Bambu Lab is known for its innovative and high-performance 3D printers, which have earned the company a positive reputation in the 3D printing community.

Among their strong lineup of 3D printers, the P1P is a budget-friendly option that’s designed for speed and customization. It’s a great choice if you’re looking for something in the mid-range market that can deliver high-quality prints.

On the other hand, the P1S takes things a step further. Fully enclosed, it includes extra cooling features and an activated carbon filter, which makes it perfect if you need something for more advanced printing projects.

In this article, we’ll compare these two printer models to help you decide which is the better fit for your unique requirements. Let’s dive in!

At a Glance

Features

Bambu Lab has integrated a host of advanced features in both of these models, setting them apart from many other 3D printers. These features are designed to maximize speed and precision, but there’s more under the hood that enhances their overall performance.

Let’s take a look!

Design

The Bambu Lab P1P and P1S share a core design centered around the CoreXY motion system, which can be an upgrade compared to the traditional Cartesian systems found in many lower-end 3D printers. This design allows both models to achieve high print speeds with impressive accuracy. Since the printhead is lightweight and efficiently controlled by two stepper motors, the CoreXY setup reduces the moving mass, minimizing vibrations and making it particularly effective for high-speed printing.

When it comes to the frame design, the P1P features an open-frame structure. This not only makes the printer easier to modify but also appeals to users who prefer easy access to the print area. The open design also supports customization, allowing users to print their own side panels if they wish to enclose the printer.

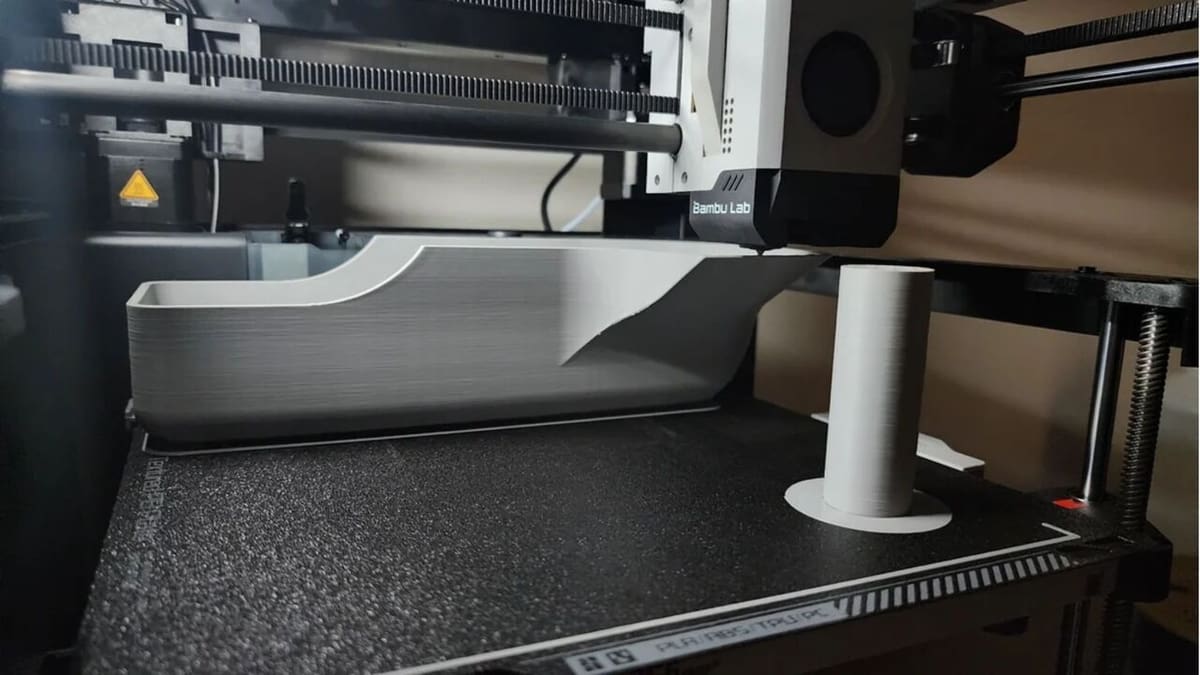

On the other hand, the P1S boasts a fully enclosed build chamber. This enclosure is made from a mix of plastic and glass, and is designed to keep the internal temperature stable – a key factor when printing with temperature-sensitive materials like ABS. The enclosed design also enhances safety by keeping heated components out of reach from curious hands or pets. Plus, it includes additional features like an activated carbon filter to help reduce odors while printing.

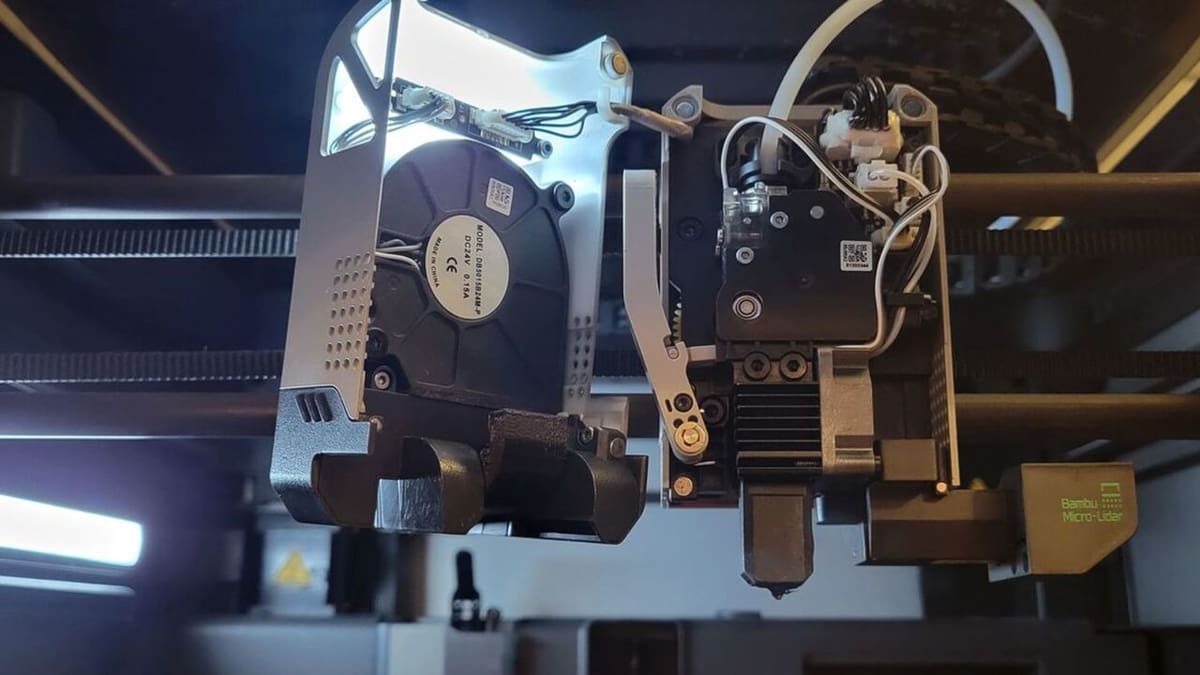

Both printers are equipped with a sturdy gantry system supported by three lead screws on the Z-axis, ensuring stable and precise vertical movement. The Z-axis is pre-leveled at the factory, but users can manually adjust it if needed. The toolhead in both models is also quite advanced. This makes both printers versatile enough to handle a wide range of filament types, from PLA to more demanding materials like PETG and TPU.

Build Volume

Both the Bambu Lab P1P and P1S offer a build volume of 256 x 256 x 256 mm, which is a bit larger than what you’ll typically find on consumer-grade FDM 3D printers. This generous size makes these models well-suited for most hobbyist and semi-professional projects, giving you the flexibility to print larger models or multiple smaller ones at the same time.

The build volume is similar to what you’d find in popular printers like the Ender 3, but the Bambu Lab models have an edge thanks to their CoreXY design. This design not only makes better use of the available space but, as mentioned, also enhances print speed and accuracy.

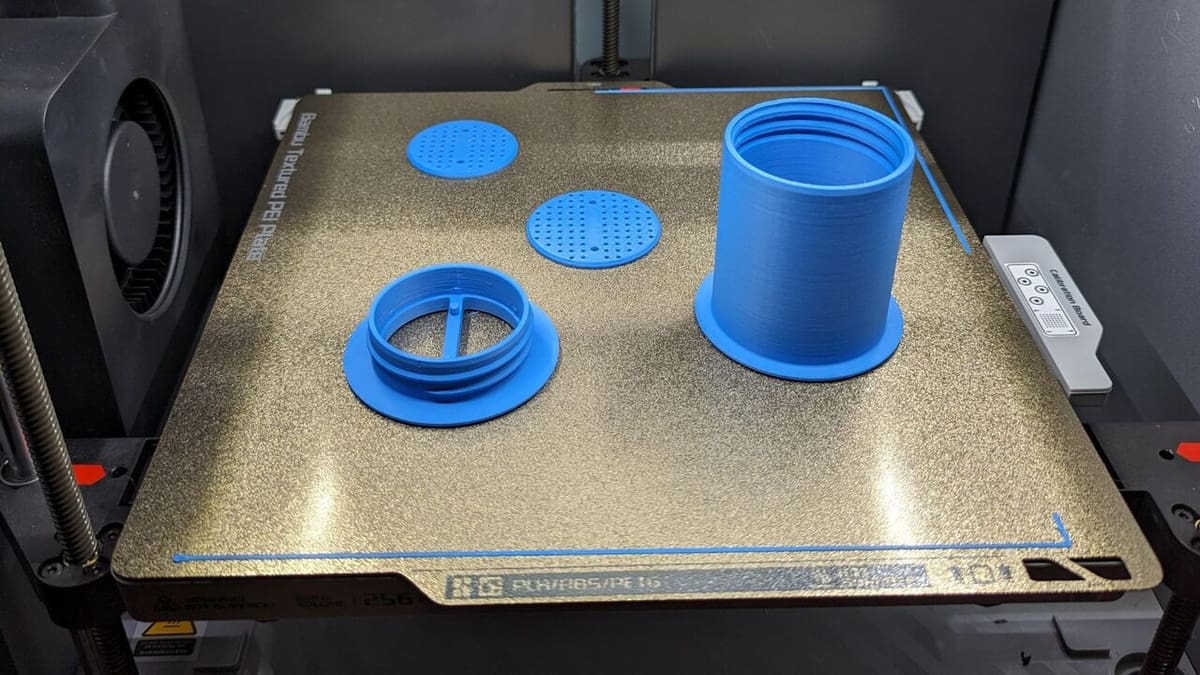

Build Plate

The P1P and P1S both come with a flexible, textured PEI build plate, which is well-known for its excellent adhesion and easy print removal. This build plate is double-sided and magnetically attached, so it’s easy to remove and replace after printing. Beyond the standard textured PEI plate, Bambu Lab offers several interchangeable build plates that you can use with either model, giving you flexibility depending on the material you’re using or the surface finish you want.

One of these options is the Smooth PEI Plate, which provides a flat, smooth surface that’s perfect for printing objects that need a level bottom layer. It works well with a variety of filaments, though it’s recommended to use glue for materials other than PLA to avoid damaging the PEI sheet.

For more specialized needs, Bambu Lab offers the Cool Plate, which is designed for printing at lower bed temperatures, and the Engineering Plate, which is optimized for higher-temperature filaments like ABS and ASA. These interchangeable plates allow you to customize your printing setup to match specific materials and project requirements, adding to the overall usability and flexibility of both the P1P and P1S printers.

Extrusion

The Bambu Lab P1P and P1S are equipped with Bambu Lab’s custom direct extrusion setup, which is highly regarded for providing precise control over filament, especially when working with flexible materials like TPU. The direct extrusion setup in these models features dual gears, which help ensure consistent extrusion by minimizing slippage. This consistency is important to achieve high-quality prints across a variety of filament types.

The hot end in both the P1P and P1S is an all-metal design capable of reaching temperatures of up to 300 °C. This allows you to print with a wide range of materials, including PLA, PETG, and more demanding filaments, such as ABS and nylon. The standard nozzle size is 0.4 mm, which strikes a good balance between print quality and speed. However, the hot end assembly also supports different nozzle sizes, such as 0.2 mm for finer details and up to 0.8 mm for faster, less detailed prints.

When it comes to printing with abrasive filaments, like those infused with carbon or glass fiber, the standard stainless steel nozzle that comes with the P1P and P1S can wear out relatively quickly. For these tougher materials, Bambu Lab recommends upgrading to a hardened steel nozzle, as it’s much more durable and resistant to wear. If you plan to print frequently with abrasive materials, this upgrade is essential, given that it significantly reduces the risk of nozzle clogging and helps maintain consistent print quality over time.

Under the Hood

Having gone over some of the external parts, let’s take a closer look at what’s not so easy to see but which is just as crucial for 3D printing.

Mainboard

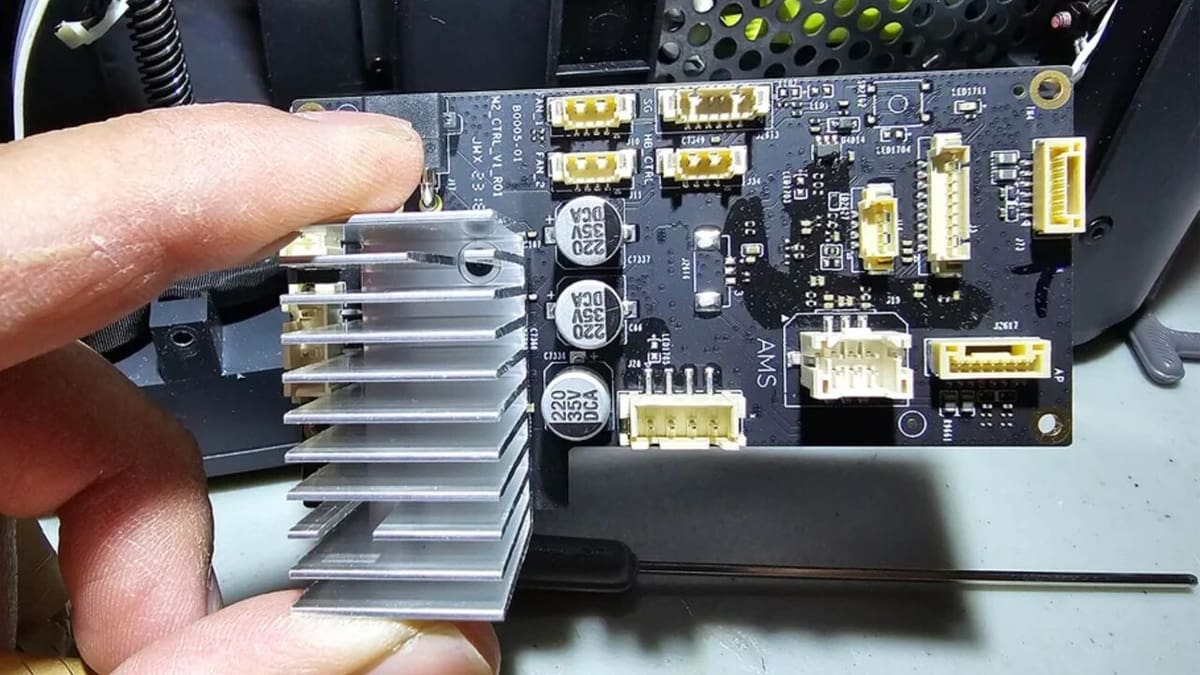

The Bambu Lab P1P and P1S are powered by the same mainboard, known as the Machine Controller (MC) board. This board is specifically designed to support the high-speed CoreXY motion system that these printers use. It plays a crucial role in managing all the printer’s moving parts, including the precise coordination of the X-, Y-, and Z-axes, which ensures smooth and accurate prints even when operating at high speeds.

While the P1P and P1S share the same mainboard, there is a slight difference in their cooling systems. The P1P’s mainboard features a vertical heatsink designed for natural convection cooling, meaning it doesn’t require an additional fan. On the other hand, the P1S’s mainboard comes with a horizontal heatsink that is paired with a dedicated cooling fan. This combination provides enhanced cooling performance, which is particularly useful when printing at high speeds or with materials that generate more heat.

Both mainboards are fully capable of handling the high-speed printing capabilities of these printers, ensuring reliable operation even under demanding conditions. Additionally, the inclusion of Wi-Fi and Bluetooth connectivity options allows for convenient remote monitoring and control, further enhancing the overall user experience.

Firmware

The Bambu Lab P1P and P1S operate on Bambu Lab’s proprietary firmware, which is specifically optimized for high-speed printing. This firmware includes advanced features such as vibration compensation and pressure advance, both essential for maintaining print quality even at maximum speeds. Vibration compensation reduces the impact of mechanical vibrations during fast movements, while pressure advance fine-tunes the extrusion flow, ensuring consistent output, particularly during rapid changes in speed.

In June 2024, Bambu Lab released a significant firmware update, version 1.06.00.00, which brought several new features and improvements to the P1 series. One of the key highlights of this update is the introduction of motor noise cancellation, a feature that was first implemented in the A1 series. This addition reduces the humming sound associated with stepper motors during long movements, making the printers quieter and slightly enhancing the quality of printed surfaces by mitigating minor artifacts.

Additionally, the firmware update introduced other enhancements such as improved thermal runaway protection, manual flow calibration, and better support for SD card usage. The update also addressed several bugs, including issues with power failure recovery and SD card disconnections during prints. You can find more details on the update in the Bambu Lab Community Forum.

Quality of Life Features

The Bambu Lab P1P and P1S are designed with a variety of quality-of-life features that enhance the overall printing experience, ensuring ease of use, reliability, and convenience for users.

Bed Leveling

Both printers are equipped with advanced automatic bed leveling (ABL) systems, designed to ensure that the first layer of your print is consistently accurate and reducing the need for manual adjustments. The ABL system works by mapping the surface of the print bed, creating a mesh that compensates for any slight unevenness by adjusting the Z-axis during printing. This helps maintain the correct nozzle distance from the bed across the entire surface, leading to improved print adhesion and overall quality.

In addition to auto-bed leveling, both models also support manual bed leveling, often referred to as bed tramming. This involves manually adjusting the bed using the knobs beneath it. Although the printers are pre-leveled at the factory, manual bed leveling might be necessary if you notice any inconsistencies or if the printer has been moved significantly, such as during transportation.

UI

The Bambu Lab P1P and P1S both feature a 2.7-inch, monochrome LCD screen paired with a physical control button, designed to be straightforward and user-friendly. This simple interface is ideal for users who prefer a no-frills interaction with their 3D printer. The screen provides essential information, such as the printer’s status, print progress, and basic controls, making it easy to manage prints directly from the machine without always requiring a connected device.

The physical control button allows you to navigate easily through the different menus and select options with precision, which is particularly handy during initial setup or when making quick adjustments. While the screen isn’t a color display, its simplicity helps create a more focused user experience, eliminating distractions and keeping attention on the core functions needed during printing.

Even though the screen lacks touch functionality or color, the overall user experience is significantly enhanced by the integration with Bambu Studio and the Bambu Handy app. These software tools offer a more visual and interactive way to manage prints, monitor progress, and adjust settings remotely. This combination of a simple, durable screen with robust software support makes the P1P and P1S accessible and convenient for both beginners and experienced users alike.

Software

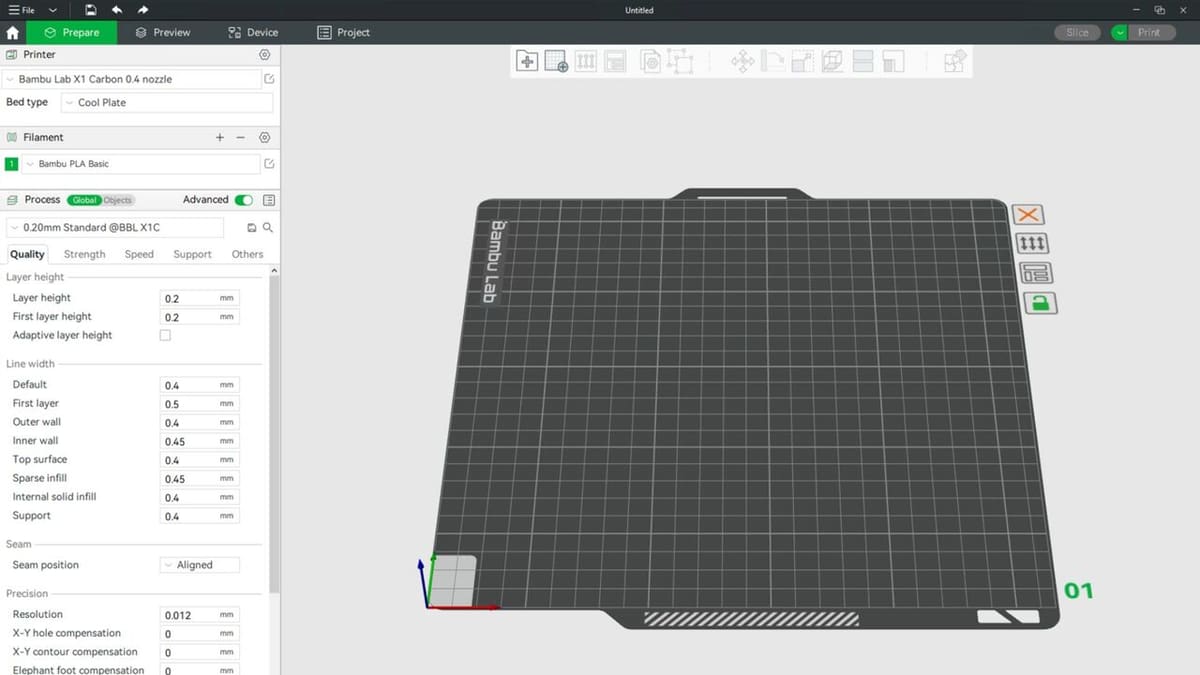

Both printers are designed to work seamlessly with Bambu Studio, a powerful and intuitive slicer that enhances the 3D printing experience. Bambu Studio is packed with features that boost usability and provide greater control over the printing process.

One of its standout capabilities is the seamless integration with the Automatic Material System (AMS), which allows users to easily manage multicolor prints and different filament types. You can set up and control the AMS directly within Bambu Studio or through the Bambu Handy app, giving you flexibility in how you interact with your printer.

Bambu Studio also supports cloud printing and real-time monitoring. This means that you can send print jobs remotely and keep an eye on the progress via the Bambu Handy app, which offers a live view of the print through the printers’ camera. The app also allows you to make adjustments on the go, such as changing temperatures or pausing the print, providing a high level of control even when you’re not near your machine.

In addition to these features, Bambu Studio offers two network modes: Auto (which uses both WAN and LAN) and LAN-only mode. The LAN-only mode is particularly useful in environments where data security is a priority, as it ensures that no print files are transferred to the cloud. This combination of features makes Bambu Studio a versatile tool for managing your 3D printing projects.

Additional Features

As mentioned, both the Bambu Lab P1P and P1S are fully compatible with the AMS, which makes them ideal for more complex projects that require different filament types or a variety of colors.

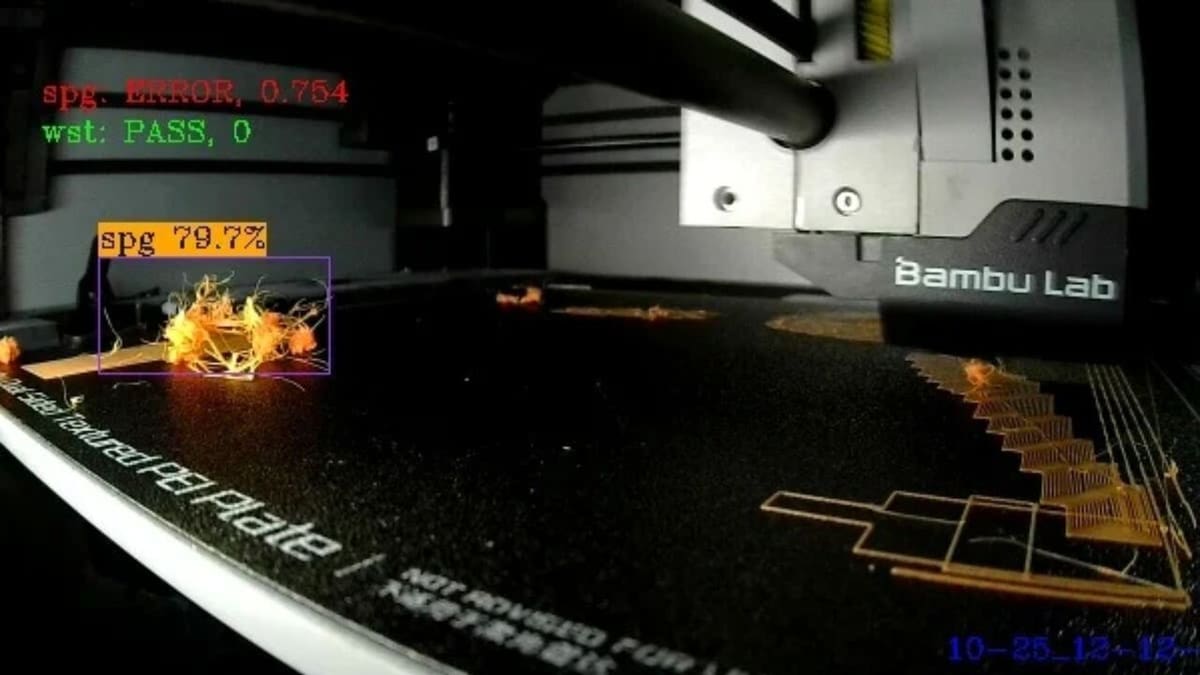

In addition to AMS compatibility, the P1 series also features an AI failure detection system. While the P1P and P1S don’t include the more advanced lidar-based detection found in the X1 series, they do come with a basic camera that can be used for remote monitoring. However, due to the hardware limitations, the AI-driven features – like spaghetti detection or air printing detection – aren’t as advanced as those in the X1 or A1 models. The camera’s lower frame rate and the less powerful processor in these models mean that, although basic monitoring is possible, more sophisticated AI-based error detection isn’t fully supported at this time.

Price

The pricing for the Bambu Lab P1P and P1S models reflects the differences in features and capabilities between the two printers.

The P1P is available for approximately $500. It’s a budget-friendly option that offers high-speed printing with an open-frame design, making it ideal for users primarily working with materials like PLA. The P1P can be upgraded with an enclosure kit, though it lacks some of the more advanced features found in the P1S.

On the other hand, the P1S is priced at around $600. This difference reflects its additional features, including a fully enclosed chamber, an enhanced cooling system, an activated carbon air filter, and a toolhead cable chain. These features make the P1S better suited for users who need to print with a wider range of materials, such as ABS and ASA, which benefit from a controlled environment.

The $100 difference in price between the P1P and P1S highlights the added value provided by the supplementary features on the P1S, which are particularly beneficial for more demanding printing tasks.

Verdict

The Bambu Lab P1P and P1S are designed to meet different 3D printing needs, each with its own distinct advantages.

If you’re looking for a budget-friendly option that still delivers high-speed printing with room for customization, the P1P is a strong choice. Its open-frame design is particularly great if you’re primarily printing with PLA, as it offers easy access and better ventilation, which can improve print quality. Plus, the P1P’s upgradeability means you can add an enclosure later on, allowing you to work with temperature-sensitive filaments like ABS. This makes it a versatile option, especially for hobbyists and educators who are exploring 3D printing without wanting to make a significant initial investment.

On the other hand, if you’re leaning toward something more advanced, the P1S might be the better fit. It builds on the P1P by adding a fully enclosed chamber, enhanced cooling, and an activated carbon air filter, which makes it ideal for printing with materials like ABS and ASA right off the bat. These added features, along with a premium toolhead cable chain and broader material compatibility, justify its higher price, making it an excellent choice for professionals and advanced users who need a controlled environment for more complex printing tasks.

Ultimately, the choice between these two models comes down to your specific needs and budget. If you’re just starting out, the P1P offers excellent value and room to grow. But if you’re already into advanced, material-intensive projects, the P1S is equipped to handle those demands.

License: The text of "Bambu Lab P1P vs P1S: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.