A CNC machine is an amazing tool for anyone who likes to make, well, stuff. From decorative engravings to functional parts, they can create just about anything. These clever little machines can also work with a wide range of materials: from soft options like foam to some harder (but still relatively soft) options like aluminum.

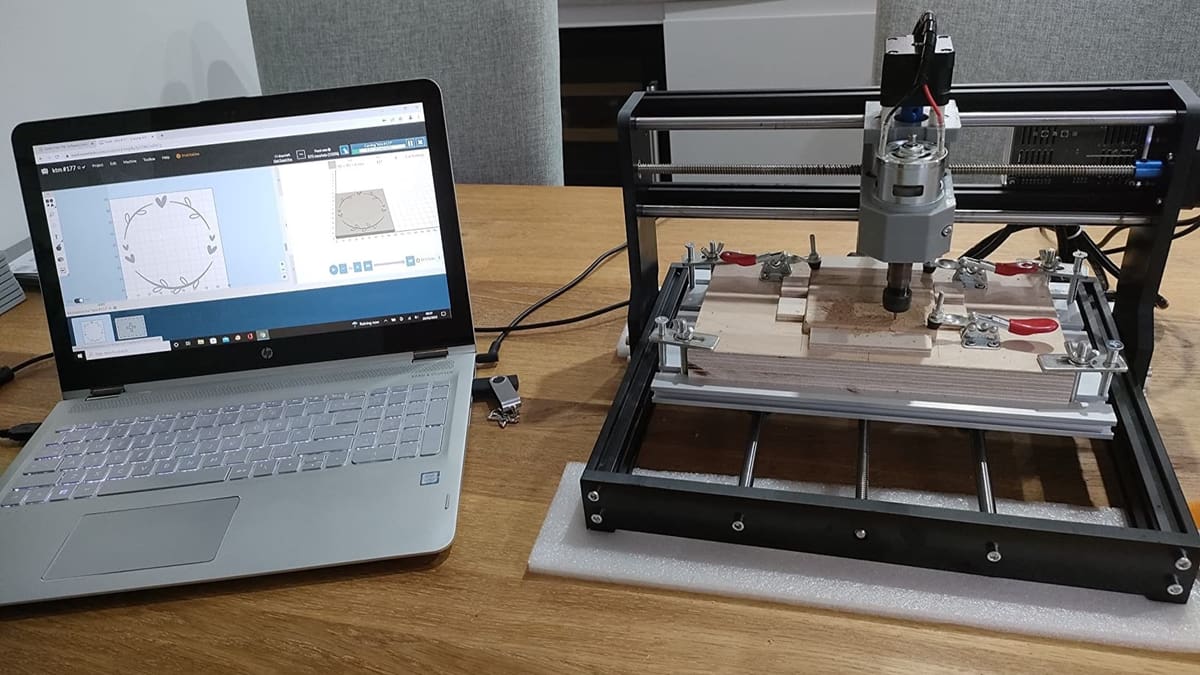

CNC 3018s (and “Pro” versions) are some of the cheapest CNC machines on the market. They’re generic CNC router setups that are a great choice for many people getting their introduction to CNC machining.

If you’ve already purchased and built your CNC 3018, you’re probably going to be wondering what software you should use to get the most out of your machine. There are many different programs that can be used to control a CNC 3018, and quite of few of them are user-friendly and free.

Before looking at our top choices, let’s go over how we made the call and a few things you might want to keep in mind when deciding which to go for.

Getting the Right Cut

When looking for CNC control software, there are a few things you should keep in mind. Most importantly, you want to make sure the software has the functionality you need. Some of these programs will generate G-code for you and run it on the machine, while others just control the machine.

Apart from functionality, there are a few other items one should consider when looking into CNC software:

- Simple user interface: An intuitive, easy-to-use, and easy-to-learn user interface goes a long way in facilitating the execution of your CNC projects. All the programs on this list are fairly straightforward, although some might offer more involved features that might take some getting used to.

- GRBL compatible: CNC 3018s run the popular open-source GRBL firmware, which means the software you choose must be compatible with GRBL.

- Reliable: A software tool that functions properly for the duration of a project is essential to the creation process. The selection in this article has the backing of companies and the community, as well as positive reviews from makers.

With these considerations in mind, here’s our list of the best software for your CNC 3018.

Easel

Easel is a browser-based CNC control program and G-code generator that provides tools for creating your own designs and running the cuts on your machine. Given its simplicity and user-friendly interface, it’s a great program for easy projects, such as simple engravings, and for beginners who are just getting started in the CNC machining world.

The program walks you through the setup of your machine and CNC operations. There are multiple built-in tools and customization settings for generating G-code, but you can also just import your own.

Easel is available to use for free after the completion of a free trial of Easel Pro, an upgraded version of the software that boasts extra features for a price of $233/year or $599/3 years. If you’re new to the game of CNC though, stick to the free software until you’ve learned the ropes a bit and save yourself some money.

- Cost: Free

- Intended purposes: CNC control, G-code generation

- Notable features & functions: Compatible with multiple CNC firmware options, works in a browser, very simple interface

- Operating systems: Windows, Mac, Linux

Universal GCode Sender

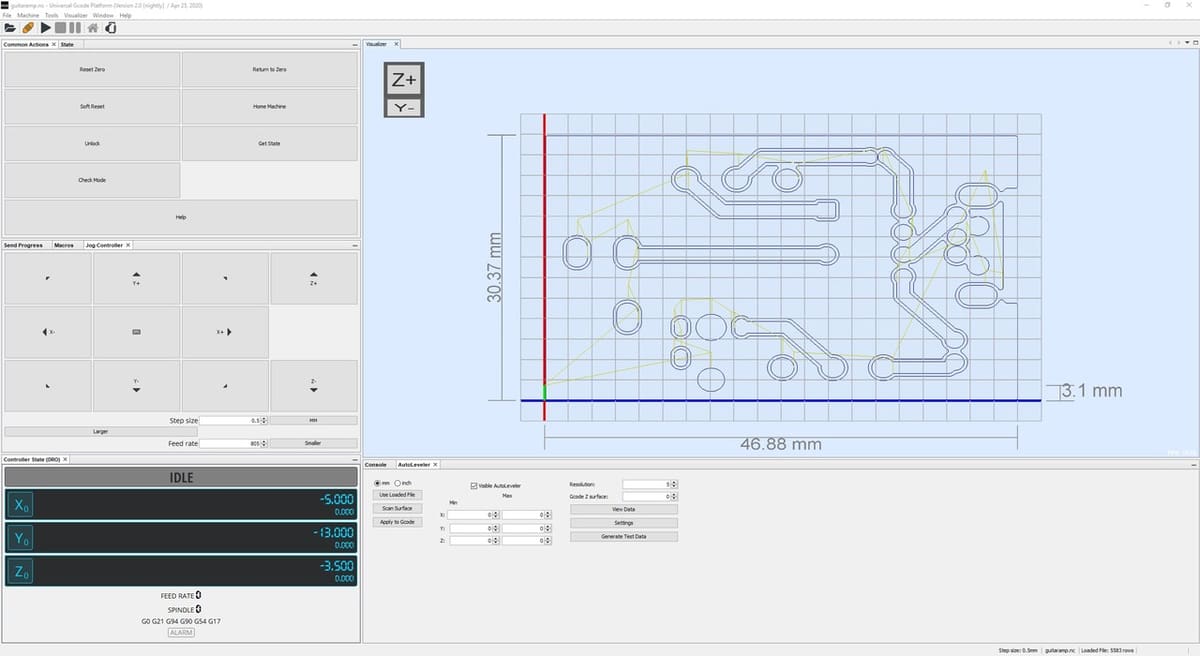

Universal GCode Sender (UGS) is CNC control software that’s very popular among makers because it’s free, open source, and regularly updated.

The program has a very intuitive interface with tons of built-in functionality. Though the program runs G-code, it will not generate it. Nevertheless, UGS is a versatile choice for controlling your CNC machine.

UGS has a helpful setup wizard for configuring your machine and settings. This program is very easy to get up and running, and there are many plug-ins you can add to get specific functionality like auto-leveling.

- Cost: Free

- Intended purpose: CNC control

- Notable features & functions: Compatible with GRBL firmware, well documented and open source, easy setup, excellent interface

- Operating systems: Windows, Mac, Linux

Estlcam

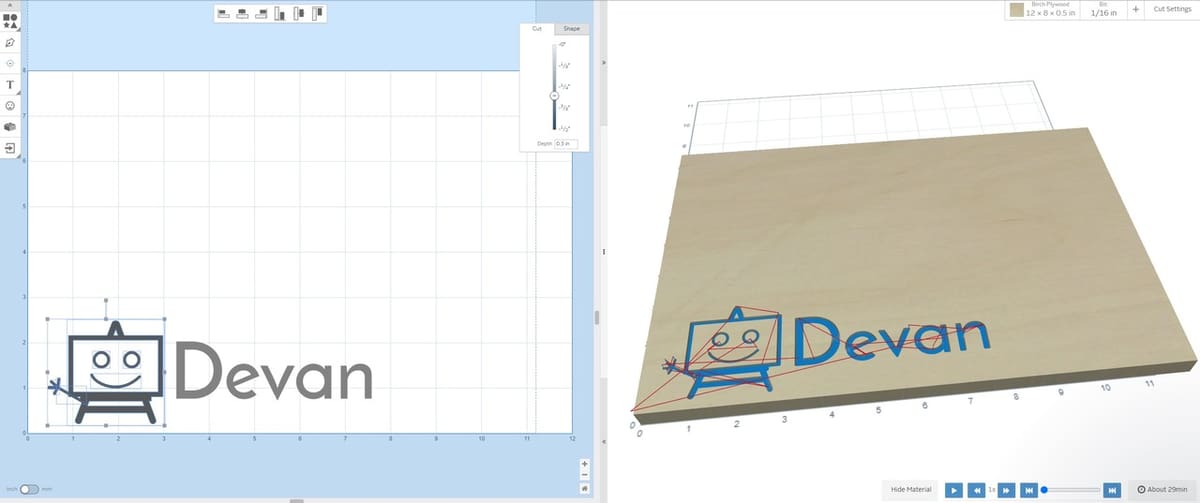

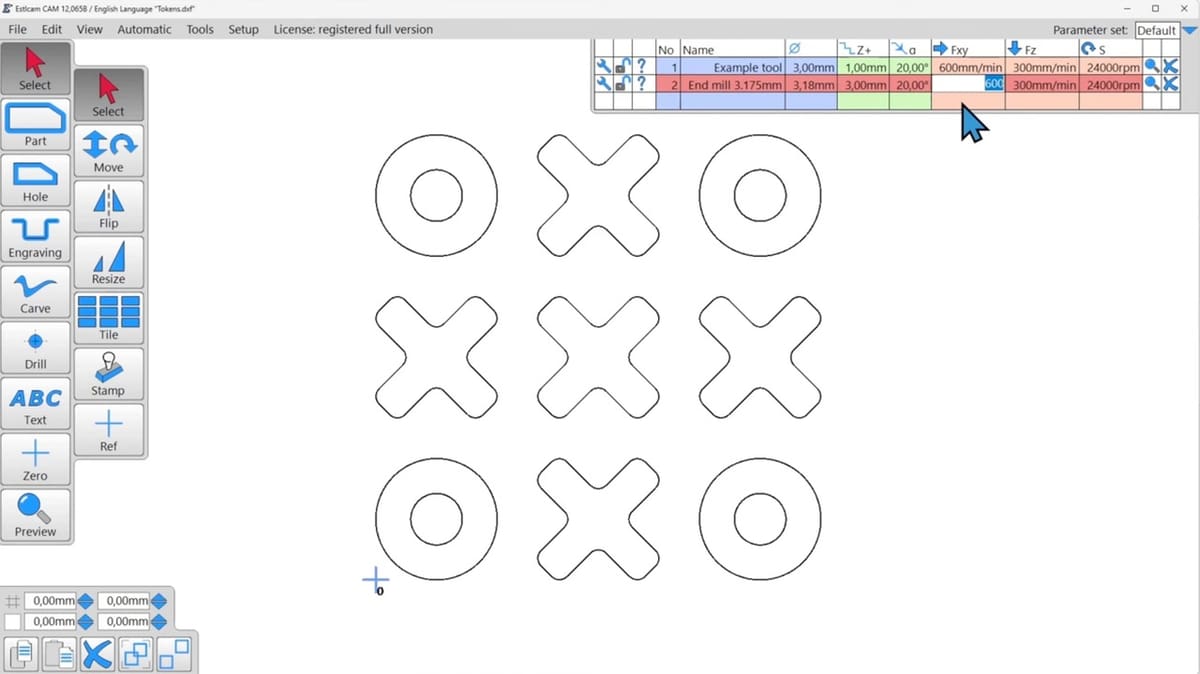

Estlcam is software designed for CNC control and G-code creation, making it ideal for hobbyists and small businesses. It supports 2D, 2.5D, and 3D toolpaths, and works seamlessly with file formats like DXF, SVG, and STL.

A comprehensive tutorial video is available on YouTube, providing detailed guidance on all major functions, which makes it easy for beginners to get started with.

Estlcam offers a fully functional free version, allowing users to try it before committing. All you need to do is download and install the version. There are no functional differences between the free and paid versions, while the former just has longer waiting times when opening and saving files. A license key is available for just ~$60, making it a cost-effective option for anyone looking to enhance their CNC capabilities.

- Cost: ~$60, but it has a free, fully functional version

- Intended purposes: CNC control, G-code generation

- Notable features & functions: Compatible with multiple CNC firmware options with a complete beginner tutorial available

- Operating systems: Windows

OpenCNCPilot

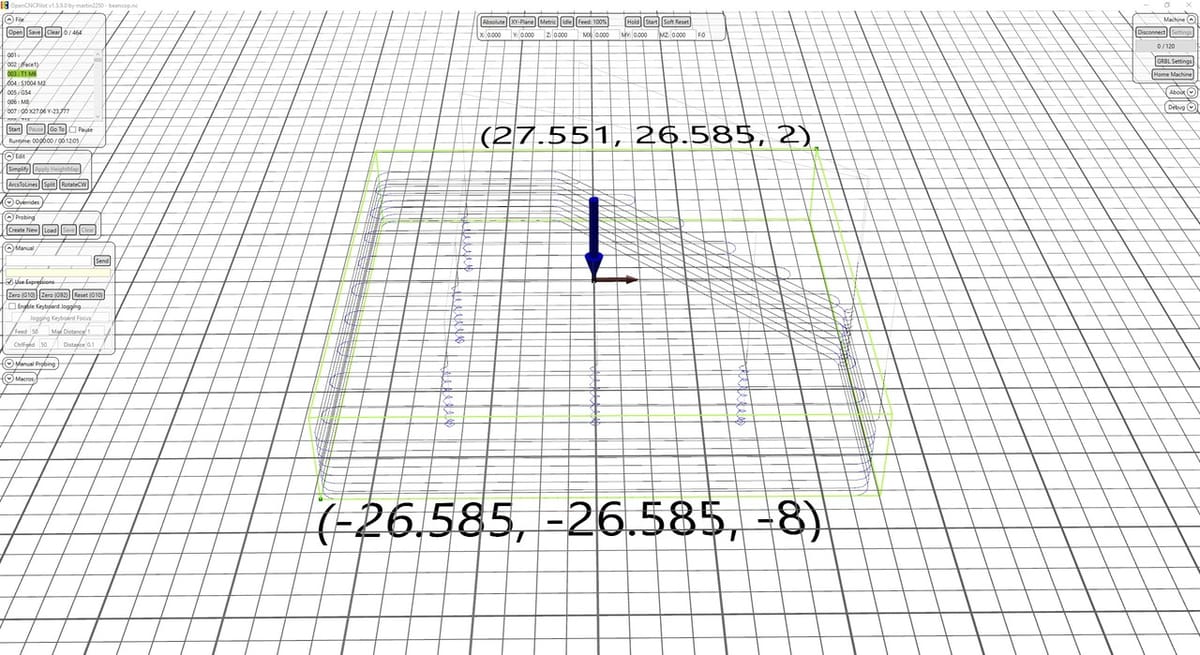

OpenCNCPilot is a lesser-known CNC control program, but it packs in a lot of functionality and is a very concise tool. With just a few clicks, you can have your machine running.

Similar to UGS, OpenCNCPilot controls only the machine. The user interface is slightly less intuitive than alternatives in this list but the program does at least incorporate an easy-to-use auto-leveling system, which lends itself very well to PCB carving. The auto-leveling, together with the probing system, makes this program very attractive to people looking to mill PCBs.

- Cost: Free

- Intended purpose: CNC control

- Notable features & functions: Compatible with GRBL firmware, auto-leveling, well documented and open source, simple interface

- Operating system: Windows

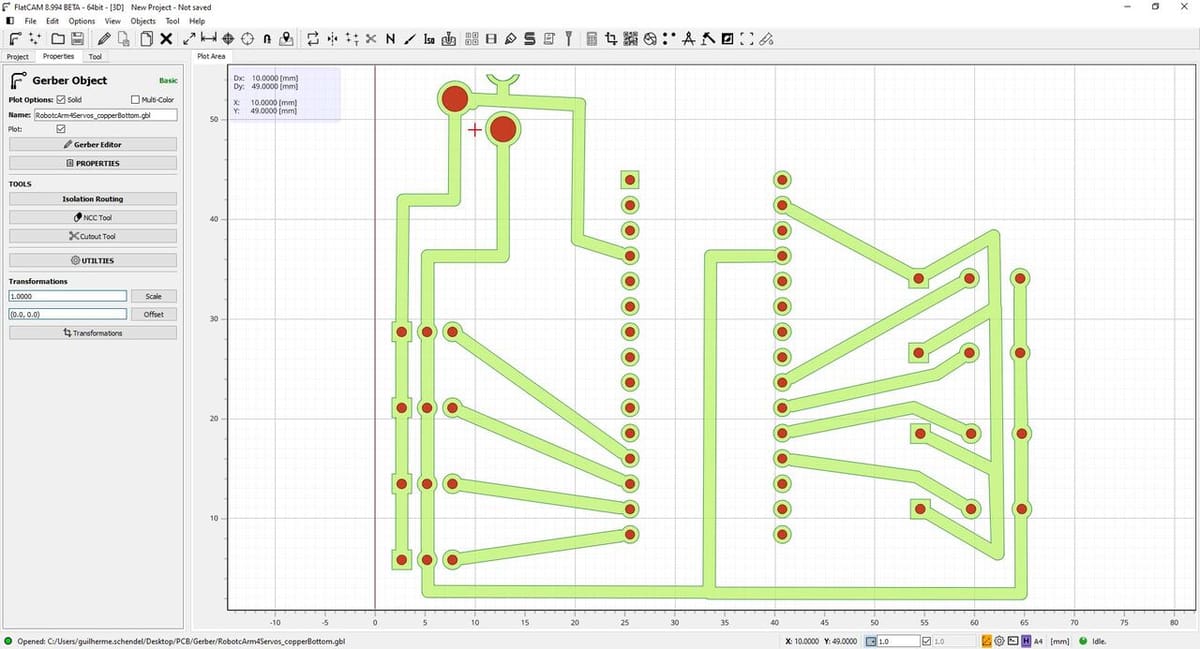

FlatCAM

FlatCAM is a specialized program for preparing CNC jobs to create PCBs on a CNC router, distributed at no cost under the MIT License. The software allows users to take Gerber files generated by popular PCB CAD programs and convert them into G-code for isolation routing. Supported file formats include Gerber, Excellon, G-code, and SVG, offering versatility for various PCB designs.

The G-code generated by FlatCAM follows the NIST G-Code Guidelines, but only supports a subset of commands necessary for planar operations. When importing G-code, irrelevant codes for the 2D view are ignored, ensuring compatibility with MACH3-compatible motion controllers. This makes FlatCAM a useful and precise tool for PCB milling projects.

- Cost: Free

- Intended purposes: G-code generation

- Notable features & functions: Very easy to create PCB toolpath from Gerber files, with a thorough user manual

- Operating systems: Windows, Linux, Mac

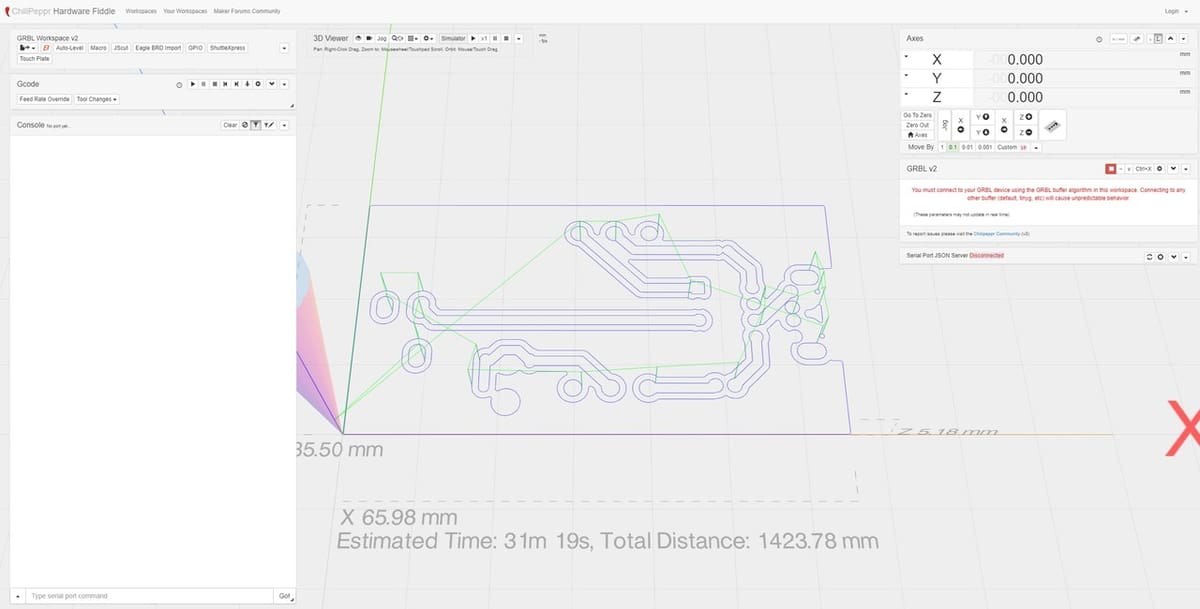

ChiliPeppr

ChiliPeppr is a browser-based CNC controller that works with multiple CNC firmware options, including GRBL. In order to get it to work with your CNC machine, you’ll have to install a simple driver to connect to the machine through your browser.

In comparison to Easel, the other browser-based option on this list, ChiliPeppr is better suited to advanced users. While Easel is an easier program to use, ChiliPeppr has a few additional features that Easel leaves out, including auto-leveling and probing. There’s also the ability to create your own workspaces, with video tutorials available towards the bottom of the site’s main page explaining how to do so.

- Cost: Free

- Intended purpose: CNC control

- Notable features & functions: Compatible with multiple CNC firmware options, auto-leveling, well documented and open source

- Operating systems: Windows, Mac, Linux

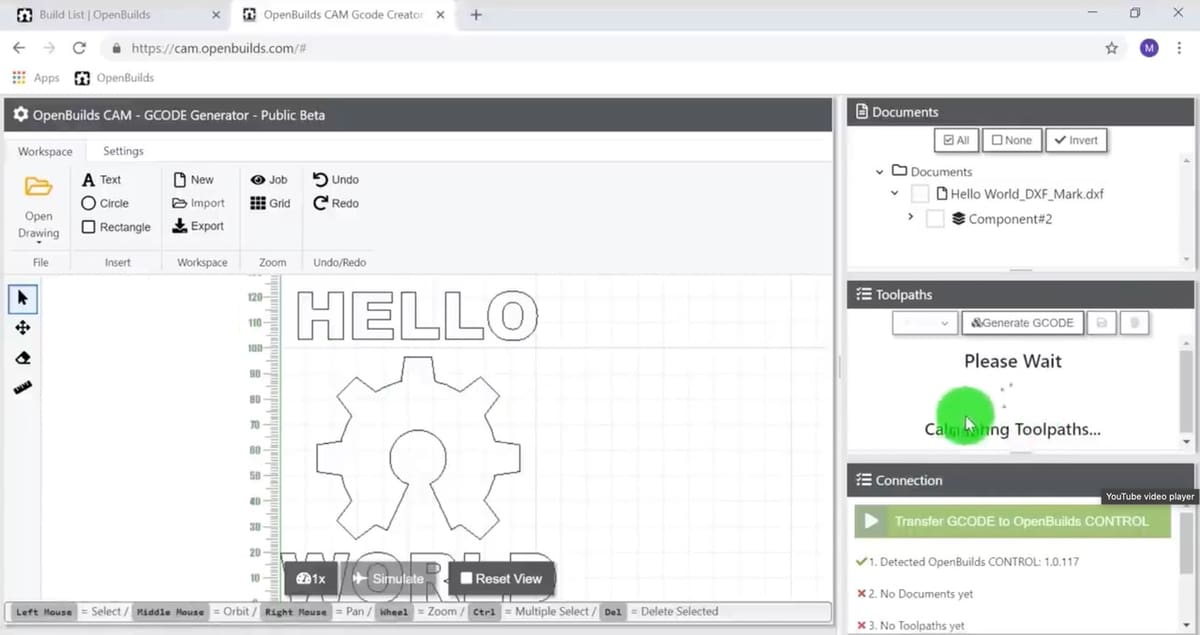

OpenBuilds Control

OpenBuilds Control is a free and intuitive application for managing CNC, laser, plasma, or dragknife machines, brought to you by one of the world’s largest maker communities. It offers a wide range of features, including “jogging your machine, running G-code, setting zero coordinates, probing operations, spoilboard surfacing, machine calibration, and more. With options for different machine profiles and custom settings, it provides excellent control and flexibility.

For a streamlined workflow, you can integrate OpenBuilds CAM, a free web-based application for converting SVG, DXF, and Bitmap files into G-code. OpenBuilds CAM allows you to easily set up toolpaths for CNC routing, laser cutting, and plasma cutting. Then, you can send the G-code directly to OpenBuilds Control, ensuring a seamless production process. However, it doesn’t support 3D files or toolpaths.

- Cost: Free

- Intended purposes: Machine control and G-code generation with OpenBuilds CAM

- Notable features & functions: Possibility of streamlining the CNC machining experience by having both OpenBuilds Control and CAM work together, beginner’s tutorial video available on the OpenBuilds YouTube channel

- Operating systems: Windows, Linux, Mac

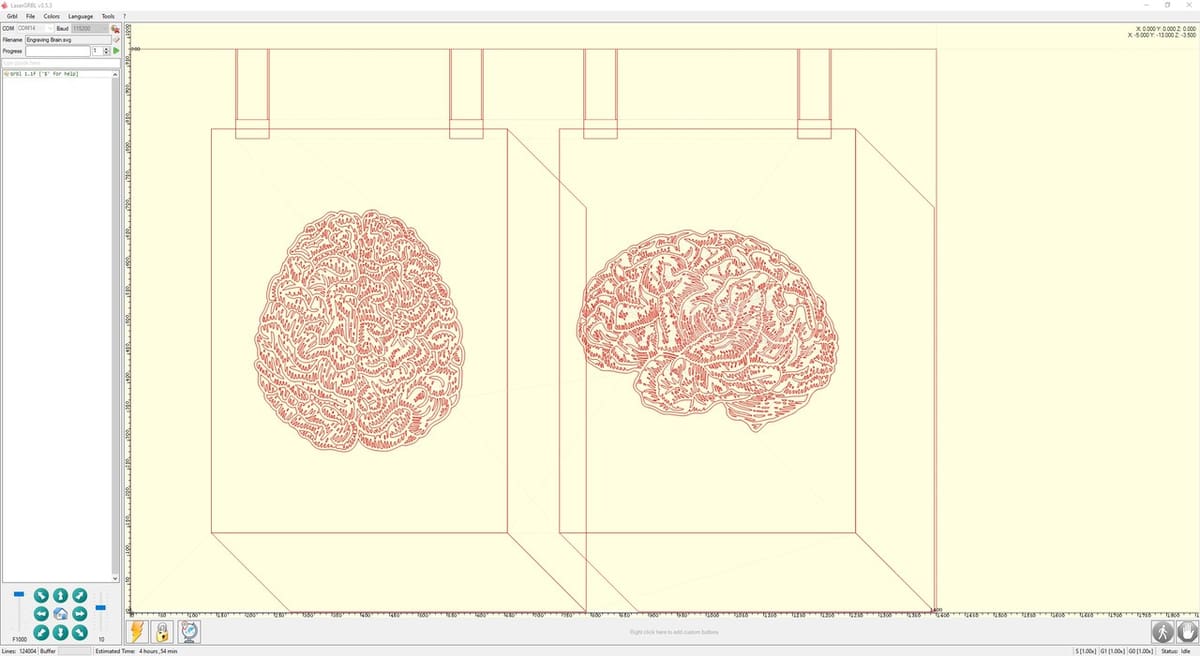

LaserGRBL

LaserGRBL is a CNC control program and G-code generator that’s unique on this list as it’s specifically designed for laser engravers. In order to be compatible with your CNC 3018, your machine will need to be equipped with a diode laser engraver toolhead.

With this software, you can use images and vector designs to easily create laser engraved items. The software automatically converts your images and designs into G-code, then runs them on your machine. Additionally, it has many options to customize your projects, from rastering images to cutting functional pieces – though cutting power is extremely limited with diode lasers.

- Cost: Free

- Intended purpose: CNC control, G-code generation

- Notable features & functions: Compatible with GRBL firmware, laser cutter control, well documented and open source, simple interface

- Operating system: Windows

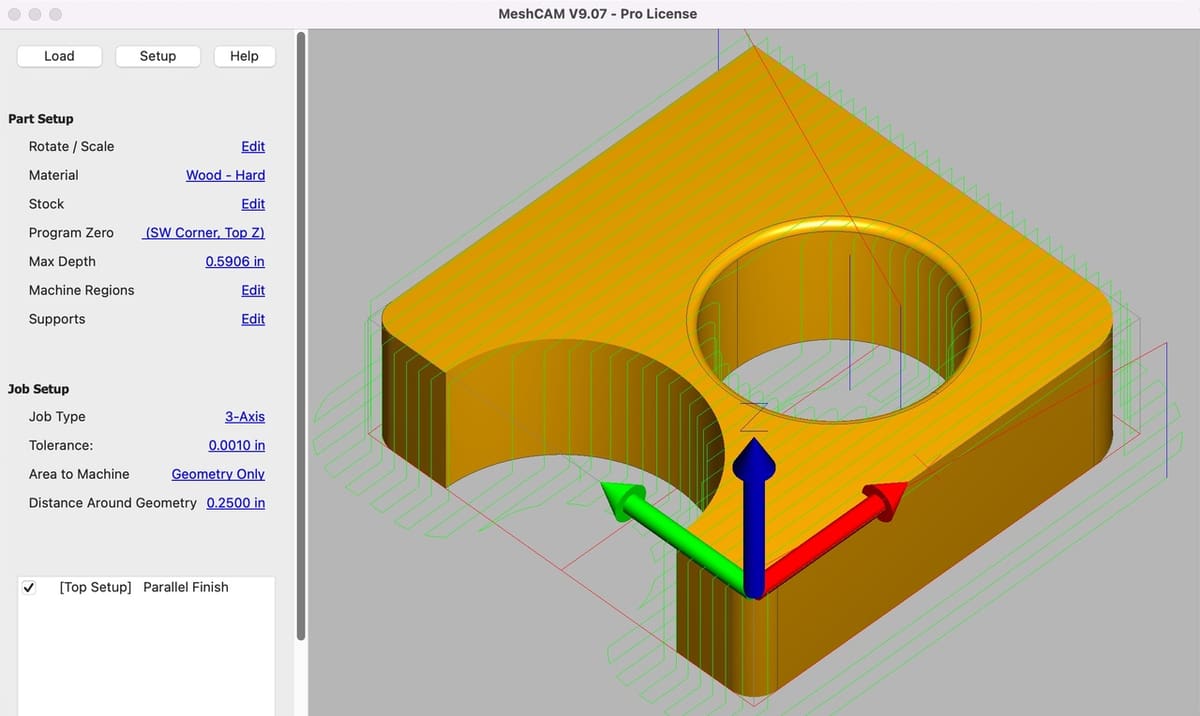

MeshCAM

MeshCAM is simple and straightforward software designed to create G-code files to get your CNC machine up and running quickly. It works with STL and DXF CAD files, as well as image formats like JPG, BMP, and PNG. Ideal for beginners, MeshCAM automatically selects reasonable speeds and feeds based on the toolpath and cutter you choose, reducing the need for manual adjustments.

This makes it perfect for novice users looking to create CNC projects without a steep learning curve. Available in both Standard and Pro versions, it’s worth noting that simulation is only included in the Pro version. MeshCAM offers a user-friendly solution for CNC milling projects, whether you’re working with 2D images or complex 3D models.

- Cost: Free 15-day trial; Standard $250; Pro $500

- Intended purposes: G-code generation

- Notable features & functions: Automatically sets reasonable speeds and feeds based on the cutter you choose and the toolpath that you’ve selected

- Operating systems: Windows, Mac

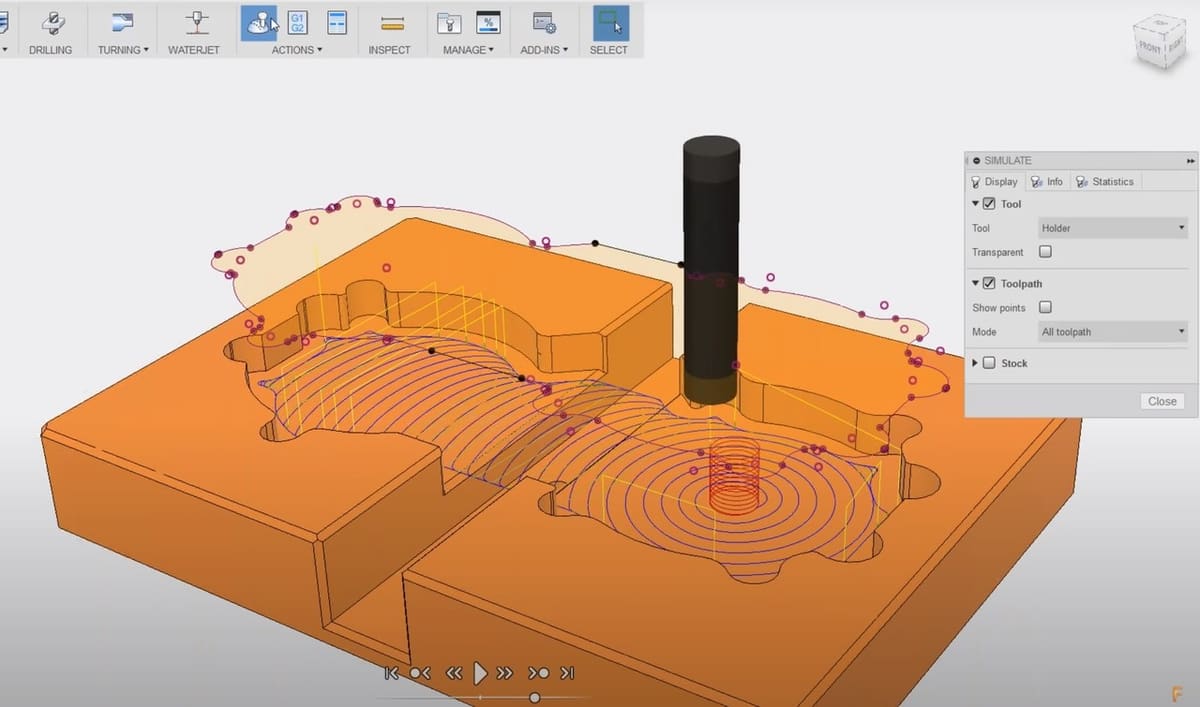

Fusion

Autodesk Fusion is a full CAD and CAM suite with tons of functionality. Many people already use Fusion to create designs for 3D printing. If you’re one of those people, it might be worth exploring the CAM side of the program for your CNC machine.

Although Fusion won’t run your device, it’s a very powerful tool for creating G-code for advanced projects. You can generate almost any cutting operation and create very complex parts.

This functionality does have its drawbacks, though. There are tons of settings to fine-tune, so learning to create the cutting operations takes a lot of trial and error. It’s probably best to consult a beginner’s guide when you start to experiment with Fusion’s CAM capabilities.

Given the steep learning curve with this software, it’s more appropriate for advanced users.

- Cost: Free for personal use – though some changes have been made to this

- Intended purpose: General purpose CAM and CAD

- Notable features & functions: Generates G-code (CAM/CAD), useful for designing parts, very versatile

- Operating systems: Windows, Mac

License: The text of "CNC 3018 (Pro) Software: The Best Programs" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.