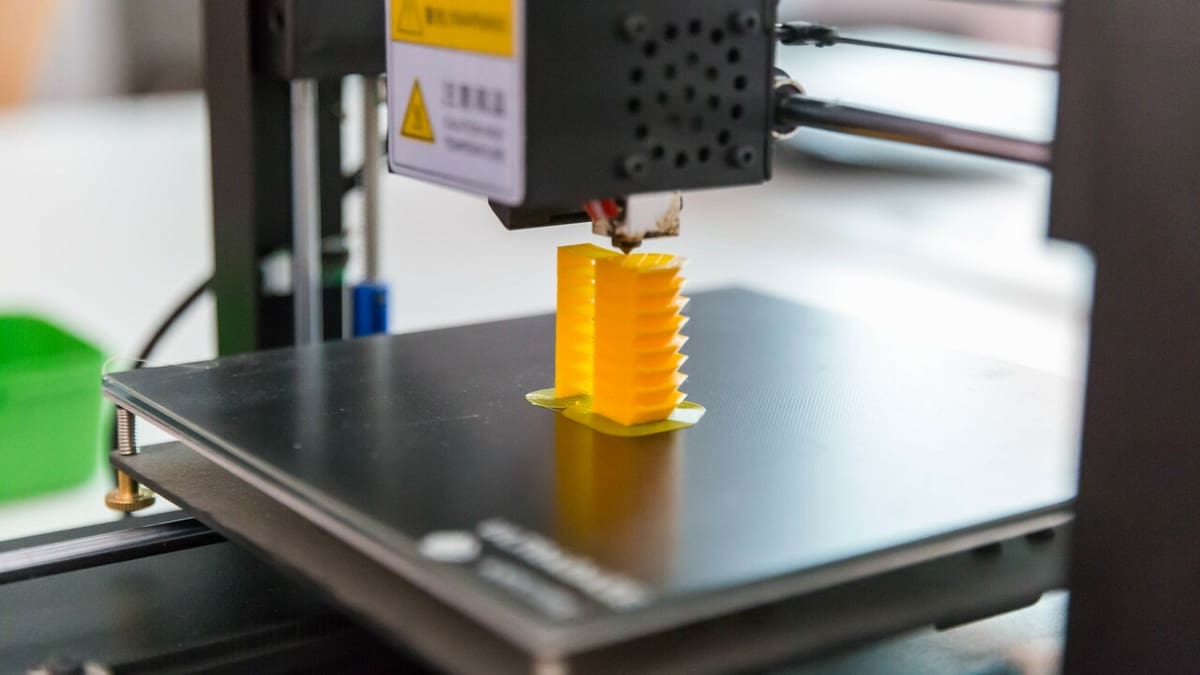

For many makers, the need for or desire of a thing often leads to the question, “print or buy?” And although 3D printing has come a long way, it’s far from completely replacing the need to purchase items. So, where do you draw the line?

In this article, we’ll be exploring when it is and isn’t worthwhile to 3D print something. The answer depends on a number of factors, including the part itself, the equipment needed to make it, what it’s made of, the required quality, and how much time you’re willing to spend. You should take all of these factors into consideration when deciding between 3D printing a part or just buying a pre-made version of it.

You may also want to consider other factors, such as customization and certain design elements. For example, 3D printing has been useful for the dental industry, as custom 3D printed teeth molds based on 3D scans can be very precise. Another example is certain aircraft parts with complex interior geometries that are simple to print but complex to create using other manufacturing techniques.

Both of these examples are very expensive to get 3D printed, but they have other advantages. In some cases, despite the cost, 3D printing might be a more suitable method of manufacturing, so there’s more to consider than just price. Here, we’ll take a look at some things to think about when you’re making the decision whether to print a part or just buy it.

Material & Quality

The first factor involves your desired product’s material and quality. While the cost of filament is almost always lower than the cost of purchasing a finished product, you should think about what you want the end result to look like and its intended function. 3D printed items are often made out of plastic; is this a suitable material for your part? If not, you might want to buy it or invest in getting it printed in metal or enhanced plastics through online printing services. Metal and other high-strength 3D printable materials can offer a lot of durability and other benefits.

For example, parts printed from Onyx material by Markforged are robust and heat deflective compared to items made from standard 3D printing materials. However, getting a part 3D printed in materials like Onyx or metal can be expensive, so this option may not be worth it.

Examples of parts made in high-quality plastic include certain drone propellers and car parts. In order to withstand the test of time and any weather conditions, these plastics are more durable but might not be compatible with a desktop FDM printer.

Some examples of parts typically made in low-quality plastics are cheap pens and binder covers. These staple products are meant for indoor use and are sold so cheaply that using a high-quality plastic would be somewhat of a waste of money for the manufacturer. 3D printing an item that is already produced so cheaply is unlikely to save you any money.

But on the other side of this, it can be worth paying for quality materials. Parts straight off the print bed are often lacking the surface finish that you might be looking for. 3D printed parts might not have the same visual appeal as store-bought products, at least not without spending a good deal of time post-processing. Other properties, like strength, might not be as impressive in 3D printed parts, though there are ways to address this.

In the end, it all comes down to a simple question: does the (potential) higher quality of a purchased part outweigh the cost savings of 3D printing yourself?

Don’t forget that high quality material and finish doesn’t have to sacrifice customization. If you have a unique design in mind but don’t think you’ll be able to achieve the desired properties or aesthetics, there’s always the sort of in-between option: 3D printing services. To find the best one for your needs and budget, check out Craftcloud.

Design

The next consideration depends on the part itself, specifically the design. 3D printing is ideal for making unique and custom parts, such as if you needed a home decor object with a specific shape and dimensions. 3D printing parts like this will be cheaper, as you probably won’t be able to find a purchasable, personalized part.

Another positive for 3D printing parts is that, essentially, if someone can design a 3D model of it, you can 3D print it. You can find millions of 3D printable models online, including STL files of products that are also available for purchase. A good example of printing a popular design is Crosslink’s video about making a phone case. The phone case in the video can be purchased online, but in this case, 3D printing is likely to be less expensive.

If the desired part is simple enough, you can even design it in computer-aided design programs such as Tinkercad and Fusion 360. If you can’t find the design you want and don’t have the expertise to model your own objects, you could even hire a designer to model a more complex part that you might want to 3D print. However, hiring a designer is expensive and would most likely cost more than just buying a part.

One example of where 3D printing might be beneficial over just buying a part would be if you needed something simple but specific, like a sofa foot. You might find the exact design you’re looking for online, but a sofa foot is a pretty simple design, so you could easily adapt another model (which is generally easier than modeling from scratch) and then 3D print it.

This process will no doubt take a longer time than buying it, but you will save some money. In situations like this, it depends on what you’re willing to do to get a part: 3D printing takes more time (though not necessarily longer than the wait for an online purchase to be delivered) and buying takes more money.

Available Equipment

When determining if it’s cheaper to print a part or buy it, you have to account for the equipment used. Your first thought of printing cost might be the filament. Printer filament is pretty cheap and a spool generally lasts a long time, so this isn’t our main concern when it comes to equipment.

However, even though 3D printing a part may seem cheaper than buying one, you also have to factor in the cost of your 3D printer. With this in consideration, it would take a lot of 3D printed parts that you would otherwise have purchased to break even on your initial investment of the printer itself.

An example of when 3D printing would be beneficial with equipment in mind would be in the automotive industry. The cost of 3D printing equipment is negligible compared to the total cost of companies buying outsourced parts and storing them. So in this case, 3D printing certain parts will lead to long-term cost reductions.

On the other hand, for a school or university department, 3D printing for end-use or prototype parts (especially if SLS printing is required) may not be worth the investment, given the high up-front costs and the space required to permanently store equipment. Of course, if you just need one or a few parts printed with special equipment, 3D printing services can be an affordable option.

For many makers, 3D printing is a hobby and a passion, so your initial investment will be justified by the potential for experimentation. Lastly, to get an even more precise calculation of cost, you might want to determine how much power your 3D printer consumes and how much this costs you.

Time & Money

One benefit of buying anything online instead of making it yourself is the time saved. Time is money, as they say, so why spend precious time designing and 3D printing parts that can be bought inexpensively at a nearby store?

When it comes to deciding if it’s worth it to 3D print an item, you should consider how you value your own time. Don’t forget to include any time spent designing or modifying a model, plus post-processing time, when you calculate your time investment. Also keep in mind that prints don’t always turn out perfect on the first go, so experimentation with print settings and re-printing may also consume time.

Realistically, printing a precise but generic object like a Lego brick wouldn’t be worth the effort, when the same object is cheap and easy to purchase (and will be more dimensionally accurate). On the other hand, if you need a specific replacement part for a product you already own, it might be difficult to find the part to buy but simple to download or create the part to print.

If you’re very conscious of your spending, or if you just enjoy the designing and printing process so much that you don’t consider it time wasted, 3D printing can often be the better option. As we’ve mentioned, the real cost of materials is low, and the benefits of customizability can outweigh the additional time required. It just depends on how much time you’re willing to spend designing (or locating a file to download if the design is already posted online) and printing an object.

If you’re trying to save money in the long run, and you already own a 3D printer, printing your own parts is a great idea. However, the ease and potentially superior quality of a purchased product will often outweigh the cost savings of 3D printing. And sometimes, the purchased product is so cheap that it’s simply not worth attempting to print! Although this could change in the future, buying parts will most likely continue to dominate over 3D printing for now.

Lead image source: Formlabs

License: The text of "Is It Cheaper to 3D Print Something or Buy It?" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.