What Is It?

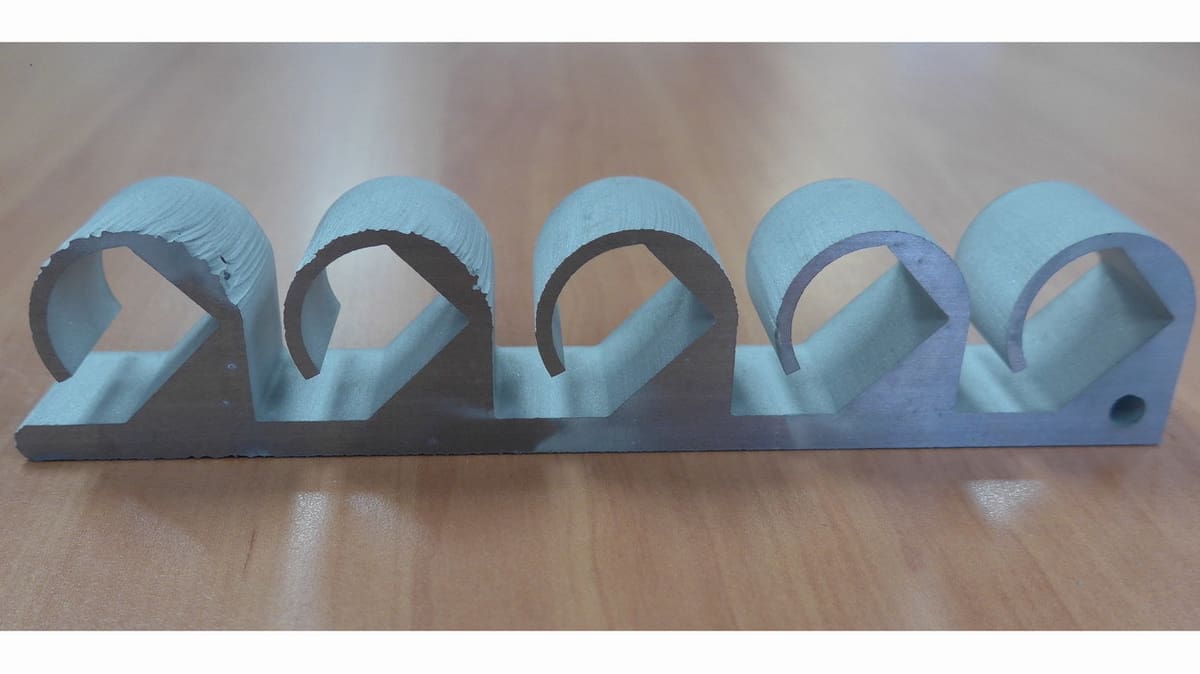

The concept of using water to cut things is pretty old. It was used for the first time in the 1800s to cut soft and thin materials, but it took almost a hundred years to develop technology that can be used on harder materials. In the last couple of decades, it’s rising in popularity and availability.

The only problem is the price of the equipment. Most people can’t afford to have a CNC waterjet cutter in their garage, and that’s where online waterjet cutting services come in.

Why Cut with Water?

There are a number of advantages that make waterjet cutting preferable for particular applications:

- Lack of heat: No heat is generated during waterjet cutting. This is useful when cutting materials that can deform or have their properties altered if overheated.

- Smooth edges: Waterjet cutting doesn’t leave a burr or rough edges.

- Thick material performance: Compared to some methods of cutting, waterjetting can cut very thick materials, up to a couple of inches, in some cases.

- Material compatibility: Waterjets can cut through a variety of hard or complicated materials that can’t be cut with conventional methods, like stone and glass.

- Safe operation: No harmful airborne particles or fumes are emitted during cutting.

- Narrow kerf: The kerf is very narrow. It’s wider than a laser but narrower than a plasma cutter.

Following some design tips, we’ll take a look at some of the biggest and most popular online waterjet services. They’re all established businesses with proven reliability.

Design Considerations

When designing for waterjet cutting, there are a few rules of thumb to follow:

- Avoid tight tolerances in thick materials.

- All internal radii should be 0.6 mm (0.025″) or larger.

- You can’t engrave with a waterjet. If you need something engraved, use laser cutting or CNC milling.

- Make sure all slots are wider than a kerf width.

- Holes should be made no smaller then 2.5 mm (0.1″).

- The accuracy of waterjet cutting machines is typically around 0.13 mm (0.005″).

- Think about the surface finish. You may be charged more for a smoother finish.

eMachineShop

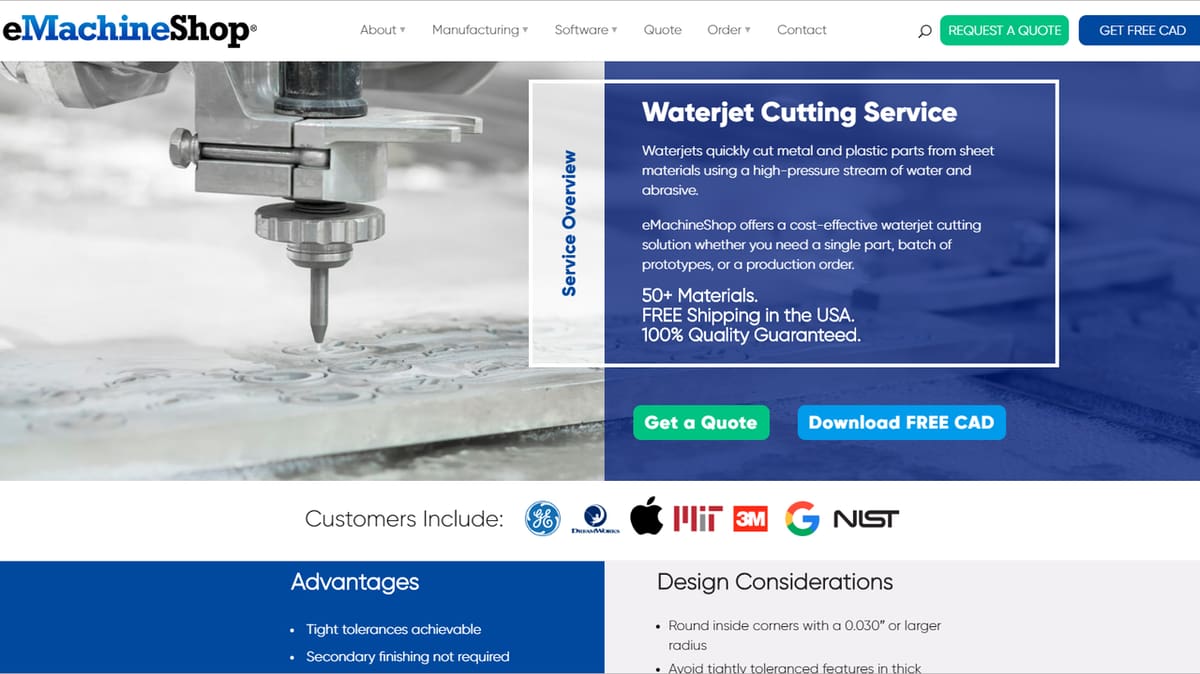

eMachineShop is a New Jersey-based company that offers manufacturing services, including waterjet cutting, CNC milling, turning, 3D printing, and injection molding. They were founded in 1999 as one of the first online machine shops. In order to provide quick and easy quoting, eMachineShop offers its own free CAD software. With this software, you can design your parts and get instant manufacturability analysis, pricing, and easy ordering.

Shipping: Worldwide

Quotes: On request, or instant with their free CAD software

Materials: aluminum, brass, bronze, copper, steel, stainless steel, spring steel, titanium, ABS, acetal, acrylic, carbon fiber, laminated fiberglass, nylon, polycarbonate, polyethylene, polypropylene, polystyrene, PTFE (Teflon), PVC, rubber, neoprene, NBR, silicone

Manufacturing capabilities: CNC milling, injection molding, 3D printing, CNC turning, CNC waterjet cutting, CNC laser cutting, EDM, CNC plasma cutting, CNC turret punching, compression molding, sheet metal bending

Supported file formats: IGS, IGES, STP, STEP, SLDPRT, 3D DWG, 2D DXF; STL and OBJ for 3D printing

Xometry

Xometry is a company offering more than just waterjet cutting services. Next to waterjet cutting, they offer CNC milling, turning, and machining. They can cut sheet metal with laser cutting, plasma cutting, and waterjet cutting. In addition, you can get your parts 3D printed, injection-molded and cast.

Shipping: Worldwide

Quotes: Instant

Materials: aluminum, copper, steel, stainless steel

Manufacturing capabilities: CNC machining, sheet metal fabrication, 3D printing (both plastic and metal), urethane casting, injection molding

Supported file formats: STEP, STP, SLDPRT, STL, X_T, X_B, IPT, 3DXML, CATPART, PRT, SAT

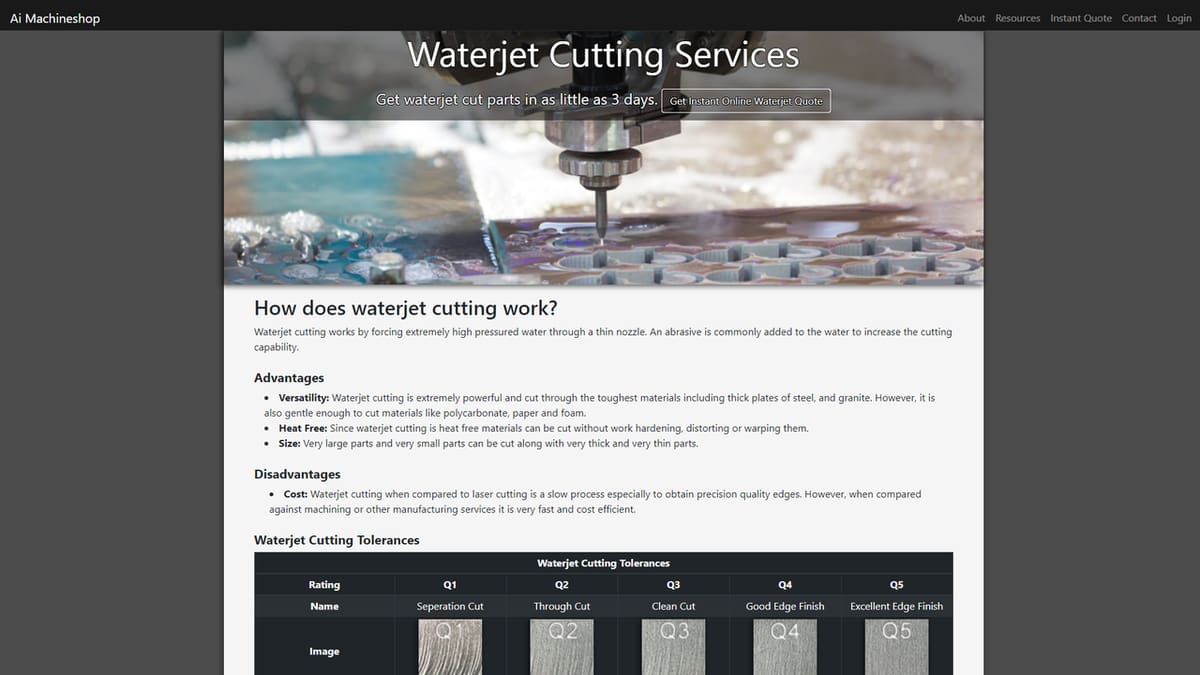

Ai Machineshop

Just like the previous two companies, Ai Machineshop offers more than a waterjet cutting service. They offer machining services and all the fabrication services needed to make a finished sheet metal part. Their services are suitable for prototypes as well as single-piece and low-volume production. So if you’re counting on reliability and high order volume, it may be best to go with a different company.

Shipping: Worldwide

Quotes: Instant for business accounts, by email if you have a personal account or plan to order larger quantities

Materials: aluminum (5052, 6061 and 7075), steel (hot-rolled, 1020, AR400), stainless steel (304 and 316), plastics (ABS, PC, UHMW)

Manufacturing capabilities: CNC laser cutting, CNC waterjet cutting, sheet metal bending, welding, drilling, tapping, powder coating

Supported file formats: STEP, STP, DXF, JPG, PDF, PNG, TIF, TIFF

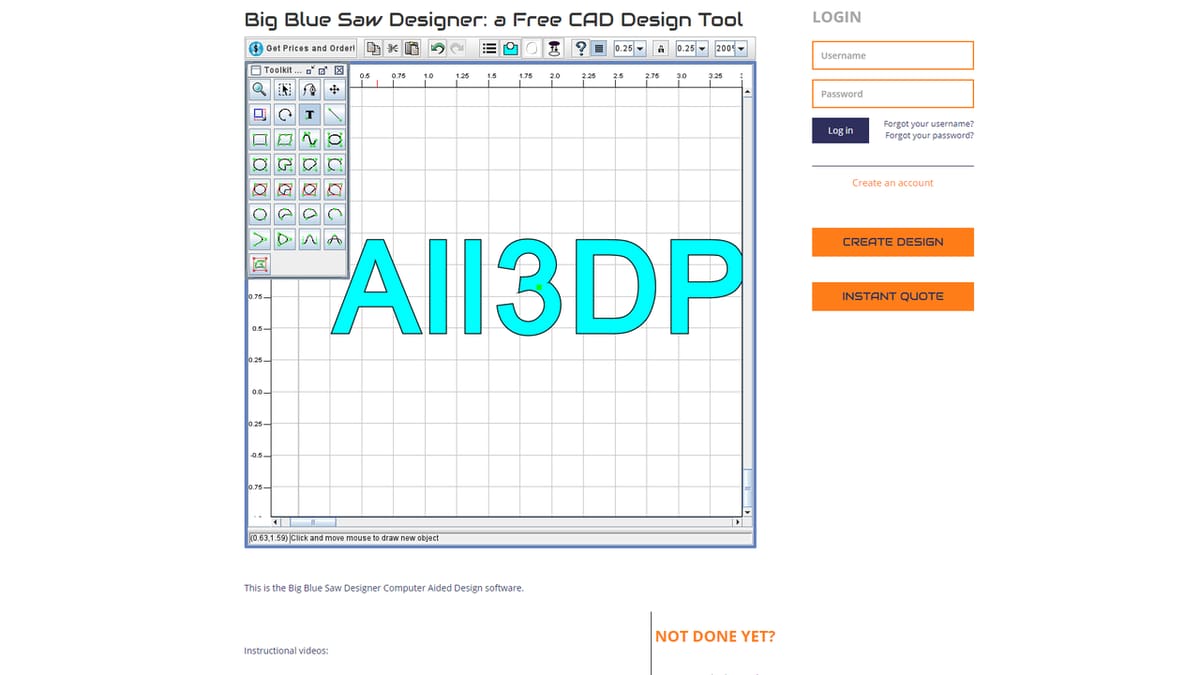

Big Blue Saw

Big Blue Saw is another service that allows you to make custom waterjet-cut and laser-cut parts. You can upload your design for an instant quote or you can use their free online CAD software to make your design.

They offer a range of various materials, but not all materials are suitable for waterjet cutting; some of them can only be cut using a laser. (Make sure to check the list of available materials.) If you’re thinking of a material that’s not on the list, like wood, leather, or fabric, contact them and they’ll try to accommodate your needs.

Shipping: USA and Canada

Quotes: Instant

Materials: aluminum (5052, 6061 and 7075), composites (carbon fiber), carbon steel, stainless steel, copper, white ABS plastic, clear polycarbonate

Manufacturing capabilities: CNC waterjet cutting and CNC laser cutting

Supported file formats: DXF, DWG, GIF, PNG, Big Blue Saw Designer JPX

Fractory

Fractory was founded in Estonia, but at the start of 2019, they moved to the UK. Soon after moving, they were awarded the Best Use of Tech award by the British Chamber of Commerce. Now they have a network of over 30 partnering manufacturers in several countries in Europe.

Though based in Europe, they deliver their products all over the world. The one way Fractory stands out in this list is in their capability to cut metal up to 200 mm (7.8″) thick.

Shipping: Worldwide

Quotes: Instant for laser cutting, everything else is by email

Materials: aluminum, carbon steel, stainless steel, galvanized steel, other materials on request

Manufacturing capabilities: CNC laser cutting, CNC plasma cutting, CNC flame (gas) cutting, CNC waterjet cutting, CNC tube cutting, bending

Supported file formats: DXF for cutting, STP and PDF for bending

(Lead image source: i-cubed)

License: The text of "Best Waterjet Cutting Services" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.