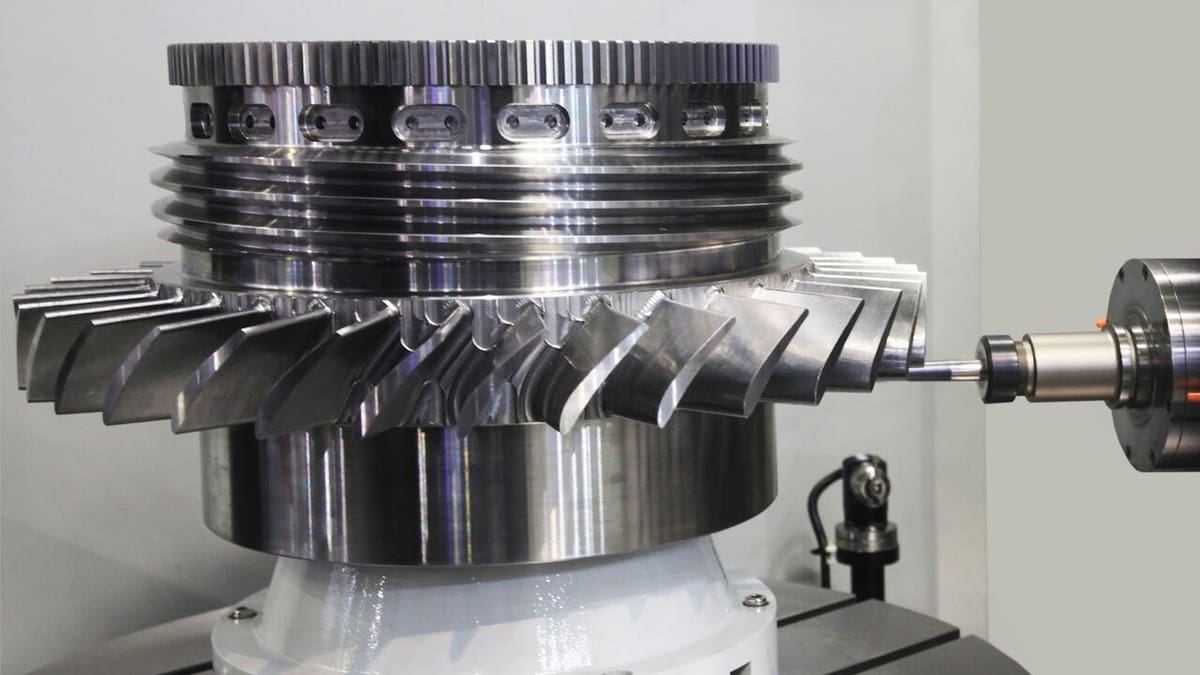

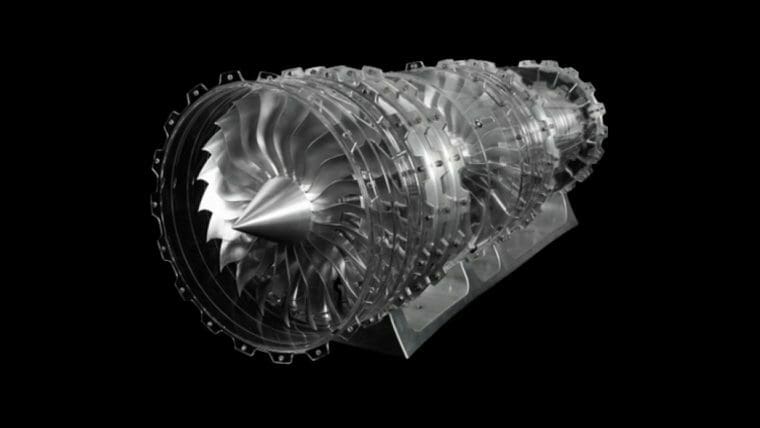

CNC machining is one of the most popular and efficient methods of subtractive manufacturing. The process is done with computerized numerical control (CNC) machines, which are operated by a machinist giving commands and setting parameters on an electronic interface.

So, what is subtractive manufacturing? In simple terms, it’s the process of removing pieces or chips from the raw material in such a way that it transforms into a desired shape. In CNC machining, this process is done with operations like turning, milling, and drilling. These are performed using machines like mills, lathes, routers, and plasma cutters.

Learning the ins and outs of subtractive manufacturing requires a high degree of training, experience, and skill. Any small mistake may cause a defective product or, at worst, health and safety hazards. In addition to the time required to learn the ropes, CNC machines are expensive. The whole setup may be a suitable investment, but because it’s a significant commitment, it may be best to leave CNC machining to the experts rather than do it yourself if you’re just getting started or aren’t looking to be hands-on on the production itself.

On the opposite side, additive manufacturing is the process of adding material layers to shape the final product, starting from zero. 3D printing is a clear example of this. Where subtractive processes can be much faster, additive ones offer the possibility of creating shapes that can’t be achieved through CNC, such as internal channels and lattice infills. Additionally, there’s almost no material waste as opposed to subtractive manufacturing, where all the removed material has to go through recycling procedures to be used again. If additive manufacturing will better suit your needs, at Craftcloud you can find a variety of manufacturers all over the world.

However, if a CNC service is what you’re looking for, below you can find the best online ones to choose from, with specific information about what they offer. But first, let’s take a look at how we narrowed down our picks.

Considerations

In picking machining shops, we took the following into consideration:

- Experience: Choosing a provider who has been in the machining industry longer will save you time and money. A company with more skill and experience will likely satisfy your needs with less hassle, even giving suggestions when they see potential problems.

- Capability: Regardless of time, capability matters a lot. Do they have the complete set of CNC machines (grinding machine, turning machine, milling machine, etc.) needed for your project? Often you will get better pricing, a quick turnaround time, and high-precision parts when you work with a provider with excellent machining capability.

- Quality control: Quality control is the litmus test of how good the quality will be. The degree of quality control should be at an acceptable or appropriate level.

- Prototype availability: A prototype or sample is an excellent way of knowing the machining capability of the CNC online service.

- Customer service: Communicating with the machining company should be very easy. They should stick to deadlines, listen to your needs, be helpful, and you should enjoy working with them.

Of course, not all of the online CNC services listed here perfectly meet all the qualities listed above, but we have carefully selected those that meet as many as possible, and all of our suggested companies have a proven track record.

Xometry

Xometry is an ISO-certified industry leader in machining services, working as a marketplace. Customers upload their CAD files to Xometry’s online Instant Quoting Engine, select the material and manufacturing process, and receive a quote in just seconds. Due to their massive partner network, Xometry will machine almost any part – the company integrates seamlessly with over 3,000 manufacturing partners in the United States, including facilities that are ITAR-qualified.

These partners support the latest CNC machining and turning process, provide remarkable finishes, and support a high level of part complexity. Xometry can also machine and inspect any 2D drawing to make sure the CNC machined parts are of the best quality.

- CNC capabilities: 3-axis, 4-axis, 5-axis, and right-angle milling, dual-spindle lathes for turning; EDM and wire EDM are available upon request; available finishes include powder coat, milled, bead blast, anodized (Type II or Type III), and custom finishes.

- Range of materials: Over 50 metal, plastic, and composite materials (aluminum, steel, acetal, ABS, garolite, etc.).

- Price quote availability: Instant quote function for registered users.

- Delivery: Depends on selected manufacturing place (i.e. the US or abroad), with Expedite, Standard, and Economy options.

eMachineShop

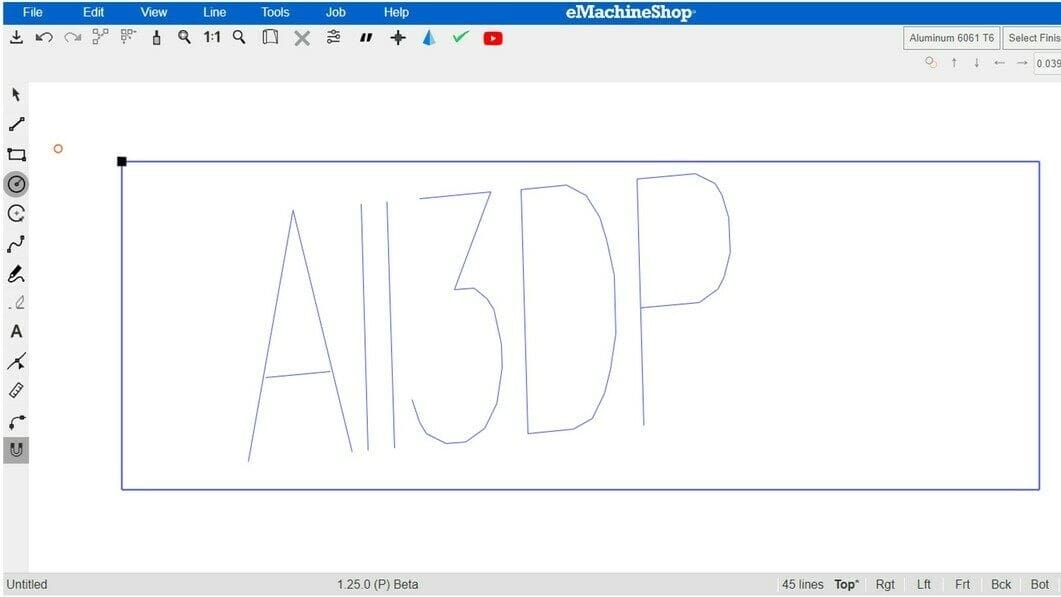

Widely recognized as the world’s first online machine shop, eMachineShop was founded with the objective of making it easy and fast to design custom parts, as well as receiving a price for them and ordering their production. They help their customers with their Resources section, which offers tutorials, CAD lessons, CAD file viewers and converters, cost reduction tips, and more.

eMachineShop offers a free CAD program that works both online and offline. This program is simple and easy to learn, as it focuses on the machining aspect of drawings and helps produce machining compatible parts. There’s an instant price quote function built-in with the program in case you’re ready to move to the next step of production after you’re done designing.

- CNC capabilities: Milling, turning, waterjet abrasion, laser cutting, wire EDM, and plasma cutting; available finishes include powder coating, anodizing, abrasive blasting, and metal brushing.

- Range of materials: Over 50 materials, including metals (aluminum, brass, titanium) and plastics (acrylic, polypropylene, PVC).

- Price quote availability: Instant quote on eMachineShop CAD; manual quote request available for CAD files (e.g. DXF, STEP, STL) or PDFs.

- Delivery: International delivery (shipping from the US); no guaranteed standard timing but the quote includes estimated delivery time.

Fictiv

Fictiv is creating an environment that enables access to fast, high-quality manufacturing, not just with the production itself, but through quality checks from on-site quality engineers. It’s ISO-certified and affords access to a network of partners to facilitate manufacturing needs.

Their technology enables instant pricing, online feedback, and automatic hole detection. This makes ordering parts much easier. Customers upload their drawings on the Fictiv website to save time communicating design intent. You can even have fun with your part designs by testing out their complexity with Fictiv’s free Complexity Quiz! Fictiv then takes care of critical features like reamed holes, bearing surfaces, and snap fits. The customer’s identity is anonymized with suppliers and the company has a dedicated customer service team to address any issues.

- CNC capabilities: 3-axis and 5-axis milling, standard and live-tooling turning, EDM, and gear hobbing; different surface finishing processes include media blasting, tumbling, and passivation (depending on material).

- Range of materials: Around 10 materials, including metals (aluminum, stainless steel, copper) and plastics (acrylic, nylon, PTFE).

- Price quote availability: Instant quote function for registered users (complex parts may be quoted in up to two hours).

- Delivery: Ships only to the US and Canada, with Fastest, Standard, and Cost-effective options.

Astro Machine Works

Pennsylvania-based Astro Machine Works is an ISO-certified company with more than 35 years of market experience. They offer a range of custom CNC machining services for various manufacturing industries, both large and small. Their machining services can cover smaller production runs, prototyping, and special blanket order arrangements.

Astro Machine Works is known for its fast turnaround times, regardless of the client’s project size and scope, as they tailor their custom CNC services to your unique manufacturing processes. This makes it easier for clients to keep up with their demanding production schedules. They operate with a regular quoting system, asking for the client’s details, contact information, and part files, and a representative contacts the customer within 24 hours to follow up, asking for further necessary details and setting up a personalized order.

- CNC capabilities: 3-axis and 5-axis milling, CAD/CAM integrated lathe machining, water jet abrasion, laser cutting, and wire EDM.

- Range of materials: No available list of materials used exclusively.

- Price quote availability: Contact a representative to get a quote within one day.

- Delivery: Information available after submitting the contact form.

Protolabs

Protolabs prides itself on having hundreds of mills and lathes in their own factory, and its CNC machining service is designed for both prototyping and low-volume production of end-use components. They can maintain consistent quality and guaranteed lead times from a single supplier with in-house part production.

To help improve manufacturability, Protolabs provides basic design guidelines. These guidelines also enhance the cosmetic appearance and reduce production time. The quoting system ProtoQuote allows for price adjustments based on aspects like materials and turnaround time. This automated quoting system accepts 3D CAD models and returns a detailed quote along with suggested design changes, if appropriate, within hours of uploading.

While the US-based facilities cater internationally, for Europe there’s a manufacturing facility in England. There’s also a Japanese manufacturing facility that caters specifically to the country.

- CNC capabilities: 3-axis and 5-axis indexed milling machines, live tooling lathe machines.

- Range of materials: More than 30 different metal (aluminum, copper, steel alloy) and plastic (ABS, nylon, PTFE) materials.

- Price quote availability: ProtoQuote for registered users, which returns a price quote within three hours.

- Delivery: Determined with price quote.

BDE INC

BDE Manufacturing Technologies is a state-of-the-art CNC machine shop that combines old-fashioned craftsmanship with the latest technology to provide innovative solutions for clients with a combination of their various CNC machines and CAD and CAM experts. The company’s mission is to remain ahead of the technology curve to become a strategic partner to its customers’ success. BDE provides quality services and is defined by precision services backed by innovative thinking.

BDE Inc has over 30 years of market experience and meets industry certifications like ISO, ASTM, ASME, ASNI, Mil-Spec, and RoHS. It serves a wide range of industries: motorsports, aerospace, energy, high-tech, medical, semiconductor, ATV, food, machine tool, electronics, and military.

- CNC capabilities: 3-axis, 4-axis, and 5-axis milling; live tooling lathes and tool room, as well as EDM precision machining.

- Range of materials: Around 15 metals (cobalt, beryllium, molybdenum).

- Price quote availability: Manual quote request available by completing a form, with no standard or guaranteed return time.

- Delivery: While mostly catering to the US, they also deliver to Canada, Singapore, The Netherlands, Sweden, and Israel, with information specified with the price quote.

Weerg

Weerg is an online manufacturing service based in Italy. They offer both 3D printing and CNC machining. They have an in-house manufacturing process, with fully automated and robotized machining capabilities. Their dedicated R&D team works to derive new and more efficient ways to improve the machining process in order to save both time and costs. A CNC design guide, which can be helpful especially for beginners, is available.

While the website offers an instant quote, Weerg assigns a technician to their customers, who checks the part files to ensure there are no mistakes with the manufacturing. The machining process itself is also overseen, and quality assurance checks are performed by the technician so that customers get the part as ordered. Weerg also launches promotional offers from time to time with discounts on certain materials.

- CNC capabilities: 5-axis milling, 5-axis live tool lathes.

- Range of materials: 17 metal (aluminum, copper, brass) and 6 plastic (polyethylene, PTFE, PEEK) materials.

- Price quote availability: Instant quote function available by providing just your email and part file.

- Delivery: Standard or Express delivery options (customs clearance times can’t be included for shipments outside of the US).

Flinchbaugh

Another US, Pennsylvania-based company, Flinchbaugh boasts versatile machines that add more value to their 4-axis capabilities. This CNC online service provider configures its equipment with Esprit, which is a trusted CAD and CAM software that optimizes its machining process together with the quote times.

With more than eight decades in the industry, Flinchbaugh has refined its processes, leading to on-time deliveries, quick turnarounds, fast communication, and minimal waste.

- CNC capabilities: Various types of milling, lathing, and turning machines.

- Range of materials: Aluminum, extrusions, stainless steel, copper, forgings, plastics, castings, and more.

- Price quote availability: Manual quote request available by filling a form, with no standard or guaranteed return time.

- Delivery: Information not available on the website (most likely available upon request).

Hubs

Hubs is an affiliate company of Protolabs’. However, it operates independently with a different business model, working as a global marketplace rather than as a manufacturing facility. They recently added a CNC machining service because they saw that the opportunity for custom, on-demand manufacturing is much bigger than 3D printing alone.

The CNC machining model is similar to their 3D printing business model: Independent CNC service providers – including ISO-certified ones – connect to a community network and receive tasks from customers through the company’s extensive network. Hubs updates prices based on material and location and also specifies turnaround times.

- CNC capabilities: 3-axis, 3+2 axis, and full 5-axis milling centers; CNC lathes and turning centers.

- Range of materials: 25 materials, including 10 metals (alloy steel, brass, mild steel) and 15 plastics (nylon, POM, PTFE).

- Price quote availability: Instant quote function.

- Delivery: Standard, Expedited, and Rapid available, although lead times depend on the chosen manufacturer.

Rapid Direct

Rapid Direct is an ISO-certified, Chinese company that is dedicated to evolving traditional manufacturing processes. They pride themselves on cutting-edge technologies such as laser and plasma cutting, 5-axis machinery, and AI software, which can deliver precision and efficiency on projects. They have successfully developed an AI-based platform that enhances the efficiency and productivity from the customer’s side.

Rapid Direct offers a comprehensive one-stop solution, be it for rapid prototyping or low or high-volume productions, with the help of their diverse manufacturing facilities. The AI helps with an instant quote function and has Design for Manufacturing (DFM) capabilities that allow it to provide the customer with suggestions regarding the design and manufacturing process.

- CNC capabilities: Milling, turning, 5-axis machining, wire EDM, die casting; surface finishes include anodizing, electroplating, bead blasting, and more.

- Range of materials: Over 15 materials, including metals (aluminum, copper, brass) and plastics (PEEK, PTFE, PVC).

- Price quote availability: Instant quote by uploading file.

- Delivery: Information available with price quote.

License: The text of "The Best Online CNC Service Providers" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.