Because of the unique characteristics of resin, its 3D printers typically include a lid or hood. However, in addition to this essential part, some makers may also opt for an enclosure: a compartment meant to offer further protection and benefits to the printing and curing processes.

For example, if the printer is set up in a room with people around, additional ventilation is needed to deal with volatile organic compounds (VOCs). If you keep the printer near a window with sunlight, you might have to consider additional UV blockage so that the printing process isn’t affected. And you’ve also got to consider where you’ll be keeping the resin (and other items) as well as where you’ll be cleaning the prints.

In this article, we’ll first go over the basics of resin 3D printing and the importance of the integrated hood. Then we’ll discuss why it can be useful to have an enclosure around the whole printing setup, why this differs from FDM printers, and more, including some options that you may want to consider adding.

Resin 3D Printing

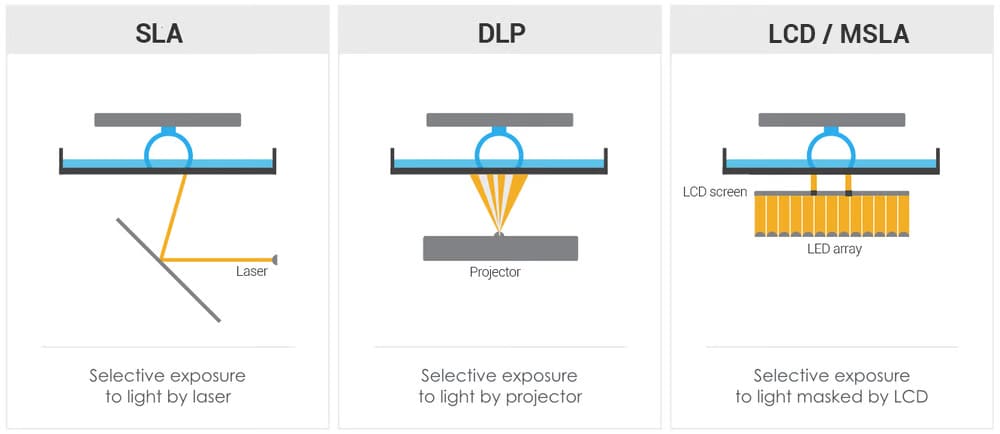

Nowadays, vat polymerization 3D printers are divided into three main technologies that differ mainly in the way that they harden resin.

- Stereolithography (SLA) printers use a UV laser to selectively cure a layer of resin one point at a time. This method of hardening resin was the first to be invented but isn’t as suitable for home use, as it’s more expensive and replacing and servicing parts is more difficult.

- Digital light processing (DLP) printers rely on a projector to flash an image of a layer on the build surface, curing the layer. This method is limited in build volume but offers fast printing speeds, with a slightly poorer surface finish.

- Liquid-crystal display (LCD) printers are now the most common type of desktop resin printers. These rely on an LCD screen that displays a mask over a UV light source. This setup is cheap and effective, which is why most entry-level resin 3D printers use LCD technology.

All three of these methods produce prints that are much more detailed compared to other methods of 3D printing. And while their printers have their differences, they all include a hood for a variety of reasons, which we’ll tackle next.

Default Setup

The liquid resin used to produce amazing prints is toxic in its uncured form and therefore requires some basic precautions when working with it, but it’s not the only reason behind the default setup that includes an integrated or removable hood.

Safety

Volatile organic compounds, or VOCs for short, are one of the main reasons the hood is necessary. Liquid resin emits VOCs and inhaling them can be detrimental to your health. Eliminating this risk is done with VOC filters or, even better, a ventilation system.

Additionally, skin contact with resin is harmful and can trigger reactions, while getting resin in your eyes is even worse. The hood combined with gloves and protective eyewear helps keep you safe, and it also protects the printer from accidental bumps, something falling in the vat (the tank of liquid resin), or other issues.

UV Light

LCD and DLP resin printers use UV light to harden layers. The printer’s hood must block UV rays to prevent your eyes from getting damaged by the light in the printer as well as prevent any stray sunlight from ruining the resin in the vat. The hood – or its windows – are usually coated with a special material that filters out UV light.

Temperature

The resin used for 3D printing works best at a temperature between 25-30 °C (77-86 °F). (For specific resins, be sure to check the manufacturer’s recommendations.) As with other forms of printing, a hood is the easiest way of maintaining a higher ambient temperature. Unless an additional heater is needed, the integrated hood that comes with a resin 3D printer is enough for this.

When Is an Enclosure Useful?

Resin 3D printers are enclosed by design so that UV light is blocked and the printer is protected, but some circumstances may warrant considering the addition of an enclosure.

- Additional UV blockage, such as a cover over the printer, can be provided by an enclosure. If the printer is in an area that is particularly exposed to sunlight, this might be needed.

- Better temperature control is possible with an enclosure, as you can install temperature sensors and heaters to create the perfect environment for the 3D printer.

- More ventilation and filtration options exist with an added enclosure. Because stock hoods rarely come with ventilation options, you can adapt an enclosure to work best for your situation, ensuring optimal ventilation and safety.

An enclosure is also useful for covering more than just the printer. Creating a controlled and safe environment for the whole work area is another advantage.

Keeping other tools in the enclosure means you don’t have to worry about spills or contamination in the work area, although you should be careful not to leave flammable items – like alcohol – that may react adversely in a heated environment or next to machines that may be left alone for extended periods. Such objects should be kept in cool, dark places, away from possible sources of ignition.

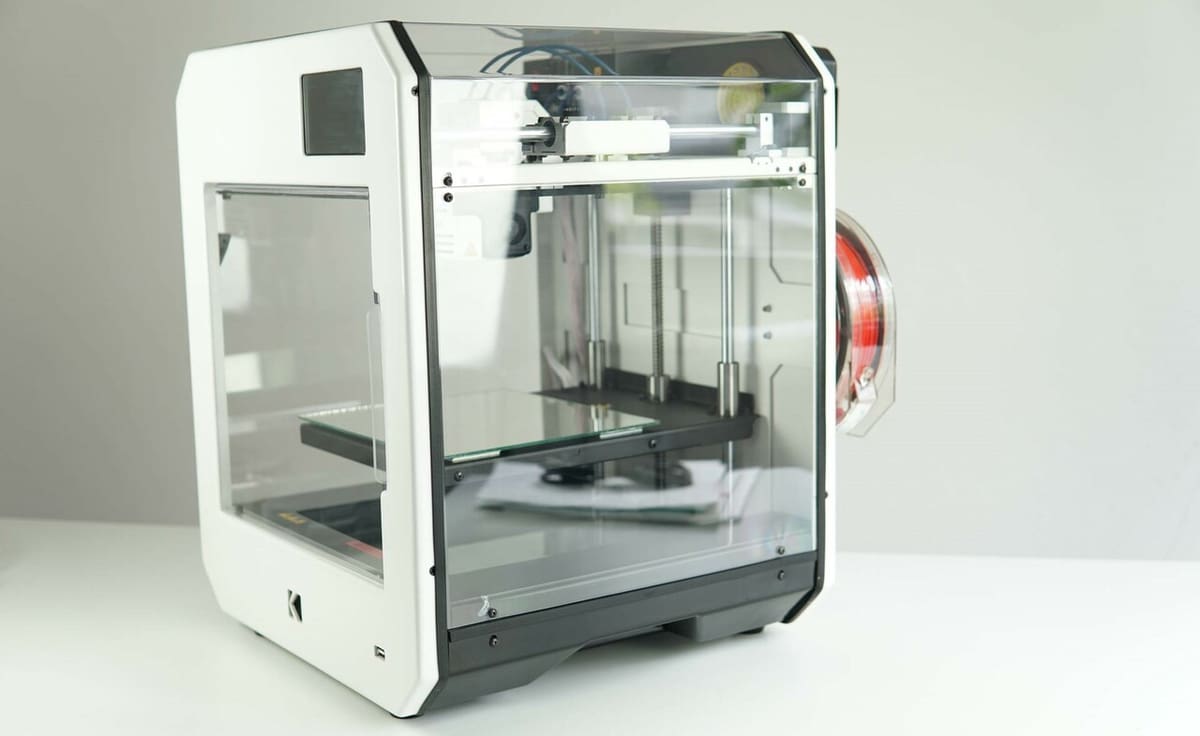

Differences from FDM Enclosures

Enclosures for FDM printers are usually used to keep ambient temperature high for plastics that require it. This means that features seen on resin 3D printer enclosures are most often omitted.

Some FDM enclosures include ventilation and VOC filters, as certain materials, like ABS, emit dangerous fumes when extruded. Enclosures for FDM 3D printers don’t need UV light filters, so they don’t come with UV shielding.

Using an enclosure made for FDM 3D printers for resin 3D printers is possible, but it’s usually not without some adjustments to ensure proper ventilation and UV light blocking. This of course depends on your specific needs.

Features & Must-Haves

When it comes to the features of an enclosure for a resin 3D printer, these are the most important to consider:

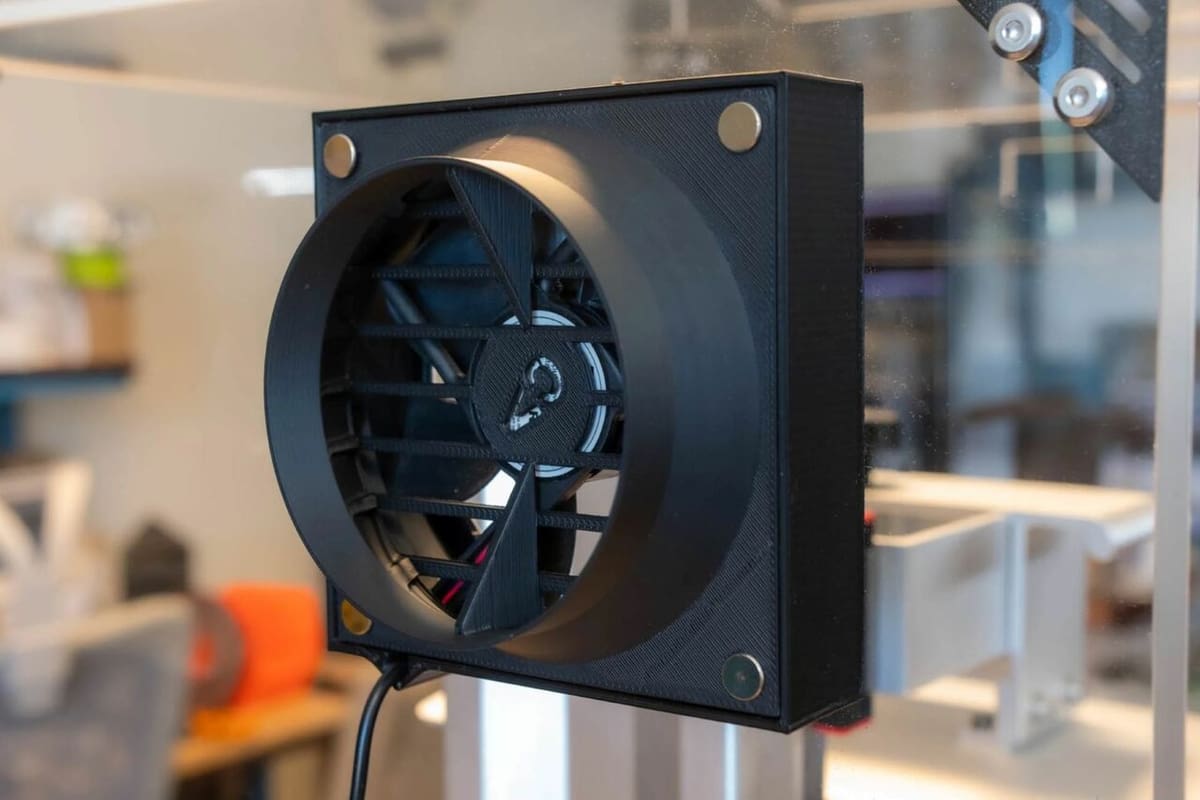

- Ventilation system: Resin printers should have a system to eliminate VOCs, either by venting them outside or filtering them out with removable filters. This can be done by either modifying the existing integrated hood with a fan and duct system or by adding an enclosure with a similar system.

- UV blocking: UV light needs to be blocked, either by filtering it out using UV light filters on acrylic panels (most common) or by adding a separate cover. The amount of UV blocking needed depends on the amount of sunlight the printer is exposed to, as the included hood usually has enough to protect your eyes.

- Temperature control: Resin printers require a sealed environment where an appropriate temperature can be maintained. This is important for optimal print quality because of the aforementioned temperature requirements of resin.

- Ease of use: Added enclosures should be easy to remove or open so that they don’t interrupt your workflow. You should also consider having a space for the hood – if it’s removable – so it doesn’t get in the way when post-processing your prints.

- Maintainability: Additional enclosures should be made of a material that’s easy to maintain and clean. A common option is acrylic, as it’s durable and, if there’s any damage, it’s easily noticeable due to it being clear.

Having a transparent enclosure is recommended but not necessary, as it allows you to keep an eye on the printer during prints.

Pros & Cons

Getting an enclosure for a resin 3D printer has it’s pros and cons. While the positives generally outweigh the negatives, it’s still important to take them into consideration when deciding if an enclosure is what you need.

Pros

- Improved safety because of cleaner air and less risk of contact with liquid resin

- Better print quality, as the resin is kept at a constant temperature at which it works best

- Easier to contain spills and splashes, maintaining a clean environment

- With a UV blocking window, easier to check up on prints during printing

Cons

- Can be big and bulky and take up valuable space

- Can be expensive

Enclosures

If you think that adding an enclosure to your setup is beneficial, there are two routes: those to DIY and those to purchase.

To DIY

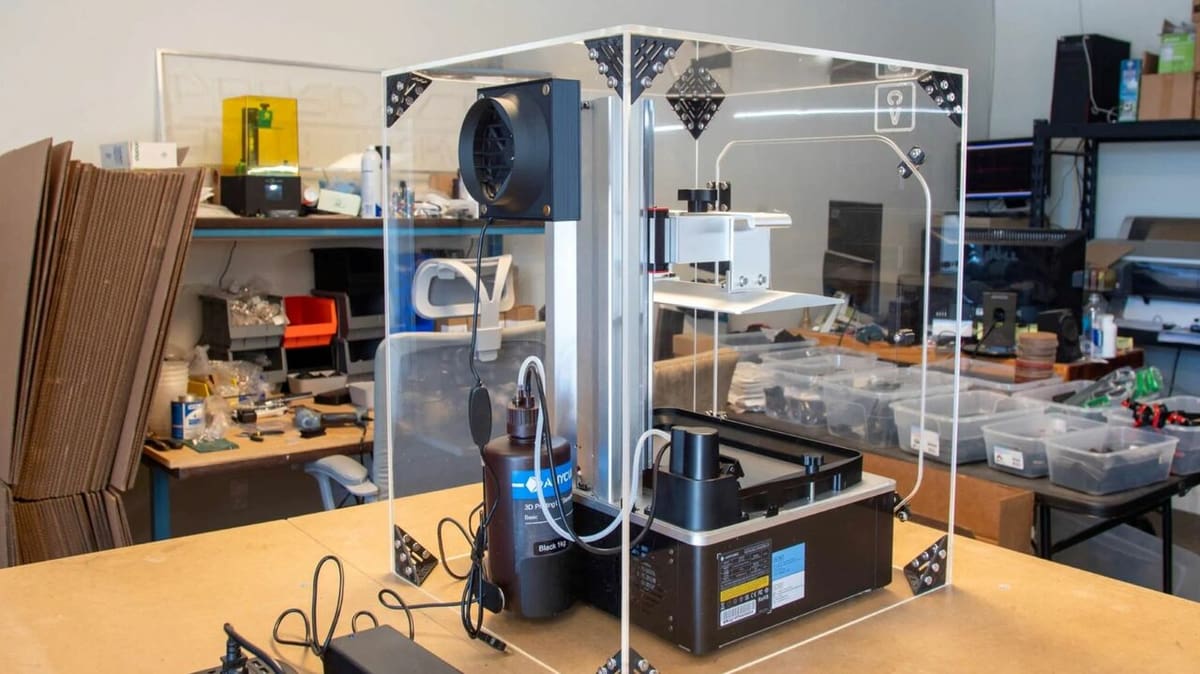

Valerian Saliou’s DIY Enclosure

This enclosure has many features. It’s big enough to contain both the printer and the washing and curing station as well as keep all the chemicals needed for printing in a controlled, safe environment. It also features ventilation to keep harmful fumes away from you.

The enclosure is based on IKEA furniture as well as a 3D printed part for ventilation, so an FDM printer is required for this project, as well as CAD knowledge to customize the part in order to fit your window.

Makers Mashup DIY Negative Pressure Enclosure

YouTube channel Makers Mashup’s instructional video shows you how to create an enclosure for your resin 3D printer using a grow tent and air ducts. This project is much simpler, as it requires fewer materials and less work to set up, with the result being a large enclosure that only holds the printer but has a very good ventilation system. The black fabric of the tent means you can’t monitor the printer while its working, but it also means additional UV light blockage.

To Purchase

3DUpFitters

This enclosure is the perfect choice if what you’re looking for is a high quality product that has been tested and designed with resin printing in mind. While it’s made for the Formlabs 3 printer, it also fits similarly sized printers.

Clearview Plastics’ Fume Extracting Hood

While similar to the previous option, Clearview Plastics’ enclosure also offers UV blocking clear panels. It also comes in different sizes and with different ventilation options depending on what you need.

License: The text of "Resin 3D Printer Enclosure: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.