Whether you need to print a toy model for your kids or a heart valve model for your patients, ordering from a 3D printing service company is the fastest and most affordable way to get custom-made objects. All you need is a digital model and a little bit of knowledge on the different types of 3D printing.

Resin 3D, which is a broad category of several technologies, offers finely detailed parts of practically any size. Prints can have realistic surface texture and true-to-life colors. You would choose resin 3D printing over other technologies when the look and finish of your part is more important than the strength or durability, generally speaking.

In other words, it’s for a model, not a tool – with some notable exceptions when it comes to industrial resin 3D printers, which we cover below.

Today’s wide range of 3D printing services can guide you through the options and materials available, but some may leave you on your own to figure out the best option. Whether your project involves one unique gift for a friend, several jewelry molds, or hundreds, even thousands, of parts for your business, we’ve collected and reviewed the top resin 3D printing services providing a range of material and technology options to help you choose the best one.

If you don’t know DLP from PolyJet, skip down to the end section where we detail each resin technology and what they’re used for.

We personally put each of the following 3D printing services to the test to explore their user interface, customer service, available materials, and cost effectiveness for 3D printing in various resins.

5 Services Put to the Test

Printing Project 1: Sculptural Object

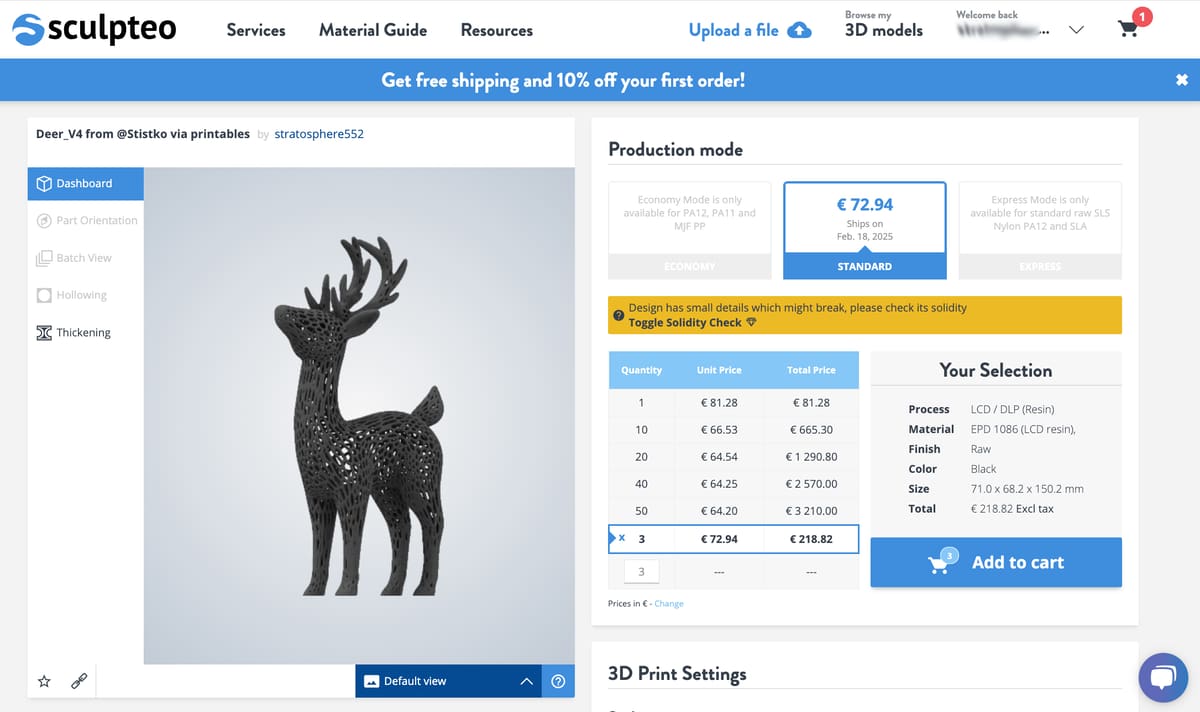

Using a detailed figurine of a deer, we tested the online quoting services of six companies to compare their offers for resin 3D printing using vat polymerization technologies, including SLA, DLP, and LCD. Not every company offers all three, but we selected the most affordable resin options for each one.

For a detailed figurine or display model like this, resin should be the material of choice due to its smooth surface (without the need for much post-processing), as it can be easily painted or stand alone. Industrial resin isn’t necessary for a display model, since although standard resins can be brittle, the finished product is not meant to be handled excessively. Some providers, however only offered industrial resin, which explains the wide range of prices.

Most Affordable: Craftcloud was by far the cheapest and easiest option for obtaining standard resin prints using SLA, DLP, and LCD technologies.

*Xometry, although advertising that it offers SLA printed resins, were not able to fulfill our special request for this project submitted via a manual quote request. SLA is currently not available through its instant quote system.

**Although Purple Porcupine does not currently offer DLP or LCD printing, it included within our custom quote an offer for standard resins printed with PolyJet at a slightly cheaper price.

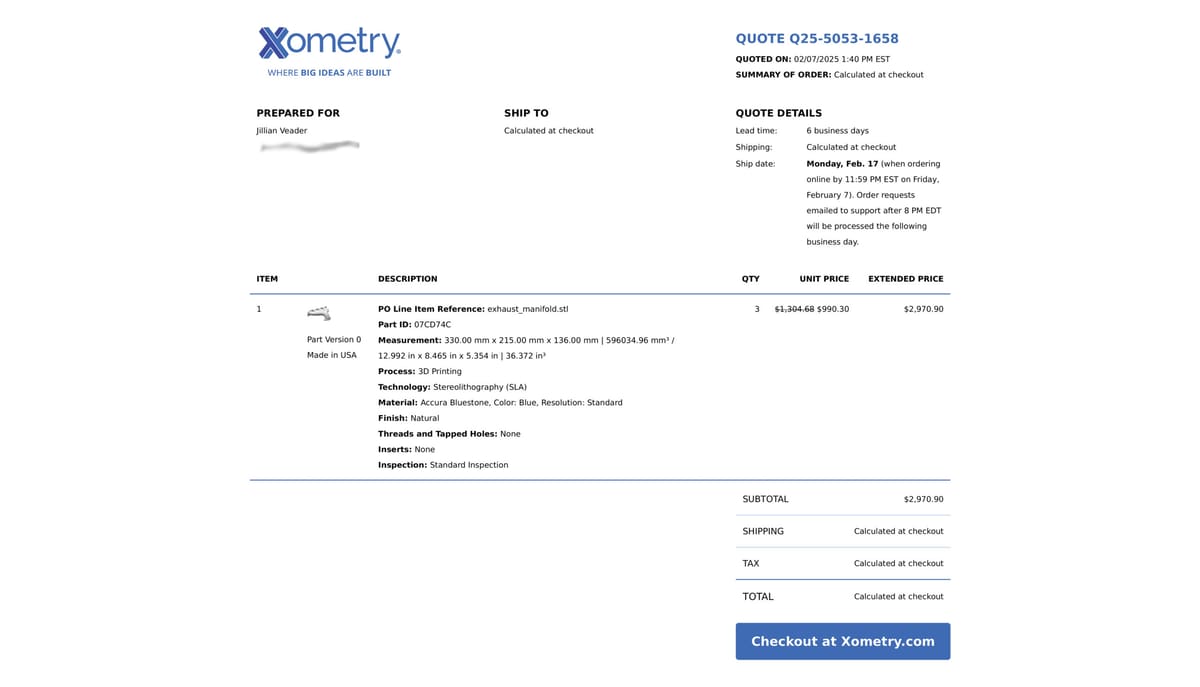

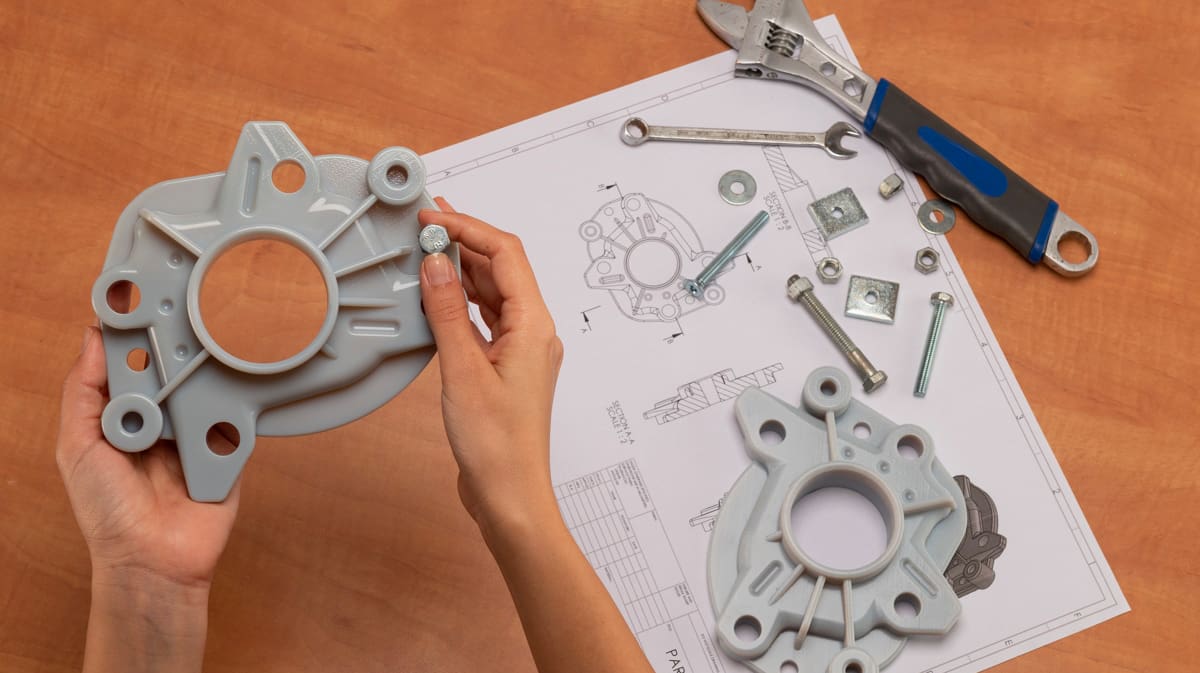

Printing Project 2: Exhaust Manifold

For this prototype, we searched for the most durable, industrial-quality resin available from each company. A part like this could be used as a model to make a mold for injection molding, or it can be used as a prototype for testing the fit and placement of a final product, which may eventually be made out of metal.

If you want a part that looks professional or like it was injection molded — without layer lines — a robust resin is a top choice.

The most affordable option available is from Craftcloud which would be printed in Stratasys Somos Taurus robust resin.

Since Sculpteo only offers prototyping resin in SLA, we opted for LCD printing, in which it offers EPD 1086.

Quick Quote Summary

- For cost-effectiveness over lead times, Craftcloud is the best choice.

- For the widest choice of resin materials, Craftcloud also came out on top.

- If you’re looking for attentive customer service and advice from engineers, turn to Purple Porcupine (U.S. only).

- If you’re based in Europe, check out RapidObject.

Craftcloud

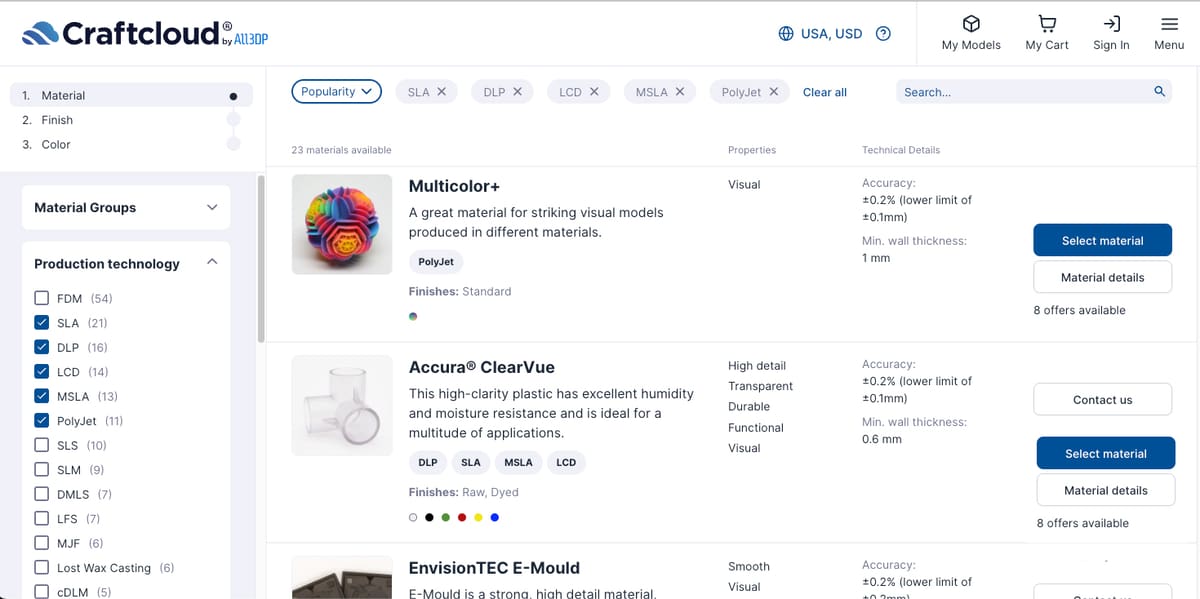

Craftcloud is a user-friendly platform that enables you to compare prices and lead times from manufacturers around the world. Because it partners with more than 150 top manufactures across the globe, Craftcloud often has the widest variety of materials and technologies at dirt cheap prices.

To obtain an instant quote, all you have to do is upload your CAD model, select the resin technology, material, and finish you need, and browse through the list to find a quote that works for you. All quotes are generated within seconds, with no sign-up required.

For resin parts, Craftcloud lists an extensive library of materials. The options include everything from standard, tough, and high-detail resins for display pieces and prototypes to transparent and elastic resins, castable resins for jewelry and metal casting, and even medical, surgical, and Carbon DLS resins.

The service works for both one-off prints, such as gifts or prototype samples, and small batches of fully functional industrial-grade parts. Craftcloud also has an extensive library of material and support documentation to help you choose the right service provider, which are all customer rated.

- Maximum build volume: 2,100 x 700 x 800 mm

- Available technologies: SLA, DLP, MSLA/LCD, PolyJet, Carbon DLS

- Detail level: 32 microns (PolyJet), 100 microns (SLA)

- Materials: 20+ options, including tough, transparent, castable, elastic, biomedical, and carbon resins

- Turnaround: Varies by the supplier

Xometry

Xometry operates a global network of suppliers for both additive and traditional manufacturing. When it comes to resin printing, Xometry advertises three different resin 3D printing technologies, including SLA, Carbon DLS, and PolyJet. It also offers wide material libraries for each technology. SLA leads the way with 17 materials, but DLS and PolyJet also have many options to choose from.

Like all the services we explored for this article, Xometry offers instant online quotes, with just an email address required to sign up. Depending on the CAD model you upload, your print may trigger a manual quote, as was the case with one of our figures below. Unfortunately, we received a message from Xometry that their team was not able to offer any custom material or finish requests at the time. This isn’t much of a surprise since Xometry is aimed at volume manufacturing and not so much the three figurine models we wanted in standard resin. We did get a quote for our automotive manifold model, which is more Xometry’s focus.

Xometry has it’s own facilities in the US and production partners in multiple countries. Most orders are eligible for free two-day shipping or ground shipping, and expedited next-day delivery is also available.

- Available technologies: SLA, Carbon DLS, PolyJet

- Maximum build volume: 736 x 635 x 533 mm

- Detail level: 100 microns (SLA); 120 microns (DLS); 45 microns (PolyJet)

- Materials: 17 SLA resins; 7 DLS resins; 4 PolyJet resins

- Turnaround: From 2 business days

Protolabs

Protolabs launched its 3D printing business in 2014 and has continued to expand. In 2021, for example, it acquired Hubs, now known as Protolabs Network. Today, the company operates 12 manufacturing centers in the U.S., Europe, and Japan in addition to a network of manufacturing partners.

We turned to Protolabs Network to test its resin printing capabilities. Currently, only SLA printing is offered for resin, but a variety of resin materials are offered, including standard, clear, tough, rigid, pro, flexible, high-temp, and durable resin. Most of these resins are available in black, gray, or white.

Protolabs offers one of the highest detail levels, making the surface a great choice for intricate, high-accuracy prototypes. Multiple surfacing options are available for resin prints and Protolabs maintains a sizeable collection of design guides for 3D printed parts. Using SLA, it can produce large-format resin parts. However, the size comes at the cost of detail quality.

Unlike many other companies on this list, Protolabs doesn’t offer separate design services. It is, however, able to produce highly detailed parts very fast, which makes it a good prototyping partner. A huge plus when it comes to Protolabs Network is its options for expedited lead times as short as two days, and expedited shipping as short as one day, at an additional cost.

- Available technologies: SLA, PolyJet, Carbon DLS

- Maximum build volume: 736 x 635 x 533 mm

- Detail level: 25 microns (SLA); 30 microns (PolyJet); 100 microns (DLS)

- Materials: Accura Xtreme White 200, Accura Xtreme Gray, Accura 7820, WaterShed XC 11122, MicroFine Gray and Green, Somos 9120, Accura 60, Accura 5530, PerFORM (SLA); 30A-95A, Rigid (PolyJet); Carbon RPU 70, Carbon FPU 50 (DLS)

- Turnaround: From 1 business day

RapidObject

If you’re in the EU or need your parts made there, Germany-based RapidObject offers SLA, DLP, and Polyjet technology for resin prints with a wide range of available materials to choose from, as well 24-hour express turnaround time for certain services.

Most materials are available for instant quoting, but some — for example, Accura Xtreme — were only available by special request. Within a few days, the support team set up my account and delivered a specialized quote (in German) for their toughest resin material, as requested. We converted the price from Euros to Dollars for this article.

- Available technologies: SLA, DLP, PolyJet

- Maximum build volume: 2,100 x 700 x 800 mm

- Detail level: 200 microns (SLA/DLP); 100 microns (Polyjet)

- Materials: 16 SLA resins, 12 DLP, 6 PolyJet

- Turnaround: From 1 business day

Sculpteo

Sculpteo has been in business since 2009 and quickly became one of the biggest names in 3D printing services (it’s also a Craftcloud manufacturing partner). In 2019, the company was acquired by BASF and it has since added a slew of new materials and services to its catalog, with options for practically every industry.

For printing parts in resin, Sculpteo offers four technologies. In addition to standard SLA printers, it offers DLS, DLP, LCD, and PolyJet printers.

Currently, the company only offers Prototyping Resin for SLA printing. For more durable resins, we looked to its LCD offerings, which can print using production-ready Ultracur3D EPD 1086, known for its flexibility and strength.

Sculpteo’s SLA parts are eligible for 24-hour express lead times. The other technologies have lead times starting at five days. The company ships worldwide, but longer distances can affect delivery times.

Sculpteo’s ordering process includes handy CAD analysis and repair tools. It also offers 3D part design and consultation, laser cutting services, and an extensive library of support and educational documents.

- Available technologies: SLA, DLS, DLP, MSLA/LCD, PolyJet

- Maximum build volume: 510 x 280 x 350 mm

- Detail level: 100 microns (SLA, DLS, DLP, LCD), 28 microns (PolyJet)

- Materials: Black, white, clear, varies by resin printing technology

- Turnaround: From 3 business days, 24 hour turnaround possible with SLA

Purple Porcupine

Don’t be fooled by the funny name. California-based Purple Porcupine is one of the earliest companies to embrace 3D printing as a tool in the manufacturing market. Created back in 2007, Purple Porcupine has helped companies of all sizes across the US create their products and grow their businesses.

Purple Porcupine provides three kinds of resin 3D printing — PolyJet, SLA, and DLP — and post-processing finishing. It has also recently added direct-to-textile resin 3D printing via Stratasys’ textile 3D printers.

Along with its printing services, this ambitious company also lists 3D scanning, 3D CAD design, RTV and cast urethane, and corporate branding services available to its clients.

Although Purple Porcupine does not currently offer instant quoting, obtaining a quote is fairly simple. Upload your CAD file, along with your contact information and any special notes about the project, and you’ll receive a custom quote within a day or two. The team is responsive and more than willing to work with you to help you find the best technology and material for your project, making the entire process feel personalized.

Note that Purple Porcupine has a minimum order requirement of $150.

- Available technologies: PolyJet, SLA, DLP

- Materials: 16 Polyjet resins; 11 SLA resins; 18 DLP resins

- Turnaround: Average lead time 3 business days

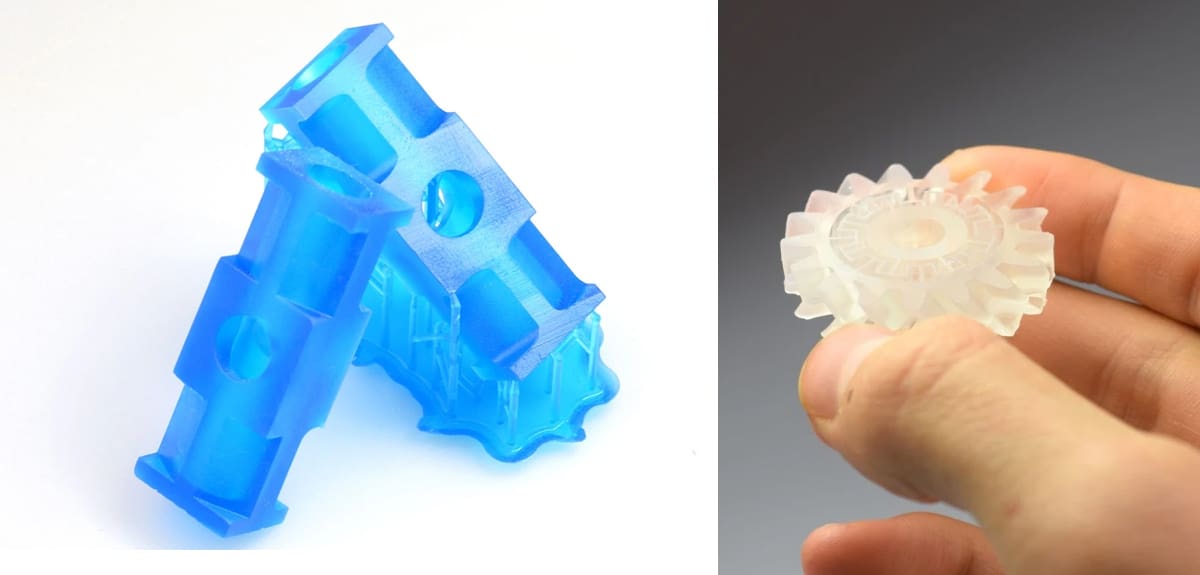

Resin 3D Printing - Simply Explained

Of all the 3D printing methods for polymer (plastic) parts, resin 3D printing is prized for its fine detail and excellent surface finish, which makes it ideal for product prototypes, molds, casts, display models, architecture models, and art, among many other applications. Some resin materials are also extremely tough, durable, wear-resistant, flame resistant, and even flexible, making the technology popular for auto parts, factory tools, and sports equipment.

When you order a part from a service provider, they’ll usually be using professional- and industrial-level resin printers and materials. Yet, some smaller services set up shop using consumer 3D printers like the ones you may have at home. Many consumer-level resin printers can produce outstanding results for prototypes, visual models, and figurines. For more durable materials you’ll want to understand your resin options.

Vat Polymerization

The most common resin 3D printing technologies are based on using a vat of liquid photosensitive plastic exposed to UV light to build an object layer-by-layer. These technologies are collectively known as vat polymerization. The category is further split into different distinct technologies, such as stereolithography (SLA) and digital light processing (DLP), and liquid-crystal display (LCD) also called masked-stereolithography (mSLA).

If you were buying a machine, the difference between these three technologies would be more important, but when ordering parts, their attributes are less of a factor. If you’re simply looking for fine detail, either technology is applicable.

Another vat polymerization process your service provider may offer is called Digital Light Synthesis (DLS), which is only available from a company called Carbon. It’s a version of resin printing that is widely used in manufacturing because it uses a range of engineering-grade durable materials and can produce very high output in terms of quantity. It’s for functional prototypes and end-use parts, such as these bicycle seats sold by Specialized and the midsoles of these shoes by Adidas.

PolyJet

If you need multi-color or multi-material parts with fine detail, such as product prototypes, you’ll want to look for a service provider that offers PolyJet technology from a company called Stratasys. This technology, which is also ideal for volumes of parts, uses inkjet print heads to deposit droplets of resin onto the print platform. The resin is immediately hardened by UV light. As there are multiple print heads, different materials can be printed at once.

PolyJet is probably to top option for multi-color medical models and product prototypes, so much so, that we have an entire service guide devoted to it linked below.

Guide to Terms in 3D Printing with Resin

Resin 3D printing service providers sometimes use a wide variety of terms to describe their technology, often mixing what a brand of 3D printer calls its technology with the more general name for the technology. For example, LFS (low force stereolithography) is what 3D printer maker Formlabs calls its stereolithography. This is important only if you’re looking for parts from a particular brand of printer to evaluate it before purchase or if you’re supplementing your production with an on-demand service and want to match the technology exactly. Otherwise, it’s just confusing.

- Vat Polymerization is a general term for SLA, DLP, & LCD

- Stereolithography (SLA) uses a laser to cure the resin

- Digital Light Processing (DLP) uses a UV light to cure the resin

- Liquid crystal display (LCD) also called masked stereolithography (MSLA) also uses UV light

- Brand-Specific Versions of Vat Polymerization

- Low Force Stereolithography (LFS) from Formlabs

- Digital Light Synthesis (DLS) from Carbon

- Material Jetting (M-Jet) is a rapid and multi-color resin tech

- Polyjet is a type of material jetting from Stratasys 3D printers

- InkJet is a type of material jetting from Mimaki

License: The text of "5 Top Resin 3D Printing Services Put to the Test" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.