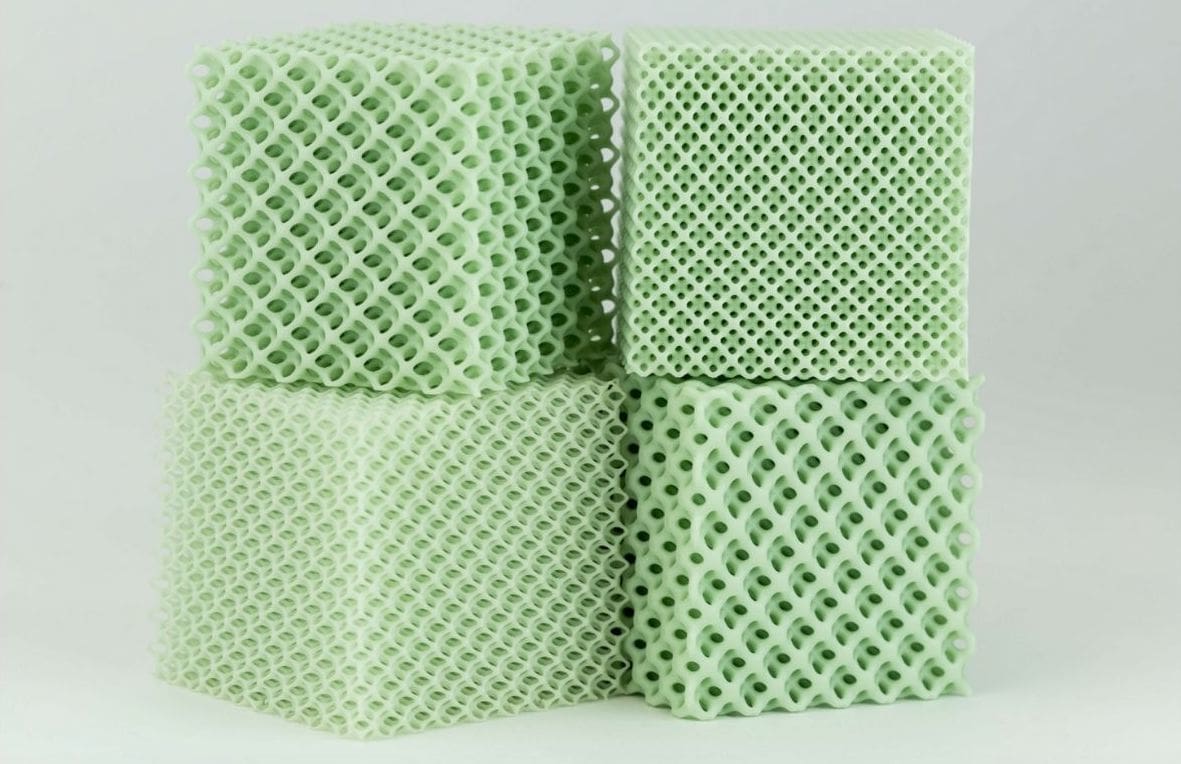

What Adidas wanted to achieve with 3D printing was to make proper use of the technology’s potential for making incredibly intricate structures. In their partnership with Carbon, the design of the Futurecraft 3D printed midsole is based on optimized data (pressure points from wearing the shoes) collected from athletes around the world. This resulted in the midsole’s complex lattice structure being denser, stiffer, or softer in certain areas.

The midsole was 3D printed on Carbon’s M2 3D printer out of curable UV resin and polyurethane. This exact material mixture also absorbs more energy than a standard midsole, which should enhance running performance. The midsoles are also quite smooth, which makes them easy to clean. However, getting them muddy or stepping in something smelly can be unfortunate, as it can be hard to reach the inner parts of the complex structure for cleaning.

After the design of the midsole was finished, the first production run of the original Futurecrafts was set to 5,000 units and priced at $300. Not surprisingly, they sold quickly. Later, much greater production numbers were put in place as the brand expanded the line, applying different uppers to the midsole, and therefore creating new models.

If you’d like to purchase a pair of Futurecraft 4D sneakers, they start at about $110 and go up to several thousand dollars.

AlphaEdge 4D

At the end of 2019, Adidas launched the AlphaEdge 4D line, another model featuring the famous 3D printed midsole. The outsole on these shoes is from Continental, a renowned tire manufacturer, while the upper part of the sneakers is made from a woven fabric called Primeknit (commonly used in Adidas shoes). Currently, these shoes retail starting at about $200.

Special Star Wars Edition

After the release of the AlphaEdge 4D, Adidas quickly announced a special edition in collaboration with Star Wars called AlphaEdge 4D “Death Star”. Featuring an all-black design with a Death Star stripe, you can now show your allegiance to the dark side on your shoes. If you happen to be a 3D printing enthusiast who likes running and Star Wars, then these shoes are a great choice.

Looking to grab a pair? They were originally priced at about $300.

Y-3 Runner 4D

As you’d expect, Adidas went ahead and started launching many different sneaker lines featuring the Futurecraft 4D midsole. The Y-3 Runner 4Ds are one of the most exciting examples, as they combine the famous Y-3 label with the hyped 3D printed midsole. In case you’re not familiar with Adidas’ Y-3 label, it’s a popular collaboration with a Japanese fashion designer Yohji Yamamoto.

Shown above are the white Y-3 Runner 4Ds, but there are also various color combinations available such as red and black. As you can imagine, these sneakers don’t come cheap; Prices start at $600, but some sizes and colors can go above $1,000.

The Latest Advancement: Ultra 4D "OG"

The most recent shoe from Adidas featuring 3D printing is called the Ultra 4D. Just announced last month on August 13th, this sneaker has the upper of the Ultra Boost and the now well-known 3D printed midsole.

If you’re an Adidas fan, this sneaker will probably be right up your alley, as it combines the futuristic approach of the brand, together with a classic Ultra Boost color scheme: The upper is a Primeknit colored in black and grey, with blue and purple accents on the back, plus it features the “Ultra 4D” model designation.

In terms of price, it will vary slightly depending on where you buy, but the retail price is expected to be $220.

What Does the Future Hold?

Despite the 3D printed midsole being very impressive and technologically advanced, there’s still a lot to look forward to. Let’s take a deeper look at two areas where improvements are sure to come.

Printing Speed

First, one of the main goals for Adidas and Carbon is to reduce the printing time required for each midsole.

In the beginning, each midsole took 90 minutes to print. As the partnership progressed, print time was brought down significantly to just 20 minutes. The goal, however, is to make that number even less and accelerate production quantity.

Mass Customization

Arguably one of the most popular topics in regards to 3D printing is mass customization, and you bet Adidas has plans for that. The Futurecraft 4D midsole is a great platform for adopting the concept of mass customization, as 3D printing can easily produce different midsoles, each suited to individual customers.

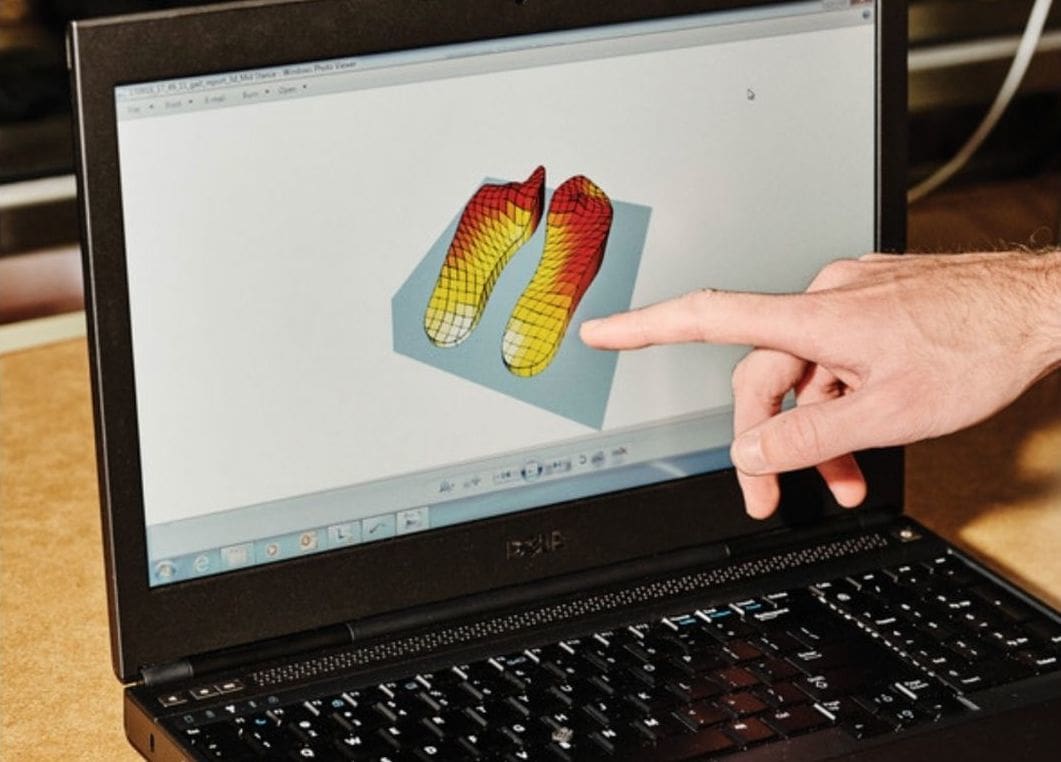

The problem with mass customization that Adidas still has to solve is in the phases before the actual printing of the midsole. In order to produce a custom midsole, specific data based on the customer’s feet and running style are needed. While this can be done via different sensors that produce a 3D render of the feet and report pressure points, it’s a very time-consuming process.

What we potentially see as a solution is some sort of a device that would be integrated into Adidas’ stores that can quickly analyze each person’s feet and send the information directly to a factory full of 3D printers. Indeed, Adidas tried a process similar to this but concluded it was still too early to adopt such a process.

Either way, we’re excited to see what the future of 3D printed footwear has to offer.

Lead image source: randygalang via Hypebeast

License: The text of "Adidas 3D Printed Shoes: The Latest Advancements" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.