Your 3D printer’s extruder slipping or clicking is a relatively common phenomenon, and chances are that you’ll encounter it at some point. Aside from the annoying sound, it can lead to significant defects in a 3D printed part. The most visible issue caused by a clicking extruder is under-extrusion, but in severe cases, you might even notice filament leaks from the hot end.

When you’re experiencing a clicking extruder, it’s a sign that something is definitely wrong with the flow of the filament. Essentially, it occurs when the extruder’s stepper motor is stalling and cycling backward, but this could occur for a number of reasons. As such, we’ve gathered some easy fixes so that you can resume your 3D printing.

Level the Bed

A leveled bed shows that the distance between the nozzle and the build platform is uniform throughout the print surface. The first layer won’t stick to the build plate if the gap is too high, but if the nozzle is too close to the bed, the material has less space to flow. This can lead to a buildup of pressure in the system, which eventually will exceed the stepper motor capacity. The result is a clicking of the stepper motor.

Always take the time to level the bed evenly and with a sufficient gap so that the filament is squished just enough to adhere to the bed. A good rule of thumb is to make the gap just enough to let a piece of paper slide between the nozzle and the bed with slight friction.

Lower the Print Speed

The right print speed is important to get a quality 3D printed part. If you print at too high a speed, the extruder will push the material too quickly, and it may not have enough time to absorb heat and melt properly. This partially melted filament can’t leave the nozzle and may even clog it. A clogged nozzle will then exert pressure back on the extruder, resulting in clicking.

If you’re experiencing a clicking extruder, it could be that you need to slow the printing speed. This should allow the filament to heat and melt properly, ensuring a smooth flow. Indeed, slowing print speed is a common remedy to a variety of issues; when in doubt, take things nice and slow.

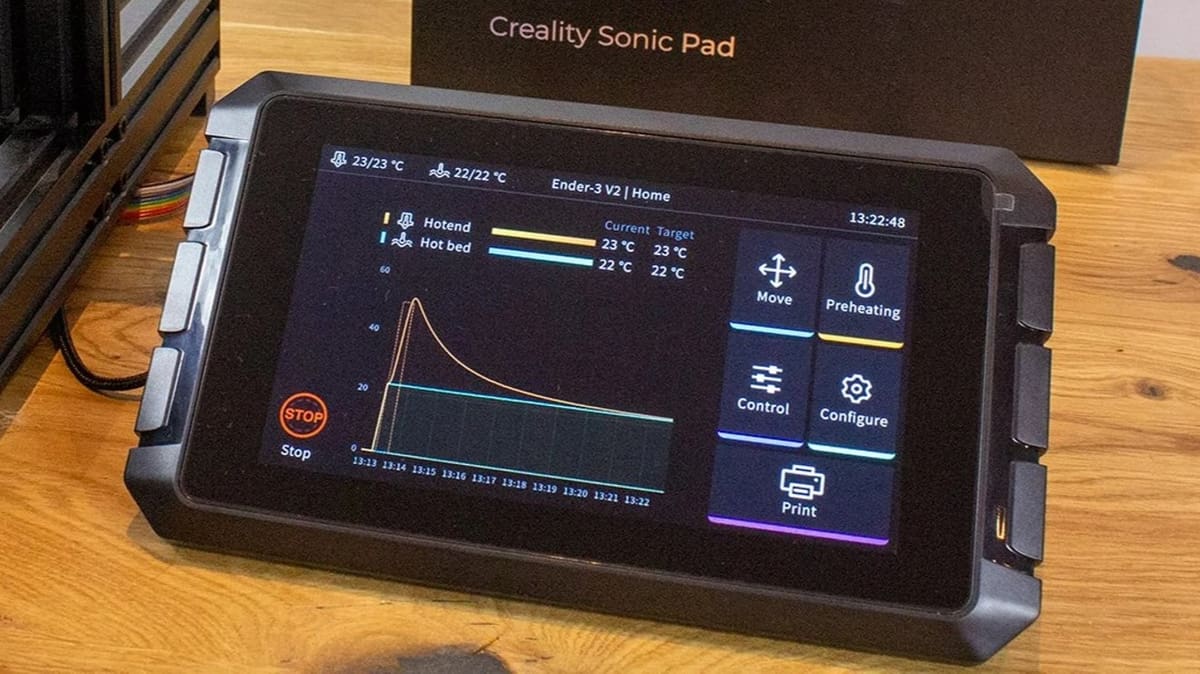

Increase the Temperature

To ensure a smooth flow of filament, it’s crucial that the temperature of the hot end is set accurately. If you set the temperature too low, the filament may not melt properly. Just as a higher speed may result in a clogged nozzle, too low of a temperature can also clog the nozzle. Once the nozzle is clogged, the filament has nowhere to go. As the extruder is no longer able to push the filament ahead, it starts “slipping”.

If you suspect that your temperature is too low, try increasing it by 5 °C at a time. Also, if you’re printing a material that requires a lower temperature than what you’ve just printed with, make sure to flush it all out before switching filaments. Otherwise, trace remnants could cause problems.

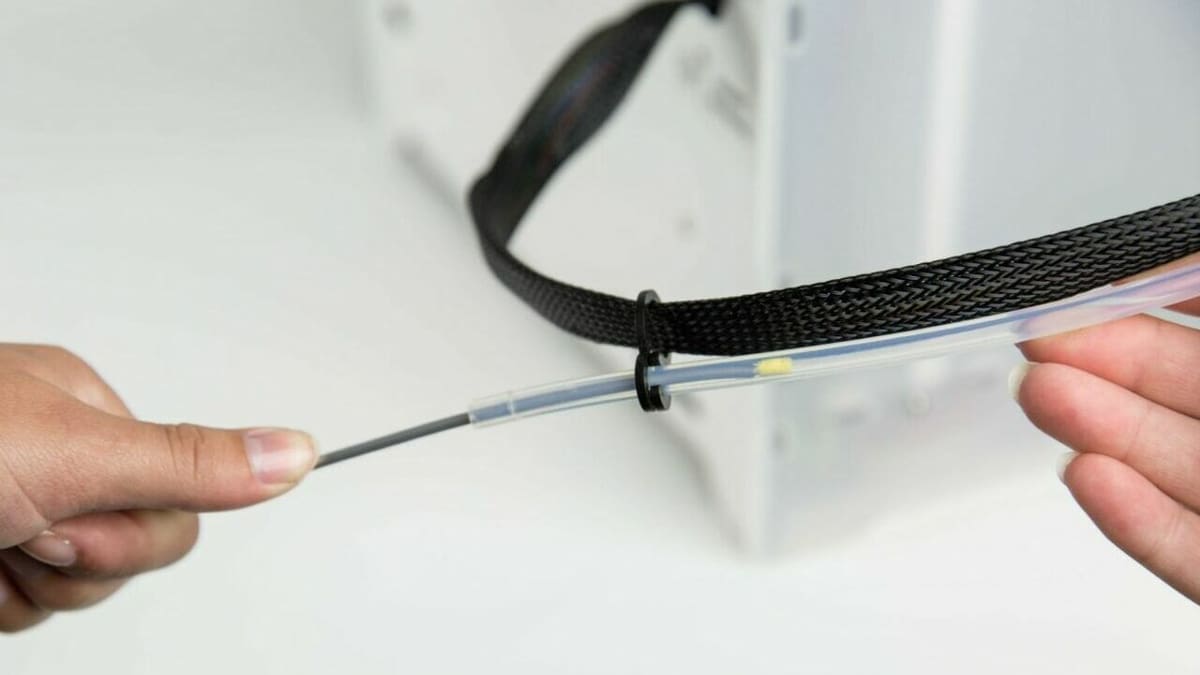

Check the Bowden Tube

In many printers, a Bowden tube guides filament from the extruder to the hot end. However, if this tube’s tolerances are too tight, the filament may experience an excess of friction while passing through. Also, if there’s any dirt or debris present, these particles can cause friction between the tube and the filament. If the friction exceeds a certain threshold, the stepper motor will be unable to push the filament, which may cause the extruder motor to slip.

These issues also cause the overheating of the extruder motor and under-extrusion in the 3D printed parts. You can easily check the PTFE tube by pushing the filament manually through it. It should be able to move freely with as little friction as possible. You should also clean the PTFE tube once a week to make sure there’s no debris in it. Alternatively, if nothing works, you can just swap out the tube for a new one.

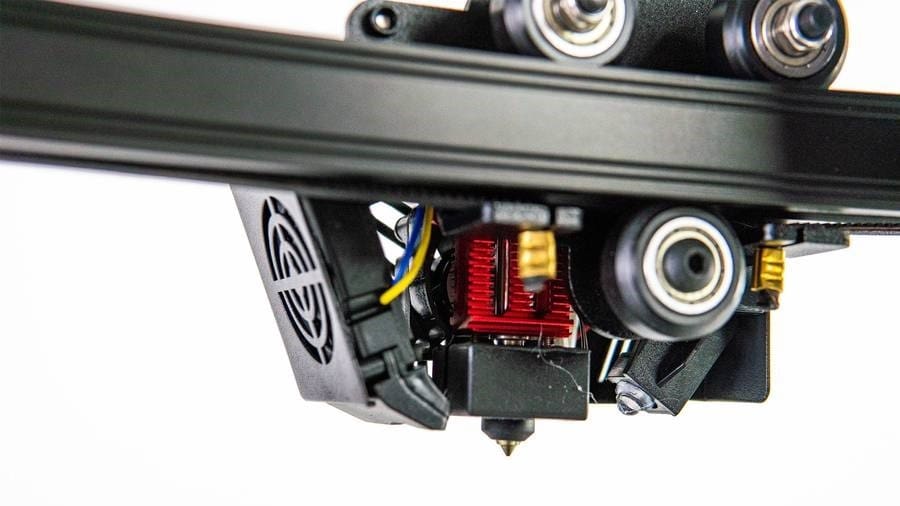

Check the Hot End & Nozzle

Hot End

Regardless of whether the extruder is Bowden or direct, most printers have a PTFE tube that lines the hot end up until the nozzle. A loose coupling could therefore allow molten filament to leak into a gap between the tube and the nozzle. Eventually, this material will cause a partial blockage and restrict the flow of the filament. This partial blockage could result in the stepper motor no longer pushing the filament forward. And at a certain point, the stepper motor will start clicking due to the back pressure.

Solving this issue will depend on your printer’s extruder. In some cases, you’ll need to disassemble the hot end completely. After that, look out for any residual lumps of filament and clean them out. Once you’ve checked that the path is completely clean, replace the faulty coupling with a new one, and ensure that the PTFE tube is completely in the heat break with no gaps.

With a Bowder extruder, this could be as simple as removing the nozzle, decoupling the tube, and pushing it all the way through the open hot end path. In any case, we recommend finding a YouTube video showing how to address the problem for your specific model of printer.

Nozzle

Small dust particles or debris may block the hole of the nozzle, which means you have a clogged nozzle. As such, the filament’s flow will be disrupted and uneven, causing a build-up of pressure in the feeder system. Similar to what we’ve discussed already, the pressure will be too much for the stepper motor. And when the stepper motor’s shaft slips, you’ll hear clicking.

This issue is more prominent in the nozzles with a smaller diameter. You can quickly remove any debris in the nozzle using a simple nozzle cleaning needle. Alternatively, or if that doesn’t work, simply swap out the nozzle. They’re relatively cheap, and replacing is easy.

Upgrade the Extruder

Apart from the stepper motor (which we’ll discuss next), there are two things to look at when it comes to your extruder: the type of gear and its spring. Let’s take a closer look.

Extruder Gear

In most hot ends, a small gear and a pulley system grip the filament. These work together to grip the filament and push it forward. However, after many hours of use and because of the gear’s soft material, the teeth on the extruder gear may eventually wear out. Thus, it can no longer hold the filament, leading to filament slipping in the extruder.

Normally, this won’t result in clicking, but it may lead to grinding. This is sort of the “opposite” problem, where the gear continues to turn but without pushing the filament.

Nevertheless, if you’re going to print a lot of harder materials, you should definitely opt for a steel extruder gear. Also, instead of having just a single gear and pulley system, consider a dual gear setup. This will lead to a better grip on the filament, ensuring that it’s being pushed evenly.

Extruder Spring

The extruder spring is responsible for the gripping force on the filament. If spring tension is too low, the extruder gear won’t properly grip the filament. Once again, this leads to filament grinding (assuming there aren’t other problems), where the filament is literally chewed up.

On the other side of the spectrum, if you set the tension too high, the gear may grip the filament too hard, where the force prevents it from turning. If that’s the case, your extruder’s stepper motor may be the one to buckle first.

Check the Stepper Motor for Defects

This should be the last of your worries and isn’t that common of an issue. Still, it can’t be eliminated completely. A quality stepper motor ensures the components are well built, and the motor itself is calibrated correctly.

Assuming your printer comes from a reliable manufacturer, the stepper motor provided should be able to deal with the necessary forces. However, it’s sometimes possible that the wiring of the motor may be faulty. It’s also possible that the current and voltage settings of the stepper motor may not be calibrated correctly.

Both issues will lead to improper functioning of the stepper motor. It can happen that the stepper motor heats quickly, and the high temperature causes it to skip steps and thus click. You can add a heatsink to the stepper motor to ease some of the heating issues. Also, you should check for any wiring defects externally. If nothing helps, change the stepper motor for a new one.

Lead image source: Locke_Kincaid via Reddit

License: The text of "Slipping or Clicking Extruder: 7 Ways to Fix It" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.