Carbon-fiber reinforced nylon is fast becoming one of the top materials in 3D printing for durable and strong-like-metal end-use parts. Used in everything from air intake manifolds on cars to any type of bracket, housing, or holder, this material enables strong parts in designs not possible with CNC machining and in quantities not affordable through injection molding.

You don’t need to know anything about 3D printing to get your parts and prototypes manufactured with this material, but it pays to have a general understanding of your carbon fiber options since they will affect the price and performance of your final part. Carbon-fiber-infused nylon is available in filament form for FDM 3D printing, as a powder for selective laser sintering (SLS) 3D printing, and there’s also continuous carbon fiber (CCF) 3D printing which involves using a dual-extruding 3D printer to imbed an unbroken band of carbon fiber inside the molten nylon material.

Despite being the ideal material for durable parts, carbon-fiber-infused polymers are not offered by most service providers. Nylon alone, without added carbon fiber, can be strong enough for many industrial applications, but the added strength of the fibers is driving the sale of carbon fiber materials and 3D printers worldwide, so hopefully, more service bureaus will catch up to demand.

In this article, we feature the top services offering 3D printing using carbon-fiber infused materials, typically nylon (PA) for both SLS and FDM technologies. We mention where you can get continuous carbon fiber parts, such as at Craftcloud, although it is rare as a service offering.

We based our recommendations on a number of factors, including material selection, ease of ordering, technology, and additional services. If you’re not sure which type of carbon fiber material you need or which 3D printing technology is best for your application, skip down to the end where we cover these topics in-depth.

Best SLS Carbon Fiber 3D Printing Services

Craftcloud

Craftcloud is a 3D printing service with more than 150 vetted manufacturing partners worldwide that offer several carbon fiber options. Although we list Craftcloud as out top pick for SLS, it is just as capable with FDM featuring 12 carbon fiber materials for use with FDM printers as well as carbon filled PA-11 nylon with SLS technology. Plus, Craftcloud is one of two service providers we’ve found that offers continuous carbon fiber 3D printing.

Upload your digital part file and select from the quotes. Unlike most other providers, you get instant quotes without having to register or create an account first.

Unlike most other providers, Craftcloud discloses the prices of each manufacturing partner, and you choose the one that best fits your criteria. Still, Craftcloud takes care of the entire process from order to delivery.

A new customer review feature launched in 2024 provides even more information about our partners to help you make the best selection. Every Craftcloud user is invited to rate and review the manufacturer that they selected to receive their part from. There are already nearly 2,000 customer reviews and experience feedback.

Carbon fiber materials (SLS):

- Carbon-filled PA-11 nylon

Carbon fiber materials (FDM):

- CF-PETG

- CF-PEKK

- CF-Ultem 9085

- Markforged Onyx (CF-PA)

- CF-PEEK

- CF-ABS

- CF-ASA

- CF-PLA

- GreenTec Pro Carbon (a biopolymer with 10% carbon fiber)

- CF-PA11 nylon

- CF-Polycarbonate

Carbon fiber technologies: SLS, FDM, FDM-CCF

Fathom

Fathom is the largest privately-owned on-demand additive manufacturing service in North America. Although they focus primarily on U.S. and Canadian customers, they have an excellent range of 3D printing and additional services in place to deliver parts quickly.

Fathom offers instant quoting through a simple online user interface. Large-scale or particularly complex parts may require a quote review, though. The company has manufacturing locations across the U.S. and is constantly expanding its network if its history of steady acquisitions is anything to go by.

Its carbon fiber offering includes carbon-fiber-filled nylon (PA11) for SLS and nylon (PA12) carbon fiber for FDM.

Carbon fiber materials:

- CF-nylon (PA) 11

- CF-nylon (PA) 12

Carbon fiber technologies: SLS, FDM

Sculpteo

Focusing on the professional manufacturer more so than consumers or small businesses, Sculpteo is a smart choice if you know exactly which technology and material your project requires.

Like other 3D printing service platforms, you can upload your 3D model and select your materials and quantity. Sculpteo offers a handy “printability” check to your digital files that we like since it can point out problems before your order goes to production. There’s also a “Solidity Check” to ensure fragile elements of your print won’t break during production.

Sculpteo’s suite of professional services positions it as a comprehensive partner for tasks such as batch production, prototyping, and design validation.

It’s also worth noting that Sculpteo’s 3D printing service can be accessed through Craftcloud.

When it comes to carbon fiber, Sculpteo offers SLS technology using Ultrasint PA11 CF powder.

Carbon fiber materials:

- Ultrasint PA11 CF powder

Carbon fiber technologies: SLS

Best Carbon Fiber 3D Printing Services for FDM

FacFox

FacFox is one of China’s most popular on-demand 3D print services, offering a broad selection of other manufacturing services, too. The company tailors its services to several industries, including architecture, medical, retail, and design.

A simple online interface lets you quickly upload models, which are then be checked for printability (and automatically repaired if not) before payment. Live tracking of the print’s progress is a nice touch, and competitive international delivery often makes it a cost-effective alternative where ever you are. The low prices come at the cost of site usability, which is not all that intuitive to navigate. But if you know exactly what material you need and which technology, it should be a smooth, quick ordering process.

FacFox, however, is the only the second 3D printing service (we’ve found) offering Markforged’s continuous carbon fiber technology (FDM-CCF), which, if you’re considering buying a Markforged machine, is a great way to test out it capabilities. In addition to continuous carbon fiber, and flame-retardant continuous carbon fiber, Facfox also offers Stratasys Nylon 12CF for FDM.

Carbon fiber materials:

- Markforged CF

- Markforged CF-FR

- Stratasys Nylon 12CF

Carbon fiber technologies:

- FDM

- FDM-CCF

Materialise OnSite

Materialise OnSite is a Belgium-based company with offices and facilities in the US. Its services are broken out into a few different manufacturing arms, which makes it a bit difficult to navigate which one you might need.

One of the strengths of Materialise OnSite is the design and consultancy services it provides to its business customers. If you’re not sure your product can or should be 3D printed, Materialise OnSite can help you analyze the real costs and potential savings.

Although Materialise OnSite offers a wide range of 3D printing technologies, it offers carbon fiber nylon only in FDM. Its material is a PA-CF reinforced with chopped carbon fiber — 35% by weight. The company says this materials has a high stiffness-to-weight ratio and is well-suited for tooling, functional prototypes, and machine parts that undergo regular stress in industries like aerospace, automotive, and industrial machinery.

Carbon fiber materials:

- Nylon (PA) carbon fiber

Carbon fiber technologies:

- FDM

- SLS

Weerg

Weerg is an on-demand manufacturing company based in Venice, Italy, and make parts mostly for its European customers. Weerg has a decent library of materials, giving it the ability to print parts for a great range of applications from fast prototyping to end-use components.

Weerg offers instant quotes through its website, but it also does customized quotes for special orders, such as when you don’t have a CAD model for your part. Custom quote requests get a response within one working day. You can also ask Weerg to verify your parts’ printability during ordering. The company ships worldwide with relatively fast lead times and offers an extensive NDA contract.

The service offers nylon PA12 carbon fiber and nylon PA6 carbon fiber, as well as PEEK CF for FDM.

Carbon fiber materials:

- CF-nylon (PA) 6

- CF-nylon (PA) 12

- PEEK CF

Carbon fiber technologies:

- FDM

All You Need to Know to Order Carbon Fiber Parts

You may know carbon fiber from its use in the auto industry for lightweight race car bodies, in the marine industry for durable yacht hulls, or even in sports for helmets and golf club shafts. These products are traditionally manufactured with carbon fiber using a process that layers sheets of fiber material into a curable resin. 3D printing with carbon fiber materials has similarities and differences.

Traditional methods involve labor-intensive layup processes, molds, and autoclave curing. 3D printing simplifies the process by eliminating the need for molds and enabling direct fabrication from digital models, which can drastic reduce the cost for prototypes and small batch production.

Traditional manufacturing is better suited for large-scale production of large and not very complex shapes, whereas 3D printing is ideal for small to medium-size parts requiring complex geometries or customizations.

When order carbon fiber parts from a 3D printing service you need to be aware of the different types of carbon fiber materials on offer and the different technologies used to 3D print the parts.

First, let’s look at the materials.

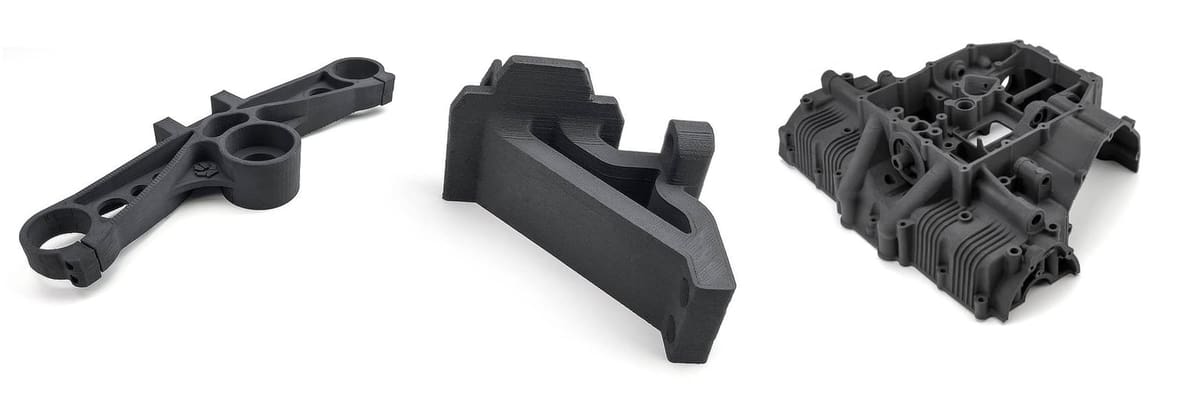

In 3D printing, carbon fiber is the additive to a base plastic. That plastic can be a standard PLA, which wouldn’t have the mechanical properties you’d need for a manufacturing tool, or the plastic could be nylon, which is already a tough material and ideal for tools. Don’t make the mistake of thinking that all carbon-fiber materials are the same. Carbon-fiber nylon, PET, PETG, PAHT, and PEEK are all good choices for durable parts.

Aside from the type of plastic the carbon fiber is in, there are three different types of carbon fiber. A material could have milled fibers in it, which are typically for aesthetic purposes. Milled fibers give plastics a matte finish and hide layer lines, which is great for prototypes that need to look just like injected molded parts.

The next type of carbon fiber is chopped. Plastics can have varying percentages, from about 10% to 35%, of chopped fibers imbedded providing various mechanical properties. These fibers, when heated during the 3D printing process, align in the direction of printing to provide strength.

The last and strongest fiber option is continuous, unbroken carbon fiber. Continuous carbon fiber (CCF), involves dual extruding nozzles where one lays down a layer of continuous carbon fiber while the other lays down a layer of another plastic material. This method creates parts that are stronger than using chopped fibers and provides a more consistent load distribution. It’s ideal for parts that don’t require carbon fiber throughout, but, instead, reinforcement in specific areas – just on the outer wall, for example.

How do you know if your parts require chopped or continuous? You could order one of each and test them or talk to the service provider about the mechanical properties your part requires.

Note that chopped fibers are the most commonly provided by 3D printing services by far, and you’d have to go out of your way to find continuous fiber 3D printing. But if this is what you need, look for a service that offers 3D printing on printers by a company called Markforged.

Just a few last tips on ordering carbon fiber parts: When you see Carbon DLS as a technology option, here Carbon refers to the name of the company, and it does not print with carbon fibers. Also, although Markforged is likely only of the only options for continuous carbon fiber 3D printing, if a company only offers Markforged Onyx as a material, this is Markforged’s chopped carbon fiber material. If you want continuous, make sure that the Onyx is being infused with continuous carbon fiber.

Carbon Fiber 3D Printing Methods

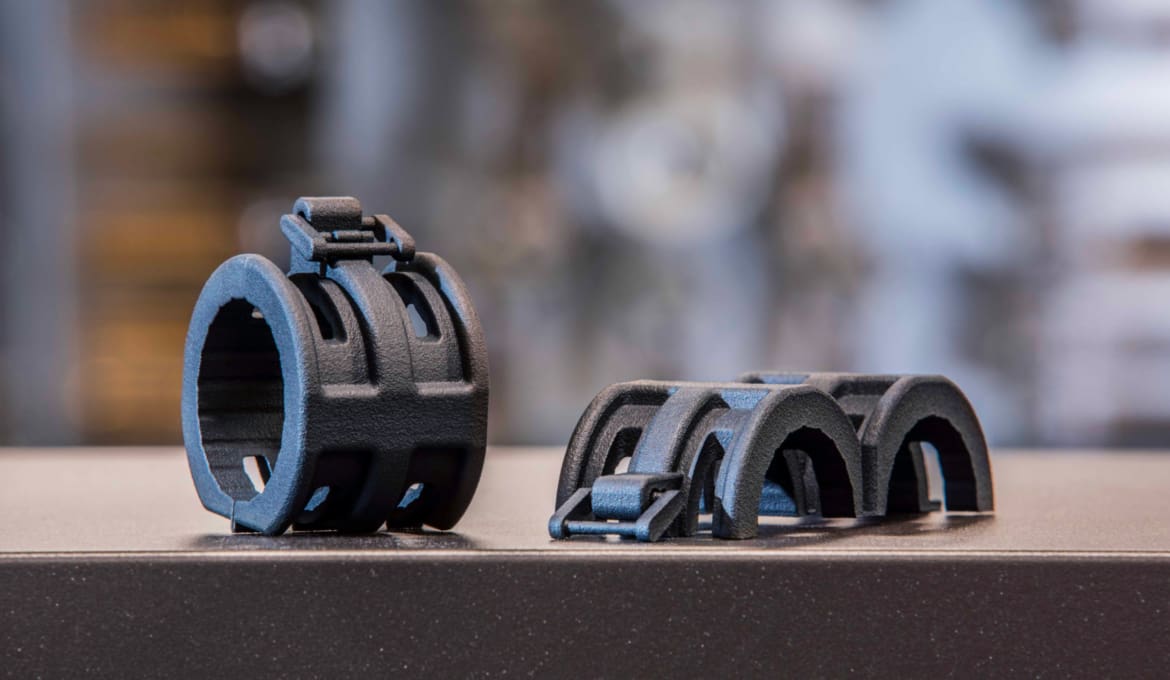

Up to now, we’ve been talking about extruding carbon-fiber-infused material using a 3D printer technology called fused deposition modeling (FDM). But there’s another 3D printing technology compatible with carbon fiber infused materials, selective laser sintering (SLS).

Prized for its ability to create engineering-grade polymer parts with excellent mechanical properties and fine resolution incredibly fast, SLS 3D printing is what engineers and industrial designers turn to for functional rapid prototypes and end-use parts.

SLS 3D printing uses high-powered lasers to fuse powdered plastic material, usually nylon, together into 3D shapes. It can create parts that are finely detailed, strong, durable, heat resistant, and flexible (when needed) all at once.

SLS also offers a high degree of predictability in material and mechanical properties, so it’s popular in aerospace, medical, and regulated industries. Furthermore, SLS printing is mostly support-free, which expands your ability to design and produce very complex geometries and cut down on post-processing time removing those supports.

Multi Jet Fusion (MJF) from machine and material HP is also a commonly used technology for jigs and fixtures, but there are no carbon-fiber materials available for MJF. Instead, MJF offers a glass-bead infused nylon 12 in addition to other nylon materials.

License: The text of "6 Carbon Fiber 3D Printing Services We Recommend" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.