Bambu Lab has quickly become one of the leaders in the 3D printing world with its high-performance and user-friendly machines that cater to all kinds of users.

Two of their standout models are the Bambu Lab P1S and X1 Carbon (or X1C), which offer precision, speed, and advanced features for different needs. While both printers share key aspects, like the CoreXY motion system, they differ significantly in areas like build quality, automation, and price.

In this comparison, we’ll highlight the main differences between the two to help you decide which printer is the best for your needs.

The Specs at a Glance

Features

Even though we’ve covered the technical specifications of both machines above, Bambu Lab has added some extra features to the P1S and X1 Carbon that you don’t usually find in other 3D printers. Let’s take a closer look to see how they compare and perform.

Design

The Bambu Lab P1S features a fully enclosed design with plastic side panels, which is excellent for controlling temperatures when printing materials like ABS and ASA. This enclosure helps reduce warping and provides a stable printing environment, making it a suitable choice for users working with temperature-sensitive materials. While the side panels are plastic, the core frame of the P1S is made of rigid aluminum, offering good stability and durability for most 3D printing applications.

Similarly, the Bambu Lab X1 Carbon also uses a sturdy aluminum frame but incorporates more advanced materials for its enclosure, including metal side panels and a glass top. This combination enhances the printer’s durability and heat management, making it better suited for more demanding materials. The X1 Carbon’s build quality provides superior resistance to vibrations and improved temperature control, which is particularly beneficial during high-speed and high-precision prints and both printers use the CoreXY motion system for precise, high-speed prints.

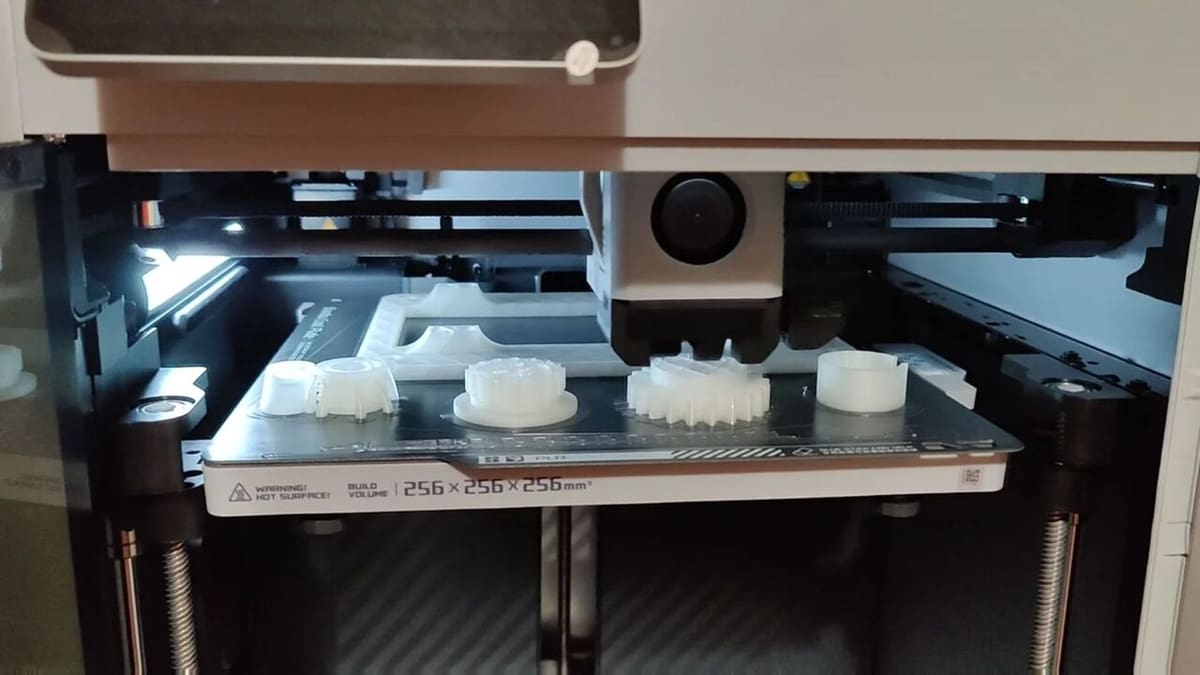

Build Volume

Both the Bambu Lab P1S and X1 Carbon offer a build volume of 256 x 256 x 256 mm, giving you plenty of space for medium to large prints. This is larger than what you get with many standard 3D printers like the Creality Ender 3 or Elegoo Neptune 4, making it great for most hobbyist and professional projects.

As mentioned, they both use a CoreXY gantry system, which ensures smooth and fast movements, enhancing print quality even with large objects. While there’s no difference in the build volume itself, the X1 Carbon’s advanced lidar-assisted first-layer calibration can help you make better use of this space for more complex prints, offering increased precision.

Build Plate

Both models come with a PEI-coated flexible steel build plate, which is known for its excellent adhesion and easy print removal. However, they’re note identical.

The P1S has a textured PEI plate, which provides consistent first-layer adhesion and is easy to clean. This is especially helpful when printing a variety of materials like PLA and PETG, which have different adhesion needs.

The X1 Carbon includes two types of build plates: the Cool Plate for lower-temperature materials like PLA, and the Engineering Plate for higher-temperature materials such as ABS and TPU. For the overall setup, the X1 Carbon also benefits from its lidar system, which enhances the precision of the first layer by scanning millions of points on the surface of the build plate. The scanned points are analyzed to ensure an even surface, allowing for optimal first-layer calibration and better adhesion, leading to more consistent and reliable prints.

Extrusion

Both the P1S and X1 Carbon feature a dual-gear direct extrusion system, capable of printing at temperatures up to 300 °C. This allows you to handle a wide variety of filaments, including PLA, ABS, PETG, and TPU.

However, the X1 Carbon comes with a hardened steel nozzle, which enables you to print with more abrasive materials like carbon fiber or glass-filled composites. In contrast, the P1S is equipped with a standard stainless steel nozzle. You can upgrade it to handle abrasive materials, but it’s not designed for them right out of the box. This gives the X1 Carbon an edge if you need to print with tougher materials from the go.

Under the Hood

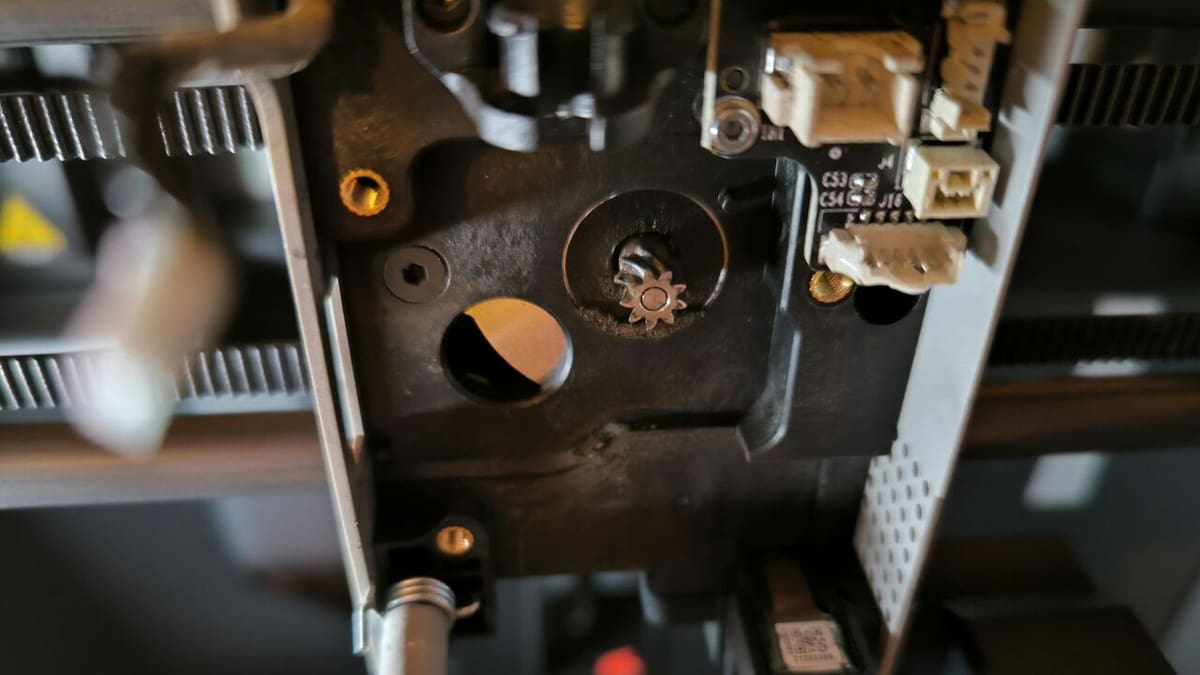

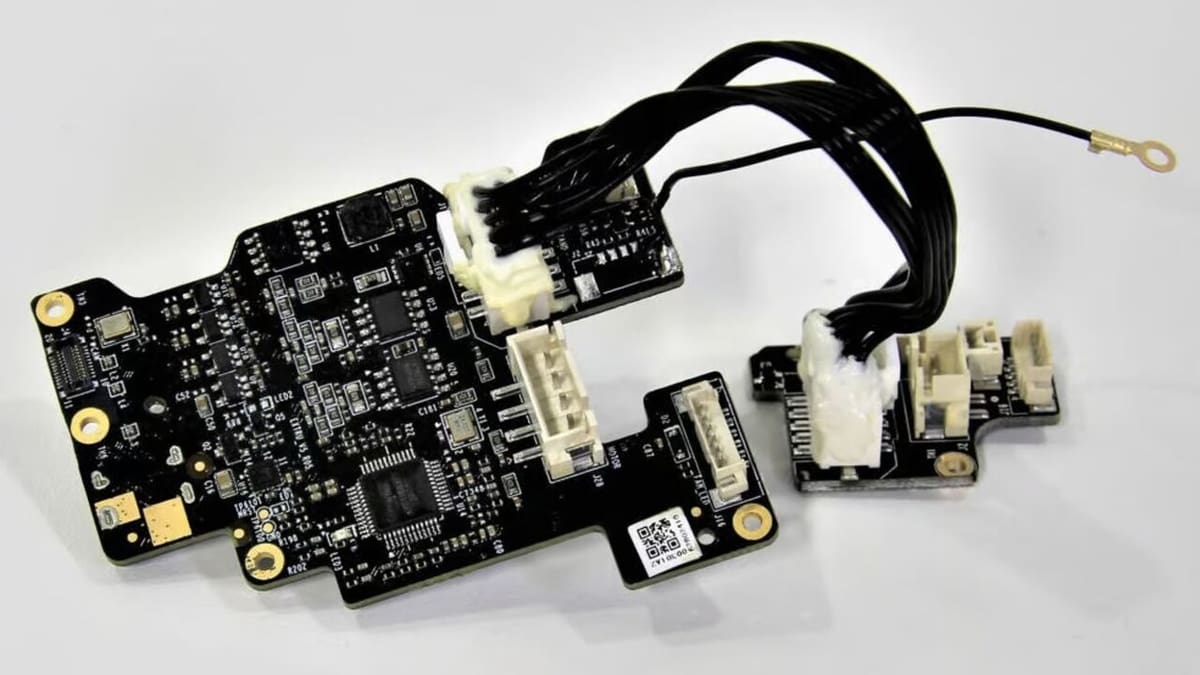

Inside, both printers use Bambu Lab’s own mainboard and have a toolhead PCB breakout board. Let’s take a closer look at what this means.

Mainboard

Both the P1S and X1 Carbon use a 32-bit proprietary mainboard. This has an SPC2168 microcontroller and it contains AT8236 motor drivers that support the CoreXY motion system, ensuring smooth and fast movements during printing. This allows both printers to operate quietly and efficiently, handling high-speed prints without sacrificing precision.

That said, the X1 Carbon takes this a step further with its AI-assisted monitoring features, powered by an onboard neural processing unit. This enables the X1 Carbon to detect potential issues, such as filament run-out or spaghetti failures, and respond proactively, offering enhanced reliability for a successful printing experience.

Firmware

Both printers run on Bambu Lab’s proprietary firmware, optimized for CoreXY motion systems and high-speed printing. The firmware on both models includes essential features like vibration compensation and pressure advance, which are key to maintaining print quality at high speeds.

The X1 Carbon benefits from additional AI features in its firmware, such as lidar-assisted bed leveling and first-layer inspection, ensuring greater precision. The printer also supports more frequent firmware updates, which often introduce new capabilities, such as enhanced print failure detection and better material flow calibration.

Quality of Life Features

There are many features that make printing easy, and Bambu Lab’s P1P and X1 Carbon offer plenty in this area.

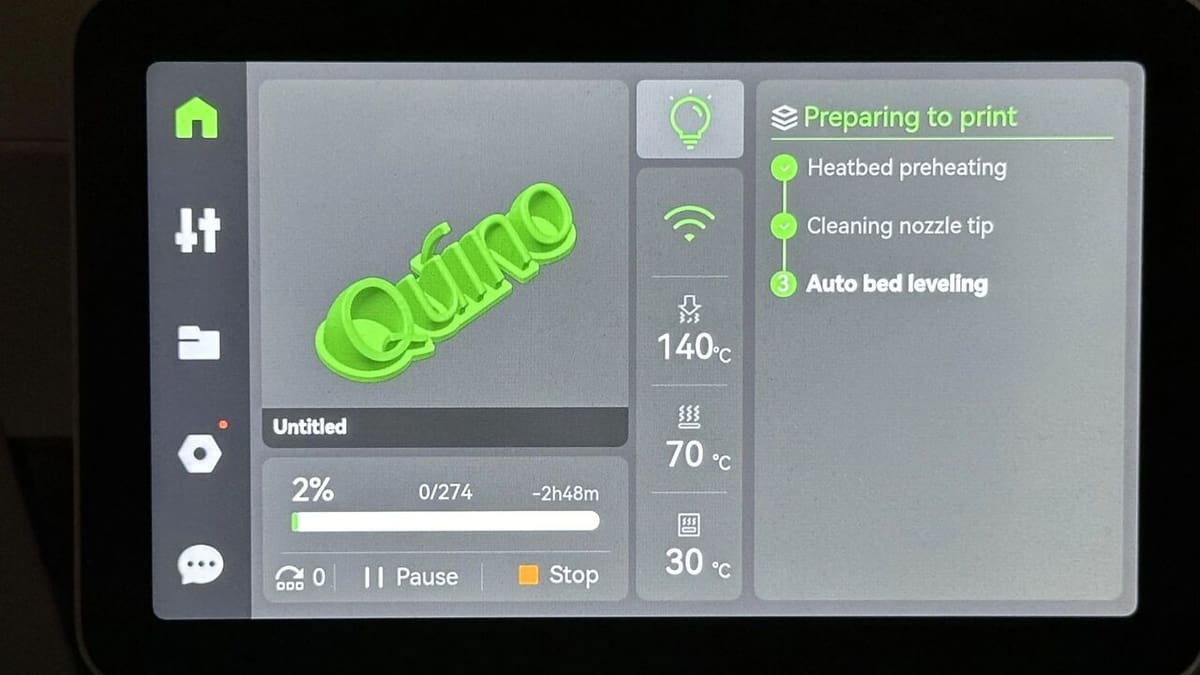

Bed Leveling

Both the P1S and the X1 Carbon offer automatic bed leveling, but they use different systems that give you varying levels of precision.

If you go with the P1S, you’ll get a force sensor-based bed leveling system, which is effective and reliable for standard prints. This means that the first layer adheres properly without having to do any manual adjustments, which is great if you’re aiming for a setup where you won’t need to tinker too much to get great results.

But if you need even more precision, the X1 Carbon steps it up with the previously mentioned lidar-based bed leveling system. The lidar sensor scans the bed, detecting any surface irregularities to ensure the first layer is laid down perfectly. The printed first layer can also be analyzed, with a notification to let you know if any issues have been found. This is especially helpful for more complex and high-precision projects, where even small leveling discrepancies can affect print quality.

User Interface (UI)

The P1S comes stock with a 2.7-inch monochrome LCD screen and physical buttons. While this setup is simple and functional, it lacks the modern touch-based interaction found in higher-end printers. The physical button navigation is intuitive for basic operations but may feel limited for users who are accustomed to more advanced interfaces.

The X1 Carbon, on the other hand, offers a 5-inch full-color touchscreen. This touch interface makes it significantly easier to navigate the printer’s settings, access real-time print data, and make adjustments. The screen also integrates more advanced print controls, offering a more user-friendly experience, particularly for professional users who demand detailed control over their prints.

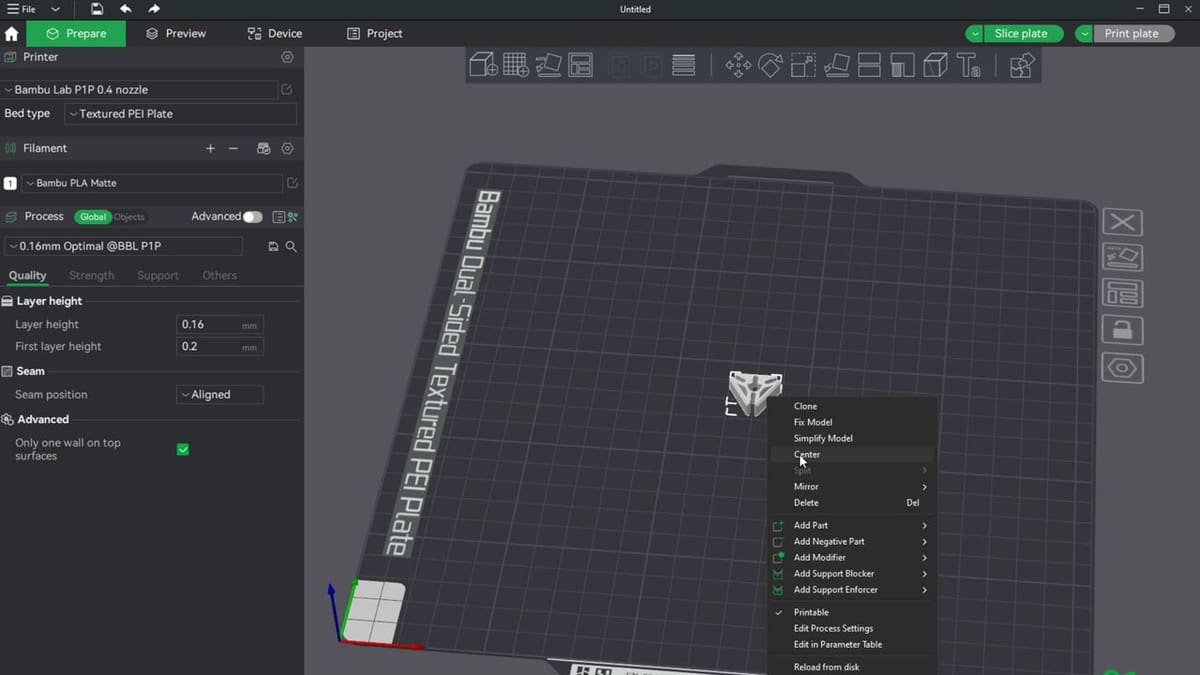

Software

Both printers use Bambu Studio, Bambu Lab’s proprietary slicing software, which is user-friendly and packed with advanced features. Based on PrusaSlicer, Bambu Studio offers pre-configured profiles for a wide range of materials. It supports features like cloud printing and real-time monitoring through the Bambu Handy app, so you can keep track of your prints remotely.

If you’re using the X1 Carbon, Bambu Studio gives you enhanced capabilities, including AI-assisted failure detection and lidar-based calibration. These advanced features offer greater accuracy in print monitoring, especially for complex, multi-material prints. While the P1S also uses Bambu Studio and supports basic monitoring, it doesn’t have the AI-driven features that make the X1 Carbon more suitable for professional environments.

Additional Features

The X1 Carbon comes with several extra features that set it apart from the P1S. For example, it includes AI-assisted spaghetti detection, which identifies and corrects potential print failures in real time. This is crucial if you’re doing long or complex prints where errors can happen partway through. Plus, the X1 Carbon has a high-resolution camera for real-time monitoring, giving you more detailed feedback than the basic camera on the P1S.

Also, while both printers can be set up with Bambu Lab’s Automatic Material System (AMS), which, with a hub, can allow for up to 16 different filaments being used at the same time, the X1 Carbon’s support is more robust. This is because it allows for a wider material range because of the previously mentioned difference in stock nozzle. So, if you need advanced material printing from the start, the X1 Carbon might be the better choice for you.

Additionally, both the X1 Carbon an P1S offers a LAN Only mode, which provides an approach between a fully offline printer and one that’s always connected to the internet. This can be especially useful if you want to prioritize security and privacy.

In this mode, you can still start and monitor prints using Bambu Studio from any device on your local network, maintaining essential functionality without relying on cloud services. The printer retains the ability to detect print failures, such as spaghetti detection, which is especially useful for long or complex prints.

However, using LAN Only mode means that certain features like remote monitoring through the Bambu Handy app, the Print History function, and firmware updates, aren’t available. This is because these require a connection to Bambu’s servers. Although this results in losing some of the printer’s remote capabilities, it can be a trade-off worth considering for security-conscious users who prefer to keep their data private and local.

Price

The Bambu Lab P1S has a price tag of $699, making it a budget-friendly option that’s great for hobbyists and small businesses. It delivers reliable, high-speed printing with all the essential features, but without the advanced automation you’d find in premium models. If you need multi-material or multicolor printing, you can get the P1S bundled with the AMS for $949. This adds a lot of versatility to what you can print, and it’s especially useful if you want to explore more complex prints without spending too much more.

On the other hand, the Bambu Lab X1 Carbon is priced at $1,199, targeting professionals and advanced users who require greater precision, automation, and material versatility. The higher price reflects the X1 Carbon’s advanced features, such as lidar-based bed leveling, AI-assisted monitoring, and the ability to handle abrasive materials like carbon fiber composites from the get-go. Like the P1S, the X1 Carbon can also be purchased with the AMS, bringing the total price to $1,449, which further enhances its capability for multi-material and multicolor prints.

Verdict

The Bambu Lab P1S is perfect if you’re a hobbyist, educator, or small business looking for a reliable, high-speed 3D printer at $699. If your budget allows it, it supports AMS for multi-material printing, which can streamline your 3D printing experience even more. While it doesn’t have some of the advanced features found in the X1 Carbon, like lidar-based leveling and AI print monitoring, it offers excellent performance for its price, and it provides an enclosed environment for temperature-sensitive materials like ABS and ASA.

If you’re a professional or advanced user who needs more precision, automation, and material versatility from the start, the X1 Carbon might be the better choice. Priced at $1,199, it comes with lidar-assisted bed leveling, AI-assisted spaghetti detection, and a hardened steel nozzle, making it perfect for handling abrasive materials like carbon fiber composites. With the AMS bundle, the price goes up to $1,449, but you get an advanced automated multicolor setup that delivers.

License: The text of "Bambu Lab P1S vs X1 Carbon: The Differences" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.