3D printing has had a sizable impact on a surprising range of industries, especially for more customized products and low-volume production lines. A good example is 3D printing’s use for prototyping: You can print out a prototype, test it on the spot, then adapt the design and print the next iteration.

Another key example is customizing personal accessories. Getting the correct fit for items like glasses is very important for anyone who needs to wear them frequently or for long periods of time. It’s not surprising, then, that 3D printing is making an impact on the eyewear market, with files available to print at home as well as companies turning to 3D printing for production.

We’ll be looking at the best 3D printed sunglasses that you can make, along with the companies using 3D printing in their collections. If you spot your perfect pair but want to leave the printing to the professionals, try Craftcloud. With suppliers around the world ready to print and ship to your door, you’ll have your new frames in no time. Just don’t forget you can’t print the lenses!

To Print

We’ve found 3D printed sunglasses inspired by everything from classic frames to internet trends. In all cases, the frames are the only thing that’s 3D printed; you’ll generally need some hardware for assembly and you’ll definitely need some lenses.

Wayfarers

These sunglasses were modeled after a pair of Wayfarer-style frames, an iconic shape from Ray-Ban. This design is very simple and easy to recreate, and the pictured frames were printed on an Anet A6.

Designing and printing these frames saved a pair of Knockaround sunglass lenses, as the original frames were broken. The frames were modeled in Cinema 4D with a channel to hold the lenses in place once pressed in.

When printing they require no supports with the front of the frame and sides of the arms orientated on the build plate. After printing, the parts can be softened into a more curved shape with a heat gun and formed to fit the wearer. You’ll also require a small screw to attach the arms.

- Who designed it? dukedoks

- How printable/popular is it? This design has 3,000 likes and 12 confirmed Makes.

- Where to find it? Thingiverse

Aviator

Aviators were the choice of pilots to protect their eyes while flying, replacing the heavier and thicker flight goggles used previously. The aviator style provided a clearer and wider picture of the environment, and the tint made it easier to fly in bright sunlight.

The hinges are the most interesting part of this design. Rather than using screws or a snap-fit mechanism, they have been designed to use some 1.75-mm (unextruded) filament as a pin to hold the temples in place. Quite ingenious!

Contrary to some other designs, these sunglasses are printed curved, so they’ll need some supports. The designer has provided print settings for Cura as a guide to achieve the best results.

- Who designed it? Stamos

- How printable/popular is it? This vintage design has 4 confirmed Makes and over 3,000 downloads.

- Where to find it? Thingiverse

Fully Printed

These stylish shades are another fully 3D printed pair of sunglasses. Similar to the Aviator style above, these use a piece of 1.75 mm filament to hold the sunglasses together. There are versions to print both with and without supports, so you can choose your printing challenge!

The designer recommends printing these frames in PLA, although PETG might have more durable results. Uniquely on this list, they also sell polarized triacetate lenses in three colors that will perfectly fit your printed glasses. Even better, a tree is planted for every pair of lenses sold!

- Who designed it? aleckerr

- How printable/popular is it? The two designs have been downloaded nearly 200 times from MyMiniFactory, and there are several impressive prints featured on the designer’s own site.

- Where to find it? MyMiniFactory, Revzn

Cat Eye

One of the most enduring sunglasses styles is a cat-eye shape. As the name implies, this classic frame style is tapered at the corners to evoke the almond shape of cats’ eyes.

These are best printed with a smaller layer height to get the best resolution for the print, minimizing the need for sanding. The designer didn’t include tabs or grooves to hold the lenses in place, so glue may be required (or a tweak to the design before printing). Small screws are also necessary to hold the glasses together.

- Who designed it? liamrichards25

- How printable/popular is it? There are 2 impressive Makes for these frames and the design has nearly 900 likes.

- Where to find it? Thingiverse

Okey Dokey

These stylish frames, dubbed “Okey Dokey”, are a classic 80s throwback. They come from a very popular MyMiniFactory designer, M Badia, who’s responsible for some other impressive 3D printable sunglasses, including these 70s-style frames and this stylish cat-eye design.

These don’t require any extra hardware, as the clever design allows the arms to simply snap into place. Unfortunately, no information is provided about the precise lenses to use, but there’s a nice groove to hold them in place if you can source them.

- Who designed it? M Badia

- How printable/popular is it? These attention-grabbing frames have 2,400 downloads and over 22,000 views. One other user has shared photos of two very clean-looking prints.

- Where to find it? MyMiniFactory

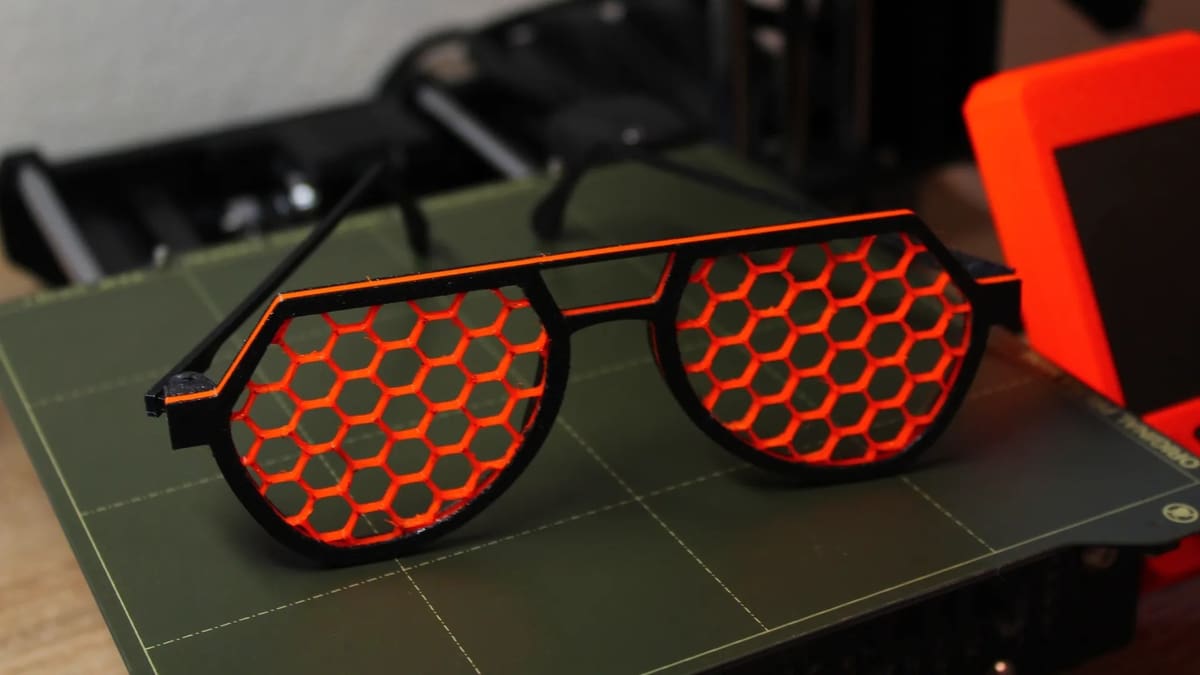

Infill-filled

This is an interesting take on sunglasses, using any of the PrusaSlicer infill patterns in the place of tinted glass. You can choose any infill percentage and pattern you like, though the designer and a couple of makers have gone with honeycomb.

The dual-color effect shown in the photo above is impressive, but if you don’t want to mess around with pausing the print to switch filaments, they look equally as effective in a single color. Like some other designs on this list, you just need two small pieces of filament to connect the glasses’ arms.

- Who designed it? gregor070504

- How printable/popular is it? Four people have shared photos of their successful prints. Just note that you’ll need supports to hold the infill up off the bed, so removal could be tricky.

- Where to find it? Printables

Deal with It

These frames were inspired by the sunglasses used in the Thug Life meme. As you can see, they were given the same pixelated style as in the videos, but when printed in colors other than black they have more of a retro 8-bit style than specifically referencing the meme.

Although not shown with lenses, the frames are designed to fit standard square-shaped lenses. Alternatively, you can skip the lenses and print them as part of a throwback costume!

Interestingly, these frames are fully 3D printed. The designer modeled everything in Blender, swapping out screws for pins so no additional hardware is required.

- Who designed it? voitec

- How printable/popular is it? This design has over 2,800 views and nearly 100 downloads.

- Where to find it? MyMiniFactory

Simple

These are a simple recreation of some neon party sunglasses, to reuse the lenses from broken frames. The smooth texture you see on these frames is because they were printed in ABS and then smoothed with acetone vapor.

To put these together, you’ll need some standard Wayfarer-style lenses and two small screws to assemble the frames.

- Who designed it? sota919

- How printable/popular is it? This designer has printed a couple of pairs of their own, and there are 2 other Makes and over 200 likes for this design.

- Where to find it? Thingiverse

Oakley-Style

These frames were modeled around the lenses from several pairs of broken sunglasses. The designer notes that the lenses appear to be a common type, so perhaps you have the same ones lying around! If not, they also explain the design process for the model, so you can create your own pair from scratch.

The pictured sunglasses were printed in PLA with a 0.2-mm layer height and 100% infill. The curved shape is achieved by applying heat to the printed parts while inserting the lenses.

- Who designed it? laisch

- How printable/popular is it? While no one has yet shared a make, the detailed Instructable means it should certainly be possible!

- Where to find it? Instructables, Printables

Solar Eclipse

If you look at a partial or full solar eclipse, it will do the same damage to your eyes as if you were looking at the sun directly. The difference is you don’t feel the need to look away, which makes it even more dangerous.

This design takes the definition of “sunglasses” to another level. Taking inspiration from the robot sunglasses, these glasses are designed to allow you to (more) safely watch an eclipse. The next total eclipse that can be viewed in North America is on April 8, 2024, so that’s plenty of time to print and prepare for the viewing.

These sunglasses do require support when printing and at least 15% infill for structural integrity. To make these functional, you need to insert sun protection to view an eclipse. Specifically, you’ll need at least two layers of mylar or solar filter film (like what’s used in telescopes). This can be purchased from an astronomy supply store or online at Amazon.

- Who designed it? JackHydrazine

- How printable/popular is it? This unusual pair of safety goggles has 2 confirmed Makes and over 100 likes.

- Where to find it? Thingiverse

Geometric

3D printing makes it easy to add cut-out designs from a part, like the patterns in these sunglasses’ arms. The designer of this model has shared the SolidWorks files for each part so you can add cut-outs, tweak sizing, and match the shape perfectly to the lenses you plan to insert. There’s an accompanying YouTube video that takes you through the process.

You’ll need a pair of old sunglasses in a similar shape to steal lenses from, or you can buy lenses and screws that suit Wayfarer-style frames. As with all 3D printed glasses, an important consideration is achieving a smooth finish, not only for aesthetic purposes but also so they are comfortable on your face.

- Who designed it? MattCarl

- How printable/popular is it? This twist on the Wayfarer shape has over 3,500 downloads and 170 likes on Thingiverse.

- Where to find it? Thingiverse

3-in-1

Why have sunglasses when they can be more than that? This maker came up with this unusual idea when repairing a pair of sunglasses. Rather than just reproducing the left arm, he decided to incorporate a USB drive in one arm and a ballpoint pen in the other!

This design is for 3D printed glasses’ arms to attach to an existing pair of frames, which means prescription wearers can be part of the fun, too! You’re only limited by the dimensions of the sunglasses to what you could fit in them.

If you want to learn how to design your own pair, follow along with the Instructables tutorial. The whole process is detailed from initial design to printing tips. Just avoid using supports in the arm cavities as they will be quite difficult to remove so you can insert your gadgets.

- Who designed it? Mat-Lek

- How printable/popular is it? It has been liked nearly 100 times on Thingiverse and has nearly 10,000 views on Instructables.

- Where to find it? Thingiverse, Instructables

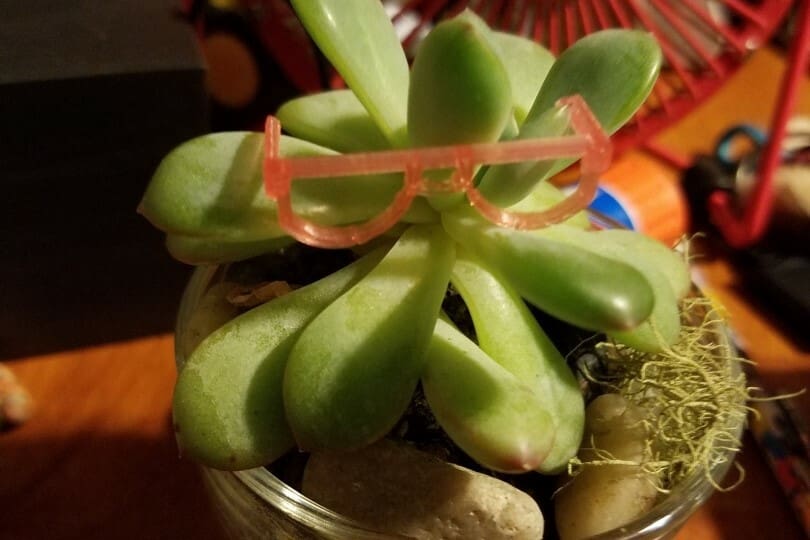

Bonus: Miniature

Not all 3D printed eyewear is for human use. Your plants and other small objects can be sun-safe, too!

These sunglasses were created solely for adding personality to tiny plants. Originally, they were intended to be used to give carnivorous plants some extra attitude. However, the weight of the glasses is better supported by plants such as succulents with sturdy leaves.

You can pick open or solid sunglasses for your plant depending on your preference. The tiny scale means these are also quite a short print, taking under 20 minutes.

- Who designed it? TTriston0

- How printable/popular is it? Over 100 downloads mean there are some cool-looking plants out there!

- Where to find it? MyMiniFactory

To Buy

Purchasing professionally 3D printed sunglasses is where you’ll see the most polished designs and products, both in the form of traditional frames and innovative designs taking advantage of the technological possibilities. Being able to purchase 3D printed frames from established brands is a great way to experience the potential of 3D printing, without relying on your own skills for the final product!

Virtual Try On

Virtual Try On is a French web tool specifically created for opticians by opticians. The web tool makes it easy to design and order custom 3D printed glasses frames, using a number of different dimensions.

3D scans of a client’s face make this possible: The OBJ file of a face scan is used to create custom frames with a perfect fit. You can even order an STL file of the frames to print yourself and test the fit and look before you order.

The frames are printed using SLS technology, allowing for greater detail and excellent mechanical properties. FDM printers are also used for prototyping. Want some fancy patterns or colors? Well, with SLS you can have them! You can easily customize the color and design of the frames for a unique look.

You can use the web tool for free with a minimum order of two pairs per month. For this reason, it’s intended to be used by optometrists, not private customers.

Monoqool

Danish 3D printed glasses retailer Monoqool is one of the more well-known names when it comes to 3D printed eyewear. They have many styles to choose from, including sunglasses-specific frames, as you can see from the collection.

Monoqool’s glasses are also manufactured using SLS technology, with polyamide powder, better known as nylon. To get their spectacular finish, the glasses are sintered in 0.1-mm layers to maximize detail. The frames are then polished with stones, then colored before assembly.

Another feature of the Monoqool designs is that they’re lightweight and screwless, which makes them easy to fit and harder to break. These frames can’t be bought online, but you can check the website to see if there’s a retailer near you.

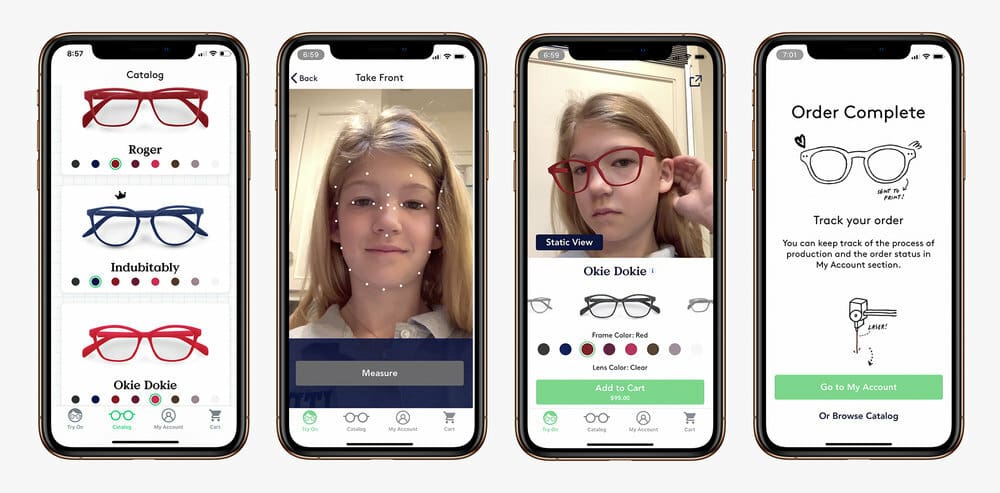

Fitz

Based in the US, Fitz focuses on easing the buying experience when choosing glasses for children, as well as producing glasses that are more durable and better fitting so kids can get on with being kids. The idea for the company came from personal experience of the difficulty of finding quality glasses for kids in a range of sizes, but the glasses and sunglasses are suitable for adult faces, too!

To order a pair of glasses from Fitz, you need to already know the lens prescription. Then, using the app, you can take accurate measurements of someone’s face, try on various frames, and order a customized pair of glasses or sunglasses.

One downside is that the app only works on newer iOS devices, as it relies on Apple’s TrueDepth camera technology for accurate face scans. For those who know the challenge of finding quality kids’ glasses, this is showing the true customization potential of 3D printing.

Specsy

Specsy is another company with an app to 3D scan your face to customize the glasses. As with Fitz, augmented reality is used to show how you would look with your selected pair. Compared to the practical, kids-focus of Fitz, Specsy has more of a style focus, with professional and sleek-looking frames.

Being available in a rainbow of colors with a clear matte finish, the frames are sure to impress. There are 10 different frame styles available, to suit square, round, and heart-shaped faces. And the customization doesn’t end with the size and color: You’re able to further tune 11 individual components of your frames.

Made from nylon, Specsy claims the frames are impact-resistant and durable. As a bonus, their frames weigh less than 10 grams. They’re only available through participating opticians across the USA and Canada, who will help you customize the frames to your preferences.

Götti

Götti is a Swiss high-end frames label that uses additive manufacturing in some of their frames and other glasses accessories. The brand came to global attention in 2021 when Oprah Winfrey wore a pair of Götti glasses during her interview with Prince Harry and Meghan Markle. Oprah is actually a long-term fan of the brand, having also worn their frames in interviews with stars like Lady Gaga and Barack Obama (just in case that has more weight than the details of their quality manufacturing)!

Frames from Götti’s Dimension collection are printed using SLS technology and then finished by DyeMansion with their print2product workflow. They started this in 2014, making them one of the first eyewear brands to incorporate 3D printing into their products.

Despite the prestige, these frames aren’t all that expensive when compared to standard designer frames. They’re also readily available from a large network of retailers all over the world.

Yuma Labs

With its first collection back in 2017, Yuma Labs was the first brand to 3D print sunglasses from recycled plastics. This meant the company could experiment with materials and shapes and avoid waste by printing on demand.

Scaling up the business has meant that 3D printing is no longer the primary production method, but the company still innovates with materials and technologies, including 3D printing. One example is a 2019 project where they worked with local children to print sunglasses from river plastic, right there on the banks of the river. Another is using plastic collected at Tomorrowland to 3D print sunglasses to sell at the following year’s festival, thereby closing the plastic loop.

Yuma Labs also regularly collaborates with other designers and companies. Recently, alongside fashion designer Henrik Vibskov, they released a new range of 3D printed sunglasses made from bio-based polyamide. Yuma Labs offers free worldwide shipping, and at the end of their life, you can return your sunglasses for recycling to avoid any plastic waste.

License: The text of "3D Printed Sunglasses: Best Models & Companies" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.