A well-maintained 3D printer is a happy 3D printer, capable of sending out flawless prints with precision and ease. One of the most important aspects of 3D printer maintenance is proper lubrication.

Lubrication ensures smooth movement of FDM printer components like linear rods, bearings, and lead screws. Regularly applying lubricants to your printer can reduce friction, minimize wear and tear, and put an end to those annoying squeaks and grinding noises. Not to mention that lubrication can significantly extend the lifespan of your printer.

Lubricating your 3D printer is a simple process that involves a few key steps. First, you’ll want to clean the areas of your printer that will be lubricated, removing any grime, dust, or debris. Then, apply a small amount of the appropriate lubricant to the designated points and gently move the parts to distribute the lubricant evenly. Remember, a little goes a long way with most lubricants. Finally, wipe away any excess to prevent it from attracting dirt or causing a mess.

In this guide, we’ll get into the world of 3D printer lubricants, looking at why they’re essential, the different types and considerations, and some of the best lubricants on the market. Let’s get started!

Printer Parts Requiring Lubrication

As mentioned, proper lubrication is necessary for maintaining the smooth operation and longevity of your 3D printer. While not every printer component requires lubrication, several important moving parts benefit greatly from regular attention and maintenance. Here are the main printer parts that require lubrication:

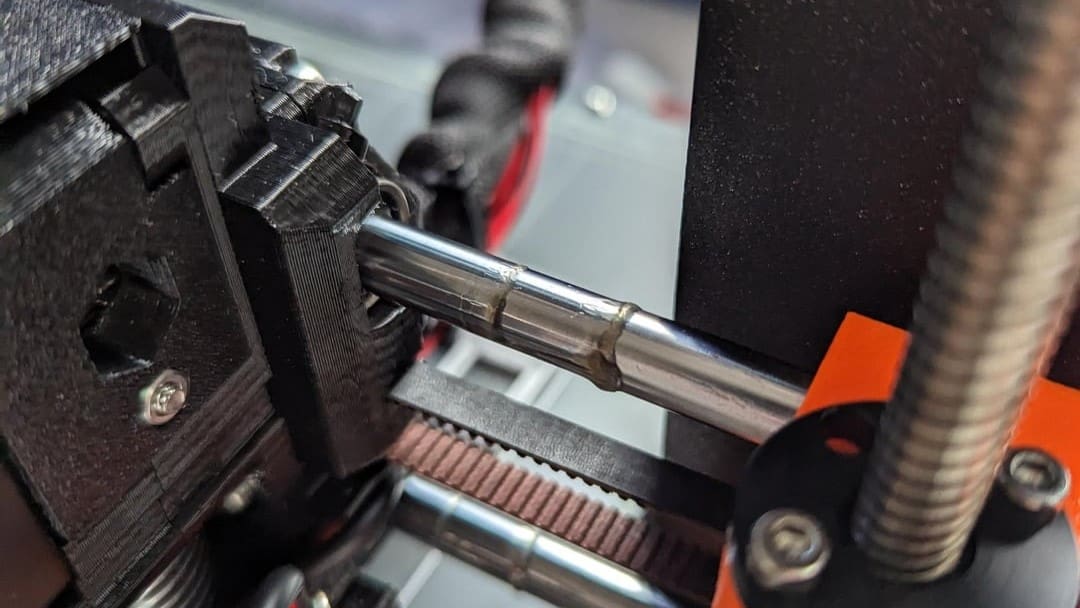

- Linear rails and smooth rods: These components guide the movement of the print head and build plate along the X, Y, and Z axes. They undergo constant friction as they slide back and forth, making them prime candidates for lubrication. Regular lubrication of linear rails and smooth rods ensures smooth, quiet, and precise movement, leading to better print quality and reduced wear and tear.

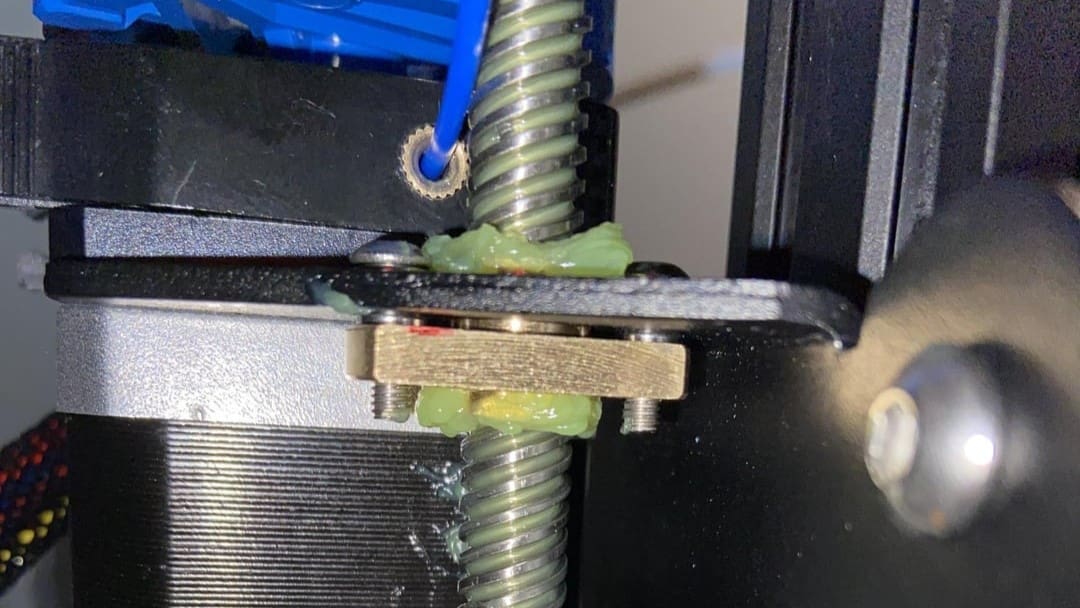

- Lead screws: Lead screws are responsible for the precise vertical (Z-axis) movement of the print bed or gantry. They transform rotational motion from the motor into linear motion, lifting and lowering the print surface. Lubricating lead screws is crucial to prevent friction, which can cause binding, squeaking, and inaccurate layer heights on prints.

- Bearings: 3D printers utilize different types of bearings, such as linear bearings, lead screw support bearings, and V-slot wheel bearings. These support moving parts and reduce friction between them. Lubricating bearings ensures smooth rotation and linear motion, reducing noise and wear.

- Extruder assembly: The extruder is responsible for feeding filament into the hot end for melting and extrusion. While not all extruders require lubrication, some models have accessible gears and other moving parts that can benefit from it. Lubricating the extruder assembly can help ensure consistent filament flow and reduce wear on the gears.

Printer-Specific Factors

Choosing the right lubricant for your 3D printer isn’t just about the type of lubricant, but also about understanding your specific printer’s needs. For the best results, always consult the manufacturer’s recommendations before lubricating your printer.

Some printers will require different types of lubricants or won’t need to be lubricated at all. For example, if the Z-axis drive screws use delrin bearings, you shouldn’t need to worry about applying lubricant, as this is a naturally low-friction material.

Temperature Range

The operating temperature of your 3D printer plays a significant role in lubricant selection. For example, printers like the Raise3D Pro3 Series, which have heated beds and are designed for high-temperature materials, require lubricants with excellent thermal stability, such as PTFE-based greases or high-temperature silicone lubricants.

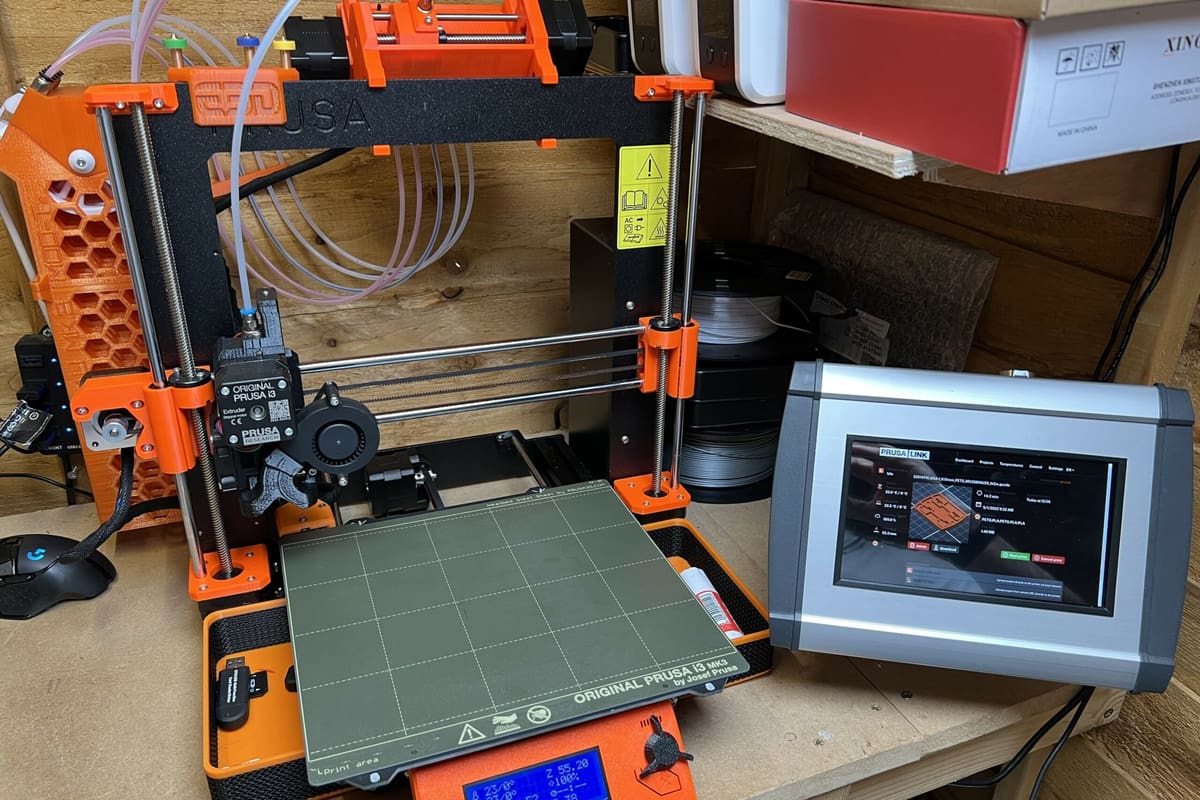

For printers geared more toward hobbyists with lower operating temperatures, like the Prusa i3 MK3S+ or Ender 3, you have more flexibility in your choice. However, it’s still important to ensure the lubricant’s temperature range exceeds your printer’s maximum operating temperature. This is especially true if your printer is in an enclosure.

Material

For most standard FDM printers, such as the Creality Ender 3, lubricating the Z-axis is typically enough. However, if your printer has additional metal bars or places of metal-on-metal contact, these may also require lubrication.

As mentioned, certain types of materials used for 3D printing components, such as delrin bearings, are low-friction and typically won’t require lubrication. That said, if you’re using hair spray for your bed adhesion, the spray can make smooth rods sticky over time. In this case, applying lubricant like a white lithium grease can ensure everything keeps running smoothly.

Environment

The environment in which your 3D printer operates can also influence your lubricant choice. If your printer is located in a dusty or humid environment, choose a lubricant with better dust and moisture resistance. For instance, in dusty environments, a dry lubricant like PTFE powder can be a good choice, as it won’t attract as much dust as grease or oil.

In humid environments, a silicone-based lubricant with water-resistant properties can help prevent moisture buildup.

Types of Lubricants

You’ll want to choose the right lubricant for your 3D printer and the specific parts that you intend to lubricate. This is important for ensuring optimal performance and longevity. There are three main categories of lubricants: oils, greases, and dry lubricants.

Oils

Oils are thinner, low-viscosity lubricants that help reduce friction and provide smooth movement. They are ideal for high-speed applications and lightly loaded parts, such as smooth rods and linear bearings.

However, they tend to require more frequent reapplication compared to greases or dry lubricants. PTFE-based oils, such as Super Lube Synthetic Oil, contain polytetrafluoroethylene (PTFE), a low-friction material renowned for its ability to reduce friction and withstand high-temperature environments.

Greases

Greases are thicker, high-viscosity lubricants perfect for heavy loads and slow-moving parts like lead screws and bearings. They offer excellent protection against wear and corrosion and typically last longer than oils.

On the other hand, they can be messy to apply and tend to attract more dust over time. White lithium grease, enhanced with PTFE for improved performance (such as Super Lube’s Multi-Purpose Synthetic Grease with Syncolon), is a common choice for 3D printing maintenance. Silicone-based greases are also a popular option for lightly loaded parts, as they’re generally safe for most plastics and some metals.

Dry Lubricants

Dry lubricants come in various forms, including powders, sprays, and solid films. They’re often preferred for applications where liquid or grease lubricants are undesirable, such as filament drive gears and parts where cleanliness is paramount.

This type of lubricant also offers low friction, high-temperature resistance, and won’t build up as much dust as oil- or grease-based alternatives. Graphite-based lubricants are a great option, as they form a dry film that resists high temperatures and repels dust. However, they may require more frequent reapplication compared to oils or greases due to their dry nature.

Note: WD-40 is not recommended for 3D printer lubrication. While it can be used as a penetrating oil to loosen stuck parts, it’s not designed for long-term lubrication and can leave a residue that attracts dust and debris. Instead, opt for lubricants that are well-suited for 3D printers, which we’ll get into later on.

Considerations

To compile the list of the best lubricants for your 3D printer, we kept several things in mind:

- Viscosity: As we saw, the viscosity, or thickness, of the lubricant should be matched to the specific application. We aimed to present a range of viscosities to lubricate your printer from print head to toe.

- Temperature resistance: The operating temperature of your 3D printer also heavily influences your lubricant choice. We’ll include some temperature-resistant PTFE-based lubricants as well as all-purpose options.

- User reviews and ratings: We tapped into the collective wisdom of the 3D printing community to be sure these choices are tried, tested, and approved by makers.

- Value for money: While high-quality lubricants may come with a higher price tag, they often deliver superior performance, longevity, and protection for your printer. Nevertheless, we’re not trying to break the bank over lubricants.

You’ll also want to keep in mind that most 3D printer manuals include instructions on how and when to lubricate your specific model. Generally, printers with heated beds should be lubricated every 75-100 hours of printing, while those without heated beds can go around 200-250 hours between lubrications.

3D Printing Lubricants

In the following sections, we’ll offer some specific lubricants that can help you maintain your 3D printer and keep it in tip-top shape. While there’s certainly some debate in the 3D printing community about which lubricants are best, the following options are often popular picks due to their performance and reliability.

Super Lube Multi-Purpose Synthetic Grease with Syncolon

First up, this grease enhanced with PTFE is a versatile choice for lubricating your 3D printer. It offers excellent lubrication and protection for metal-to-metal and metal-to-plastic applications, and it’s suitable for printer parts like lead screws, bearings, and other components requiring a thicker lubricant.

Many users praise Super Lube grease for its versatility and performance, using it for years without any issues. However, it’s recommended to use this grease sparingly on your printer. Apply just a thin coating, as loading too much on can cause bearings to stick together.

- Type: PTFE-based grease

- Size: 14 oz (414 ml)

- Price: ~$23

Tri-Flow Superior Dry Lubricant

This PTFE-based dry lubricant excels at providing a clean, non-sticky film that reduces friction and wear. Plus, it doesn’t attract much dirt or dust. Its high-temperature resistance makes it perfect for filament drive gears and plastic-on-plastic contact points.

It has a 4.6-star rating at Amazon, with many users praising the durability of the lubricant. However, a couple of reviews note that it’s rather temperature sensitive. Keep in mind that a little goes a long way with this lubricant.

- Type: PTFE-based dry

- Size: 2 oz (59 ml)

- Price: ~$10

DryFluids GlidePower Dry Lubricant

GlidePower is a long-lasting dry lubricant known for its exceptional adhesion and corrosion protection properties. Its unique formula offers low friction, high water and wear resistance, and high creep ability. It’s suitable for a wide range of 3D printer parts, including shafts, spindles, guides, rollers, sliding, and ball bearings.

To use this lubricant, simply spray it on the part’s surface and wait about a half hour until it’s dry. The bottle comes with a fine tip to help you ensure precise application. Users mention that you should be able to notice a difference in the friction almost immediately, with little to no resistance.

- Type: Dry

- Size: 0.8 oz (25 ml)

- Price: ~$24

Super Lube Synthetic Oil with PTFE

Next, we have another option from Super Lube. Their Synthetic Oil with PTFE is a versatile lubricant infused with PTFE (Teflon). It has enough viscosity to stick well to your printer’s guide rods, and won’t immediately attract dust. The other nice thing is that it has a good heat tolerance, so you don’t have to worry about it coming into contact with the printer’s heating element or any other electronic components.

This product has a 4.7-star rating at Amazon, with many users mentioning that it’s great for hard-to-reach areas and reduces the noise of their 3D printer, especially on the Z-axis lead screw. However, some people note that the oil is messier to use than Super Lube’s grease lubricants.

- Type: PTFE-based oil

- Size: 4 oz (118 ml)

- Price: ~$10

Krytox GPL205 Grease

Last but not least, this high-performance grease is a great option to use on linear rails, bearings, and lead screws and offers longevity, so you don’t have to spend time reapplying often.

The lubricant has a 4.5-star rating at Amazon, with many happy users commenting on its performance and noise-reduction abilities. While it’s rather expensive, a little does go a long way with this grease.

- Type: PTFE-based grease

- Size: 0.5 oz (15 ml)

- Price: ~$25

License: The text of "The Best 3D Printer Lubricants: A Buyer’s Guide" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.