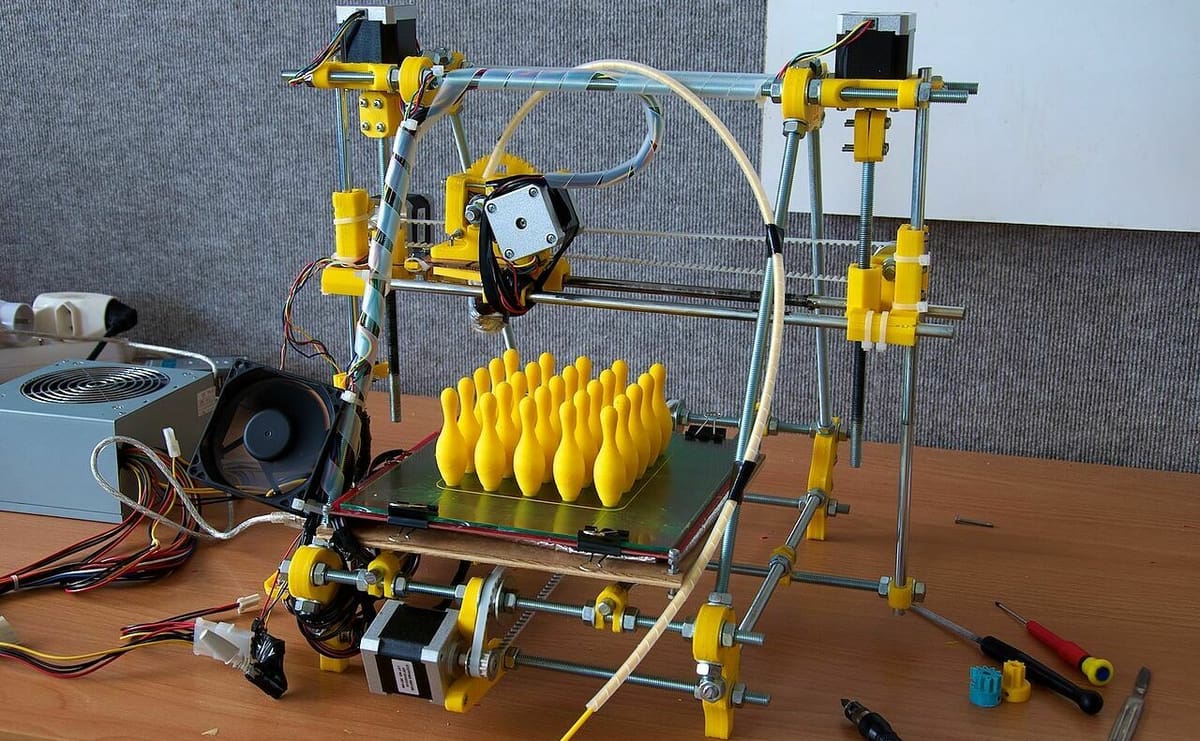

The term “bed slinger” has been widely used by 3D printing community members to describe the majority of hobbyist 3D printers, where the bed “slings” along the Y-axis (hence the name “bed slinger”).

Simply put, a bed slinger is a fused deposition modeling (FDM) 3D printer that uses a Cartesian motion system, with the printhead moving along the X-axis, the bed moving along the Y-axis, and the gantry (the axis or axes in which the printhead moves) along the Z-axis.

In this article, we’ll examine what this means in more detail, as well as some pros and cons of such a printer. Lastly, we will look at a few common and popular examples of bed slinger 3D printers.

Let’s get started!

Motion Systems

A bed slinger has a Cartesian motion system. What does this mean?

Cartesian FDM printers work with the Cartesian coordinate system and have three axes of motion: the X-, Y-, and Z-axes. Movement in these directions can be coordinated by different motion systems.

A bed slinger uses a Cartesian motion system, with each axis working independently. In a bed slinger 3D printer, the printhead is on the X-axis, the bed is on the Y-axis, and the gantry is on the Z-axis. This means that the X-axis motor(s) controls the X-axis (printhead) independently, the Y-axis motor(s) controls the Y-axis (bed) independently, and the Z-axis motor(s) controls the Z-axis (gantry) independently.

Note that all bed slingers are printers with a Cartesian motion system, but not all printers with a Cartesian motion system are bed slingers. For example, the Ender 5 has a Cartesian motion system, as each of the three axes are controlled independently. However, it’s not a bed slinger, as its bed does not sling along the Y-axis.

Compare this to the CoreXY motion system, where the XY-axis is simultaneously driven by two (or more) motors, and the Z-axis is driven independently. For a more different take, the delta motion system uses three “arms” to control the printhead (all three arms move simultaneously to move the printhead in one axis). Each arm is driven by a motor, hence all three motors control the printhead simultaneously.

Typically, a stepper motor is attached to power transmission components, such as belts or leadscrews, and together with a linear motion component (such as linear rails or V-slot wheels) they drive the printhead, gantry, and bed.

Now that we know how bed slingers work, let’s look at some of their pros and cons.

Pros & Cons

As expected, a bed slinger 3D printer has different advantages and disadvantages.

Pros

- Simplicity: A bed slinger has a straightforward motion system and working principle. As such, new users can understand FDM much quicker.

- Ease of set up: A bed slinger’s simplicity allows the printer to be assembled quickly and easily, making this design a good choice for beginners.

- Cost: The simplicity allows for a lower and cheaper part count, hence it’s a type seen very commonly on budget or entry-level lists of printers. This makes bed slingers have great value-for-money, as they can still provide great print quality (albeit at lower speeds).

- Maintenance: A bed slinger 3D printer is easy to maintain, troubleshoot, and repair, as its design allows for direct access to parts like screws and motion components.

Cons

- Acceleration: As a bed slinger “slings” the bed across the Y-axis, the Y-axis motor has to move a large mass of the bed. The moving mass increases when heavier parts are being printed. Looking at it from a mechanics perspective, Newton’s second law of motion states that F = ma (Force = Mass x Acceleration). Therefore, with the same force from the motor and a larger mass, acceleration is lower.

- Speed: As accelerations correspond with speed (Final velocity = Initial Velocity + Acceleration x Time), a lower acceleration results in a lower speed, so the maximum speed in a certain time and distance is also relatively lower when compared to other types of 3D printers.

- Resonance: A larger moving mass has a larger momentum (Momentum = Mass x Velocity), which results in more resonance. Input shaping a useful feature for combating this and to counter ringing, but even so, maximum recommended accelerations will be lower than printers with other motion systems. Input shaping is also more difficult to implement as the mass of the bed increases throughout a print, and optimal input shaping values will differ depending on the moving mass. For a bed slinger, there isn’t a “one-size-fits-all” perfect value to use.

- Footprint: Bed slinger printers have a large footprint as the bed has to move horizontally across the whole Y-axis.

- Difficulty to enclose well: A bed slinger’s large footprint means an enclosure must be large, which results in lower enclosure temperatures for a passively heated enclosure. This is because the same heater from a bed needs to heat up a larger enclosure, and a larger enclosure loses more heat to the surroundings. This can be limiting if you want to print more advanced materials, such as ABS, which benefits from an enclosure.

Popular Printers

Now that we’ve looked at how a bed slinger 3D printer works and its pros and cons, let’s look at some popular options in the market.

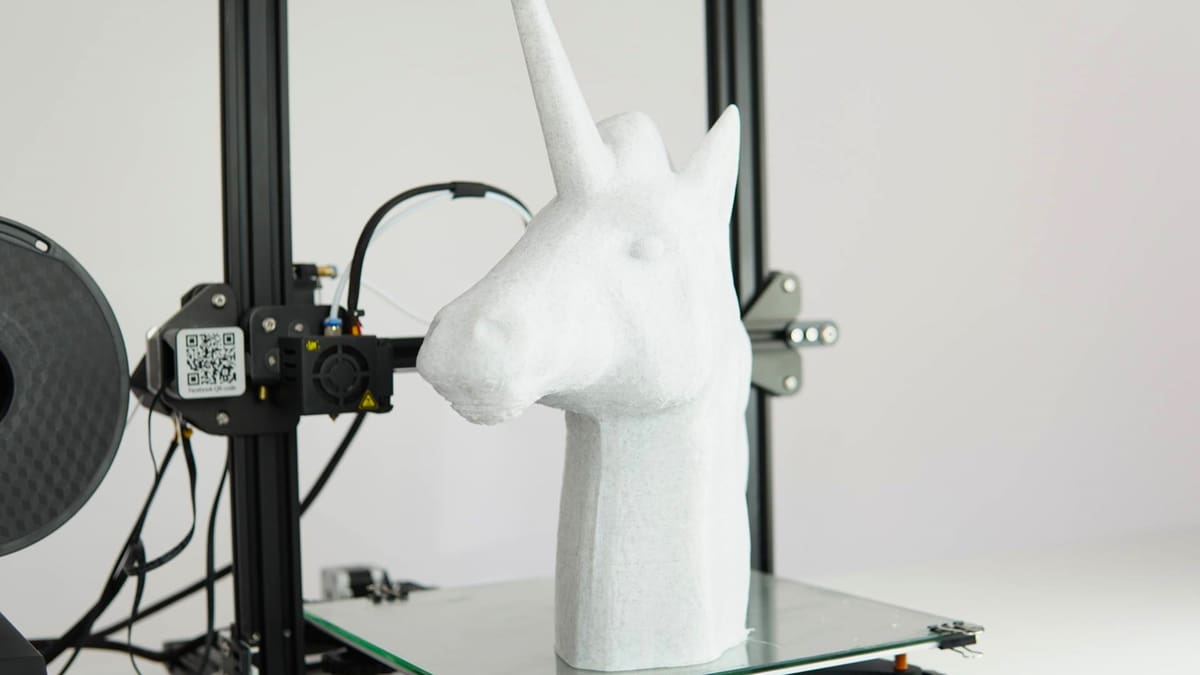

Prusa i3 Series

Originally named the Prusa Mendel back in the RepRap days, the Prusa i3 series has undergone a few iterations in the past 10 years, each adding new improvements and features.

Known in the community for its reliability (but also price), this pioneer is the printer that led to the explosive popularity of the bed slinger design, and paved the way for other machines such as the Ender 3 and its clones.

Just this year, the Prusa i3 Mk4 was introduced to combat the speed, acceleration, and resonance limitations of the bed slinger design by using upgraded motors and input shaping.

That said, the straightforward but still (mostly) reliable design has been given a run for its money lately, with CoreXY printers rising in popularity. Because of their advantage over the bed slinger design, similarly-priced CoreXY offerings from Bambu Lab (with many intelligent features) are reshaping the market.

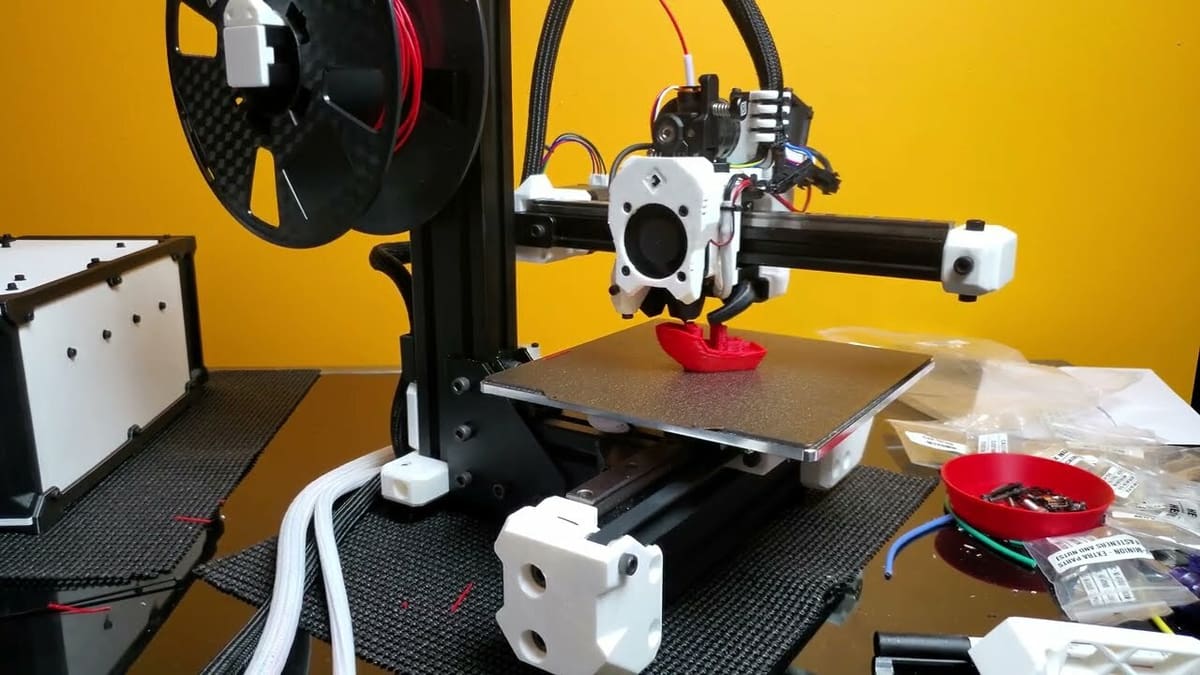

Ender 3 Series

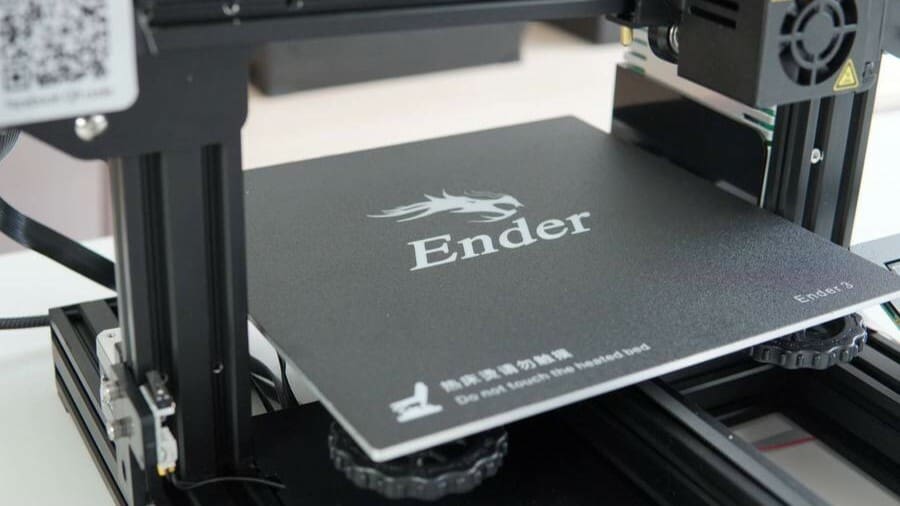

Everyone has heard of the king of low-cost 3D printers, the legendary Ender 3. It has been the go-to beginner machine since its release, and the Ender 3 is loved for its great out-of-the-box print quality, low price, and upgradability.

Its tremendous popularity led to the release of many different variants, including the latest Ender 3 V3 SE. With features like hands-free auto-bed leveling, a direct extrusion setup, a silent mainboard, and dual leadscrew Z-axis at around $200, this (quite) high speed printer further pushes the boundaries of low-cost, hobbyist 3D printing.

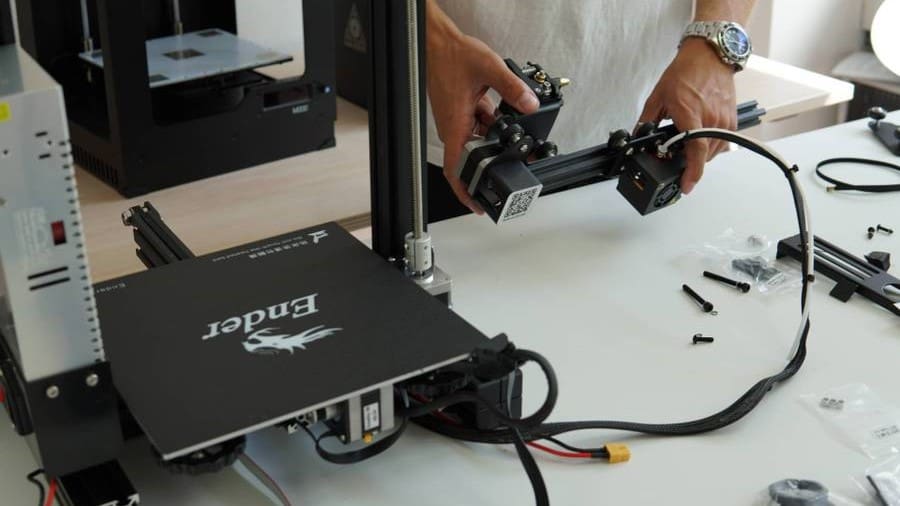

Bambu Lab A1 Mini

The Bambu Lab A1 Mini is the newest offering from Bambu Lab, a company that recently shook the hobbyist FDM market with their X1 and P1 series printers. These CoreXY machines package many features of DIY printers, such as high speed and print quality, but as an easy-to-use, off-the-shelf option.

The A1 Mini is targeted toward beginners or customers with a tighter budget, hence the bed slinger design. However, it still retains excellent features such as hands-free auto bed leveling, X- and Y-axis linear rails, and even a new active flow rate calibration method using a nozzle load cell. It comes in at around $300 for just the A1 Mini, and closer to $460 with their new compact multi-filament system, the AMS lite.

License: The text of "Bed Slinger (3D Printing): What Is It Exactly?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.