Laser engravers and cutters are a big deal for makers: They let us engrave decorations, names for keepsakes, or serial numbers for assembly, among many other applications. Point your laser at your material, shoot it just so, and the material sublimates – that is, vaporizes instantly without turning liquid first. That’s laser engraving in a nutshell.

Hobby laser engravers fall short on one thing: engraving metal! That requires a whole lot of power and special optics, which means a high price tag that’s out of reach for many save for industry professionals.

That said, laser engravers are becoming increasingly more affordable. In this article, we’ll take a look at the technologies bringing the price tag down, what hobby metal engravers can actually do, and we’ll share some of our favorite machines.

Let’s dive in!

What Lasers Can Engrave Metal?

Most makers are familiar with CO2 and diode lasers. The former uses a CO2 tube to generate a laser beam, while the latter compresses energy from a diode into a laser beam using lenses. Neither of these technologies can generate enough power to engrave metal – marking, yes, but definitely not engraving. So, we won’t be looking at any of those machines.

That leaves fiber laser engraving and infrared laser engraving. We’ll tell you more about them below, but please note that because these technologies and machines come from an industrial background, safety features are very different from traditional CO2 laser engravers. They mostly revolve around the user wearing protective equipment, rather than built-in features like optical shields, with some exceptions.

Fiber

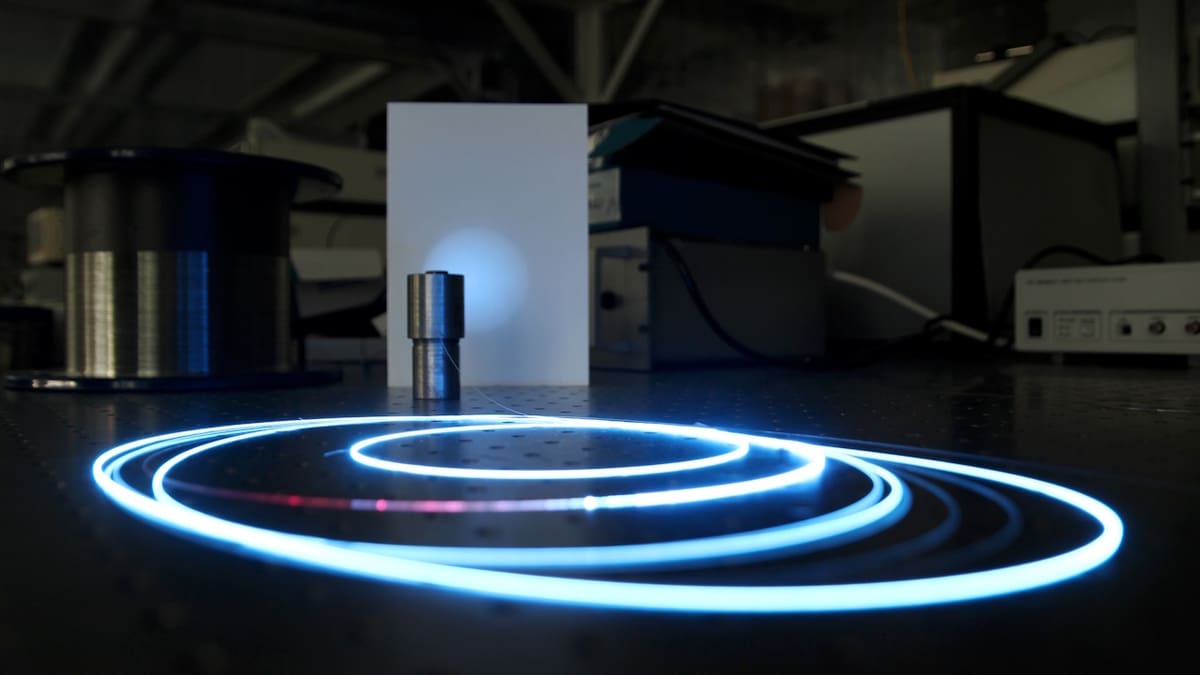

Fiber laser engravers shoot a laser beam from a laser diode through optical fiber cables coated with one or several rare-earth materials. The result? A beam that packs a lot of energy at different wavelengths, allowing it to engrave metals. Fiber engravers can also engrave stone, ceramics, and other hard materials thanks to the combined properties of rare-earth materials. But their engineering makes them big and expensive.

Infrared

Infrared laser engravers also use laser diodes as a source but use mirrors to transport the laser beam. It’s less expensive and more convenient, leading to machines three to four times smaller than fiber engravers. The price to pay: a loss in power and less versatility in metals due to the absence of an optic fiber coated with rare-earth materials, which lock the properties of the laser beam to a specific wavelength.

Considerations

Whenever one considers purchasing equipment – especially something as expensive as a fiber laser engraver! – it’s important to shop around, compare machines with each other, consider their abilities as well as how they fit in one’s workshop. Here’s how we approached this guide:

- Price: Hobby-grade machines are more affordable than their industrial cousins but can still range from $1,500 to several thousand dollars. Sales can help to put a significant dent in the price tag, however. Along with the price of the machine, it’s important to consider whether they’re compatible with existing equipment to help you save some money? Will you need to buy new software licenses, or is one included for free?

- Features and user experience: We picked machines that are relatively close in power, examined what they let you do, and how easy it is to do it. For example, do you have to prepare materials and position them by hand? Are there any automated features to make engraving easier and faster?

- Reliability and customer support: Will the laser be your new workhorse or need extra accessories out of the gate? If you run into problems, will you it be easy to find help with customer support – or will you have to rely only the community of users?

Hobby-grade machines that can engrave metal are relatively recent and expensive. User feedback from the usual sources – Amazon, Reddit and other social media platforms – can be rare. To make up for that, we cross-referenced all of the above plus customer reviews on vendor websites to get an accurate portrait of each machine.

At a Glance

Atomstack MR20 Module

Our first entry is a little different from other engravers in this selection. The Atomstack MR20 module is much more affordable because it’s not a whole engraver. Instead, you’re buying only the cutting head and laser beam generator to mount on a compatible Atomstack laser engraver you already own. According to company, the module can be mounted on all Atomstack frames.

There are advantages to this approach, namely several thousands dollars in savings and a larger work area than most fiber engravers, which usually use what is called a “galvo system” to aim the laser beam at the target with mirrors instead of moving a cutting head around. You’re also saving space using one machine for several applications, and you can just reuse software you’re already familiar with (like Lightburn).

This creative take on fiber lasers comes with compromises, though: slower speeds for starters as well as different safety measures from regular fiber engravers. Definitely consider investing in appropriate protective glasses or a shield for your engraver frame!

Users needing help will be able to put in tickets with Atomstack customer service or turn to dedicated official and fan communities on Facebook. While there is a dedicated Reddit community as well, it’s relatively small. The larger Laser Engraving subreddit may be a better bet.

- Laser type: 20W fiber

- Price: ~$1,600, although sales may bring down the price

xTool F1

Our next selection is a relatively recent kind of laser system. The xTool F1 packs both an infrared-and-diode laser generator. It can engrave metals with the infrared system and traditional materials like wood, paper, or acrylic with the diode system. Best of both worlds!

Thanks to its infrared system, the F1’s form factor takes less space than traditional fiber engravers, and there are no cables. It uses a galvo system for faster engravings over a 179 mm x 179 mm surface and can be set up on any stable surface – or even held at 90 degrees! Its framing system with a blue LED makes up for the lack of autofocus. It also runs both on xTool’s very powerful Creative Space software and Lightburn.

The F1 has some trade-offs, though. It’s less powerful than regular fiber engravers, so you’ll need a several passes to get similar engraving depths. Make sure to secure objects and materials so they don’t shift between passes. As for the 10W diode laser beam, it might be too weak to cut wood or plastic thicker than 3 mm but will perform well for engraving.

For a step-up in power, speed, and features, consider the xTool F1 Ultra. This fiber-and-diode hybrid engraver features all of the above plus 20W of power for both laser systems, a larger work area, autofocus, and an optional conveyor belt module. Everything you need to turn it into a small desktop factory. Of course, all of this comes with a steeper price tag: between $3,700 and $4,800.

One last warning about hybrid systems: If one engraving system is down, you might be able to use the other, but the whole machine will eventually need servicing.

Users needing help will find dedicated support on the xTool website with phone and email options. Official and community Facebook groups exist for support as well. Although an official xTool subreddit exists, you might prefer the Laser Engraving community due to its size.

- Laser type: Hybrid 10W diode and 2W infrared

- Price: Starting at about $2,000, although sales may bring down the price

OMTech Galvo Compact 20

Those of you with a hobby CO2 laser engraver will recognize OMTech. The Galvo Compact 20 is their entry model into the world of fiber laser engravers. It attempts to make fiber engravers as compact as possible with as many systems as possible inside the chassis – similar to their Polar line of CO2 laser engravers.

You can instantly see the pros of this approach. There’s no need for outside optic fiber cables. A self-contained laser beam generator makes this machine extremely portable compared to other fiber laser devices. It’s also compatible with Lightburn, as is traditional with OMTech machines.

There is a trade-off, of course. The compact size of the machine also means a smaller 110 mm x 110 mm work surface. In addition, all the systems combined in one chassis might make it more difficult to maintain or service.

With that said, the Compact 20 still manages to offer an optional rotary tool to fit that small space. Finally, compact OMTech machines often focus on the bare necessities; additional accessories might be needed to make the most of this engraver. All in all customers seem to love this engraver as seen in the 4+ star reviews on the manufacturer’s website.

Customer support is available over phone, email, or chat. There are also large communities of OMTech users on Facebook and Reddit for peer-to-peer support. For Reddit, once again, turn to the larger Laser Engraving group for help.

- Laser type: 20W fiber

- Price: Starting at around $2,200, although sales may bring down the price

Cloudray LiteMarker 60W

We have one extra pick for you: an industry-grade machine for extra-committed power users. The LiteMarker Pro 60W is a fiber laser engraver with a 200 mm x 200 mm engraving area and the speeds you can expect from a galvo system. And it even comes with a rotary engraver.

The LiteMarker Pro is user friendly, thanks to Lightburn compatibility and plenty of training materials on Cloudray’s YouTube channel. It has 205 5-star reviews on the vendor’s website, and users have been raving Cloudray’s customer service as far back as four years ago – a must in that price range.

Like all machines, there are cons to the pros: The LiteMarker 60W is absolutely not movable and is entirely focused on production. As usual with fiber engravers, safety is entirely on the user, so wear protective specs and work in an isolated space as needed.

Customer support is available through the Cloudray website, along with a community support forum. Both official and grassroot Facebook groups exist. As always, Reddit’s Laser Engraving community group is preferred due to its size and activity.

- Laser type: 60W fiber

- Price: Starting at ~$7,600, although sales may bring down the price

Material Considerations

In closing, we want to look briefly at some of the maker world’s favorite metals to play with.

Steel and aluminum make the top of the list because they’re used in most tech gadgets and everyday-carry items. It’s also relatively inexpensive compared to precious metals. This opens the door to customizing tablets, laptops, dog tags, or knives – some of the most popular examples of laser engraving customization to this day.

Brass and copper are next. Their relative softness makes them easy to engrave at lower power settings, they’re easy to find, and customized jewelry and plaques are very popular engraving applications. Engraved brass and copper can make almost anything look instantly unique, thanks to all they’re associated with it. Think pirates, treasures, or dark academia libraries!

There are plenty other options out there aside from these four materials. Silver or coated metals are a great example, but they all come with their own challenges, such as ease of engraving or exposing raw metal to the environment. Consider this as you explore the possibilities.

License: The text of "Laser Engravers for Metal: 4 Machines That Actually Work" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.