Anything but Dull

As many know, “boring” can have two meanings: as an adjective, it means not interesting, whereas the noun refers to an incredibly interesting subtractive manufacturing method! Here, we’ll be covering the latter definition, and more specifically, its computer numerical control (CNC) version.

CNC boring is a technique that accurately enlarges a pre-drilled or cast hole. From kitchen appliances to construction, this method is commonly used in a variety of industrial processes.

In this article, we’ll talk more about CNC boring, how it works, where it’s used, and give you a couple of options for getting your very own CNC borer. Without further ado, let’s dive into the exciting world of boring!

What Is It?

CNC boring is the act of enlarging an already drilled or cast hole to a specific diameter. Because of its accuracy, it’s often preferable to drilling.

This process is mainly accomplished with machines like lathes, boring mills, and jig borers, and they come in many different forms, such as horizontal, vertical, and even material-specific machines. Boring jobs for smaller workpieces tend to be on a lathe while boring jobs for larger workpieces are carried out on boring mills.

How Does It Work?

To achieve the right size hole, a boring machine’s head will slowly move into the hole that was pre-drilled or cast, gradually scraping away at the outer walls in a controlled fashion. In turn, this results in a larger hole.

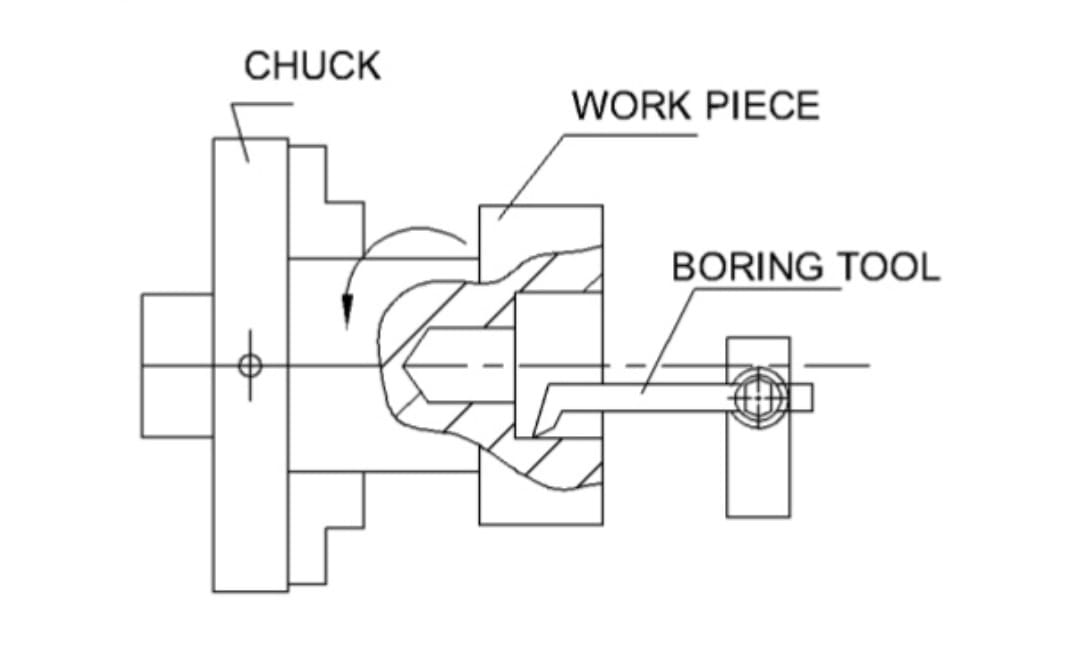

The main parts of a boring machine are:

- Chuck: A clamp that firmly holds the workpiece in place.

- Workpiece: The piece that’s being worked on by the boring machine.

- Boring tool: A tool that scrapes away at the outer walls of the hole.

These are similar to what’s used on both milling machines as well as lathes.

Where Is It Used?

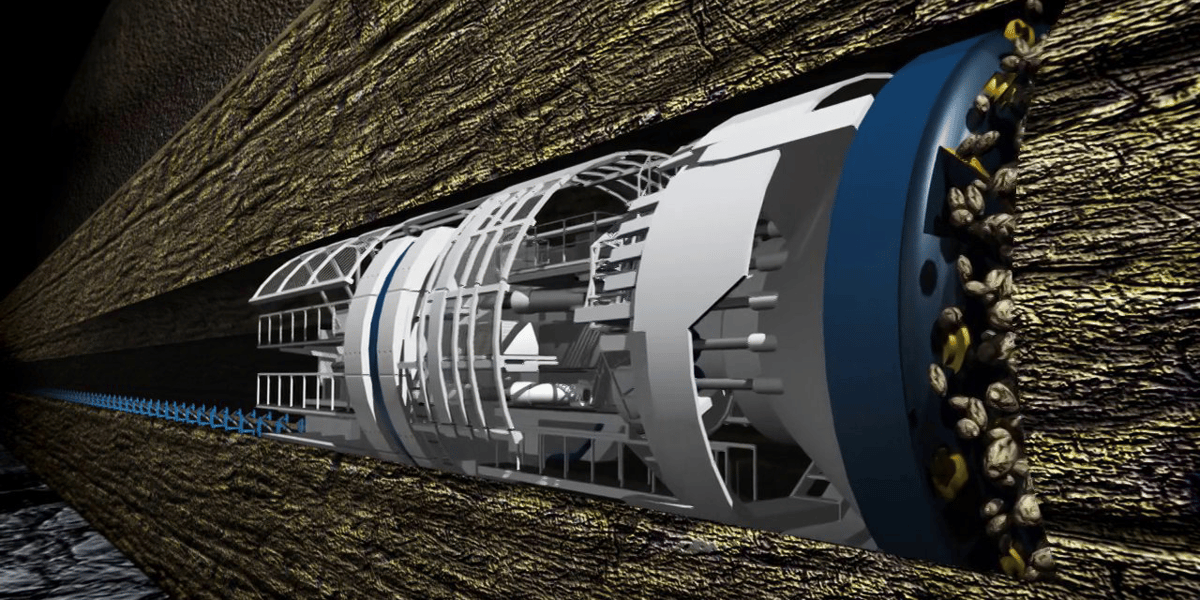

Industrial uses for CNC boring include jobs on assembly lines, such as boring holes for engine cylinders and screws, or even tunnel creation. Industrial CNC machines are in the price range of the $100,000s.

Many hobbyists also use boring in (smaller-scale) projects that require accurate holes for parts, such as bearings and dowels. The price of a CNC boring machine for a hobbyist ranges from a couple hundred to thousands of dollars.

If you’re looking for a hobbyist boring machine, here are two recommendations:

WEN Lathe

This is a great woodworking lathe for any kind of hobbyist, as it can fit workpieces up to 12 inches long and 8 inches wide. This machine has also earned Amazon’s choice for lathes.

Price: ~$169

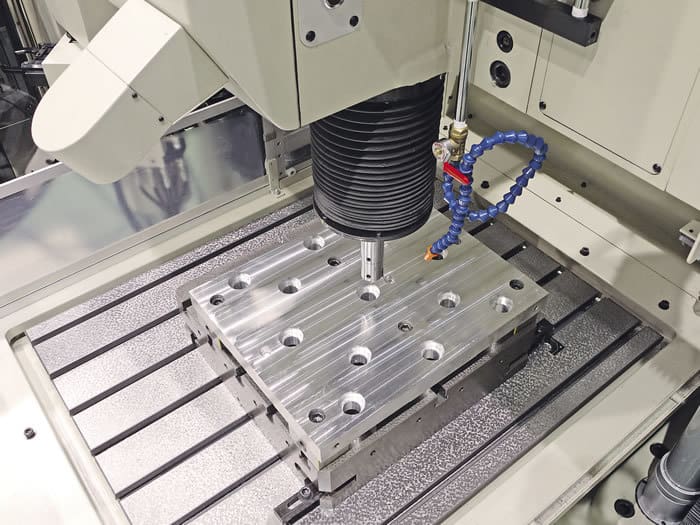

Proxxon Micro Mill

This mill is a popular choice among hobbyists because it’s quiet, precise, and vibration-free. It has a light and slim design that should be ideal for most spaces.

Price: ~$410

How Does It Compare?

There are many specific differences between boring and other CNC methods, but the most significant is that boring is far simpler than other methods, as it doesn’t require complex toolpaths.

Though it can have some complexity in certain applications, at its core (pun intended), boring is simply creating holes accurately. Also, boring only works with circles, and it isn’t practical to bore any other kind of shape, whereas other types of CNC methods, such as milling, can create almost any shape.

Lead image source: Rolingmetal via YouTube

License: The text of "CNC Boring: All You Need to Know" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.