Bambu Lab has made quite the splash in the 3D printing space with its state-of-the-art 3D printers, most notably with their X1 and P1 series. The team aims to transform the way we use 3D printing, offering previously commercial-level features on their hobby-grade machines. While Bambu Lab primarily focuses on 3D printers, they also launched their own line of filament.

One common theme you can expect with Bambu Lab filament is that it comes with a slightly higher price tag than comparable spools from other brands. This higher cost can be linked, in part, to the RFID tags that come with each spool, which allow their AMS system to automatically detect what type and color of filament you’re using. They do, however, make up for the higher prices with above-average print quality on most 3D printers.

If you’re looking for a particular color or feel, you can buy a pack of filament swatches through Bambu Lab, which is a complete collection of their current material options. Each swatch contains a 5-digit filament code that you can enter on their website to find the exact color and material combination, should you want to order a new spool. If you do decide to order these swatches, you may want to consider printing off their Swatch Board Display for easy viewing.

If you’re only concerned about getting high-quality prints out of your 3D printer, regardless of material cost, Bambu Lab filament may be for you. In this article, we’ll go over the company’s different filaments to see what they have to offer. But first, let’s see what the community has to say about Bambu Lab’s line of filaments.

Community Response

While Bambu Lab’s filament hasn’t had quite the same impact as their 3D printers on release, it’s still a great contender that much of the community enjoys. Many makers praise Bambu Lab filament for its ease of use and quality. It simply just prints with little to no issues.

The biggest complaint with Bambu Lab filament seems to be unreliable stock, with many people having to wait before they can stock up on their favorite filament types and colors. This is especially true during sales events.

Some makers have complained Bambu Lab refills are noticeably more brittle than the original spools upon arrival or that they tangle much more frequently. That being said, a large majority of the community stands by the refills and have had minimal issues using them.

Apart from minor issues, such as low stock and winding reliability, it seems that Bambu Lab has some good-quality filament on their hands. Just be sure to give it a few hours in a dry box before use. Now, let’s get into the filaments!

PLA

PLA has long been a popular filament, known for being readily available, affordable, and easy to use. Bambu Lab’s PLA Basic delivers on two of those points, costing slightly more than the average spool of PLA. While not suited for mechanical parts, PLA is a great choice for general-purpose printing, especially if you plan on printing simple models or toys.

Some makers have compared Bambu Lab’s PLA Basic to that of PLA+, with first layers and layer adhesion performing similarly to established brands. It seems to print well, offering reliable print quality.

In addition, they offer a decent selection of colors across their different PLA variants. Refills also are available, allowing you to reuse your original spool. This is slightly cheaper than buying another roll.

- AMS compatible: Yes

- Colors: 21, including purple, blue, green, and beige

- Recommended settings: Hot end 190-230 °C, heated bed (with PVP glue) 35-45 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$23, ~$20 for refill

Variations

- Aesthetic: Matte, Silk, Basic Gradient, Sparkle, Metal, Marble, Glow, Dual Color

- Specialty: Aero

- Composite: See the section on fiber-reinforced filaments below.

PETG

PETG is often the second filament of choice that makers will gravitate toward after PLA. It’s known for providing a bit more flex than PLA while maintaining a similar ease of use. PETG is an upgrade in terms of UV resistance, making it a suitable choice for prints that you intend to use outdoors.

Bambu Lab’s PETG Basic is in the process of being retired and replaced in favor of their new PETG HF. The new formulation is a high-flow blend that allows for much faster print speeds than traditional blends. It also addresses the oozing issues that are commonly found in PETG prints. For the best print quality, however, the company notes that the filament must be dried before use.

- AMS compatible: Yes

- Colors: 14, including lime green, red, and lake blue

- Recommended settings: Hot end 230-260 °C, heated bed (with PVP glue) 65-75 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$23, ~$20 for refill

Variations

- Translucent: In addition to clear translucent, Bambu Lab offers nine additional translucent filaments of various colors, comparable to sea glass in appearance. For best results, you’ll need to follow their guide.

- PETG-CF: See the section on fiber-reinforced filaments below.

ABS

ABS is well-known for its durability, strength, and thermal resistance. It’s a great material for parts that need to withstand stress or impact, such as pipes or housing for electrical parts. When printing ABS, an enclosure is recommended to prevent warping, as it ensures a stable printing environment for your part.

Bambu Lab ABS is a versatile filament, giving you excellent strength to create long-lasting parts. This material is a step up from PLA and PETG in terms of strength and durability, provided you have an enclosure to print it in.

- AMS compatible: Yes

- Colors: 15, including olive, purple, yellow, orange, and blue

- Recommended settings: Hot end 240-270 °C, heated bed (with PVP glue) 80-100 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$23, ~$20 for refill

Variations

- ABS-GF: See the section on fiber-reinforced filaments below.

ASA

ASA has quickly become a favorite filament choice in the 3D printing community, completely replacing ABS for many. It has amazing UV resistance, great temperature resistance, and is relatively tough, making it the perfect filament for extended outdoor use. If you need a new birdhouse, electrical outlet cover, or gate latch, ASA should be your first choice.

Similar to ABS, you’ll want to have an enclosure handy when printing with Bambu Lab’s ASA. The material doesn’t produce as potent a smell as ABS, though you’ll still want plenty of ventilation when using this material. ASA maintains the easy post-processing that is expected from ABS, including the possibility to vapor smooth for an injection-molded finish.

- AMS compatible: Yes

- Colors: Six, including green, blue, red, and black

- Recommended settings: Hot end 240-270 °C, heated bed (with PVP glue) 80-100 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$30

Variations

- ASA Aero: This filament provides a lighter weight and lower density for your prints, as it’s specially designed for weight-sensitive prints such as RC airplanes and vehicles.

- ASA-CF: See the section on fiber-reinforced filaments below.

TPU

TPU has long been the go-to choice for flexible prints. When you have a part that requires both structural strength and flexibility, TPU is your best bet. The flexible nature of this filament gives it excellent impact absorption. It’s a great material for casual and dedicated makers alike, giving you the option to print flexible toys or functional gaskets and seals.

Bambu Lab’s TPU HF has a Shore hardness of 95A, which is pretty standard. This means you can expect the filament to have some give without making it too difficult for your extruder to push it into your hot end. TPU is notorious for requiring a much slower print speed than other filaments in order to get quality prints. Bambu Lab’s TPU HF is designed to print much faster than typical TPU, with a recommended maximum print speed of about 200 mm/s. This is much faster than the typical 40 mm/s that most TPU brands recommend.

It’s recommended to dry your TPU at about 70 °C for 8 hours before use. Since it’s hygroscopic, TPU absorbs a lot of moisture from the surrounding environment, which can lead to defects in your prints if it’s not dried properly. As this is a flexible material, it’s not recommended to use it in your AMS system or 0.2-mm nozzles, as it can easily lead to clogs.

- AMS compatible: No

- Colors: Six, including red, blue, yellow, and white

- Recommended settings: Hot end 220-240 °C, heated bed (with PVP glue) 30-35 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$42

Nylons

Nylon is one of the most durable 3D printing materials around. It’s highly resistant to UV, capable of withstanding many chemicals that other filaments can not, and has excellent anti-abrasion properties. This makes nylon the choice material for engineering-grade prints that may see plenty of wear and tear over time. If you plan on making any fasteners, gears, or other parts that will be put under repeated mechanical stress, nylon is a good choice.

While Bambu Lab does not yet have a pure nylon filament available for sale, they have fiber-reinforced blends available, specifically carbon and glass fibers (for the latter, see the section on Bambu Lab’s fiber-reinforced filaments). Keep in mind that fiber-reinforced blends are abrasive and will wreak havoc on some nozzle materials. Further, they’re best printed with larger nozzle sizes. So, be sure to check with the manufacturer for compatibility details.

Lastly, nylon filaments are notoriously hygroscopic. So, it’s recommended to dry the filaments at 80 °C for 12 hours before printing.

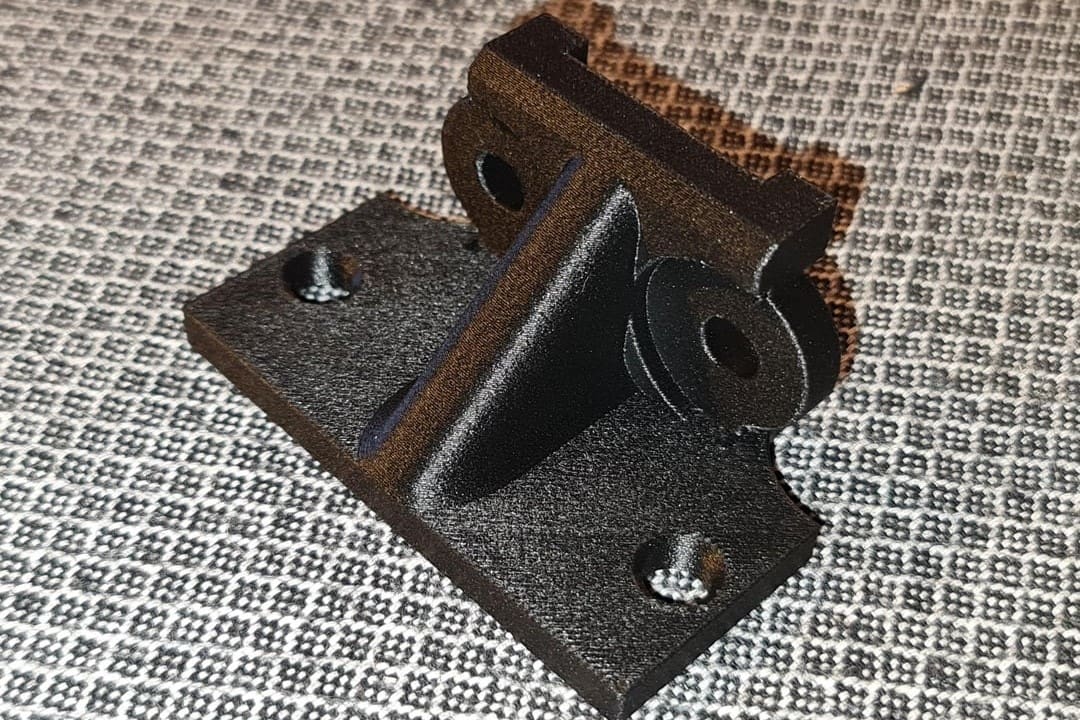

PA6-CF

Bambu Lab’s PA6-CF is a composite of PA6 (nylon 6) and carbon fiber, significantly increasing rigidity in prints while providing decent impact resistance and heat resistance. Similar to other carbon fiber blends, PA6-CF is perfect for printing engineering-grade parts such as brackets, motor vehicle parts, and mechanical housings where low-vibration materials are needed.

- AMS compatible: No

- Color: Black

- Recommended settings: Hot end 260-290 °C, heated bed (with PVP glue) 80-100 °C

- Sizes: 1.75 mm (0.5, 1 kg)

- Price per kg: ~$80

PAHT-CF

PAHT-CF is the updated nylon filament from Bambu Lab that’s a composite of PA 12 (also known as nylon 12) and carbon fiber, meaning it boasts excellent low-water absorption along with the many strengths carbon fiber brings to the table. The HT stands for high-temperature, signifying that the material was engineered with temperature resistance in mind and reportedly can withstand temperatures up to 194 °C without deforming.

The tight layer adhesion makes this material a great choice for creating injection molds and jigs where dimensional accuracy is a must. Compared to PA-CF, the PAHT-CF filament has 133% improved impact strength. Given it’s more rigid compared to PA-CF, this filament is compatible with the AMS.

- AMS compatible: Yes

- Color: Black

- Recommended settings: Hot end 260-290 °C, heated bed (with PVP glue) 80-100 °C

- Sizes: 1.75 mm (0.5, 1 kg)

- Price per kg: ~$95

PPA-CF

PPA-CF is a fiber-reinforced nylon blend that offers double the strength capacity of traditional nylon blends, approaching metal-like levels of mechanical properties. The precision and stability of PPA-CF make it suitable for industrial-grade printing for automotive parts and prints that will be subjected to constant heat.

Bambu Lab’s PPA-CF is their premium blend, with a price to show for it. Bambu Lab boasts an almost 50% increase in strength and a whopping 102% stiffness increase over their PA6-CF blend, making it one of their toughest material options available. This material’s low water absorption rate makes it great for reliable paddles and replacement parts for boats and watercraft.

At the time of writing, this brand new filament is sold out, but more spools are anticipated to be in stock by mid-October 2024.

- AMS compatible: No

- Color: Black

- Recommended settings: Hot end 280-310 °C, heated bed (with PVP glue) 100-120 °C

- Size: 1.75 mm (0.75 kg)

- Price per kg: ~$200 (~$150 per 0.75-kg spool)

Polycarbonate

Polycarbonate (PC) is known for being a tough material to print and an even tougher printed part once finished. Requiring high hot end temperatures and a heated enclosure, PC is often referred to as a professional-level 3D printing material. It’s typically used for making parts that will see a lot of wear, such as hinges, jacks, or even carabiners. If you need a strong, reliable, and fire-resistant part, you can’t go wrong with PC.

Bambu Lab’s PC filament boasts strong rigidity, meaning less shrinkage in prints and better dimensional accuracy. Just be sure to dry it thoroughly before use!

- AMS compatible: Yes

- Colors: Black, white, transparent, clear black

- Recommended settings: Hot end 250-270 °C, heated bed (with PVP glue) 90-110 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$40

Fiber Reinforced

If you’re looking for a material for printing functional prototypes, long-term durability, or superior chemical resistance, a fiber-reinforced material is what you need. These high-performance materials are blends of traditional filaments mixed with fiber additives that lend a much-needed performance boost.

The drawback is that high-performance materials are often much more difficult to work with compared to materials such as PLA. These filaments may require stricter preparations to get a good print, heated enclosures, high-temperature hot ends, and plenty of experience fine-tuning your print settings. Bambu Lab’s X1 Carbon 3D printer was made specifically to print these types of materials.

The two main fiber blends are carbon fiber and glass fiber. You can find a carbon fiber blend for most of the basic material types at this point, and with good reason. Carbon fiber provides a very noticeable improvement in dimensional accuracy, part stiffness, and strength. This overall durability enhancement makes carbon fiber blends very appealing for final functional parts.

Glass fiber provides a similar boost to performance as carbon fiber blends, with a focus on enhancing chemical resistance, thermal resistance, and dimensional stability. Both types of blends have the added benefit of creating a noticeable texture on prints that does a great job of hiding the layer lines.

As we mentioned in the nylon section, fiber-reinforced filaments are very abrasive, so softer nozzle materials such as brass or stainless steel are not recommended. For many of the these filaments, Bambu Lab notes that a hardened steel nozzle is mandatory for printing. Also, keep the nozzle diameter in mind. According to the company, a 0.2-mm nozzle is not compatiable with any of these filaments.

PLA-CF

PLA-CF is becoming a more popular material. The ease-of-printing that traditional PLA provides combined with the enhanced durability of carbon fiber makes this material great for a variety of applications. One of the biggest advantages of PLA-CF is the increase in the X- and Y-axis tensile strength, though tests have shown a slight decrease in Z-axis strength. Unlike normal PLA, PLA-CF needs to be kept dry to maintain consistent print quality.

Bambu Lab’s PLA-CF is designed to be a lightweight and easier-to-print alternative to ABS, with similar durability characteristics. This filament produces a matte-like finish on prints, with layer lines being virtually invisible thanks to the carbon fiber texture. This makes PLA-CF a good choice for practical prints that need both durability and an aesthetic finish.

- AMS compatible: Yes

- Colors: Seven, including black, red, and blue.

- Recommended settings: Hot end 210 – 240 °C, heated bed (with PVP glue) 35 – 45 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$35, ~$32 for refill

ASA-CF

ASA-CF combines the stiffness and weather resistance of ASA with the durability of carbon-fiber reinforcement to create a very reliable material for outdoor use. Load-bearing prints such as furniture and brackets will benefit from the enhanced properties of this material.

Bambu Lab’s ASA-CF specializes in dimensional accuracy, making it a good choice for large-scale projects that require a lot of pieces that need to fit together precisely. This blend in particular also has a matte finish that gives the prints a more professional appearance right off of the print bed.

- AMS compatible: Yes

- Color: Black

- Recommended settings: Hot end 250-280 °C, heated bed (with PVP glue) 80-100 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$37

PETG-CF

PETG-CF marks a significant upgrade in terms of material performance, especially when compared to alternatives such as PLA-CF. Layer bonding is enhanced with this blend, as is the material’s impact strength. This makes PETG-CF a suitable material for high-performance drone parts and other RC models that require both durability and flexibility.

Bambu Lab’s PETG-CF has the added benefit of increasing print quality over traditional PETG, with reduced clogging and stringing. You can expect cleaner overhangs and a shiny carbon fiber finish that hides layer lines well.

- AMS compatible: Yes

- Colors: Six, including violet purple, indigo blue, and malachite green

- Recommended settings: Hot end 240-270 °C, heated bed (with PVP glue) 65-75 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$35

PET-CF

This material combines everything we know and love about PET and gives it the carbon fiber treatment. In short, PET is much more rigid and durable than PETG, making it more suitable for these types of high-performance prints.

Bambu Lab’s PET-CF is very well suited for parts that are designed to be load-bearing. This blend can also withstand high amounts of heat and humidity while maintaining structural stability, making it a good choice for parts that may be exposed to water or the outdoors. An enclosure is recommended to prevent as much warping as possible.

- AMS compatible: No

- Color: Black

- Recommended settings: Hot end 260-290 °C, heated bed (with PVP glue) 80-100 °C

- Size: 1.75 mm (0.5, 1 kg)

- Price per kg: ~$85

ABS-GF

ABS-GF brings a lot of improvements to the traditional ABS material, enhancing mechanical properties as well as aesthetics. Most notable improvements come in part strength, stiffness, and greater temperate resistance. In terms of ease-of-use, ABS-GF is much easier to print then basic ABS, as the added glass fiber makes this blend less susceptible to warping and deformation while printing.

Bambu Lab’s ABS-GF is idea for prints that are going to see a lot of use and prints that will always be visible, as the glass fiber texture reduces layer line visibility while providing a matte-like finish. Hooks, clamps, and wall mounts are a few examples where ABS-GF makes a compelling option.

- AMS compatible: Yes

- Colors: Eight, including red, white, and blue

- Recommended settings: Hot end 240 – 270 °C, heated bed (with PVP glue) 80 – 100 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$30

PA6-GF

PA6-GF is outperformed in most structural metrics when compared to PA6-CF, with both a lower layer adhesion and a lower rigidity. Where the glass fiber blend does pull ahead is in customizability. There are multiple color options available, allowing you to personalize your prints. To top it off, PA6-GF has a max print speed of ~130 mm/s, beating out its carbon fiber counterpart by 30 mm/s

Unlike PA6-CF, Bambu Lab’s PA6-GF is AMS compatible. This, combined with the multiple color options, makes PA6-GF a good option for multicolor printing functional parts that don’t require the absolute maximum durability that you can find. Knobs, adapters, and camera mounts are just a few of the many options you have when printing with PA6-GF.

- AMS compatible: Yes

- Colors: Eight, including lime, orange, black, and white.

- Recommended settings: Hot end 260 – 290 °C, heated bed (with PVP glue) 80 – 100 °C

- Size: 1.75 mm (1 kg)

- Price per kg: ~$60

Support Materials

Support filament is, as the name implies, a filament that is meant to be used strictly as support. It’s often more brittle than traditional filaments, allowing you to break it off of your model with ease. Using a separate material for supports means there is less of a chance that your supports stick to your model and create unsightly marks upon removal.

Support Filament

Bambu Lab has created its very own support filament, formerly known as Support W and Support G, specifically for use with their AMS system. They offer support materials for PLA/PETG, ABS, and PA/PET. Each material is specially designed to print with the same settings as their material counterparts. While all of the support filaments are water insoluble, the support for ABS is dissolvable in limonene. Be sure to double-check your support material settings before attempting to print with it.

To prevent issues with adhesion, it’s recommended to dry your support filament for 8 hours at 55 °C before use. For the PA/PET materials, Bambu Lab notes that drying is a requirement.

Settings for Support PLA/PETG

- AMS compatible: Yes

- Colors: Nature

- Recommended settings: Hot end 190-220 °C, heated bed (with PVP glue) 35-60 °C

- Size: 1.75 mm (0.5 kg)

- Price per kg: ~$70 (~$35 for 0.5-kg spool)

Settings for Support ABS

- AMS compatible: Yes

- Color: White

- Recommended settings: Hot end 240 – 270 °C, heated bed (with PVP glue) 80 – 100 °C

- Size: 1.75 mm (0.5 kg)

- Price per kg: ~$30 (~$15 for 0.5-kg spool)

Settings for PA/PET Support

- AMS compatible: Yes

- Color: Green

- Recommended settings: Hot end 280-300 °C, heated bed (with PVP glue) 80-110 °C

- Size: 1.75 mm (0.5 kg)

- Price per kg: ~$80 (~$40 for 0.5-kg spool)

PVA

PVA is Bambu Lab’s solution to hard-to-remove support material, as it’s completely water-soluble. The material provides a solid base for the rest of the model to print on. After the print job is complete, soaking the part in water will allow the supports to cleanly come off. This eliminates the chances of damaging your model during support removal, while also leaving a smooth support interface surface on the part.

Bambu Lab’s PVA is compatible with PLA, PETG, as well as the carbon fiber reinforced versions of both filaments.

- AMS compatible: Yes

- Color: Clear

- Recommended settings: Hot end 220 – 250 °C, heated bed (with PVP glue) 35 – 45 °C

- Size: 1.75 mm (0.5 kg)

- Price per kg: ~$80 (~$40 for 0.5-kg spool)

Bundles

Bambu Lab offers a couple of filament bundles to help you get started with your 3D printing journey. Most of these bundles are curated to a specific printing style, while others are dedicated to providing new 3D printer owners with a one-stop shop to supply them with everything they need without overwhelming them with options.

Bambu Lab has had many bundle variations enter and leave their store, such as an AMS-Lite specific bundle and an Essential Starter Pack bundle. There are currently only two bundles available, both of which are a great value purchase if you’re looking for bulk filament. If you know someone who is into 3D printing, these bundles can make a great gift as well!

Variations

- CMYK Lithophane Bundle: This bundle option comes with four different PLA filament colors, including cyan, magenta, yellow, and white. It’s meant to be used with their AMS system to create multi-color lithophanes.

- PLA Basic Refill Bundle: This bundle contains two 1-kg spools of PLA Basic filament at a reduced price per spool in exchange for a reduction in color options.

Reusable Spool

If you own a 3D printer, you know just how much waste the hobby can create, especially when it comes to empty spools and packaging. In an attempt to reduce the amount of waste that comes with shipping filament spools, Bambu Lab has created reusable spools.

With these, users can purchase filament refills rather than entire spools when they run out of their favorite materials. Many of their filament options already ship with reusable spools. FilamentStories has a great video showcasing how to properly refill your spool.

Their Bambu Reusable Spools are also a great way of using your favorite filament brands on the AMS system, as it doesn’t support every spool size out there.

Their Bambu High Temperature Reusable Spools are designed for use with materials that require a higher temperature to print. The spools themselves have an increased temperature resistance of 90°C, while the Bambu Reusable Spools can only withstand temperatures of about 70°C. This makes the High-Temperature Spools compatible with ABS, ASA, PA6-GF, ABS-GF, PAHT-CF, PET-CF, PA6-CF, PC, and TPU 95A HF.

License: The text of "Bambu Lab Filament Buyer’s Guide" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.