Prototypes & End-Use Parts

If you need spare parts, shop tools, factory aids, rugged parts or prototypes, then SLS is the 3D printing technology you’re looking for, and it’s more accessible than you thought.

You don’t need to own your own printers or even know much about the technology to get the part you need produced fast. Instead, try an on-demand 3D printing service. With the growing number of these services, you can get your single part or small batches of parts printed without making large investments. With a printing service, it’s a good way to see if the technology suits your application before committing to a printer purchase.

If you’d like to understand SLS printing technology a bit more, skip to the SLS 3D Printing Explained section below.

To make our list of best services, on SLS provided needed to meet or exceed a few basics in the following categories:

- User-friendliness: A website where you can easily upload your designs and get a quote before you commit.

- Material selection: The ability to print in a variety of SLS materials, such as nylon (carbon-fiber filled), polypropylene (PP), and flexible materials (TPE, TPU).

- SLS printer brand: Although not every service provider listed which SLS printers they print with, most on our list did. This is important when you’re looking to evaluate the technology before you make your own printer purchase.

- Free guidance or troubleshooting: If you’re new to SLS or don’t have a printable digital file of your part, can you find self-help resources or reach out for live help?

- Post-processing: SLS parts don’t require much post-processing, but services that offered coloring and finishing options got bonus points.

Top SLS 3D Printing Services

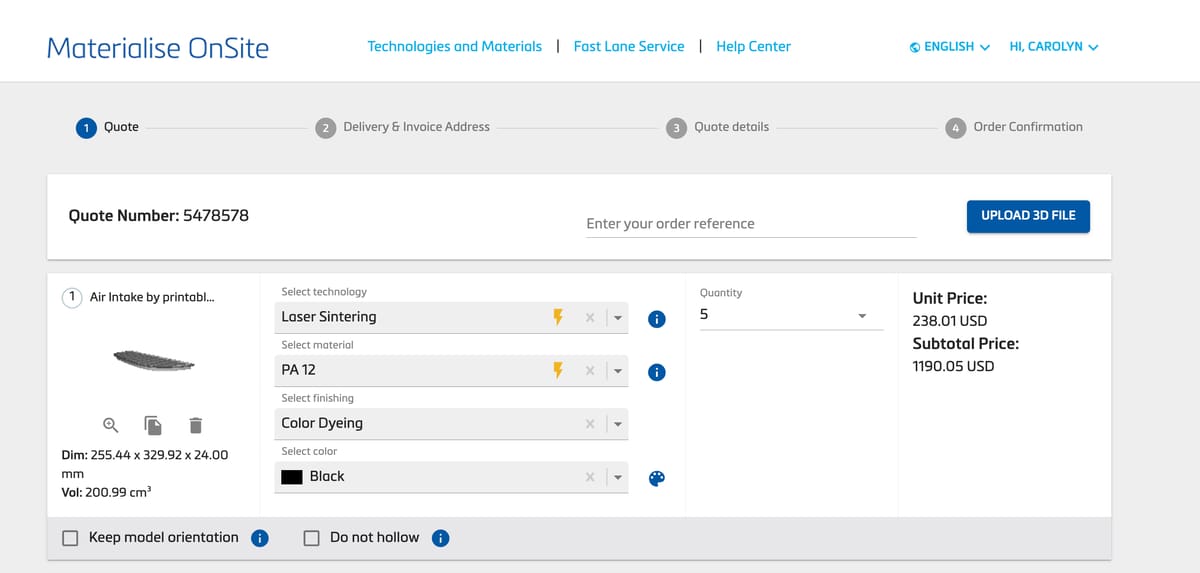

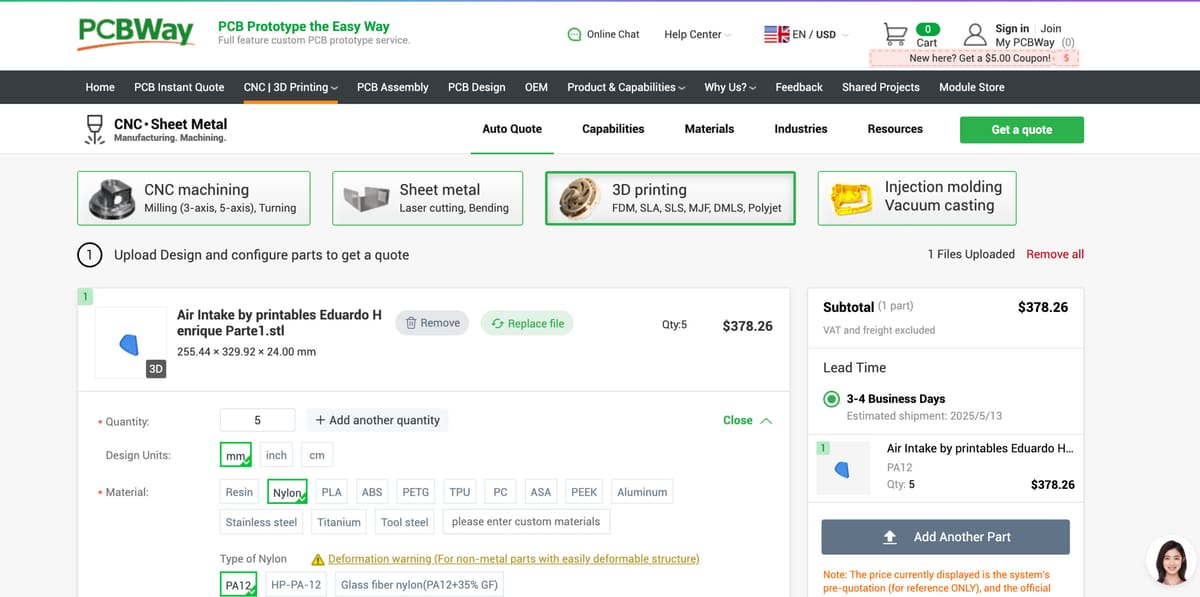

*Sample Part: To give you a sense of the prices you can expect from these services, we uploaded the same sample part to each and requested a volume of five, 3D printed using SLS technology in nylon 12, and dyed black. The part we selected is a simple but large auto air intake vent designed by Printables user Eduardo Henrique and measuring 255.44 x 329.92 x 24 mm. Prices are without shipping.

Craftcloud

Craftcloud is more than just a 3D printing service. It helps you compare prices and technologies from different services to find one that fulfills your needs at a price you’re comfortable with.

Craftcloud partners with more than 150 printing service providers across the globe and it makes comparing them easy. All you need to do is upload your CAD model, pick the material and finish you need, and browse through their generated list to find a quote that fits your needs. Craftcloud generates quotes in real time without hidden fees, so you will always get an accurate quote.

Users can choose between four SLS nylon materials suitable for a wide range of applications. The materials can be dyed to dozens of different colors, offering a high level of customizability. The service works for both one-off prints, like gifts or prototype samples, and small batches of fully functional industrial-grade parts.

Craftcloud also has an extensive library of material and support documentation to help you choose the right service provider.

- Maximum build volume: Varies by supplier

- Detail level: Varies by supplier

- SLS Materials: Nylon PA12, Nylon PA6, Nylon PA11, Nylon PA11 carbon fiber

- Turnaround: Varies by supplier

- Finishing: Color dyeing, waterproofing, satin polishing

Fathom

Fathom is the largest privately-owned on-demand additive manufacturing service in North America. Although they focus primarily on US and Canadian customers, they have an excellent range of 3D printing and additional services in places to deliver high-quality parts quickly.

Fathom offers SLS printing with five different materials — two varieties of Nylon PA12 and PA11 each, and TPU. With glass-reinforced and flame-retardant material options, Fathom can produce both prototypes and functional end-use parts for a variety of demanding industries. The company also says carbon-filled nylon is available on request, but it isn’t included in their standard materials.

Fathom offers instant quoting through an online user interface that’s gotten less user-friendly over the years (your password will expire and the system only accepts what it thinks are “professional” email addresses). Large-scale or particularly complex parts may require a quote review, though, and not an instant one. The company has manufacturing locations across the U.S. and is constantly expanding its network if its history of steady acquisitions is anything to go by.

In addition to 3D printing services, Fathom offers extensive post-processing services for additive manufacturing, including finishing, dyeing and coloring, assembly, polishing, and more. The company can also help customers with part design, concept development, and quality assurance. Fathom provides a comprehensive package of additive manufacturing services — if you’re located in North America.

- Maximum build volume: 320 x 320 x 610 mm

- Detail level: 100 microns

- SLS Materials: nylon PA12, nylon PA12 GF, nylon PA11, nylon PA11 carbo fiber, nylon PA11 FR, TPU

- Turnaround: 2-4 business days

Materialise

Materialise has been active in additive manufacturing for more than 30 years. Over this long history, they’ve built a reputation with their software solutions, but the company also offers a large range of on-demand 3D printing services, including SLS printing technology.

Materialise offers seven materials including specialty options such as Bluesint PA12 consisting of 100% recycled powder and flame-resistant PA 2210 and 2241 FR materials. Materialise is a great option for environmentally-conscious users or those requiring high-grade parts for demanding applications.

It is interesting to note that although the size of single parts is limited to a maximum dimension of 630 x 330 x 550 mm, Materialise says it can create parts with practically unlimited dimensions by splitting prints into several sub-components. Post-processing options include sandblasting, polishing, sealant treatment, dyeing, and painting.

Delivery times aren’t the fastest — starting at 4 business days for most materials, while some, like PA-GF, require up to 8 days. However, Materialise can produce parts smaller than 200 x 100 x 100 mm with only two-day lead times.

Their catalog also lists design, engineering, and rapid prototyping services for additive manufacturing, in addition to consultation and training. Ordering online is quick and easy, with instant quotes.

- Maximum build volume: 630 x 330 x 550 mm

- Detail level: 120 microns

- SLS materials: Bluesint nylon PA12, nylon PA12, PA-AF (Aluminum Filled), nylon PA-GF, PP, nylon PA 2210 FR, nylon PA 2241 FR

- Turnaround: From 4 business days

Protolabs

Protolabs was founded in 1999 with the goal of reducing lead times with prototyping. Its 3D printing service launched in 2014 and has been expanding it ever since. In 2021, for example, Hubs came under the Protolabs family. Today, the company operates 12 manufacturing centers in the U.S., Europe, and Japan.

Protolabs’ SLS 3D printing service has a good material range, covering five options from standard Nylon PA12 to glass- and mineral-filled options and more. The company can produce parts at great speeds. Protolabs says lead times for SLS-printed prototypes and functional parts can be as short as one business day. A new low-cost economy shipping option was recently added to Protolabs’ delivery methods.

For post-processing services, Protolabs’ standard SLS service includes bead blasting. It also offers priming and dyeing options. Other post-processing methods that may be available for certain SLS parts include clear coating, nickel plating, decaling, and polishing.

Unlike many other companies on this list, Protolabs doesn’t offer design services for CAD models. They do however, have a nice library of design tips and guide materials available to help businesses new to 3D printing. With very fast production speeds and simple instant quoting, Protolabs is a good prototyping partner.

- Maximum build volume: 482 x 482 x 431 mm

- Detail level: 100 microns

- SLS Materials: nylon PA12, nylon PA12 GF/MF, nylon PA11, PP, TPU

- Turnaround: From 1 business day

- Finishing: clear coating, nickel plating, polishing

Protolabs Network — formerly Hubs — is the company’s service that focuses on rapid prototyping, with hundreds of manufacturing partners around the world. Protolabs Network offers a more limited menu of SLS printing — only nylon PA12 and nylon PA12 glass-filled (GF) materials — but may offer greater speed than its parent. Users can get their parts from uploading to production in less than five minutes using the company’s intuitive instant order system. The service also offers fast lead times from 3 business days.

Forge Labs

Forge Labs is a North American-based 3D printing services company founded in 2016 with locations in Canada and the US. It offers several types of 3D printing and when it comes to SLS, it offers a good selection of materials and finishes.

The company offers a digital file upload for an instant quote and if you don’t have a digital file, the company offers design services to bring you concepts, drawings, and ideas to life. Forge Labs also offers reverse engineering services.

- Maximum build volume: 700 x 380 x 580 mm

- Detail level: 60 microns

- SLS Materials: nylon PA12, TPU 88A, nylon PA12 GF, nylon PA12 ESD, black nylon PA12

- Turnaround: From 2-3 days for small- to medium-size parts

- Finishing: dyeing, painting

Protiq

Protiq is a Germany-based manufacturing service provider that offers a range of additive manufacturing solutions including SLS. Like other companies on our list Protiq offers rapid prototyping, on-demand production, and custom manufacturing for customers who upload their 3D models, choose the desired material. Setting Protiq apart, however, is its focus on industrial manufacturing.

Protiq is a marketplace of manufacturing partners. Once you upload your file, Protiq checks it for errors and can even repair it. After you select your materials and technology, in the shopping cart, you can save individual offers, forward your projects to colleagues or go straight to checkout.

Protiq has been the additive manufacturing wing of the Phoenix Contact Group, the electronics and automation manufacturer, since 2010.

- Maximum build volume: 660 x 360 x 550 mm

- Detail level: 60 microns

- SLS Materials: nylon PA12 (PA 2200), nylon PA12, nylon PA12 glass bead, nylon PA12 aluminum-filled, nylon PA12 FR, TPU-90, PEEK, PA6X, PP

- Turnaround: 2 business days within Germany

- Finishing: unknown

Quickparts

Quickparts’ on-demand print service and global network of providers offering a wide range of plastics and metal printing along with design and engineering services. The company has been SLS 3D printing parts for many years and has the expertise to recommend materials and finishes if you’re not certain what you need.

The company uses SLS 3D printers by 3D Systems exclusively because they used to be the on-demand service provider of that company before breaking off on their own.

- Maximum build volume: 340 x 340 x 600 mm

- Detail level: 60 microns

- SLS Materials: nylon PA12, nylon PA12 GF, nylon PA12 high temperature, TPU

- Turnaround: 1 business day

- Finishing: Color dyeing, spray painting

Sculpteo

Sculpteo has been in business since 2009 and is one of the biggest names in 3D printing services. In 2019, the company was acquired by BASF and has since added a slew of new materials and services to its catalog, with options for practically every industry.

Sculpteo offers nine materials for SLS printing, giving users a very wide variety of options. Thanks to the breadth of materials choices, Sculpteo can SLS print parts for practically any application, from detailed demonstration models and prototypes to functional technical components. With standard nylon PA12, the service can also produce very large parts.

The company also offers a wide range of post-processing options, although the availability depends on the material. Options include polishing and chemical smoothing, as well as dyeing or painting certain materials with up to 19 colors.

Sculpteo’s SLS-printed parts have lead times ranging from 2-15 business days, depending on part complexity, material, and surface finishing. The ordering process gives instant quotes and includes handy CAD analysis and repair tools. Sculpteo also provides 3D part design and consultation, laser cutting services, and an extensive library of support and educational documents.

- Maximum build volume: 675 x 366 x 545 mm

- Detail level: 100 microns

- SLS materials: nylon PA12/PA12 (gray), nylon 3200 GF, alumide, Ultrasint TPU 88A, Ultrasint PA6 MF, Ultrasint PA11 carbon fiber, Ultrasint PA 11, Ultrasint PA 11 ESD

- Turnaround: 2-15 business days

- Finishing: Painting and color dyeing, chemical smoothing, satin polishing, electroplating

Xometry

Today, Xometry operates a global network of more than 5,000 suppliers for both additive and traditional manufacturing.

When it comes to SLS printing, Xometry has a good range of material options. Most of the materials are based on nylon PA12, with various additives mixed in to give it different mechanical properties. Filling options range from carbon fiber and glass beads to mineral fibers, aluminum, and flame-retardant materials. Xometry can also print with nylon PA11 EX, a material with high impact resistance and elasticity.

For post-processing, Xometry offers multiple services including such things as vapor smoothing and tumble polishing, but also nickel plating, a rarity, and dyeing with 5 colors.

All 3D printed parts produced in the US through Xometry are eligible for free two-day shipping or ground shipping. Expedited next-day delivery is also available. The company can also ship parts internationally and has production partners in multiple countries. The Xometry website offers instant quotes based on an uploaded CAD model and selected options.

Xometry also offers rapid prototyping, high-volume production, and custom assembly services, which is great if an all-around production partner is needed.

- Maximum build volume: 330 x 330 x 559 mm

- Detail level: 120 microns

- SLS Materials: nylon PA12, nylon PA12 GF/CF/AF/HST/FR, nylon PA11 EX

- Turnaround: 3-4 business days

- Finishing: Color dyed, polishing, vapor smoothing, nickel plating

PCBWay

The popular PCB manufacturer China-based PCBWay has upped its game and introduced the option to order 3D prints directly from its website. Alongside various circuit boards and SMT assembly options, you can now have your model 3D printed in around 30 different materials. FDM, SLS, SLA, MJF, PolyJet, and SLM manufacturing are the main technologies offered.

We like PCBWay’s SLS offering because it offers a large build volume (400 x 390 x 390 mm) and a range of custom finishes including electroplating and glazing. Plus, the prices are very low.

In addition to 3D printing, PCBWay offers a wide range of prototyping and manufacturing processes like CNC machining, vacuum casting, and injection molding. There are also options to add metal inserts to the parts, mark prints with serial numbers, or even assemble them. And to make your part even more aesthetic, the surface finishes offered include electroplating, spray painting, and sanding.

- Maximum build volume: 400 x 390 x 390 mm

- Detail level: 60 microns

- SLS Materials: nylon PA12, nylon PA12 GF, TPU

- Turnaround: 1 business day

- Finishing: Color dyeing, spray painting, electroplating, glazing, polishing

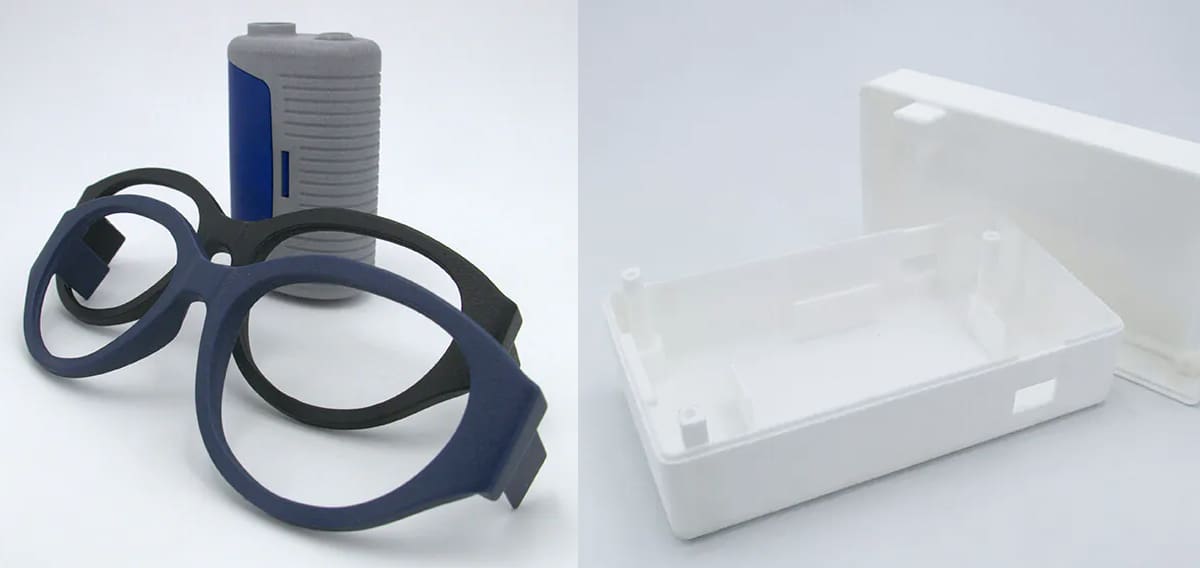

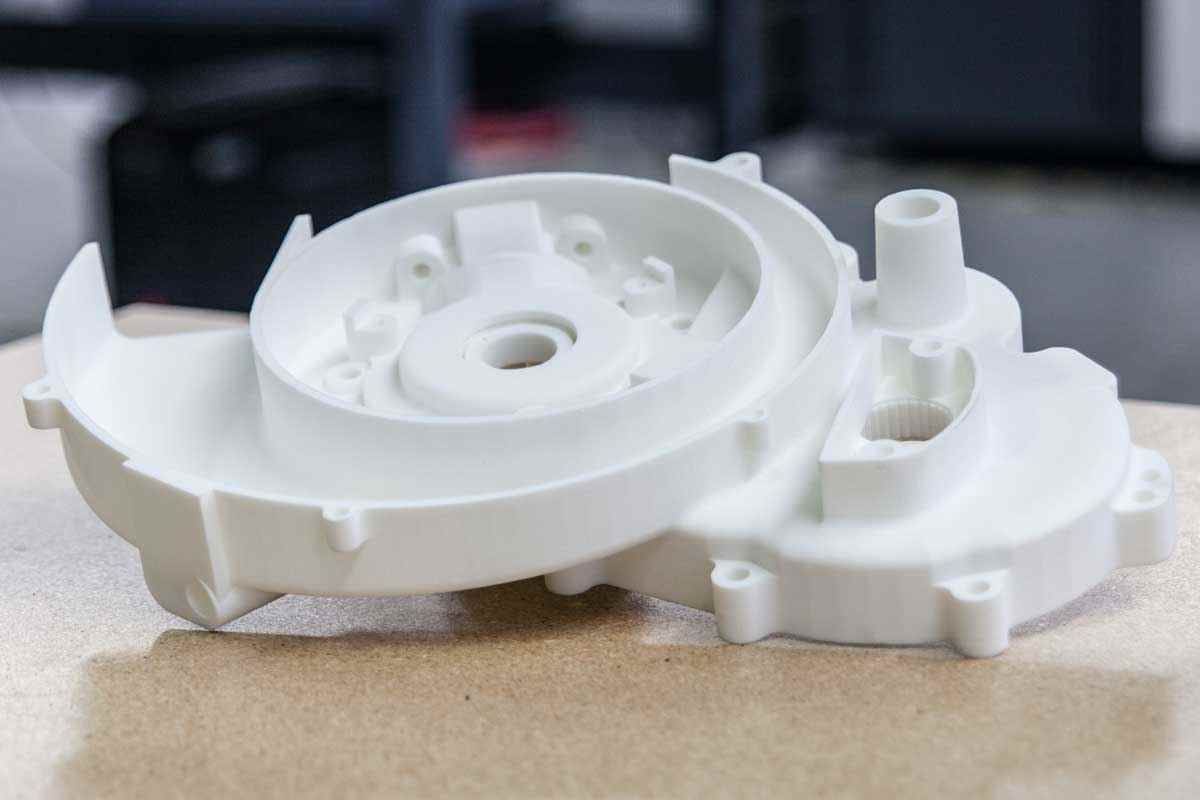

SLS 3D Printing Explained

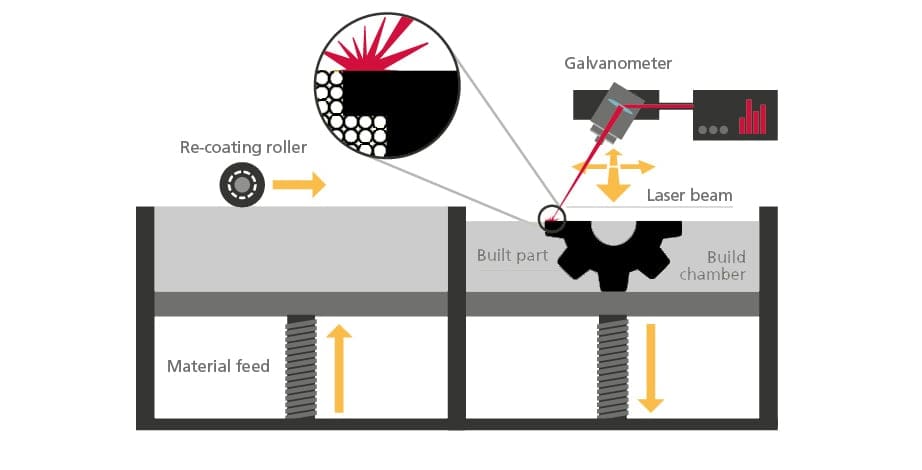

SLS printers harden thermoplastic powders into solid objects using a high-powered laser (generally CO2, diode, or fiber). Due to the intensity of the laser beam, SLS printers are typically considered more difficult to operate than other technologies, like FDM or SLA, which further reinforces their industrial reputation. SLS is the printing technology of choice for everything from consumer goods to factory tools to aerospace components. These 3D printers, coupled with tough materials, such as carbon-fiber-infused nylon, produce accurate, strong parts at high speeds.

At the beginning of the printing process, a fin or a roller spreads a very thin layer of plastic powder across the printing bed. The laser beam then scans the printing bed according to the desired part geometry, selectively sintering (fusing materials together using heat and pressure) parts of the powder together — hence the technology’s name.

Once the laser has finished melting one layer, the print bed lowers by the height of one layer. The coating apparatus then re-coats the chamber with powder, and this process repeats until the part is finished. SLS is already a fast technology, but some printers feature two-way coaters that can spread powder from both directions, achieving even higher print speeds.

A great advantage of SLS printing is that the parts generally don’t require supports. The unfused powder in the printing chamber props up the part and provides all the support it needs. As a result, SLS printing can easily produce very complex geometries, such as overhangs, hollowed or latticed internal structures, and sharp corners.

The laser technology, combined with the lack of supports, allows operators to fill the chamber with multiple parts. SLS is an ideal 3D printing method for low-volume manufacturing. With larger SLS printers, one print run could produce dozens or even hundreds of individual parts.

One more advantage of the technology is the ability to recycle unused powder. The average recycling rate is around 50%, but some machines and services — such as Materialise — offer options for 100% powder recycling rates. Recycling material can deliver great cost savings while also helping preserve resources and the environment.

But SLS does have its drawbacks as well. The parts take a long time to cool after printing, which can somewhat hinder the fast production speeds. Additionally, due to the powder material, raw SLS parts have an unevenly colored and relatively rough surface. To get completely smooth surfaces and uniform colors, the parts need post-processing, such as polishing and dyeing.

Understand SLS Materials

All SLS materials come in powder form and all are in the plastic family. Their properties range from stronger than solid aluminium to softer than rubber and everything in between.

Of course, you can sinter metal powder, however that’s a relatively new process called Cold Metal Fusion and to date, All3DP does not know of any 3D printing service provider offering this material.

For selective laser sintering (SLS), these are the most commonly used types of powders:

License: The text of "10 SLS 3D Printing Services We Recommend" by All3DP Pro is licensed under a Creative Commons Attribution 4.0 International License.