Since its start in 2016, Anycubic has grown rapidly and become a go-to brand for 3D printing hobbyists and enthusiasts. The Chinese company is known in the industry for the value and ease of access they provide to entry-level 3D printing hobbyists. What started as an idea between childhood friends has grown into a large company with 24/7 customer service and a wide range of popular products, including 3D printers, filaments, resins, and accessories.

Anycubic boasts some of the most high-quality yet affordable FDM 3D printers on the market with its Kobra and Vyper series. These feature-packed printers have earned many fans with their sleek design and solid print performance, along with a relatively low price tag. While they share many similarities, these two printers also have some characteristics that set them apart, including a $60 price difference.

In this article, we’ll compare Anycubic’s Vyper and Kobra and take a closer look at several features of these popular printers, including the design, build volume, UI, software, bed leveling, and of course, the price, to help you get an idea of the differences between them. Let’s dive in!

At a Glance

Features

A table full of specs can only tell you so much. In the following sections, we’ll look at both printers, feature by feature, in order to give you a better sense of how they really compare.

Design

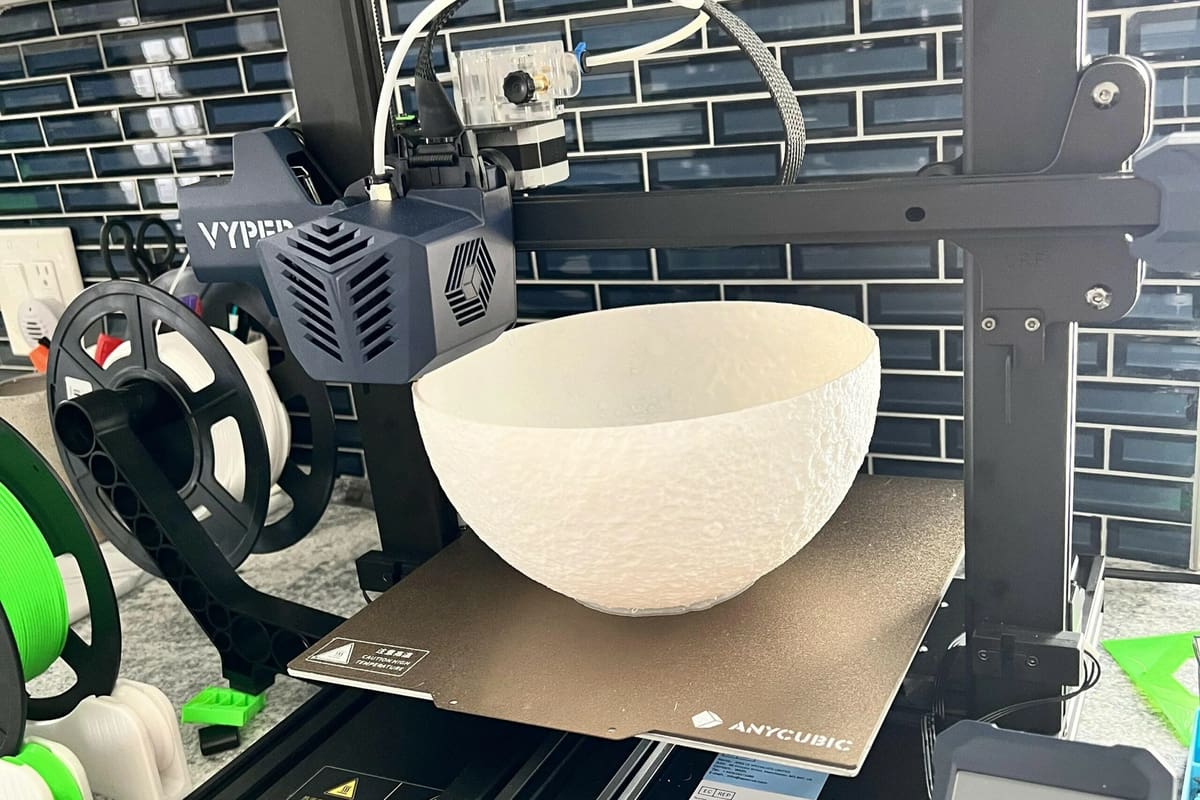

In terms of design, the Vyper and Kobra share many similarities. The Vyper is a stylish printer boasting cool blue details and angular plastic parts. While the Kobra looks and feels a bit cheaper, the design is streamlined and uncluttered. Both of these Ender 3-style printers have frames that feature aluminum extrusions with plastic engravings and hot ends that can reach a maximum temperature of 260 °C.

As for the differences, the Kobra has a single thread for the Z-axis, while the sturdier Vyper has a double thread, which is designed to last longer. Additionally, the Kobra only has one cooling fan, while the Vyper is cooled by a dual-fan system. The double photoelectric limit on the Vyper ensures a reduced zero position error, more stable operation, and an even print.

The Vyper and Kobra both come with a handy toolkit to make assembly and maintenance easier. The toolkit houses a wire cutter to cut the zip ties that come with the parts, an Allen Key set, as well as a couple of spanners.

Build Volume

The Kobra offers a 220 x 220 x 250 mm build volume, which is a pretty modest size. However, it’s a decent size for the price. The Kobra is geared toward 3D printing beginners and hobbyists, so this volume should not be a problem for most users looking to gain some printing experience.

If you want to flutter your wings into the realm of greater creative possibilities, the Vyper may be the more suitable option for your needs. This printer has a build volume of 245 x 245 x 260 mm, which is a sizable upgrade.

Build Plate

Both the Vyper and Kobra printers feature PEI spring steel magnetic build plates, which is a fantastic platform for the price tag. PEI-coated spring steel has high toughness and resistance to impact loads, and the coating is scratch-resistant. Similar to glass beds, this material makes it easy to remove your 3D printed parts.

PEI-coated metal sheets are compatible with a wide range of filaments, including PLA, ABS, and PETG. Anycubic notes that the build plate on both models can sustain a maximum bed temperature of 110 °C.

UI

The user interface (UI) is an important aspect of any 3D printer, as it affects how you control and interact with it during the printing process. Both the Vyper and Kobra feature a 4.3-inch, full-color touchscreen. The LCD screen is conveniently placed in the right corner of the printer. All in all, the UI on both printers is pretty much identical. Interacting with the printers using the large, portrait-oriented touchscreen should be nice and simple. The interface is intuitive, bright, responsive, and clearly well-designed.

In addition, the UI of both models is an upgrade from the 2.4-inch LCD screen on Anycubic’s Kobra Go and Kobra Neo, which come with a knob control. One YouTuber noted that it’s useful to be able to control the beeping sound on contemporary 3D printers, and you can access this feature in the Vyper’s UI.

Extrusion

One of the main differences between these printers is the extruder setup. The Kobra features direct extrusion, while the Vyper has a Bowden-style extruder. Adding a direct extruder to the Kobra enhances reliability and retraction performance, while the Vyper’s Bowden extruder, along with the double thread Z-axis, dual motors, and dual cooling fans, results in faster, quieter, and neater prints. Direct drive extruders are better suited than Bowden extruders for printing flexible filaments, like TPU. If you plan to print these types of filaments, you can upgrade your Vyper and increase its performance by purchasing or printing a direct extruder.

Other than the extruder itself, the systems are pretty similar. The Vyper has a volcano-style hot end, while the Kobras boast a basic PTFE-lined hot end. Both are compatible with E3D nozzles and can reach a maximum of 260 °C. It’s worth noting that dual-gear extrusion is implemented in the Vyper to mitigate wear losses due to excessive use, and the Kobra system feels a bit basic in comparison.

Software

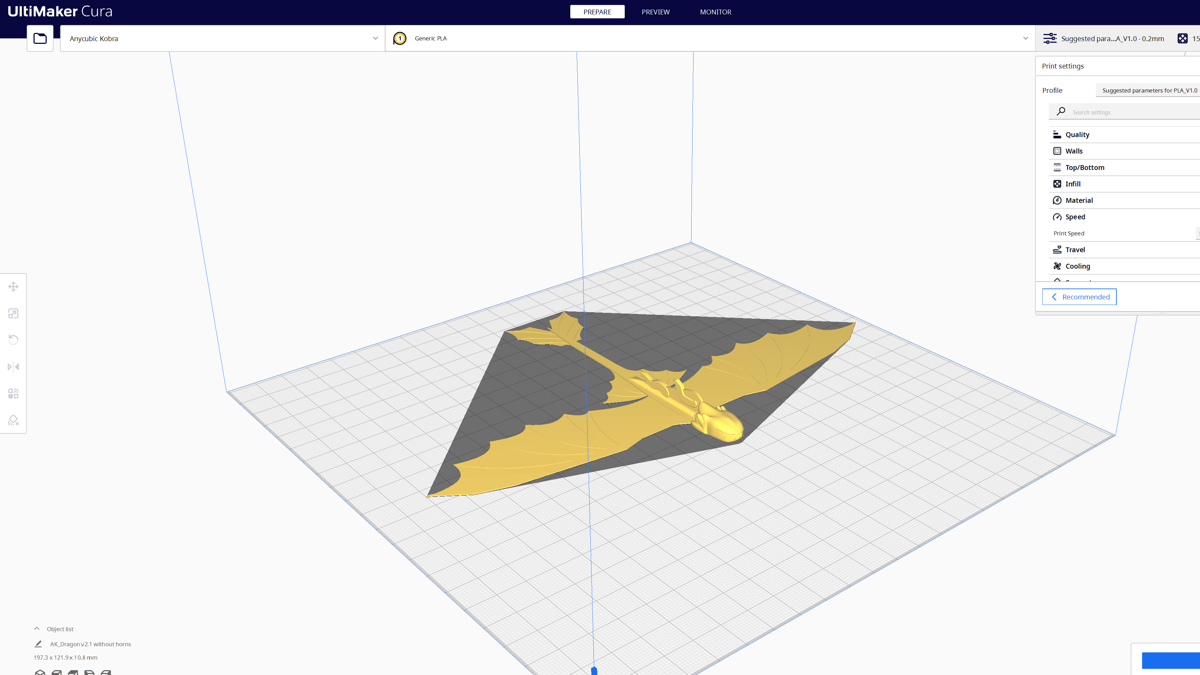

As a machine that runs on G-code, these printers are compatible with most software. You can take your pick of popular options like Cura, PrusaSlicer, Repetier Host, and Simplify3D, among others.

The SD card that comes with the package on the Kobra and Vyper features test files and pre-built 3D printing profiles for common filaments like ABS, TPU, PLA, and PETG in Cura, which is the slicing software recommended by Anycubic.

Bed Leveling

Automatic bed leveling is an important feature of both printers. While the cheaper Kobra has 25-point automatic bed leveling, the Vyper has a 16-point automatic bed leveling system. The Kobra is designed with beginner users in mind and houses a thorough, one-time auto-leveling system to take the guesswork out of the process. It uses Anycubic’s LeviQ, an inductive probe-based mesh-bed leveling routine, to map out 25 points across the print bed and measure how much they deviate to help ensure an even first layer.

In comparison, the Vyper’s automatic leveling system maps out 16 points on the print bed. It only takes 3 minutes, after which no Z-axis adjustments should be required.

Mainboard

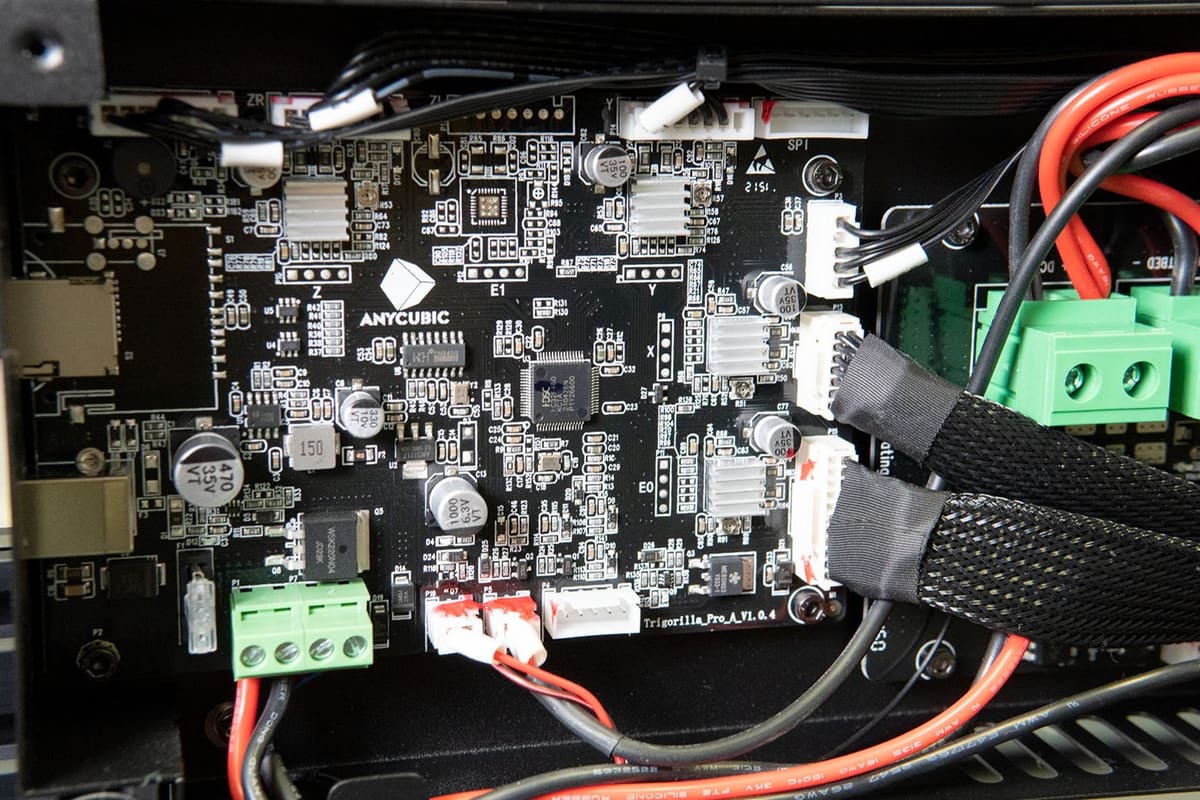

The Vyper holds a 32-bit Anycubic mainboard with TCM2209 stepper motor drivers. The stepper driver allows the Vyper to keep its movements quiet, making it a solid choice for users who prefer silent running.

A 32-bit Anycubic-designed Trigorilla Pro A V1.0.4 mainboard powers the Kobra. While the stepper drivers (TMC2209s on the X-, Y- and Z-axes, and MS35775 on the E) are soldered to the board, meaning you won’t be able to swap them out easily, slightly more advanced features, like the Kobra’s sensorless homing, are possible. The Kobra has a 400W power supply, while the Vyper draws a maximum of 350W while pre-heating filament and heating the bed.

Price

Price is one of the most important factors when deciding to buy a 3D printer. Ideally, a printer should offer quality results for an affordable price tag. As mentioned before, Anycubic is known for its selection of budget-friendly 3D printers, and the Vyper and Kobra are no exceptions.

The Kobra is about $300, which is a fantastic price considering its standout features. Capable printers with auto-bed leveling, direct extrusion, and a PEI-coated bed often come with a much higher price tag.

On the other hand, the Vyper costs $360, about $60 more than the Kobra. For the price bump, you can expect to see some more deluxe features, such as higher overall print quality, a dual-gear filament feed, and a larger build volume. Whether or not the extra cost is worth it depends on how you plan to use your printer.

Verdict

So, in the end, which printer is better? Considering the features offered by both the Vyper and Kobra, there’s no clear answer. Judging by the double threads for the Z-axis, dual-gear extrusion, and other technologies included in the Vyper, this attractive printer offers a slightly more premium experience. Plus, it’s designed with longevity in mind, and you can always upgrade the machine if you wish to have a direct extrusion setup.

As the more budget-friendly option, the Kobra offers great value. This printer houses an array of components that help deliver high-quality prints. While it may not be as pretty as the Vyper or able to withstand as much heavy use, it’s a capable machine that’s enjoyable to use.

The Kobra may be the way to go if you want to make high-quality prints on a budget or you’re just starting with 3D printing. The Vyper is a great option for hobbyists who use their 3D printer more regularly and want room for future upgrades in their machine.

License: The text of "Anycubic Vyper vs Kobra: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.