In resin-based 3D printing, each layer is formed by hardening a liquid resin using a light source in a process known as curing. This is the defining trait of resin-based printing, which is also referred to as resin 3D printing or vat polymerization.

Resin printers can achieve a much higher resolution and precision compared to other desktop solutions such as FDM 3D printing. This is why the technology is often used for aesthetic purposes, like visual prototypes and artistic models, or finely detailed parts, like those found in the jewelry industry.

Yet, ordinary photopolymer resins are somewhat fragile, and they leave the smaller details on your prints susceptible to cracking and snapping. Some companies have addressed this issue by introducing tougher and more durable resins. This is an especially popular move, as resin 3D printing continues to become more common and affordable.

Let’s look at what tough resin is, how it’s used, and how it compares to standard resins. At the very end of the list, find some printing tips for best results.

Introducing Tough Resin

Tough resins are developed for applications that require materials capable of withstanding high strain and stress. In fact, the mechanical properties of the cured parts produced by tough resins can even rival industry-grade plastics, as we’ll see later.

Balancing strength and compliance, tough resin is a great choice for strong, functional prototypes and assemblies that need to undergo short periods of mechanical stress. This makes it ideal for wearables, gadgets, and other objects that need to withstand some wear and tear.

Such resins can pose their own challenges when compared to standard resins. Some may require professional 3D printers, and others are simply well above the budget for most hobbyists and home power users. We’ve compiled a list of our favorite tough resins for you to weigh the options for your specific needs. But first, let’s cover some more background.

How Does It Compare?

For comparison, below are some of the main properties of tough and standard resin:

Tough Resin

- Produces sturdy, shatter-resistant parts

- Ideal for functional prototypes and mechanical assemblies

- Has excellent resistance to cyclic loads

- Not suited for thin walls (1 mm is the recommended minimum)

- Harder to remove from the build platform than standard resins

- May cost up to $300/kg

Standard Resin

- Produces fragile parts with low impact resistance

- Ideal for detailed and high-resolution prints

- Produces smooth surface finishes

- Affected by color (like smooth/shiny finishes)

- Relatively easy to use

- Low cost

Material Properties

You’ll note that for tough resins, every manufacturer provides technical specifications regarding mechanical behavior. We won’t get into much detail on these properties, although some basics can be extremely helpful for the uninitiated in material engineering (most of us).

Tensile strength is a value representing the maximum tensile force (pulling two ends of the material away from each other) that a material can handle before critical damage, while Young’s modulus evaluates how much force is necessary to start deforming it.

Shore D hardness tells you how hard or soft a material is, where higher numbers denote higher hardness. There are several different Shore Hardness scales. Flexible resins typically use Shore A, and tough resins use Shore D.

It’s also important to consider a material’s impact strength, which quantifies its ability to withstand sudden and intense impacts or forces. It’s measured through standardized tests like Izod impact. This involves striking a rod-shaped sample and measuring the energy lost per unit area (J/m) or cross-sectional area (J/m2).

Samples can have a V-shaped indentation (notched) and or be unnotched. The notch acts as a stress concentrator, revealing a material’s susceptibility to crack propagation. Unnotched samples showcase overall energy absorption. In this article, we’ll report the notched Izod test results when available.

So now that we’ve covered the basics, let’s get started on the top picks for ABS-like tough resins! Note that we’ve organized them starting from the most affordable.

Elegoo ABS-Like 3.0 Pro

Elegoo has been producing resin 3D printers for quite some time now, and not everyone knows that it manufactures 3D printing materials as well, both resins and filaments. When it comes to tough options, its ABS-Like V3.0 Pro is a standout.

As you might have guessed from the name, this is the third version of the brand’s ABS-Like resin and it was formulated for higher heat, scratch, and impact resistance; the first version was meant to be used for more rigid parts. You can dive deeper into the resins’ specs by checking out Elegoo’s product comparison page.

Reviews at Amazon confirm that this material is tough. Beth Claire noted that this resin provides a smooth surface and durable prints. J. A. added that it cleans up easily, although it’s not necessarily more scratch resistant than Elegoo’s other options.

Because Elegoo resins are predictably formulated to work with their printers, the UV wavelength is 405 nm. This makes them compatible with LCD (MSLA) and DLP printers.

- Impact strength: ~28 J/m

- Tensile strength: ~40 MPa

- Young’s modulus: ~542 MPa

- Shore D hardness: 81-84

- Colors: Six, including clear green, yellow, and translucent

- Cost: ~$24/kg

Inslogic Tough Resin

Inslogic is a relatively new player in the 3D printing materials market, but it already offers a great catalog of both resins and filaments. The belief behind their products is that the machine is only half of the equation for great projects – the other half is high-quality materials.

One of the materials they offer is Tough Resin. This was formulated to provide great scratch resistance, thanks to the matte surface that it leaves on the piece; in addition, it aims to offer a high tensile strength. Inslogic suggests using it for functional parts, tools, as well as snap-fit assemblies.

Although only three people have left a review at time of writing, the rating of Inslogic Tough Resin is 4.7 on the official website. Dave W. has shared that the parts printed with it are durable and don’t break easily. Furthermore, he has printed an articulated dragon – a type of models that are known for being fragile – and it’s still holding strong.

Like many resins on this list, it’s compatible with most DLP, LCD, and SLA machines on the market, with a UV wavelength between 385 and 405 nm.

- Impact strength: 35 J/m

- Tensile strength: 48 MPa

- Young’s modulus: 1840 MPa

- Shore D hardness: 84

- Color: Gray

- Cost: ~$32/kg

Sunlu ABS-Like

Available for a little over ~$30 per kilogram, among Sunlu’s resin offerings, ABS-like is another budget-friendly tough resin and is available in over a dozen colors. The manufacturer claims that the resin has a pleasant and minimal odor, but some users have reported a noticeable or strong smell.

The reviews confirm that it has good fluidity and produces parts with decent tensile strength. They also highlight that this resin is consistently durable across many batches of print, striking a good balance between flexibility and toughness.

However, if your project requires more flexibility, you can consider Sunlu’s high-toughness flexible resin that has a lower Shore hardness of 70D and better ductility. For absolute toughness and temperature resistance, there’s also the high-temperature resin with a Shore hardness of 88D while boasting a tensile strength of 43 MPa and Young’s Modulus of 2,070 MPa.

Sunlu can brag 4.7 stars at Amazon, with over 1,410 reviews. Daniel shared that the resin delivers great detail prints and accurate parts. M. Hehe has even tested how a ball would hold when printed with this material. The print didn’t break even when bounced and thrown.

Sunlu ABS-Like resin is cured at 405 nm and it’s compatible with a wide spectrum of machines that includes 4K and 8K LCD, DLP, and SLA printers.

- Impact strength: 60 J/m

- Tensile strength: 34 MPa

- Young’s modulus: 1,020 MPa

- Shore D hardness: 75-80

- Colors: 13, including a few clear colors and two shades of gray

- Cost: ~$36/kg

Siraya Tech Blu-Tough

Siraya Tech’s Blu is one of the most popular tough resins in the market, partially due to its low price point. At a little under $50 per kilogram, this resin is comparable to standard resins in cost while still providing better mechanical properties.

Blu is advertised as a fast and easy-to-use resin that works well with most desktop 3D printers as well as common cleaning and post-cure methods.

Siraya Tech Blu-Tough can brag a 4.5-star evaluation at Amazon, with over 350 reviews. A customer has shared that this is the perfect material for engineering projects that need dimensional accuracy and resistance. Justin Hawley has confirmed that this material is great for functional parts but has also noticed that supports are tougher to take off the prints.

Be aware that it was designed for LCD and DLP printers, not SLA. Siraya recommends printing Blu at temperatures of 25 °C or above, although a heater is rarely required.

- Impact strength: 45 J/m

- Tensile strength: 39 MPa

- Young’s modulus: 1,500 MPa

- Shore D hardness: 85

- Colors: Seven, including Clear V2, Emerald Blue, Easy Grey, and Nylon Black

- Cost: ~$46/kg

eSun Hard-Tough Resin

Among eSun’s resins, its Hard-Tough offer is a urethane acrylate resin that claims to have hardness and toughness comparable to ABS filament and is able to produce prints that can withstand impact and wear.

When it comes to usage, eSun provides printer-specific setting recommendations on the product page for download. Generally, it’s recommended to print at temperatures between 18 and 35 °C. For post-processing, eSun also recommends placing the parts in a 50 °C oven for 20 minutes after the post-cure step.

With almost 450 reviews at Amazon, this resin is quite popular. Nathan Allan stated that this material produces highly accurate parts with minimal shrinkage. Paul Jacobson shared that he used this resin for some parts for his Jeep. They held up road driving and didn’t break when he was installing the prints.

eSun specifies on its website that the curing wavelength of this resin is in the 395-405 nm range and that this material is compatible with LCD machines.

- Impact strength: 40-110 J/m

- Tensile strength: 30-60 MPa

- Young’s modulus: Not listed

- Shore D hardness: 75-81

- Colors: Black, cold white, gray, blue

- Cost: ~$55/kg

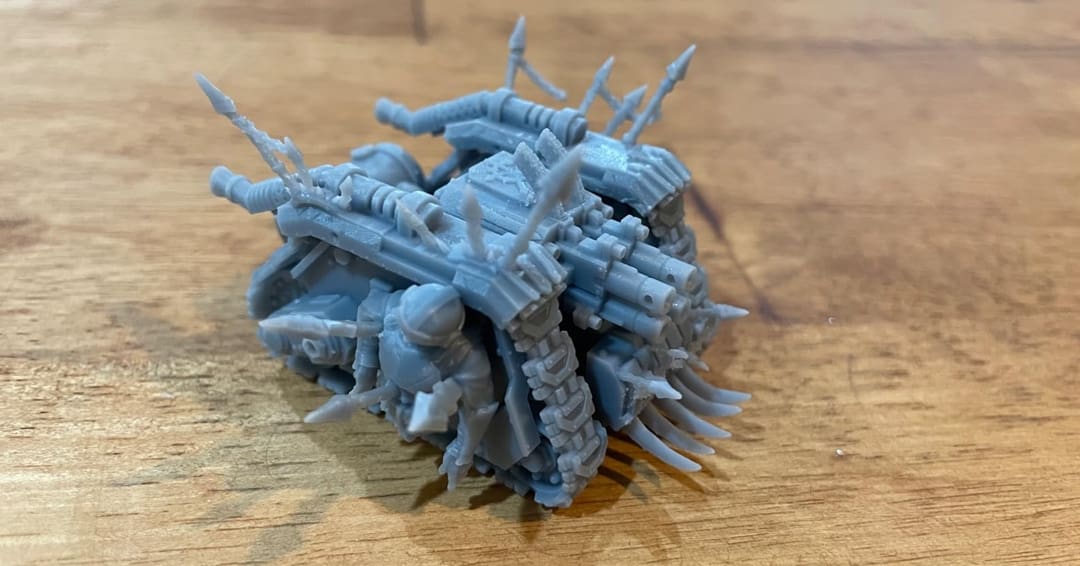

Resione M58

When it comes to creating durable models or projects requiring robustness in high-stress environments, Resione M58 ABS-like tough resin could be a perfect choice. There are also two other notable variants, M68 and K. Both share similar material properties but have ~10% higher impact strength.

For M58, think printed miniatures, action figures, even dental models – anything that needs to survive an accidental tumble. M68 suits projects involving model building, artwork, or props, while K is the preferred choice for higher-precision figures and parts. However, it’s important to note that the manufacturer advises against its use in underwater scenarios.

What if your project demands resilience against water exposure and needs more toughness? Resione formulated HT100 for this purpose, and it’s available at a similar price. This is a heat-resistant resin that not only withstands room temperature water but can endure boiling water for some hours, along with other high-temperature and pressure circumstances.

When it comes to makers, Izabela noted that the resin produces durable parts that don’t break or snap even when used daily. Brett Beekmann added that it works great with print-in-place models, providing resistant joints that don’t get loose quickly.

All resins are compatible with most UV 395-410 nm DLP and LCD resin 3D printers.

- Impact strength: 51.4 J/m

- Tensile strength: 52.3 MPa

- Young’s modulus: Not reported

- Shore D hardness: 87

- Color: Light gray

- Cost: ~$60/kg

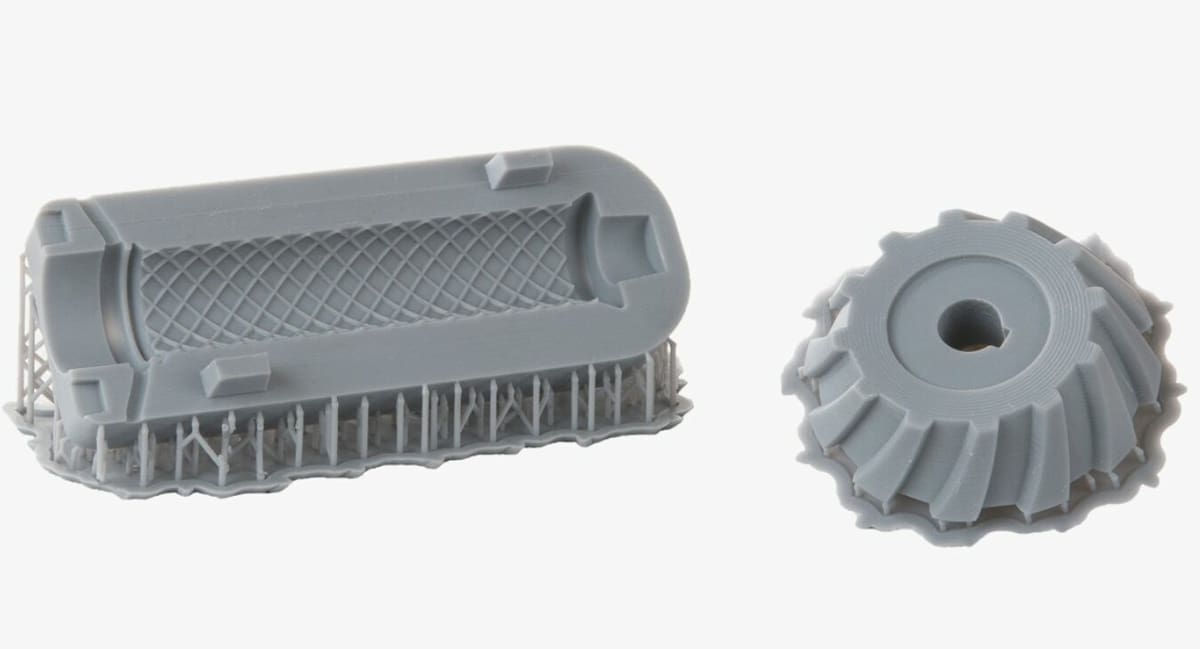

Photocentric UV High Tensile Resin

Photocentric’s UV High Tensile Resin makes parts with considerably high tensile strength and overall durability. Like other tough resins, this material requires some special handling like pre-heating the resin up to 30 °C prior to printing.

Though it was designed to work with Photocentric’s 3D printers, it’s compatible with most LCD and DLP printers on the market. The company even provides a list of compatible third-party 3D printers and instructions on how to calculate the proper exposure times based on the output power of your machine.

- Impact strength: 8.1 kJ/m2

- Tensile strength: 65 MPa

- Young’s modulus: 2,610 MPa

- Shore D hardness: 80

- Color: Gray

- Cost: ~$65/kg

Anycubic ABS-Like Resin+

Anycubic is another brand that has a catalog of resins. Their ABS-Like Resin+ has a generous variety of colors to choose from, and the material has a lower concentration of harmful volatile organic compounds (VOCs) according to the company.

Its toughness comes from the addition of polyurethane acrylate in its formulation, which gives this material a higher tensile and bending strength. Anycubic also claims it has a longer conservation period (up to 18 months).

The ABS-Like Resin + can boast 4.5 stars at Amazon. Tyler notedthat the parts printed with these materials are much less brittle compared to standard resin ones. Another fellow maker highlighted that the prints are durable and that it’s easy to work with this material.

Anycubic ABS-Like Resin+ offers great compatibility with a curing wavelength range of 365-405 nm. This makes it compatible with numerous LCD and DLP machines, as well as SLA resin printers.

- Impact strength: 45 J/m

- Tensile strength: 35-55 MPa

- Young’s modulus: 1,400-1,600 MPa

- Shore D hardness: 84

- Colors: Seven, including Aqua, gray, white, and transparent

- Cost: ~$70/kg

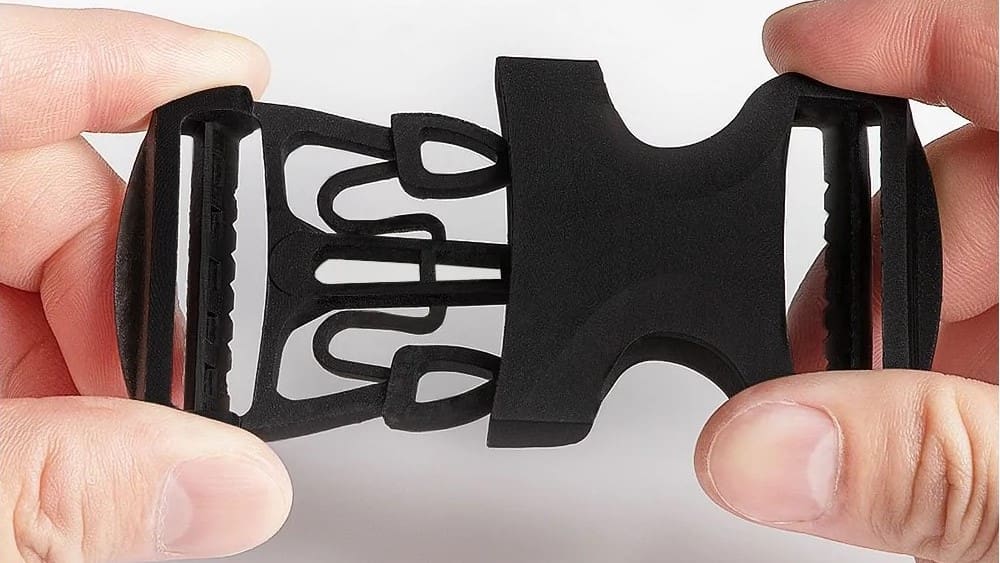

Phrozen Onyx Impact Plus

Phrozen Impact-Plus is a tough resin that has been developed through a collaboration between Loctite and Phrozen. Designed with durability and flexibility in mind, this resin also showcases one of the highest impact resistance among its counterparts, ensuring that printed models or parts maintain their integrity and return to their original shape after bending.

This combination of high-impact resistance and exceptional flexibility positions the Phrozen Impact-Plus as an ideal resin for projects demanding toughness and the ability to withstand cyclic loading. It’s particularly useful for applications like belt buckles or other functional parts. Not to mention its impressive weight endurance, with objects printed from this tough resin capable of carrying loads exceeding 150 kg!

As for the community, maker Jim shared that the parts printed with this material adhere well to the build plate and are really durable. Furthermore, this resin produces prints that are not as brittle as other brands’ options. The biggest complaint about the material is the lack of suggested settings, which leads to many tests to find the best parameters.

Although Phrozen doesn’t specify the curing wavelength of this resin, on the official website you can find the suggested settings to use with Phrozen resin printers, which are LCD machines.

- Impact strength: 137 J/m

- Tensile strength: 30.6 MPa

- Young’s modulus: 943 MPa

- Shore D hardness: 72

- Color: Black

- Cost: ~$105/kg

Formlabs 2000

Formlabs’ Tough 2000 resin is a reformulated version of their old Tough Resin. According to the company, it’s the strongest resin in its portfolio, offering the same – if not better – properties than those of ABS plastic.

As with any Formlabs material, Tough 2000 was developed for use in their own machines, namely the Form 2 and Form 3. Formlabs highly recommends post-curing times of 60 minutes at 70 °C to bring out the best mechanical properties.

You can find some great advice and feedback about Formlabs Tough resins on the Formlabs forum. Maker rkagerer noted that Tough 2000 keeps up with the resistance expectations but it doesn’t replicate details as much as Standard resin. Jmorris has also shared an insight about the differences between the 1500 and 2000 versions, highlighting that the former is more flexible but the latter has a higher impact resistance.

Formlabs produces SLA resin printers, so it’s not surprising that its resins are formulated for these machines. Although Formlabs doesn’t specify the wavelength of this material, the company states that it’s compatible with all its SLA machines.

- Impact strength: 40 J/m

- Tensile strength: 46 MPa

- Young’s modulus: 2,200 MPa

- Shore D hardness: Not listed

- Color: Gray

- Cost: ~$150/kg

Liqcreate Strong-X

Liqcreate’s Strong-X is perhaps the toughest resin on this list. Boasting a 91 MPa tensile strength and 135 MPa flexural strength, it can easily be applied for heavy-duty uses. Strong-X also provides high-temperature resistance, enough even for injection molding applications.

And yet the coolest part is that it can be printed on most budget DLP and LCD printers, including the Anycubic Photon, Elegoo Mars, and Wanhao D7. (See the full compatibility list.) The only downside is cost: Priced at around $175 per kilogram, it’s one of the more expensive resins in the market.

Similarly to the Phrozen Onyx Impact Plus, Liqcreate Strong-X has been appreciated by users for its strength but there are some grievances for the difficulty of finding the right settings. For instance, on 3DJake KH Hawaii has shared that it’s strong and rigid if cured properly and M. Luijten has confirmed stating that it’s perfect for functional parts.

- Impact strength: 20 J/m

- Tensile strength: 52-84 MPa (dependent on the UV post-curing process)

- Young’s modulus: 2,900-3,400 MPa

- Shore D hardness: 87-90

- Color: Gray

- Cost: ~$175/kg

Loctite 3843 HDT60 High Toughness

Loctite is a brand best known for its adhesives, sealants, and chemicals in general. While photocurable resins fit the description, it might come as a surprise that Loctite produces and sells resins for 3D printing.

Loctite 3843 HDT60 High Toughness resin is a professional material that provides high impact strength and moderate temperature resistance. This material is extensively documented, from printing settings to post-curing instructions, so be sure to check its datasheet for more information.

iMakr has shared on YouTube his experience with this resin. He concluded that this material features a discrete temperature resistance and a high impact strength, making this resin perfect for functional applications.

It’s compatible with any DLP printer that covers the 386 nm wavelength spectrum.

- Impact strength: 53 J/m

- Tensile strength: 51 MPa

- Young’s modulus: 1,800 MPa

- Shore D hardness: 67

- Colors: Matte black, white, clear

- Cost: ~$180/kg (black), ~$220/kg (other colors)

B9Creations ESD-Rigid Resin

The superb mechanical properties of B9Creations’ ESD-Rigid Resin make it more than just a tough resin. Besides showing one of the highest tensile strengths of all tough 3D printing resins, it has a high heat deflection temperature and is electrostatic discharge (ESD) safe.

For this reason, it can produce static-dissipative parts appropriate for ESD compliance and high-stress applications. Yet, all these perks come at a high cost and added requirements, including a special hardware kit by B9Creations that includes a Wax Release Agent and a compatible build platform.

B9Creations ESD-Rigid Resin features a curing length between 385 and 405 nm, making it suitable for LCD, DLP, and SLA machines.

- Impact strength: 24 J/m

- Tensile strength: 68.1 MPa

- Young’s modulus: 2,600 MPa

- Shore D hardness: 87

- Color: Black

- Cost: ~$360/kg

ETEC E-Rigid Form

To finish off this strong list, we have ETEC’s E-Rigid Form. This is a polyurethane-based resin that can produce parts that rival injection-molded ones. It offers high tensile strength and good heat deflection temperatures, being ideal for both functional prototyping and end-use parts.

The E-Rigid Form is also water resistant, with an absorption rate of 0.67% for 48 hours of exposure. It’s an engineering-grade material that the manufacturer advises using with their own 3D printing platforms such as the Envision One and the D4K.

- Impact strength: 30 J/m

- Tensile strength: 68-73 MPa

- Young’s modulus: 2,950-3,250 MPa

- Shore D hardness: 87

- Color: Black

- Cost: Available on request only

Useful Printing Tips

There are a handful of general tips when printing with tough resins. While each resin manufacturer provides its own specific recommendations, the following guidelines should also be observed:

- Layer height: Tough resins usually print better at 50 and 100 microns.

- Supports: Avoid printing directly on the build platform, since it can be really hard to remove. Fully supporting the part might be beneficial, as support structures can be broken instead. Warming the build platform with heated air can also make life easier during part removal.

- Cleaning: Unless otherwise stated by the manufacturer, tough resins can be washed in regular isopropyl alcohol (IPA). Make sure you don’t leave the piece in IPA for more than 20 minutes, as this may cause it to become brittle.

- Post-curing: Tough resins reach their optimal properties when properly post-cured. Be sure to follow the instructions from the manufacturer, as some resins post-cure better in different wavelengths and with an additional heat source.

- Speed: When working with tough resins, adjusting your lift and retract speeds is crucial. Due to their higher viscosity, tough resins benefit from slowing down lift and retract speed. Additionally, increasing the temperature slightly can decrease the resin’s viscosity, allowing for faster speeds.

License: The text of "The Best Tough ABS-Like Resins" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.