Bambu Lab has become one of the premier 3D printer manufacturers in the hobbyist and small business spaces.

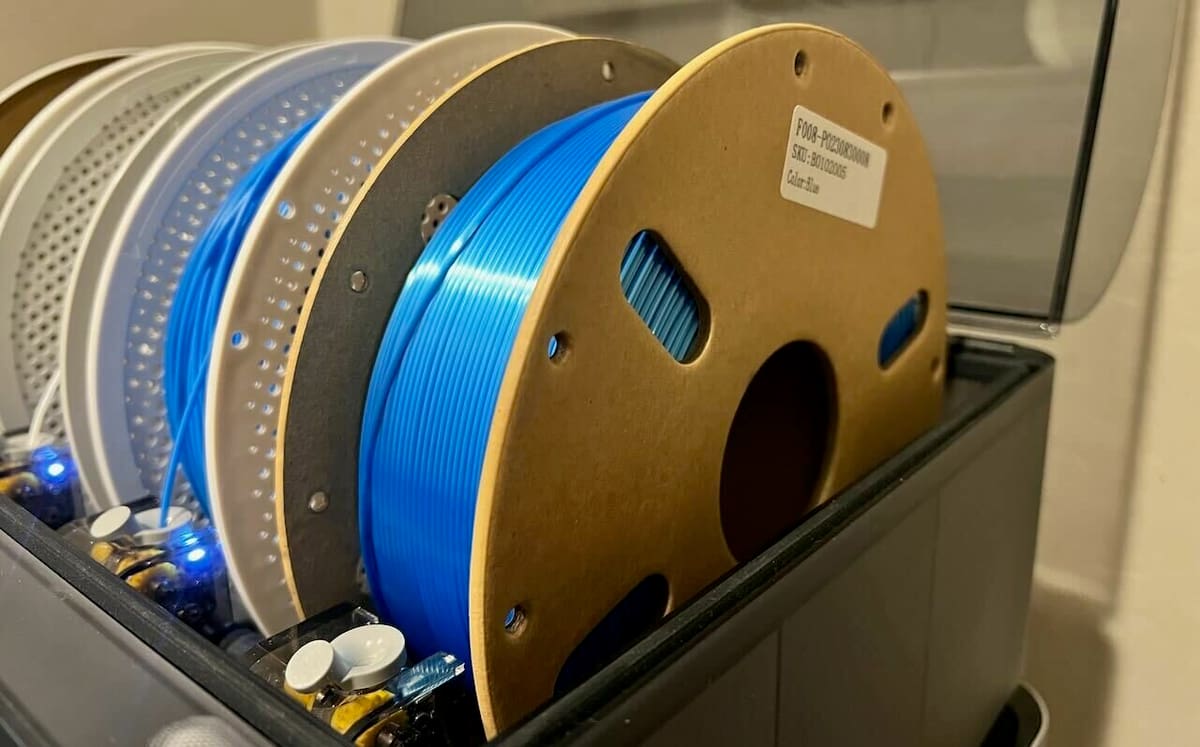

Along with their cutting-edge technology, the Automatic Material System (AMS) is one of their standout features. This system, which is compatible with the X1 and P1 series of 3D printers, consists of four slots to hold four different filament spools, plus a feed motor. With a hub, this unit can be daisy-chained with 3 more, which can mean that your setup can have up to 16 colors!

While it’s a great system, it’s not without its quirks. One of the debated issues is the use of cardboard spools, which aren’t exactly compatible with or recommended by Bambu Lab. The function of the AMS can be compromised by several issues when using cardboard spools, the most significant of which is slippage of the spool.

In this article, we’ll examine the Bambu spools, things to look for when not using Bambu spools, and finally go over a few workarounds for the use of cardboard spools.

Proprietary Spools

Bambu Lab’s filament spools are manufactured to be compatible with the AMS and are the obvious first choice. They have created a reusable spool system that includes the possibility of buying filament refills instead of purchasing them again with a new spool, which leads to more waste. These refills (as well as the filaments that come with the spool) include RFID chips that are read automatically by the setup, so that the machine knows the color and type of filament it’s about to print with.

Arguably one of the major drawbacks of using Bambu filament is the lack of variety in their color choices. While they do have silks, mattes, and dual-color options, and there are 20 PLA colors, there are still other choices not available through Bambu, such as tri-color or fades, or PETG variations beyond 15 colors and transparent options.

So, while the proprietary spool is a great choice, there may be a few times when you might have to use non-Bambu filament.

Other Spool Options

Many manufacturers are still using plastic in their spools, but there is no standardization in the designs. While most plastic spools share a similar circumference, the thickness of the spool edges isn’t consistent and has been known to cause pull-back issues in the AMS.

Cardboard spools can present even more issues, as cardboard can leave a residue on the rubber AMS rollers and can cause clogging. Additionally, the spools can deform and cause feeding or retraction issues.

This being said, there are many manufacturers using cardboard for their spools, a growing trend that’s an attempt at minimizing plastic waste, so owners of a Bambu Lab AMS system will benefit from becoming familiar with them and finding ways to have them in their setups.

Let’s take a look at how you can minimize issues if you’re using cardboard spools in your AMS.

How to Use a Cardboard Spool in Your AMS

Several factors can make your AMS run better if you’ve got a cardboard spool or two ready for use, and opting for the right preventive measures will help you ensure the best possible printing experience.

Just Run It!

Many users have stated on Reddit and other online forums that they use cardboard spools and have had very few, if any, issues. They do state that they have to clean the rollers more frequently and they do get dust built up, but most don’t mind the little extra maintenance. Plus, users note the difference in quality and size of the cardboard itself can yield better (or more involved) experiences.

Electrical Tape

An early solution to adapt the cardboard spool was to simply wrap the edge of the spool with electrical tape. While this is better than bare cardboard, you can still get slippage in the AMS and have some feeding issues. Plus, it can be cumbersome to tape every spool that you want to use if you’ve got a huge collection of filaments. That said, it can also help avoid dust buildup, so it may well be worth the effort.

PLA-Printed Ring

This solution involves 3D printing a PLA ring for the spool, and it appears to be, by far, the most popular solution. There are several designs, but, for example, these have a lip around the inside edge and grip the spool, making them better than some others. Using these PLA strips makes the AMS function nearly as well as using Bambu-branded spools.

Re-Spooling Your Filament

You can move your filament from a cardboard spool to a Bambu spool using a system that transfers the filament from one spool to another. There are several designs online, but this one by maker GekoPrime is simple to print and use. Because Bambu includes default files to print both halves of their spools, it’s straightforward to move the filament from the cardboard to the plastic spool with the winder.

Learning to use cardboard spools in your AMS will broaden your choice of colors and make your multicolor prints that much better. No matter which method you use, you will still get a great print out of your Bambu. Try them all and see what’s best for you. Happy Printing!

License: The text of "How to Make a Cardboard Spool Compatible with the AMS" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.