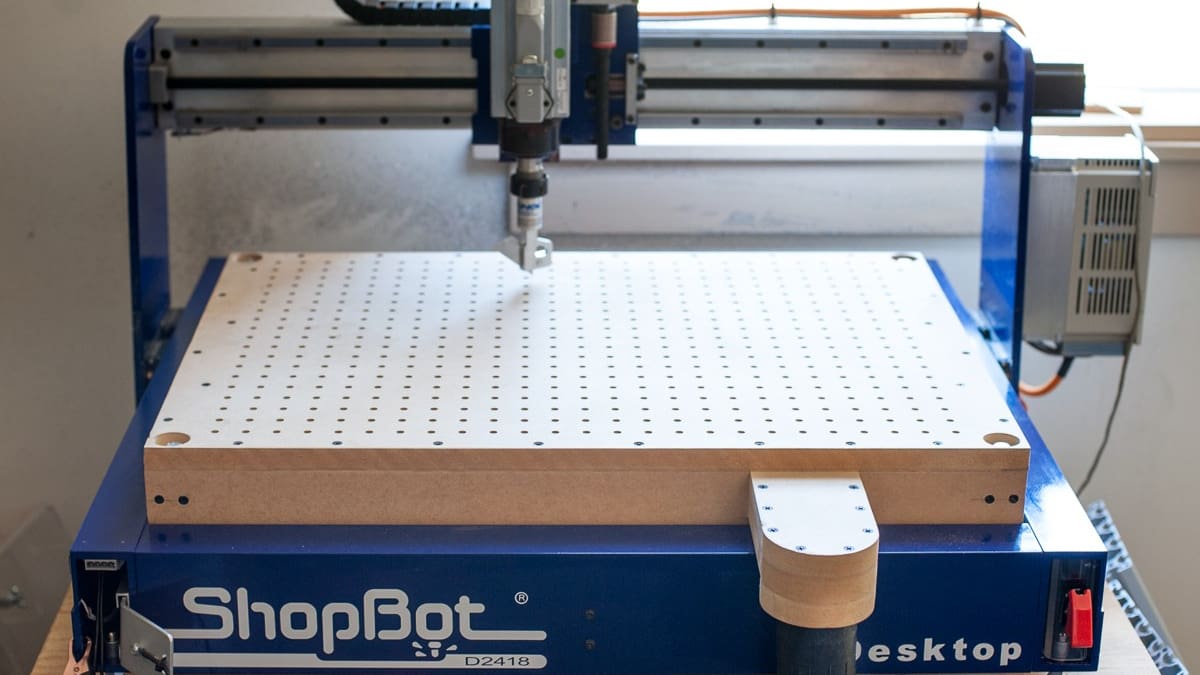

When working with a CNC router, you might consider using a vacuum table, which is a system for securing workpieces during machining. Without a vacuum table, a workpiece might be held in place with a vice, clamps, or screws. These can mark the workpiece or limit the work area by being in the way of the path that you wish to machine.

Because a vacuum table is completely underneath the workpiece, you don’t run into clearance or path issues. You’re also able to hold a variety of differently sized and shaped workpieces, something you’re limited by with other methods.

In this article, we’ll go over the practicality of using a vacuum table and several options for getting one, from buying to DIYing!

A Good Base

A typical vacuum system is comprised of a perforated tabletop with a vacuum chamber underneath the surface and a vacuum pump to keep the vacuum chamber below ambient pressure (pressure of the air around the workpiece). This creates a difference between the air pressure inside the vacuum chamber and the ambient pressure. The pressure around the workpiece tries to move in and equalize the pressure in the vacuum chamber, holding the workpiece in place.

As a general tip, the amount of holding power you have on a part will depend on its surface area. The larger the surface area of the part in contact with the table, the stronger the force holding it down. Vacuum tables are also suitable for more than just one machine, as they come in a variety of sizes, styles, and mounting types, making them quite accessible.

There are many different vacuum tables (both purchased and DIY) available to suit your CNC router. We’ve narrowed down the best options based on the following criteria:

- Compatibility: This is one of the most important factors when looking for a vacuum table for your CNC router. We omitted any solutions that are only compatible with a specific brand or product line. We looked for tables that can work with a variety of differently sized solutions for any setup – some are even modular.

- Popularity: This means that they have been thoroughly tested by numerous people and verified that they’re good solutions. With that popularity also come additional accessories and tools, provided by manufacturers or the community.

- Community support: Having an active support option or user base can make all the difference for you during installation and setup. All our selected options either have support from the manufacturer, a dedicated community, or both, ensuring there’s a place for any questions or issues you may have.

Let’s dive in!

To Purchase

Purchasing a vacuum table can be the way to go if you want a tough and ready-to-use solution for your CNC router. Most of them are available in packages or have support staff ready to help you put together a system perfect for your needs.

Because many of the purchase options are machined or cast out of aluminum, they can be quite expensive. Additionally, there’s the possibility of being locked into proprietary hardware.

When looking to purchase a vacuum table, be aware of the size constraints, both in terms of how small a part can be and whether it will fit your machine. Some sellers list the tops and bottom parts of a vacuum plate separately, so what may seem like a really good deal is actually only half of what you need.

Follow along for our list of starter kits and ready-to-buy vacuum tables!

Rockler Vacuum Clamp Pods

An unconventional design, Rockler’s solution is a collection of vacuum pods, rather than a tabletop. This makes the solution quite compact and versatile, as it’s easy to adjust for different sized workpieces and for other kinds of work. This type of vacuum clamp is a good, cheap option that’s scalable.

The pods are compatible with T-track and slotted CNC tables or screw mounts, which means that they can essentially be put anywhere. However, it’s important to consider where you are machining, because if the vacuum with one of the pods is broken, the workpiece may come loose. As a tip, wherever you place the pods, avoid machining all the way through the material blank to avoid breaking the vacuum.

Even though these are modular and you can connect many of them together, they do come with some limitations. At minimum, you need a vacuum pump that can generate 25″ of mercury (inHg) or approximately 0.85 bars, which can be used with up to four pods. If you want to use more than four pods simultaneously, you’ll need multiple pumps or a more powerful one. In terms of size, the workpiece also needs to have at least one flat face that’s at least 100 x 100 mm to get a good hold.

- Manufacturer: Rockler

- Price: ~$60 for a two pod starter kit

- Sizes: A pod is 146 x 165 x 22 mm with mount and fittings

- Mounting method: T-track, slotted CNC, or screw mounts

ClampuSystems

Most ClampuSystems vacuum tables are made from aluminum, but some may have a different core depending on their application. The vacuum tables are high quality, but for high precision and surface accuracy, customers are advised to take off approximately a mil (0.0254 mm) of the thickness from the top surface of the table. Keep in mind that, once this is done, the vacuum table can no longer be returned.

There’s a variety of sizes and styles, from the smallest at 132 x 132 mm to the largest at 1,213 x 863 mm. If you can’t find what you’re after, don’t fret! Custom sizes are also available.

For mounting, all ClampuSystems’ vacuum tables have an approximate 6 mm lip around the base to clamp them in place. In terms of product range, they vary from standard aluminum vacuum tables, tables that have multiple vacuum areas, and tables with a breathable vacuum surface for very thin or flexible materials. They also offer right-angle and precision vice vacuum tables, but these aren’t compatible with CNC routers.

- Manufacturer: ClampuSystems

- Price: ~$120 to ~$12,000

- Size: 132 x 132 mm up to 1,213 x 863 mm

- Mounting method: Clamps

CNC Step USA

For a more budget-minded option, look to CNC Step USA. Rather than being built from aluminum, the tops are made from plastic. This has a dramatic impact on cost, but also means they aren’t as robust as other options and are prone to warping.

Unlike other vacuum tables, the ones from CNC Step USA are compatible with shop vacuums, so no expensive vacuum pump is required. Obviously, you won’t be able to get the same holding power or life out of a shop vacuum, but on a budget, it’s a good way to keep costs down and use existing tools.

Another benefit of these tables is modularity: You can connect multiple tables together if you need a different size. This is easy, too! Each side of the table has vacuum connectors so you won’t have excessive tubing running everywhere. For those doing batch production, there’s an added benefit: The tables come with locating pins to easily align pieces in the same position repeatedly.

- Manufacturer: CNC Step USA

- Price: Up to $1,335

- Size: 220 x 320 mm up to 1,500 x 1,000 mm

- Mounting method: Bolts or clamps

NEMI

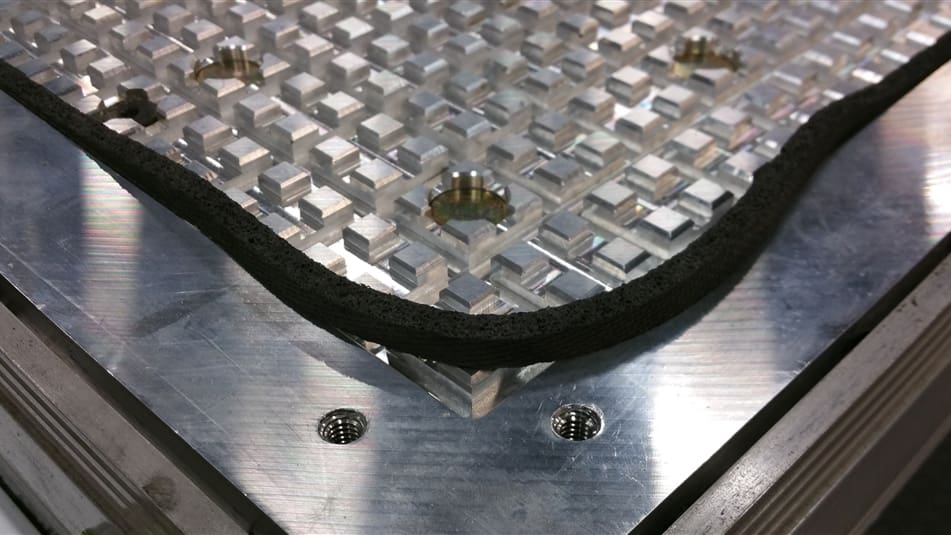

NEMI’s vacuum tables are high quality, made from cast aluminum, and then precision machined by a CNC to create the grid. Unlike other options, the grid tables and plenums (routes for the air up to the table) are separate pieces, purchased as separate units, then assembled together.

The grid fashion for how the table has been designed allows you to cordon off areas for the vacuum. For example, if you had a 500 x 500 mm table and your workpiece was 300 x 300 mm, you could block off that area so that the vacuum only worked where it needed to. This would be done by inserting a gasket in the gaps of the grid for whichever areas you’d want to block off.

If you have some strangely shaped workpieces, their pod accessories may come in handy. One of the most notable pods is their vice lineup. They’re particularly helpful for blanks that the vacuum just isn’t able to hold in place. They also raise the stock of the grid table so there’s little chance of damaging the table during operation.

- Manufacturer: NEMI

- Price: ~$400 to ~$16,000

- Size: 190 x 812 mm up to 1,828 x 5,486 mm

- Mounting method: Bolts, or clamps for larger machines

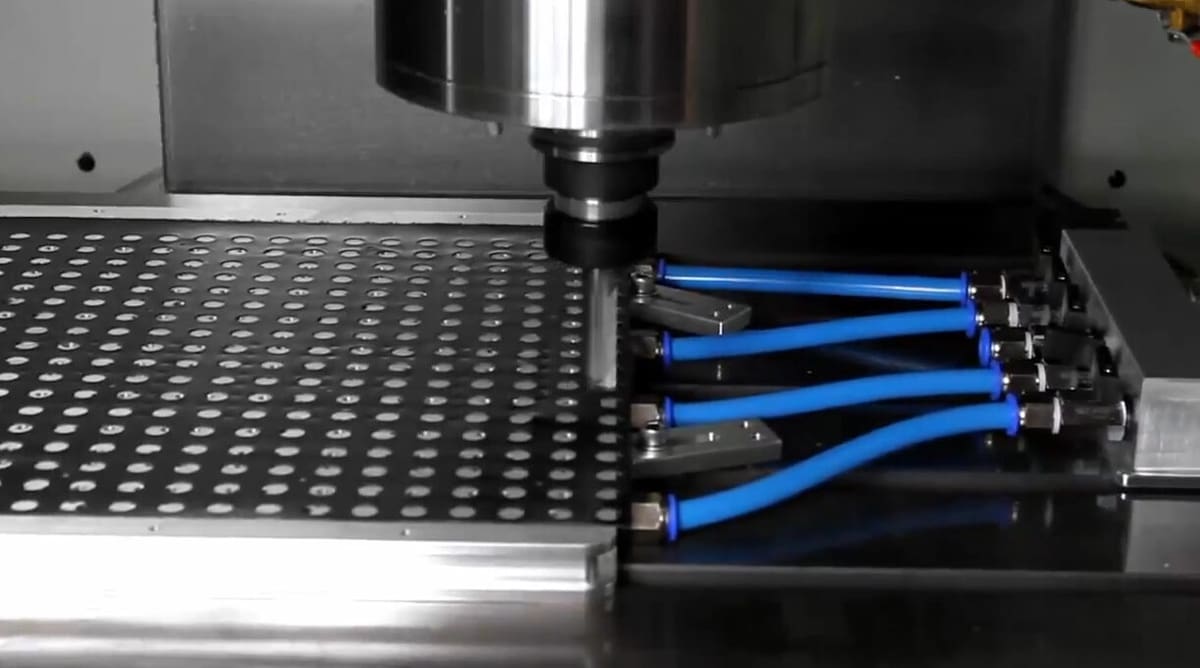

Pierson Workholding

Most vacuum tables are for advanced hobbyists or seasoned professionals who can piece together their own parts and know what they’re doing. Pierson Workholding’s vacuum tables take a more entry-level approach. If you buy one of their starter packs, it includes everything you need to get started, except for the air compressor.

Conveniently, you don’t need to worry about small particles or cutting fluid getting into the vacuum system, as the vacuum power unit has a dedicated exhaust port to flush out particulates. You can also hook up multiple vacuum power units to one table, enabling you to hold up to nine parts on one table.

Their table is mounted using a fairly simple toe clamp system that slots into the T slots on your router, making them compatible with almost any machine. If you need to machine strange geometry or a selection of parts, their top plates are perfect. They are solid plates that allow you to mill parts that might be otherwise difficult to hold down.

- Manufacturer: Pierson Workholding

- Price: ~$1,300 up to ~$2,300 for starter packs

- Size: 241 x 355 mm up to 457 x 609 mm

- Mounting method: Toe clamps

Vacuum Tables UK

Many brands sell one vacuum table designed to suit various materials in general. But if you’re looking for top performance, it may be worth looking at Vacuum Tables UK’s lineup. They offer three different tables, one for metalworking, one for wood and plastic, and the other for paper and foils. The reason they offer different options is that each material demands its own specifications for optimal hold.

While you can mill a variety of stock with these tables, you can’t use just any table to machine every material well. Materials like wood and plastic or paper and foils are more easily damaged than metal, and as such the tables are designed with that in mind. As a disclaimer, using these tables will not make your router capable of milling materials that it’s not designed for.

Similar to Pierson Workholding, rather than buying each component separately they offer kits with pretty much everything you need (apart from an air compressor). Solutions are for both DIY and hobby users, or for more professional use cases. They mention that premium kits require a compressor that can produce 45 L of clean air every minute at 5 bars of pressure. If you have that, then you’re off to the races.

- Manufacturer: Vacuum Tables UK

- Price: ~$80 up to ~$4,500

- Size: Custom designs available, starting from 200 x 120 mm

- Mounting method: T-slots

To DIY

DIY options are great if you want to stretch your money. Many of these options can be made from components that you can get at a hardware store. The downside is that they’re not as powerful or robust as the ready-made options because they aren’t made from materials like aluminum or powered by powerful vacuum pumps.

For DIY options, get in contact with people who have used designs you’re considering. They can give you a lot of insight into the strengths and pitfalls of the design and any necessary modifications. Try to avoid designs with very large vacuum chambers, which are known to be unstable. Many vacuums won’t be able to create a strong enough vacuum to hold parts down well and if you upgrade the vacuum, it may damage the table if it isn’t properly designed.

If you don’t have a lot to spend or want to challenge your CNC skills, check out our DIY picks.

Universal Hold-Down System

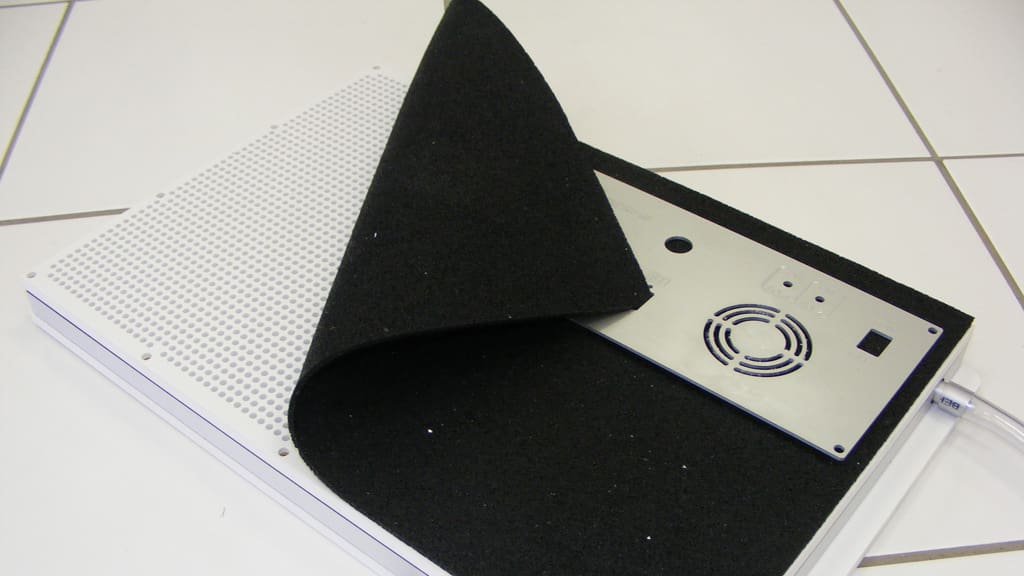

Another DIY vacuum table, this time created by Dan Spangler from Make: Magazine. The motivation behind this design was to create something that could hold down a sheet of leather and cut using a drag knife attached to the CNC, essentially turning it into a Cricut or Silhouette machine, working in the same manner as they do.

The holding strength of Dan’s solution depends on how many holes in the table are covered. Unlike other solutions, you can’t easily cordon off the table according to part size. For best results you need to cover all the holes, so that the blank material stays put.

The main issue is that this is a hollow box, so there’s a lot more air to remove compared to other solutions, which are usually two pieces held together. This solution is glued together, making it great for easily cleaning out chips, dust, or anything else that gets drawn in.

- Designer: Dan Spangler via Make: Magazine

- Price: ~$50 (materials only)

- Size: Customizable (ensure your vacuum is strong enough for the area)

- Mounting method: Screws

Clamped

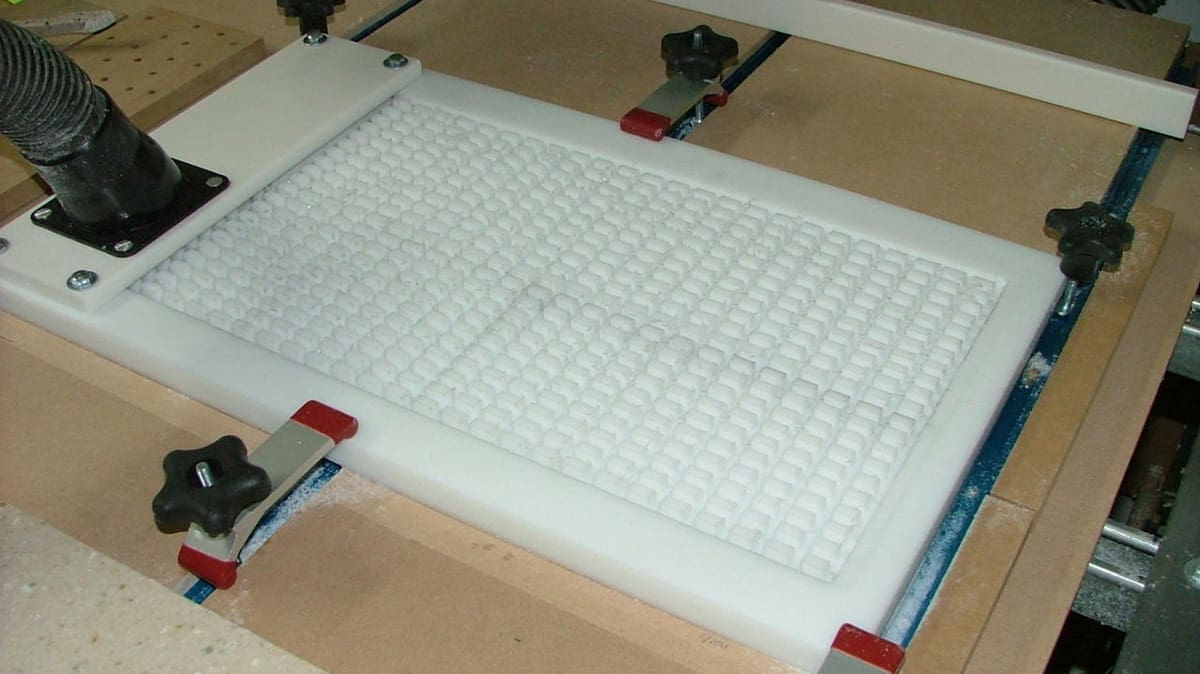

In the RC space, you’re often working with delicate components. RC Groups user tom43004 tackled this by making a vacuum table out of high-density polyethylene in such a way that parts aren’t easily damaged. It’s also cheap to make, so if it breaks not much is lost.

For easy installation, it mounts to your CNC table using clamps that slot into the T-slots. It’s not all easy though; one flaw with this design is that you can’t easily isolate areas of the table to hold your work. The recommendation is to use a piece of poster board or vinyl around the workpiece for a better hold and seal.

Unlike CNC tables, which you can’t mill yourself or would take a number of hours to complete, this design is quick and easy. The designer reports that they made theirs with less than an hour of cutting, with one completed in less than 10 minutes with a special cutting bit.

- Designer: tom43004 via RC Groups

- Price: ~$20 for small size and ~$40 for large (materials only)

- Size: 300 x 400 mm and 330 x 500 mm

- Mounting method: Clamps

Romaxx CNC

Romaxx CNC took a bit of a different route with this option. They detail, in general, how vacuum tables are made – specifically by them. With this information, you could plan out how to build your own, which is exactly what some users have done.

Regarding material, they state that it must be something dimensionally stable and that doesn’t easily flex. Metals are especially good candidates since Romaxx CNC routers are able to cut Aluminum. You could also choose HDPE, ABS, or Delrin to name a few, making the table easier to make and lighter.

Some of the aspects of the post are inapplicable, such as the table bring milled using a mill rather than a router, but the same principles apply. If you choose a plastic base, it’ll make things a lot easier, and you’ll be less prone to marking the part you’re working on.

- Designer: Romaxx CNC

- Price: ~$30 or more depending on the material (materials only)

- Size: Custom

- Mounting method: Clamps

License: The text of "The Best CNC Vacuum Tables" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.