There are many reasons to 3D print with polypropylene — its chemical and moisture resistance, light weight, excellent durability and toughness — and just as many reasons to leave it to professionals at a 3D printing service. This material is notoriously tricky to print. It exhibits poor bed adhesion, high propensity for warping, significant shrinkage during cooling, and tendency to string and ooze. Plus, it’s difficult to apply finishing, like sanding.

Polypropylene (PP) requires expertise and 3D printers tuned to its finicky nature.

This is why so many turn to 3D printing services when they need PP parts, especially engineers looking to prototype using the same end-use material that the product will be injection molded in, for more accurate testing. Polypropylene can be 3D printed using several technologies, including economical FDM and more robust SLS and MJF, yet each has its own advantages and limitations.

If you need PP prototypes or final parts with the characteristics only PP can provide, we sought out the top services that can deliver parts economically and fast. If you want to know more about PP to ensure it’s the right materials for your project, skip to the end where we dive deeper into its properties.

To ensure that out picks for the top services provide you with as much value as possible, we’ve taken the following into consideration:

- Wide variety of available finishes

- Easy and modern user experience

- Best price for the best quality

And now, check out the list!

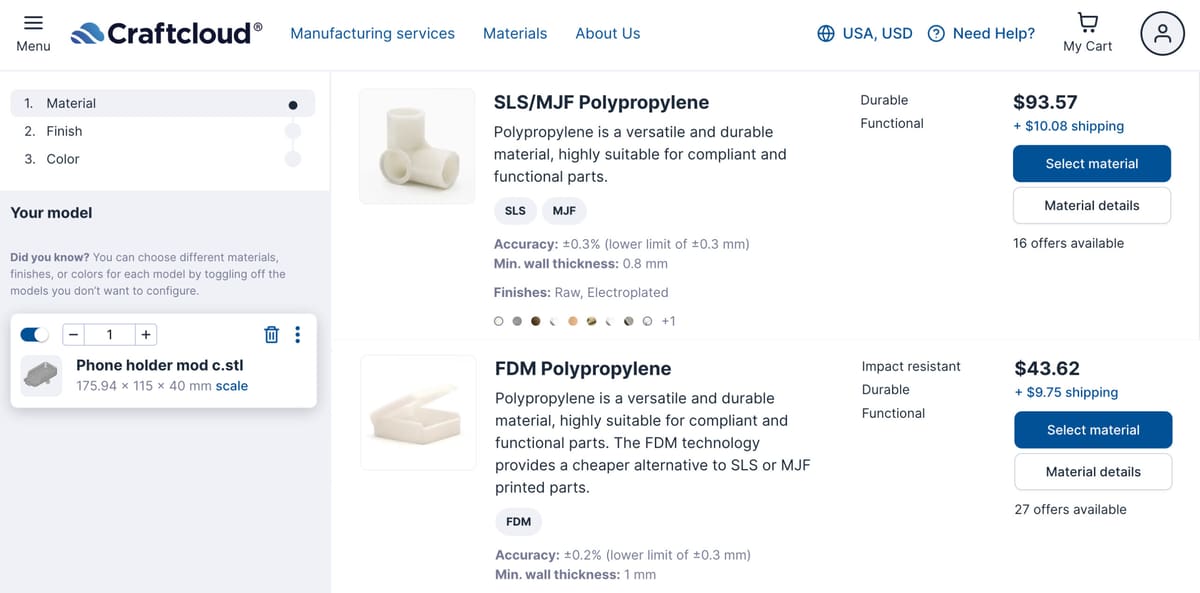

Craftcloud

Craftcloud is more than just a 3D printing service. It enables you to compare prices and services from different manufacturers and find the right offer at the right price. Instant quotes are generated based on your model(s) and location.

This service offers polypropylene part production in SLS, MJF, and FDM in a range of colors, including black, where as most other services only offer white or natural. When it comes to finishing options you can leave the part “raw” or choose sanded or even electroplated.

Craftcloud’s user interface is simple and intuitive, and there support staff to help you no matter which Craftcloud partner you select.

- Available finish: Sanded, electroplated

- User experience: Very user friendly

- Pricing: Very competitive

- Paying methods: Credit card, PayPal, Bank/Wire Transfer and others

- Shipping: Worldwide shipping available

Protolabs

Protolabs is a firm dedicated to providing manufacturing services like CNC machining, injection molding, and 3D printing. They offer multiple 3D printing technologies, including SLS for 3D printing polypropylene.

There’s an instant quote generator that’s easy to use, but you’ll need to create an account first. Once you put in your order, you’ll notice a high price if you only wish to have a single model made.

In case you’re ordering a bigger batch of products, say more than 10, prices immediately start to drop. It’s a normal situation, though, as manufacturing costs decrease the more copies of a part you produce.

- Available finish: Natural (off-white)

- User experience: You have to register before using the live quote generator; ordering is fairly straightforward

- Pricing: High when ordering only a few parts, but competitive when ordering large batches

- Paying methods: Credit card

- Shipping: Worldwide

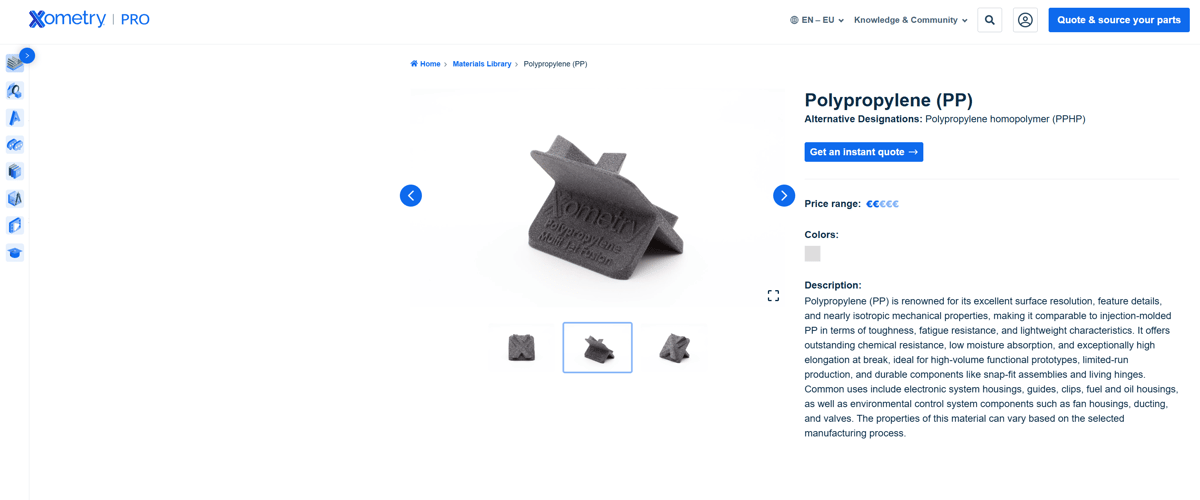

Xometry

Xometry his another provider that relies on a nationwide network of manufacturing partners. It offers instant quotes that can be filtered by production method, material, and lead time.

Registration is mandatory if you want to use Xometry. Though it may be a bit overwhelming for regular consumers ordering a print, for business clients, Xometry’s features leave nothing to be desired. We think their Instant Quoting Engine is clearly geared towards industrial clients. It comes with a printability check and various part certifications. We found the order process to be straightforward.

- Available finish: Standard, dyed black, or custom (painted, plated, or additionally sanded)

- User experience: The live quote generator makes it easy to order parts online

- Pricing: Minimum order value of €30 (not including shipping)

- Paying methods: Credit card, PayPal, bank transfer and others

- Shipping: Yes

Stratasys Direct

Stratasys is one of the largest 3D printer manufacturers in the world so it makes sense that they would also offer contract additive manufacturing, which they call Stratasys Direct.

Its website offers mountains of resources on additive manufacturing, including case studies, design guidelines, an interactive material wizard to help you select the right plastics or metals for your application, and a “contact an engineer” button for more in-depth help.

The company has seven manufacturing locations throughout the US and one in China, in addition to a global manufacturing network with partners in Europe, Asia, South America, and the Middle East.

In our experience, there was no instant quote option, since every material has a “requires a manual quote” tag on it, yet they did get back to us via email promptly.

- Available finishes: Natural Grey/Standard Black dye finish

- User experience: Requires a login and the quote generator isn’t instant

- Pricing: No minimum order required

- Paying methods: Credit card or purchase order

- Shipping: Yes

Materialise OnSite

Materialise OnSite is an online 3D printing service, offering a very wide range of technologies and materials.

As you’d expect, polypropylene 3D printing is available by laser sintering. Parts have a sandy look (because of the sintering) and are available only in a translucent, off-white color. However, the smallest details on your parts can be perfectly manufactured.

The order process is simple: Upload a 3D model to their instant quote generator and select the material and finish. The minimum order value is €50, and shipping is an additional cost. Customers can pay with credit cards or via PayPal.

The main downside to using this service is the minimum order value; it’s not the most cost-effective if you need a smaller part to be 3D printed in PP.

- Available finish: Natural (off-white)

- User experience: The live quote generator makes it fast and easy to order parts

- Pricing: Minimum order value of €50 (not including shipping)

- Paying methods: Credit card or PayPal

- Shipping: Worldwide

Bonus: PPprint

We’re throwing in this rapidly growing German company because PPprint GmbH specializes in printing with only polypropylene. Because they focus on only one material, including producing their own polypropylene filament, and you can be assured that your print will be in good hands. Add to that great customer service, technical support, and individual training and workshops, and you’ve got a company that you can trust to get you the best print possible made in its own 3D printer factory.

Unfortunately, the company doesn’t offer a quick and easy online instant quote option. You need to send them a request and their service team will get back to you. But they do offer design services for creating an STL file or scan an object for printing, as well as providing rapid prototyping, one-off, and small series prints.

Why 3D Print With Polypropylene?

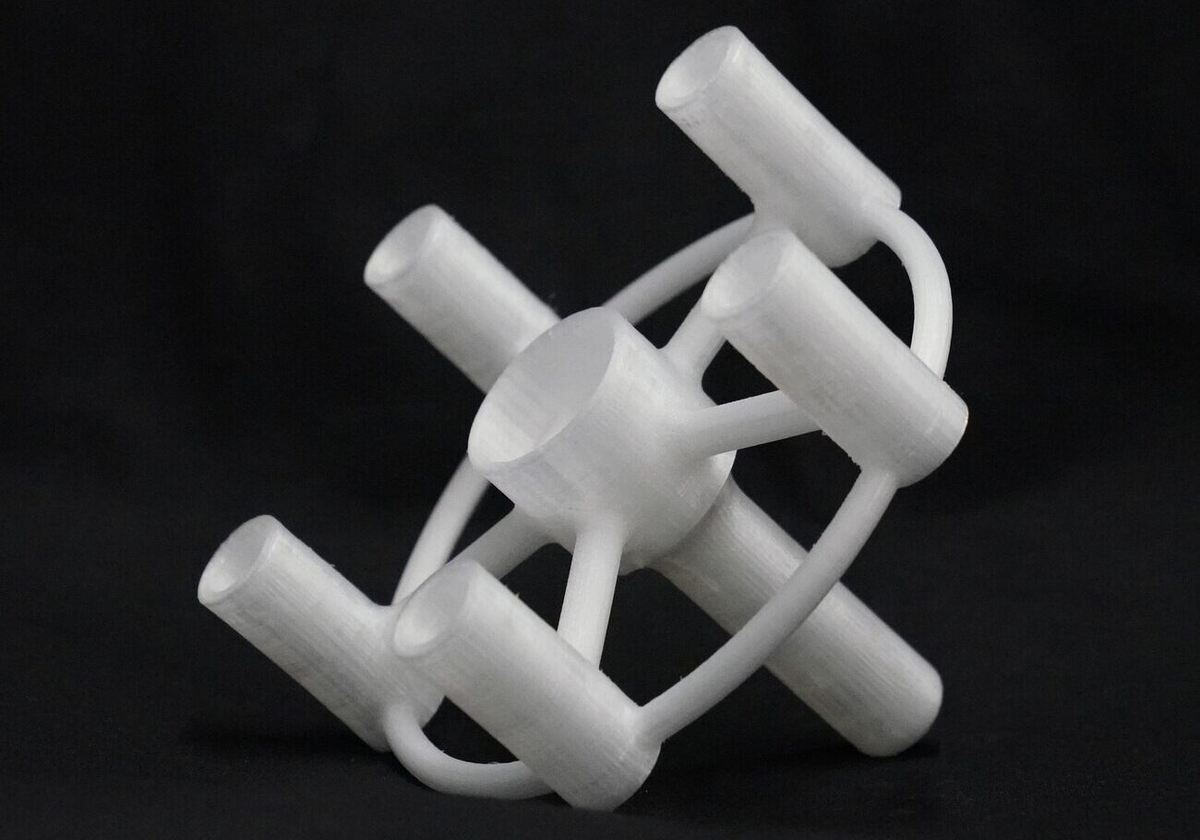

Polypropylene (PP) is a thermoplastic with a semi-crystalline structure that’s used for mass-producing products ranging from toys to utensils to medical equipment. Although not necessarily a household name, it’s the second most commonly used plastic in the world.

What enables it to be used in so many different applications is its useful properties:

- Fatigue resistance: This property is the reason why your shampoo lid is made from polypropylene. It retains its shape after being bent or subjected to torsion. This makes it suitable for living hinges which are usually not achievable with more familiar 3D printing materials like PLA, ABS, or nylon.

- Heat resistance: Compared to other plastics in the market, polypropylene’s high melting point makes it an excellent option for laboratory and food appliances (containers, kitchen utensils) where high temperatures are required.

- Impressive tensile strength: Polypropylene is known for its excellent strength-to-weight ratio, making it a strong yet lightweight material.

- Lightness: Polypropylene has a low density and therefore is lower in weight compared to other plastics.

- Impermeability: Polypropylene is highly impermeable. This property is essential for total immersion applications in medical and industrial products.

- Food safety: According to the Food and Drug Administration, polypropylene is generally considered safe for food and human contact and does not include the controversial additive Bisphenol A (BPA). (However, depending on the mixture used, current research suggests that endocrine-disrupting chemicals found in the plastic could still be at risk of leaching into foods and drinks under certain conditions.)

- Smooth surface finish: Printing with polypropylene results in a smooth surface finish, which cuts down on post-processing.

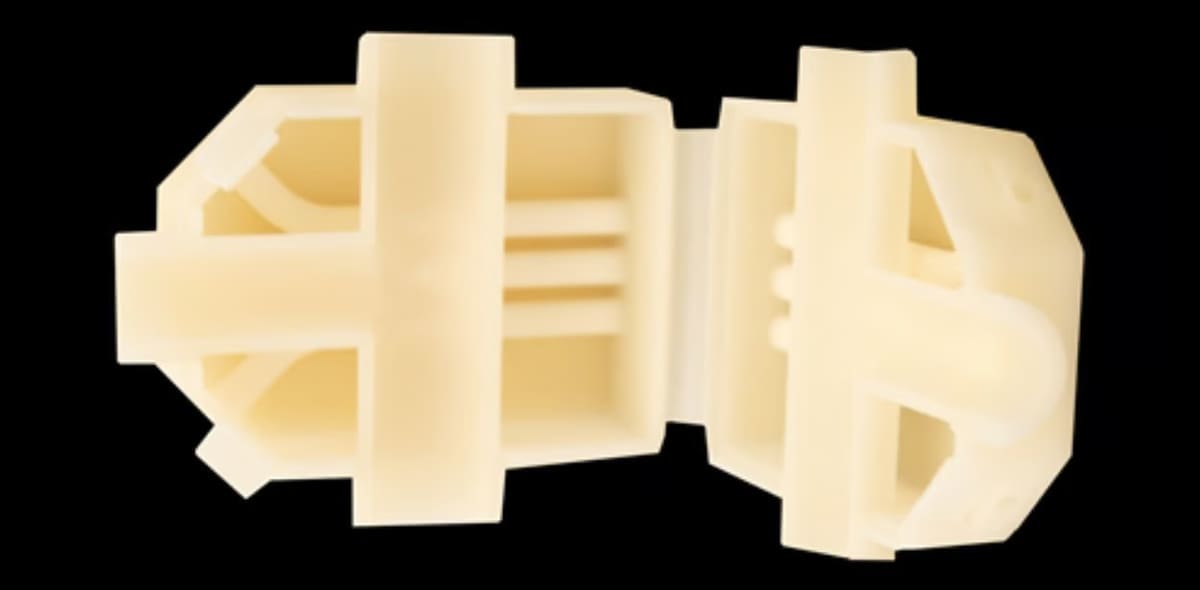

Printing with PP

When you 3D print PP it retains all of its sought-after properties and is great for anything that needs to be light, water-tight, durable, and a bit flexible. Hinges, for example, represent a very popular use, since PP can repeatedly bend without breaking. However, when you consider how to 3D print polypropylene, challenges easily arise, especially bed adhesion and warping. If you’re using polypropylene FDM filaments you’ll also ideally want an enclosed 3D printer for the heated bed chamber.

The good news is that 3D printed polypropylene has very similar characteristics as when it’s injection molded. At the same time, polypropylene can be 3D printed on both FDM and SLS machines. There are tons of 3D printing services out there offering materials like PLA, ABS, PETG, and other common plastics, but PP is rare to find. Once you do find PP as an available material that a 3D printing service offers, you’ll notice they typically use SLS technology. The main reason is that those who need PP parts are usually professionals who want the best possible quality, which is achieved via SLS. (FDM can’t quite compete with the level of precision.)

Using a 3D printing service takes out the work and hassle of printing with PP. But which one should you go for? Read on to see how we decided and what our top picks are.

Lead image source: UptimeFab

License: The text of "5 Polypropylene (PP) 3D Printing Services We Recommend" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.