Post-Processing Made Easy

The stereolithography (SLA) 3D printing process is known to provide very accurate and precise 3D prints. Most machines on the market handle layer thickness as low as 25 μm, resulting in high quality and smooth finishes. SLA 3D printing does offer some challenges, though, especially regarding post-processing.

Besides clearing support structures, a couple of extra steps are also needed, like rinsing and washing parts prior to finishing them with UV curing. This process involves some messy business, including handling uncured resin (which is toxic) and using cleaning agents like isopropanol alcohol that can also be harmful.

At the end of the day, the less physical handling of such products the better, which is why SLA wash-and-cure stations are highly recommended. These machines have become more widespread, especially in the consumer market, with most budget SLA 3D printer manufacturers offering their own models.

In this article, we’ll be going over everything about Anycubic’s Wash & Cure 2.0, the second version of their popular machine. Let’s start with its main features.

Features

Anycubic, a 3D printing company based in Shenzhen, produces and sells one of the most popular budget SLA printers of all: the Photon series. The first Wash & Cure machine was released a couple of years ago, receiving its latest update in early 2020.

The main features include:

- Dual purpose: As implied, this machine serves two purposes. The washing part is done in a liquid container that’s automatically stirred to remove any excess resin, while the curing involves shining UV lights at the parts while they rotate on a spinning turn-table. Note that these can’t be done at the same time.

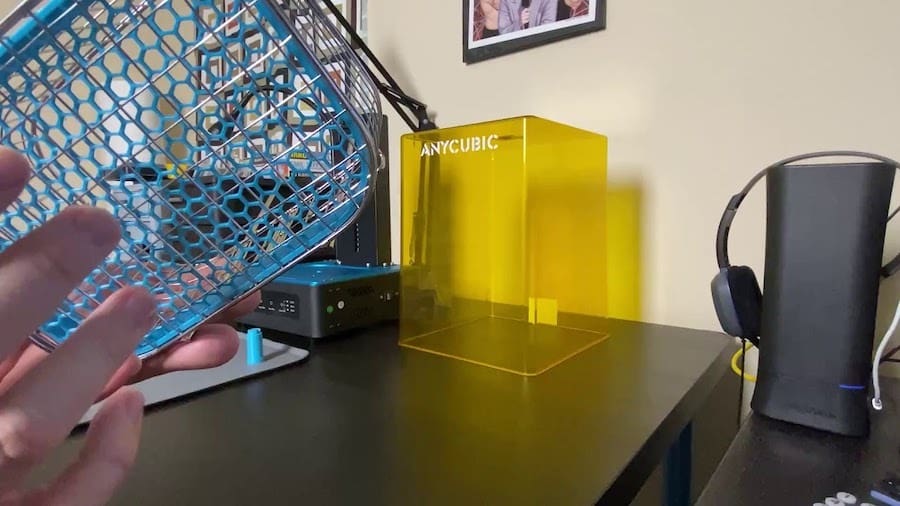

- Enclosed washing: A unique feature, the washing phase is done in a way that the liquid container can be completely sealed at the top, avoiding any unwanted spiling. Parts can be washed when still attached to the build table.

- UV-blocking cover: The yellow transparent cover is said to block 99.95% of the UV light used to cure the models. This particularly relevant for safety reasons as prolonged UV light exposure is dangerous to the eyes and skin.

- Rotating platform: This ensures every surface is cured evenly. The 2.0 version comes with a reflective sheet that’s placed below the platform prior to start curing. The reflected UV light hits downward surfaces of the model that otherwise would be difficult to reach.

In addition, it’s well worth noting that the UI has been significantly simplified: the Wash & Cure 2.0 has only one button to switch modes and a knob to set the timer. It’s also compatible with most SLA 3D printers with similar build sizes, like the Elegoo Mars.

The Bottom Line

Anycubic’s Wash & Cure 2.0 offers two main benefits: safety and practicality. According to some users, it’s very convenient and a great investment for SLA makers.

With this machine, the exposure to raw resin is minimal. By washing prints still attached to the build plate, the subsequent steps like support removal are done with models already clear of resin. As a bonus, the build plate is also ready for your next print.

Curing parts in a controlled environment is not only efficient but also practical. The turntable eliminates the need to reposition parts during the process, while the timer provides consistent curing over different batches of parts and helps to avoid overcuring.

And finally, the price. At around $150, the Wash & Cure 2.0 has great cost-value. It’s highly unlikely that a DIY washing or curing station would be as efficient as this machine for a similar price. The liquid container of the Wash & Cure is reusable, reducing the waste of cleaning agents and the costs associated.

Specifications

Now for the technical specs:

- Rated power: 25 W

- Input voltage: 110/220 V

- UV wavelength: 405 nm

- Timer range: 1 to 60 minutes

- Machine size: 225 x 235 x 365 mm

- Wash size (container): 120 x 74 x 165 mm

- Cure size (platform): 140 x 140 x 165 mm

- Weight: 3.7 Kg

Where to Buy

You can find the new Anycubic Wash & Cure (2.0) from the following online retailers:

License: The text of "Anycubic Wash & Cure: Review the Specs" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.