A computer numerical control (CNC) router is a machine built for cutting and carving materials. Basic CNC routers work along three axes of movement, just like a 3D printer. This includes the forward-backward axis (X), the side-to-side axis (Y), and the up-down axis (Z).

3-axis routers are limited in how complex a part they can machine, so more advanced machines include a fourth axis, known as the A-axis. And while X, Y, and Z cover linear movement, the A-axis is about rotational movement.

In some cases, the A-axis consists of a headstock and tailstock, mounted on the machine’s worktable, that spin the workpiece similar to a lathe. In other cases, the A-axis is found on the gantry and is capable of rotating the spindle laterally in order to reach around the sides of workpieces.

If you’re looking for something with a little more capability than the average 3-axis CNC and you’re no stranger to the functions of CNC machining, a 4-axis machine is probably for you. However, if you’re just starting out in the world of CNC, consider a 3-axis router, as they tend to be much simpler and easier to operate.

In this list, we provide several options ordered from least to most expensive, with one bonus at the end! Before we check them out, let’s take a closer look at how we narrowed down our picks.

Considerations

There are lots of factors that should be looked into when purchasing a 4-axis CNC router. To help you make your decision, here’s what we considered while narrowing down the choices for this article:

- User-friendly: We looked for routers that include a comprehensive set of features and which should be able to handle most tasks thrown at them. Plus, routers with a simple or intuitive setup process were prioritized.

- Space-efficiency: The compactness of the routers on our list was an important consideration. A space-efficient router has a small total footprint with respect to its working volume.

- Reliability: The robustness, durability, and reliability of a 4-axis router is incredibly important. No matter what the applications are, it’s crucial that it perform consistently, without the need for constant maintenance.

- User reviews: It’s important to consider the experiences that other users have had with these routers, and so positive reviews and ratings were taken into account extensively while compiling this list.

With the main considerations out of the way, let’s go over our picks.

StyleCNC STM6090

Made by StyleCNC, this router offers an enticing price considering what it includes. The STM6090 adopts the classic layout and dimensions of a basic 6090 CNC, except that it’s built around a set of welded steel legs, which add to the rigidity of the machine. The T-track table features sacrificial PVC inserts, so you don’t need to worry about damaging the table with the bit, and the fourth axis can be easily installed or removed.

The STM6090 also features gear-driven X- and Y-axes and an oil reservoir with a manual pump in order to lubricate the linear slides and the drive pinions. This feature is typically found in industrial contexts, where it greatly simplifies maintenance.

The overall look of the machine is clean, with all the electronics hidden away below the table and sheet metal guards covering all mechanical components. Closed-loop memory in the DSP remote control means the machine can remember what it was doing in the event of a failure.

- Working dimensions (X, Y, Z): 600 x 900 x 150 mm

- Fourth axis: Removable unit consisting of a rotary headstock, three-jaw chuck, a bed, and a sliding tailstock; 140-mm max workpiece diameter

- Spindle: 2.2-kW liquid-cooled spindle, up to 24,000 RPM, computer-based RPM setting

- Other features: DSP remote control with closed-loop memory

- Price: Starting at ~$3,000

- Get it from: StyleCNC

MicroKinetics Benchtop

This CNC resembles a classic benchtop milling machine more than it does a router, which makes for some unique advantages and disadvantages. The main disadvantage is the capacity, which cannot accept very large workpieces.

In exchange, you get a more rigid frame compared to most routers as well as the ability to work with many different materials. While the spindles on typical CNC routers range from approximately 10,000 to 24,000 RPM, the spindle on the MicroKinetics CNC features a spindle speed range of 75 to 2,800 RPM, which is better for harder materials like steel and cast iron. This machine would be excellent for the production of fine, delicate parts, such as gears, pinions, augers, jewelry, and components with threads.

Overall, the machine is fairly versatile. It’s compact size makes it convenient for small workshops and the headstock allows workpieces to be mounted faceplate-style. Yet, the screws driving every axis still yield working tolerances of 0.0001″.

- Working dimensions (X, Y, Z): 5 x 6 x 9 in (127 x 152 x 229 mm)

- Fourth axis: Removable headstock and tailstock, with headstock comprised of a horizontally-mounted rotary table and a removable three-jaw chuck

- Spindle: 0.5-hp DC spindle motor, computer-controlled

- Other features: Handwheels mounted on each axis for manual positioning

- Price: Starting at ~$4,400

- Get it from: MicroKinetics

StyleCNC 1325

If you’re looking to get the most bang for your buck, this CNC machine could be the one for you. The 1325 model from StyleCNC is a full-blown industrial machine with all standard features, including a large 4′ by 8′ capacity. The rotary fourth axis is constructed ruggedly with cast iron, and the sliding tailstock is similar to a lathe. The X- and Y-axes are driven by helical rack and pinions, and the Z-axis employs a ball screw, guaranteeing smooth, reliable, and precise movements across all axes.

The 1325 comes with lifetime customer support, ensuring that you’ll always be able to receive professional advice and guidance should the need arise.

Note that the rotary fourth axis at the front end of the machine runs parallel to the X-axis, but you can upgrade to include a fourth axis that runs parallel to the Y-axis for added length capacity. Further, bed length options range from about 3′ to 8′.

Promising customer reviews and comprehensive tech support make this a worthy inclusion on this list.

- Working dimensions (X, Y, Z): 1,300 x 2,500 x 200 mm

- Fourth axis: Fixed three-jaw rotary headstock and sliding tailstock; 300-mm max workpiece diameter

- Spindle: 3.0-kW liquid-cooled spindle, up to 24,000 RPM, computer-based RPM setting

- Other features: T-track style table, option to upgrade to a vacuum table, option to upgrade fourth axis, DSP remote control for manual positioning

- Price: Starting at ~$5,400

- Get it from: StyleCNC

Makera Carvera

A sleek and professional desktop machine, the Makera Carvera is a powerful CNC tool. It boasts extensive features, with automatic tool-changing, an easily-attachable laser module, auto-probing, and integrated dust collection systems. It promises a smooth user experience, whether that be in routing, milling, engraving, or even PCB manufacturing. The Carvera is able to cut a variety of materials, including aluminum, carbon fiber, FR4, acrylic, and more.

The optional 4th-axis module, together with the sub-0.01-mm precision, will let you easily machine 3-dimensional objects on a small, benchtop scale. The consensus around the Carvera is that it is a highly capable machine for hobbyists; with its extensive line-up of features, simplicity, and reliability, this machine is an attractive choice for those who are new to the field of CNC machining.

Although it has a relatively underpowered (and proprietary, so you can’t change it) spindle, the Carvera can be used in a diverse array of applications – not many other CNC machines can switch from cutting wood to making PCBs between two jobs. Even more, Makera provide comprehensive setup guides on installing and configuring the 4th Axis module on their YouTube channel, making the process even easier.

- Working dimensions (X, Y, Z): 92 mm (diameter) x 240 mm (length)

- Fourth axis: Optional module

- Spindle: 200-W, up to 15,000 RPM

- Other features: Automatic tool-changer, automatic probing, dust collection

- Price: ~$6,500 (with 4th axis); ~$6,900 (with 4th axis and PCB pack)

- Get it from: Makera

iTech K60120

The iTech K60120 is an industrially-built and rugged CNC router. With its 3-horsepower liquid-cooled spindle, there’s no shortage of materials you’ll be able to cut, ranging from soft and hard woods to aluminum and acrylic. The router also features a standardized tool-changer and a powerful dust collection system, which will let you machine parts more efficiently, with less clean-up afterwards.

There are two models under the iTech K60120 name that are nearly identical, with the K60120Z offering higher Z and extra Y dimensions. The 4th-axis module for this router allows for the machining of parts up to 80 mm in diameter, with any length that will fit into the 600 x 1,220 x 200 mm working volume (600 x 1,245 x 250 mm for the K60120Z).

This machine uses high quality lead-screws and linear guides, making it capable of roughly ±0.05 mm tolerances, with around 0.1 mm of backlash.

- Working dimensions (X, Y, Z): 600 x 1,220 x 200 mm working volume, 80 mm diameter

- Fourth axis: Removeable module

- Spindle: Air-cooled 2.2-kW spindle

- Other features:

- Price: ~$9,200

- Get it from: Scott & Sargent

ShopSabre 23

The ShopSabre 23 is a great middle-of-the-road CNC router for both serious hobbyists and professionals alike. ShopSabre is an American brand that touts its high-quality machines.

Their model 23 is a modular machine, with many optional features, including a set of steel legs, a vacuum table, and a rotary fourth axis that runs the length of the Y-axis. The ShopSabre has a powerful 3.5 horsepower spindle, making higher feed-rates on hard materials much more achievable than on other machines on the market. For a benchtop machine, this CNC is built robustly. Ball screws drive all three linear axes and the gantry is constructed of machined aluminum plates and a heavy wall tube.

The ShopSabre 23 is a great choice for machining harder materials like metals.

- Working dimensions (X, Y, Z): 30 x 40 x 5 in (762 x 1,016 x 127 mm)

- Fourth axis: Fixed headstock with a four-jaw chuck and a sliding tailstock; 8″ (203-mm) max workpiece diameter

- Spindle: 3.5-hp AC spindle motor, manually-controlled

- Other features: Options for vacuum table, steel legs, vacuum pump, dust collector, wireless MPG, computer stand, touch probe

- Price: Starting at ~$9,500

- Get it from: ShopSabre

Apollo 4-Axis Router

The Apollo 4-Axis router certainly packs a punch, providing reliable and precise operation. The machine boasts a vacuum-bed which, together with the pneumatic material locating pins, enables secure workpiece holding. As well as this, the Apollo has a powerful 9-kW spindle, capable of speeds of up to 24,000 RPM. Its automatic tool-changing functionality enables you to switch between up to 10 different tool-heads in a single job.

Well-suited to both industrial and smaller-scale operations, the Apollo router comes with the 4th axis pre-installed, reducing setup complexity and making the machine easier to use, while reducing its flexibility in terms of applications.

The machine comes with a range of bed-sizes, starting at 1,300 x 2,500 mm. With the ability to cut a wide range of materials, including acrylics, aluminum, brass, wood, foam, and rubber, the Apollo is certainly a formidable machines.

- Working dimensions (X, Y): 1.3 m x 2.5 m; 1.5 m x 3 m; 2 m x 3 m; 2 m x 4 m; custom sizes also available

- Fourth axis: All machines come with 0-180o of spindle rotation

- Spindle: Air-cooled 9kW (12hp) spindle (up to 24,000 RPM)

- Other features: Automatic tool changer, pneumatic bed, locating pins

- Price: Starting at ~$9,700

- Get it from: Manntech Machinery

LWM Maverick 3x5

The Maverick 3×5, made by Legacy Woodworking Machinery (LWM), is the Rolls-Royce of CNC routers. LWM makes numerous CNC routers, some boasting high-end features like automatic tool change.

This machine isn’t the largest, but it’s built like a tank and intended for heavy use in production shops. Clocking in at 1,350 pounds, it’s a good thing that this machine comes on caster wheels! Best for if you’re looking for a durable and long-lasting workhorse.

With respect to fourth-axis operation, of note is the vertical worktable, which can be found at the end of the normal worktable. It can be manually positioned at different angles, allowing the operator to perform machining operations (like cutting mortises and tenons) on the end-grain of workpieces.

The machine comes with a stock Mach3 CNC controller and plain working area, which can be upgraded to a Delta CNC controller with a vacuum bed, for improved work-holding and better finishes on parts with less effort!

- Working dimensions (X, Y, Z): 49 x 24 x 8 in (1,245 x 610 x 203 mm), expandable up to 56 x 36 in (1,422 x 914 mm)

- Fourth axis: Rotary; 10″ (254-mm) diameter by 50″ (1,270-mm) capacity

- Spindle: Liquid-cooled, 3-hp spindle, 12,000 to 24,000 RPM, optimized for cutting wood

- Other features: Manually positionable vertical worktable, automatic Z-axis tool-setting pad

- Price: Starting at ~$16,000

- Get it from: Legacy Woodworking Machinery

Bonus: Universal 4th Axis Kit

Although it’s cheating a bit, this bolt-on fourth axis is worth mentioning because of its popularity and price; it can be added to most 3-axis CNC routers.

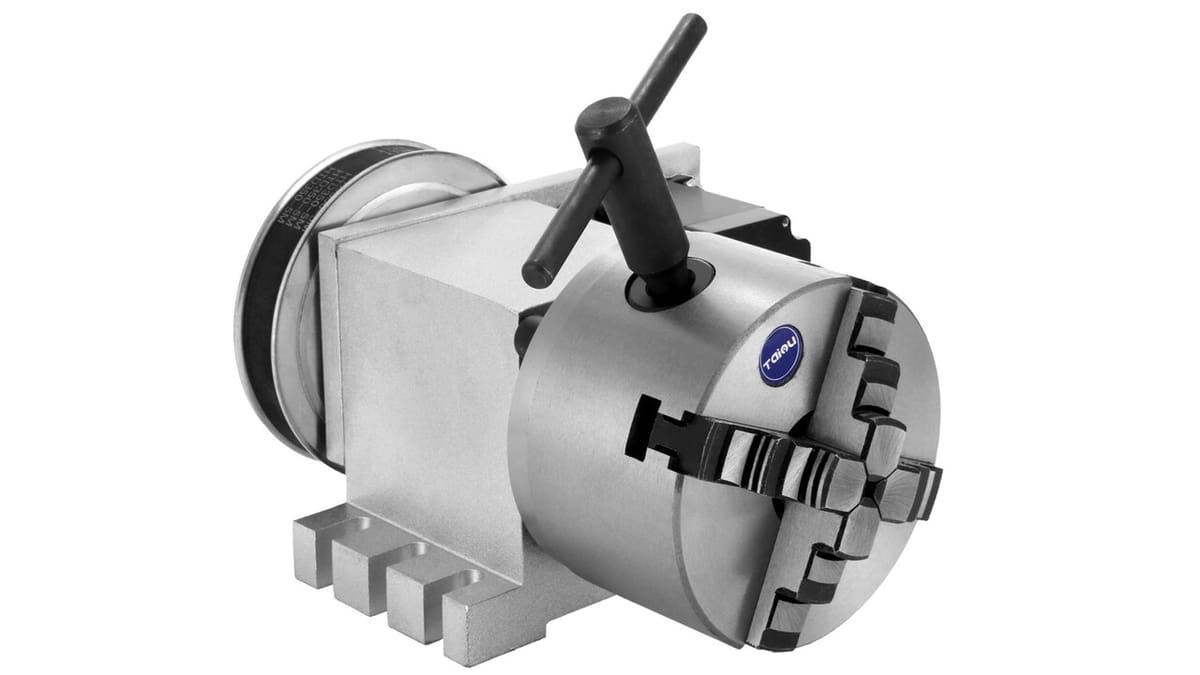

As you may have noticed, many of the devices in this list have removable headstocks or tailstocks that simply bolt onto the bed of the CNC and plug into the electrical system to give it 4-axis capabilities. Buying just the plug-and-play fourth axis assembly allows you to easily turn a 3-axis CNC machine into a 4-axis one.

Purchase

At only ~$220 (£170), the Vevor Rotary Axis kit is an inexpensive and straightforward way to add 4-axis functionality to your existing 3-axis router or mill. With a sturdy 4-jaw chuck, this module promises to hold your workpiece securely, and the 57-2A stepper motor can easily integrate with control boards that have a slot for additional motors.

This rotary axis can by default support parts of up to 100 mm in diameter, but this will of course depend on the height of your router’s cutting tool and bed.

- Working dimensions (X, Y, Z): ≥130mm diameter

- Fourth axis: Module that can be installed on most routers

- Spindle: N/A

- Other features: 4-jaw chuck, comes with chuck key and soft jaws

- Price: ~$220

- Get it from: Amazon

DIY

If you have fabrication experience, another option would be to build the rotary fourth axis headstock from scratch out of off-the-shelf components. You can find lathe chucks, stepper motors, and timing pulleys inexpensively online if you wish to take this route. Check out this YouTube video for more information on building your own fourth axis.

- Price: Varies

- Get it from: Hackaday (there are several other sites and guides)

License: The text of "The Best 4-Axis CNC Routers" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.