The Bambu Lab X1 Carbon was officially launched in mid-2022 following a successful Kickstarter campaign, which raised an impressive $10 million. Soon after, the Bambu Lab P1P arrived as a more affordable, stripped-down version.

Behind Bambu Lab is a highly skilled team of mechanical and software engineers, many of which are ex-staff of the drone company DJI. It’s safe to say that their printers are developed by experienced experts.

In any case, both printers made a splash in the hobbyist 3D printer market due to fast print speeds and quality comparable to DIY printers (such as those from Voron Design), but as a turnkey solution. Astoundingly, they come at a competitive price point, similar to the cost of building a DIY printer yourself.

If you’re looking to buy a Bambu Lab printer, you may be wondering which model is best for you. In this article, we’ll take a close look at the differences between these two printers in terms of features, design, and price, and see how they stack up. Let’s dive in!

At a Glance

Features

While we’ve covered the technical specs of both printers above, Bambu Lab has some more tricks up their sleeves with the P1P and X1 Carbon, including some features not commonly found on other 3D printers.

We’ll now take a closer look to see how well the two printers truly stack up against one another, and how their performance compares.

Design

Although both printers are built on the same sheet metal frame, the X1 Carbon is fully enclosed, featuring a slick and refined aluminum-trimmed box with side panels and a glass top panel and front door. On the other hand, the P1P’s unenclosed design gives it a more stripped-down look. Inside the X1 Carbon’s enclosure, you’ll find large auxiliary fans, but not in the P1P. But don’t worry, you can always upgrade this later!

Both printers also share an identical CoreXY gantry and Z-axis assembly, with metal rods on the Y- and Z-axis, and carbon fiber rods for the X-axis. The carbon fiber rods reduce mass from the gantry, allowing it to move faster at better resonances. The Z-axis is controlled by three leadscrews belt-driven by a single stepper motor.

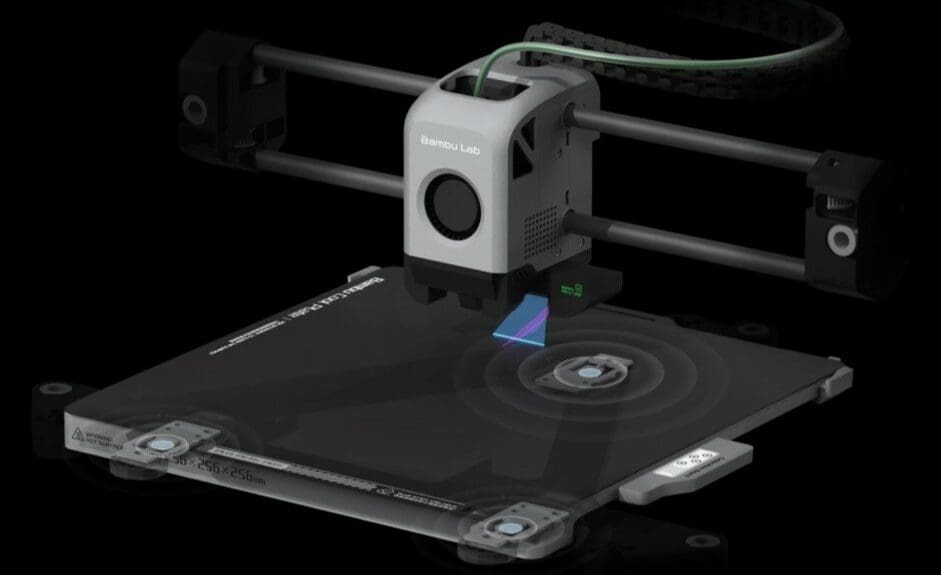

The toolhead may look similar on both printers, but attached to the X1 Carbon’s toolhead is a lidar (“depth effect”) sensor. This increases the capability of the X1 Carbon, which we will look into in more detail later on.

Also, the X1 Carbon has a cable chain to route the wires from the toolhead, while the P1P has a simple harness. Not a big deal, but it sure looks cooler!

Build Volume

The P1P and X1 Carbon both have a build volume of 256 x 256 x 256 mm, including a small 18 x 28 mm inaccessible exclusion zone. While it’s possible to remove this to recover the full print volume, it’s not recommended unless you absolutely need the extra space.

Regardless, the build volume is still slightly larger than your average bed slinger, such as the popular Ender 3 line, and will be sufficiently large for almost all functional and aesthetic prints.

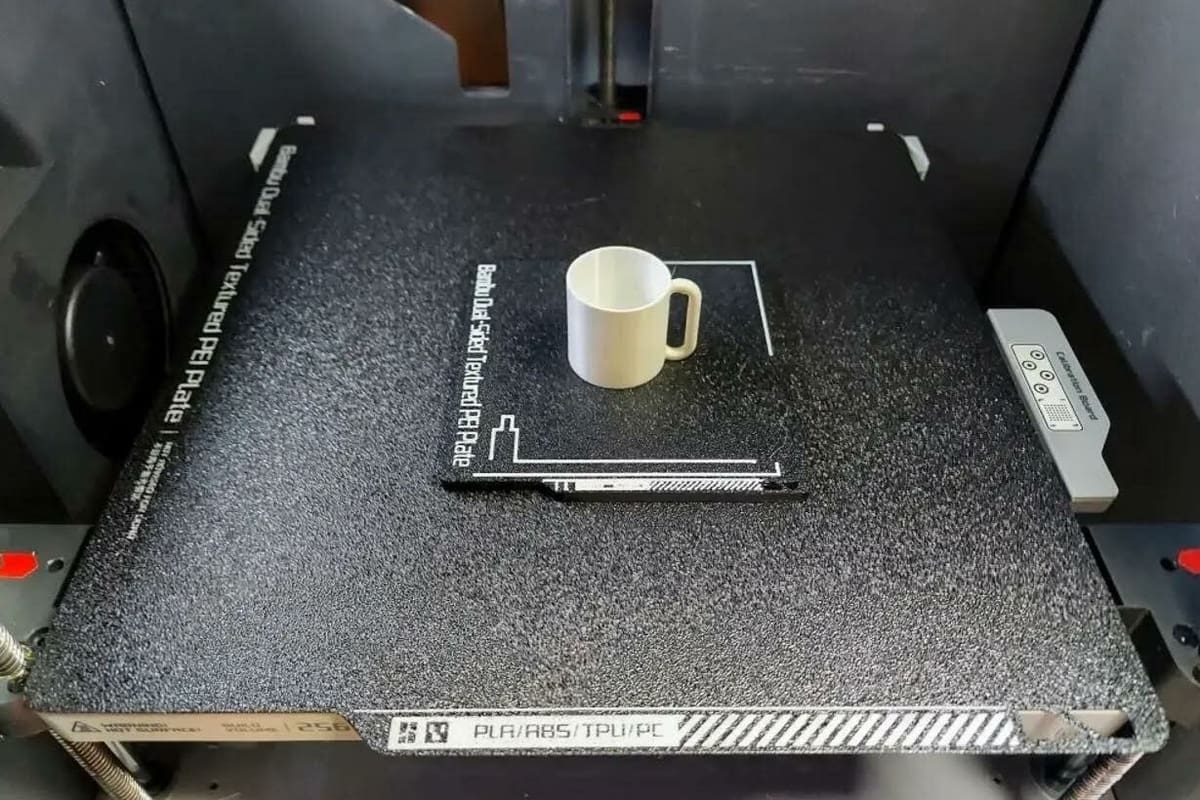

Build Plate

The build plate is one of the most important aspects of a 3D printer. A good build plate should adhere well, release well, and last long, and plays a critical role in ensuring a successful and seamless print experience.

The P1P comes with a PEI-coated, magnetic spring steel build plate. This is a favorite among users as it provides good adhesion and easy print removal for almost all filaments, without the use of any adhesive or removal agent.

The X1 Carbon comes with the Bambu Cool Plate and Engineering Plate. Both are magnetic spring steel plates, and typically require a glue stick as a release agent due to filament sticking too well. The Cool Plate is intended for PLA, TPU, and PVA, and leaves a relatively smooth finish on the bottom surface of the printed part. The Engineering Plate is for PETG, ABS, TPU, PA, and PC. New engineering plates have a textured finish, while the older ones feature a smoother finish.

Recently, Bambu Lab released their High Temperature Plate, a magnetic spring steel smooth PEI plate. As it adheres excellently and allows for easy removal of almost all filaments (except PETG) without any adhesive or removal agent, this aftermarket upgrade may be appealing to users who prefer a smooth finish on their parts.

Extrusion

Under the toolhead cover, the P1P and X1 Carbon share similar extrusion systems, albeit with small differences.

Both printers use Bambu Lab’s custom direct extruder. This compact dual-drive extruder is 53:9 reduction geared and driven by a small NEMA 14 pancake stepper motor. The P1P has non-hardened stainless steel drive gears, while the X1 Carbon comes with hardened steel ones.

In addition, the P1P and X1 Carbon both use Bambu Lab’s custom integrated nozzle hot end. This means the nozzle can’t be swapped without swapping the entire hot end. Both printers come with a 0.4 mm nozzle, but more sizes are available for upgrade. The all-metal hot end reaches a maximum temperature of 300 °C, and achieves a maximum volumetric flow rate of 24 mm3/s with below 5% under-extrusion. The X1 Carbon’s hot end comes with a hardened steel nozzle, while the P1P has a non-hardened stainless steel one.

The hardened drive gears and nozzle of the X1 Carbon allow for printing of abrasive materials, such as carbon fiber-filled filaments. Without the hardened drive gears and nozzle, abrasive materials will quickly wear out the drive gears and nozzle, so the P1P is unable to print these materials. However, the P1P can always be upgraded with hardened drive gears and a new hot end.

Under the Hood

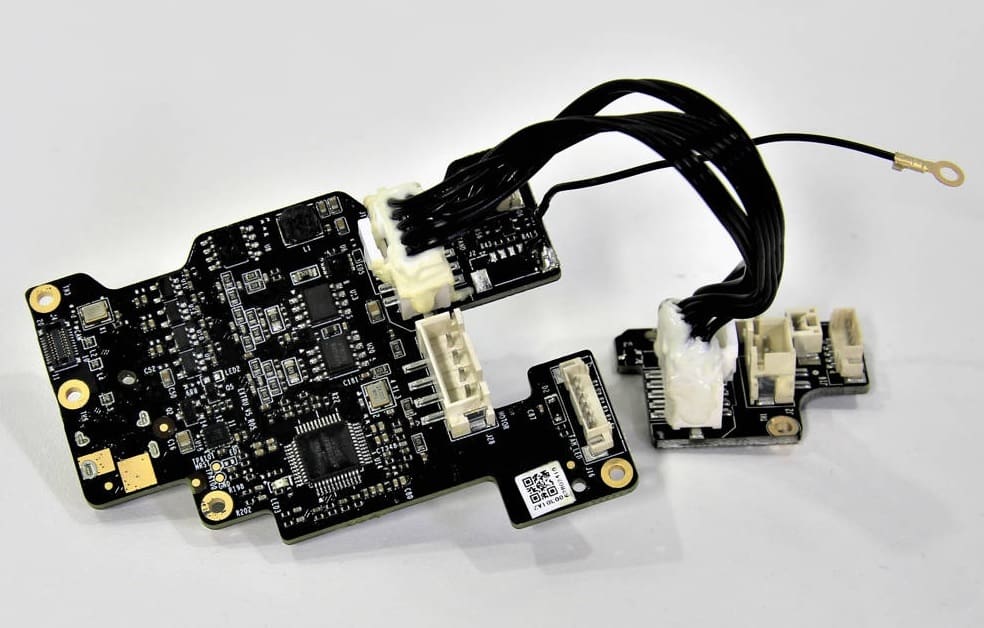

Under the hood lies Bambu Lab’s proprietary mainboard, with both printers using a toolhead PCB breakout board.

Mainboard

The mainboard is 32-bit with a SPC2168 microcontroller, and contains AT8236 motor drivers, an unusual choice for a 3D printer. Although it allows for high speed, it was a bit on the noisier side – that is, until the firmware updates came along.

The X1 Carbon has a small mainboard cooling fan, while the P1P does not. The machine works fine without it, but it’s certainly nice to have, especially if you plan to enclose your P1P. You can find further details about the electronics from this YouTube video and the Bambu Lab Wiki.

Firmware

In terms of firmware, both the P1P and X1 Carbon run on Bambu Lab’s proprietary firmware.

This firmware calibrates input shaping (for both printers), pressure advance (for the X1 Carbon, using its lidar sensor), and incorporates other useful features such as camera streaming. The X1 Carbon and P1P both come with a camera, but the P1P’s has a lower resolution (1080 p in the X1 Carbon, 720 p in the P1P) and frame rate (30 fps in the X1 Carbon, 0.5 fps in the P1P).

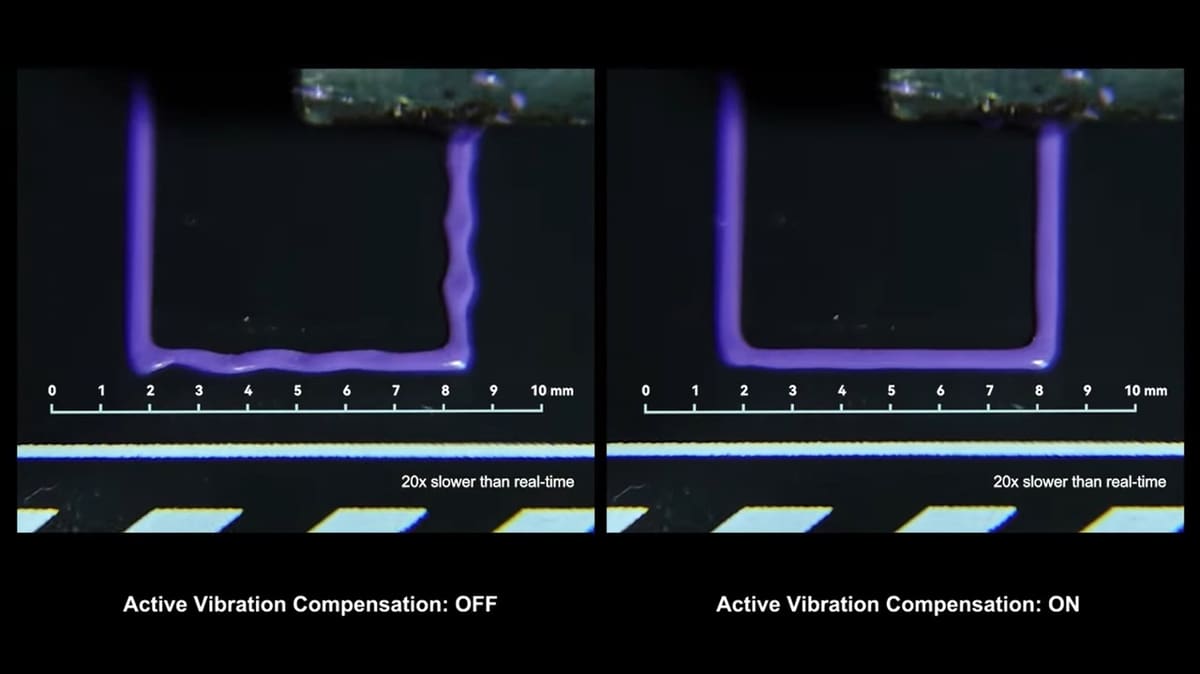

Bambu Lab’s firmware update also included a notable new feature: active motor noise cancellation.

A calibration routine runs through various motions, senses vibration levels and frequencies, and similarly to noise-cancelling headphones, generates sound at same frequency but in an opposite phase, so that both waves go through destructive interference and cancel each other out. In the case of stepper motors, the driver can generate a wave form as close to a sinusoidal wave as possible, rather than a square wave, to smooth out the vibrations on the motor. The great news is, this feature is available on both the X1 Carbon and P1P!

Users report that while this noise cancellation is largely helpful for motor noise, the part cooling fan on the toolhead and auxiliary fans on the X1 Carbon produce a large amount of noise (often even more than the motors), so the speed of the fans you use can largely affect the overall noise of the printer.

Quality of Life Features

There are a variety of features that make for an easy printing experience, and Bambu Lab’s P1P and X1 Carbon have plenty to offer in this regard.

Bed Leveling

Today, bed leveling is a standard feature, even on low-cost printers. As you may have guessed, both the P1P and X1 Carbon feature fully automated, hands-free bed leveling.

There are three screws underneath the bed for manual bed tramming, although both printers have their beds correctly trammed from the factory. To level the bed and set the Z offset, the nozzle repeatedly taps three points on the bed, triggering the three load cell sensors in the bed.

The X1 Carbon’s lidar sensor scans millions of points across the bed to an accuracy of seven microns, checking for any possible inconsistencies or failures. If the AI detects a sufficiently high confidence of a problematic first layer, the printer will stop and prompt the user. Then, you can decide whether to stop or continue the print.

UI

As its name suggests, the user interface (UI) is where the user interacts with the printer. It contributes to the overall user experience.

The P1P adopts a more dated 2.7-inch monochrome, pixelated (192 x 64 px) screen, and is controlled by a clickwheel. On the other hand, the X1 Carbon comes with a large 5-inch (120 x 720 px) full-color LCD touchscreen, with an interface custom designed by Bambu Lab.

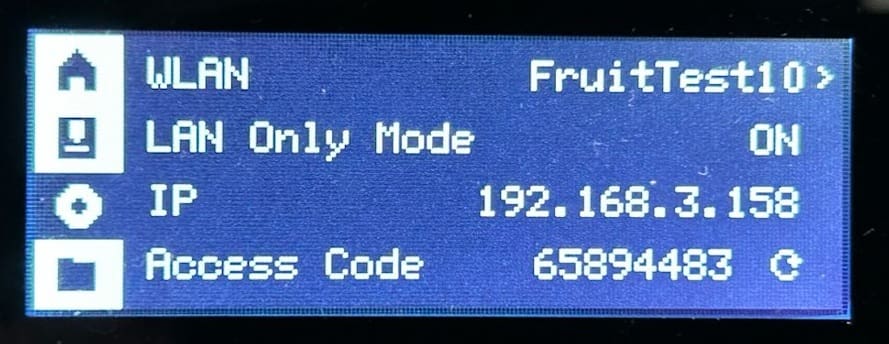

Both displays provide good functionality for controlling the printer, including heating, starting prints, loading and unloading filament, connecting the printer to the cloud, and others. It comes down to whether you prefer a modern touchscreen or a simple, old-fashioned screen.

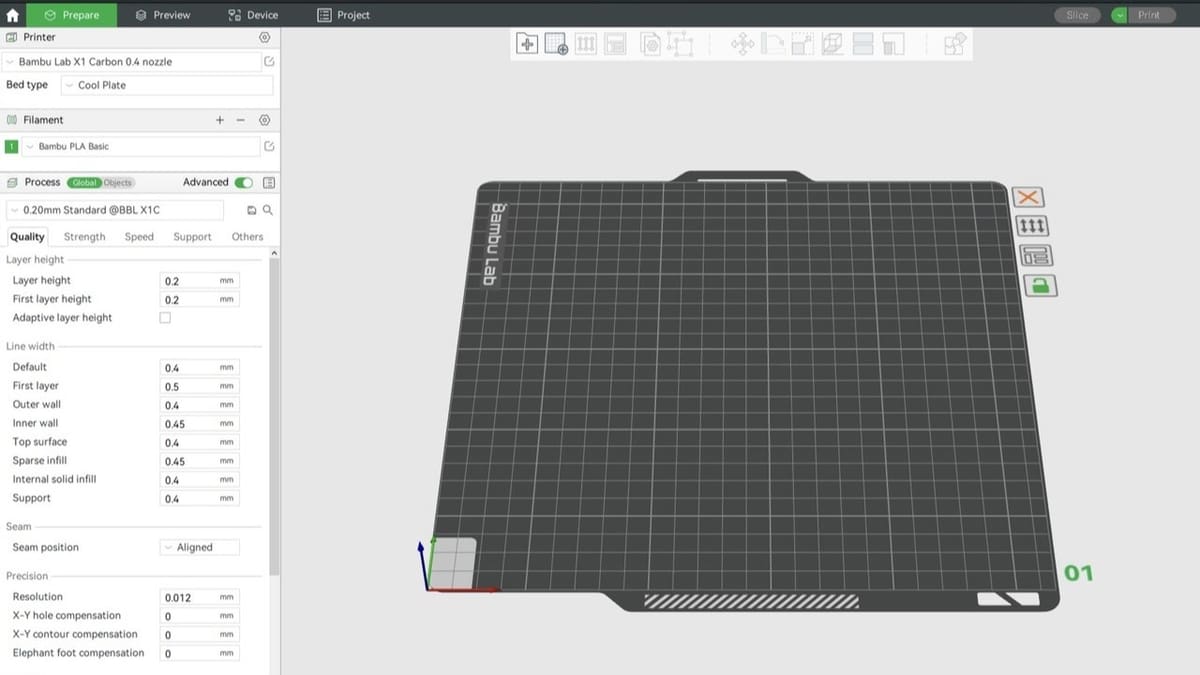

Software

The P1P and X1 Carbon run on Bambu Lab’s slicer, Bambu Studio. It’s based on PrusaSlicer, which is based on Slic3r. This slicer is feature-rich, and incorporates ideas from SuperSlicer (a community version of PrusaSlicer with more adjustable settings), such as advanced cooling logic and dynamic print speeds.

It has built-in and tested profiles for common materials, including PLA, PETG, and ABS for both the X1 Carbon and P1P. While the slicer is open source, it also includes closed-source aspects, namely Bambu Cloud connectivity and Bambu Lab connection utility for controlling Bambu Lab printers through an encrypted data link.

Additional Features

In addition to everything mentioned above, there are still a few more noteworthy features offered by both the X1 and P1P – if to different extents.

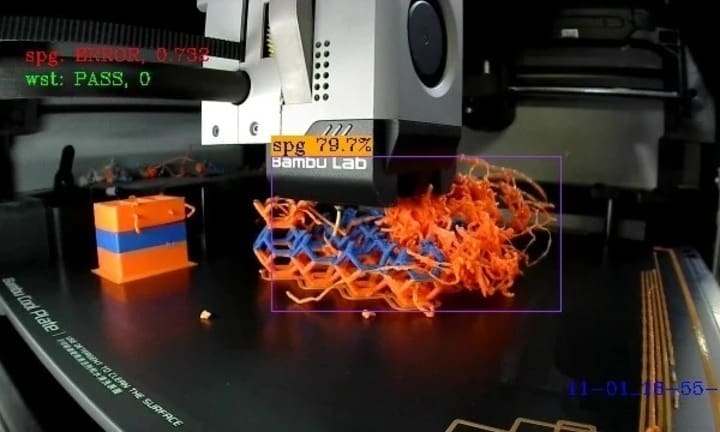

AI Print Failure Detection

The X1 series (including the X1 Carbon) can detect print failures (also called “spaghetti” – emulating the looks of jumbled up filament) based on the processing power it has. This system uses a machine-learning algorithm and all the data processing is done locally. Images are fed to the detector, which is an object detection neural network. This neural network then finds the bounding box of the potential spaghetti with a confidence value (confidence threshold depends on the sensitivity level selected by the user). If the confidence value exceeds the confidence threshold over the past 10 frames, a spaghetti or print failure is detected and the print will be automatically halted.

Unfortunately, the P1P doesn’t have this feature as it’s powered by much less capable central processing unit (CPU) to save cost – which also explains its camera’s extremely low frame rate. The CPU doesn’t have nearly sufficient power to process images and run Bambu Lab’s machine learning algorithm locally. A future update might be possible, where images are sent and processed through the cloud (for processing power).

Interfacing Options

You have a few options to operate both printers:

- Through the cloud: Your prints and files will be sent in through the Bambu Lab cloud and then to your printer. This gives you the ability for your control and monitor your printer anywhere through the Bambu Handy app.

- Through LAN: You can run the printer on LAN Only mode, so that it’s only connected to your local network. This means that the printer can still communicate with the slicer as long as it’s connected to your local network, but it can’t interface with any device that isn’t.

- Offline printing: You can print through an SD card, similar to printers without network capabilities.

Price

Price is arguably the most important factor when deciding whether a machine is for you. The P1P is priced at around $699, a little over half of the X1 Carbon’s $1,199 price. Let’s examine the value aspects of each printer:

- Lidar: This sensor on the X1 inspects the first layer and helps tune pressure advance. Pressure advance will allow for more precise corners. However, you will get better results for both printers by manually tuning.

- Material choices: The X1 Carbon’s enclosure is able to maintain a decent chamber temperature of 50 °C, just enough to print engineering-grade materials like ABS. Its hardened drive gears and nozzle also allows it to handle abrasive materials. On the other hand, the P1P’s unenclosed design and non-hardened stainless steel drive gears and nozzle limits its material range to hobby-grade materials such as PLA and PETG. However, you can always upgrade your P1P.

- User experience: The X1 Carbon is a highly refined printer that provides a better user experience than the P1P. From its glass top and front door to the large full-color HD touchscreen, it’s pretty luxurious.

- Others: The P1P has other cost-saving features, such as a lower quality camera, and it lacks auxiliary, mainboard, and chamber regulator fans. Most of these features can be upgraded later if required.

Verdict

We’ve now taken a close look at each of these printers, but which one is right for you? Simply put, the P1P is designed to be a minimalist, stripped-down version of the X1 Carbon. Both printers share many similarities, but have their own unique pros and cons. To help you decide, consider which printer better fits your budget, whether you plan on printing engineering materials, and how important user experience is to you.

In summary, the P1P is great for those who plan to print hobby-grade, non-abrasive materials, such as PLA and PETG. Coming in at a much lower price point, it can be seen as a high-speed upgrade from open-frame bed slingers, and users can always upgrade the machine. The X1 Carbon is for those who intend to print engineering-grade, abrasive materials and are looking for a more luxurious user experience.

If you want to print engineering materials but don’t mind a less luxurious user experience, consider Bambu Lab’s new P1S, which has some of the X1 Carbon’s practical features, such as the enclosure, and is priced similarly to the P1P at $699 ($949 with the AMS). Happy 3D printer shopping!

What's Changed?

This article is updated on a rolling basis pending significant updates of either of the featured machines. We have included some firmware updates by Bambu Lab, most notably AI print failure detection and active motor noise cancellation. There have also been some other bug fixes and improvements, such as better support for third-party filaments, Wi-Fi connection stability, and touchscreen responsiveness.

You can read more about the updated firmware release notes for the X1 Carbon and the P1P.

License: The text of "Bambu Lab P1P vs X1 Carbon: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.