3D printing is a versatile technology that can be an invaluable tool for countless projects. Sometimes, however, additive manufacturing just won’t cut it. That’s when CNC milling, a type of subtractive manufacturing, comes in. CNC machines can make large-scale parts out of wood, which would be impossible for a desktop 3D printer.

The ability of a CNC router or mill to create large-scale parts isn’t this technology’s only advantage. Milling parts out of wood allows makers to retain the wood’s natural beauty and strength. If you don’t know where to start, get inspired by checking out our list of the best sites for CNC wood designs!

Though CNC cutting and carving wood is quite incredible, not every machine is. But before we look at the machines, let’s figure out what we’re looking for.

Considerations

“Best” is a pretty non-descriptive adjective for the machines in this list. Let’s qualify the term by defining a set of criteria we took into consideration for whether or not a CNC machine made the cut.

- Value for money: Get the best cut for your buck! The quality of a CNC mill is determined by a variety of factors: the machine’s rigidity, components, motion system, spindle, and operating system, to name a few. A good CNC machine will bring the most features and the greatest quality for the lowest price.

- Small footprint: A larger machine will let you create a greater variety of projects. However, not everyone has a massive workspace, so the best mills will offer a larger cutting-space-to-footprint ratio. This means you can make big projects without wasting space.

- Range of materials: Naturally, all these machines can cut wood. However, it’s helpful to understand the material cutting capabilities of your machine so that you can anticipate how well it will perform with different materials, especially hardwoods.

- Easy to use: What’s the use of a machine that you can’t figure out how to use? A clean user interface, easy maintenance, and straightforward tool changing are all key to a machine’s ease of use.

- Active community and support: Comprehensive customer support and community feedback are extremely helpful in learning how to properly and successfully operate your woodcarver.

So, now that we know what we’re looking for, let’s take a look at some CNC machines for wood carving that are as incredible as the projects they’ll help you create! Note that the machines aren’t listed in any particular order.

Carbide 3D Shapeoko 4

Carbide 3D is known for not cutting corners when building woodcutting machines. They make their own electronics, design their own hardware, write their own software, and machine their own parts. The Shapeoko 4 (which replaced the Shapeoko 3) is one stellar result of all this in-house work.

The Shapeoko 4, like the 3, is available in three different sizes to fit in any workshop, including the huge XXL model that quadruples the cutting space of the original! The 4 is much more than an upgrade to the 3, however. It’s a cut above other options, with increased strength and stability. Carbide 3D has also introduced a hybrid table design that makes holding down cutting material a breeze.

Shapeokos come with everything you need to start cutting wood, plastic, and even aluminum. Assembly requires an hour or two and the detailed set-up guide outlines the remaining steps to turn a file into a finished part. If you get stuck, Carbide 3D is renowned for its outstanding customer support and the Shapeoko also has a huge community ready to wrestle through issues with you.

If you’re willing to spend a bit more, the Shapeoko Pro is also an extremely capable option, with increased performance that matches its price.

- Price: ~$1,700 (4), ~$2,050 (XL), ~$2,300 (XXL) (base prices)

- Cutting area: 17.5 x 17.5 x 4 in (4), 17.5 x 33 x 4 in (XL), 32 x 33 x 4 in (XXL)

- Materials: Plastic, woods, and soft metals (aluminum, brass, etc.)

- Quality: 0.05-mm dimensional accuracy

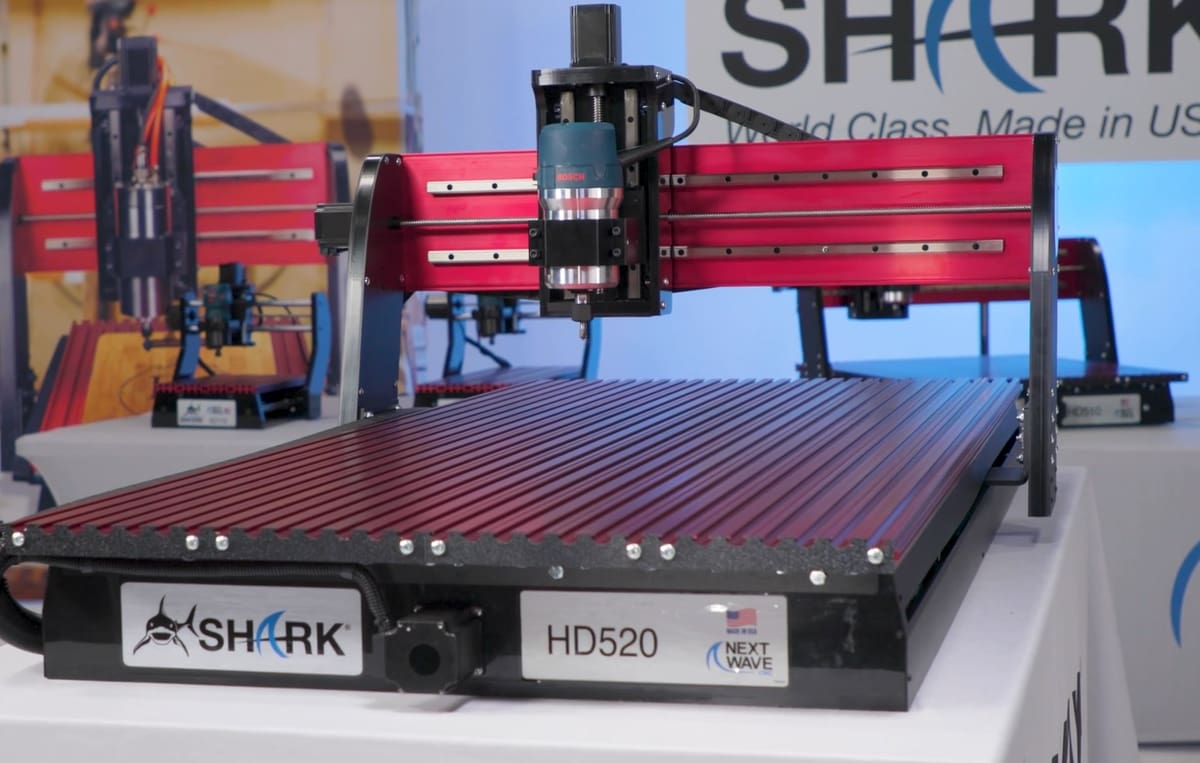

Next Wave Shark HD520

Next Wave Automation makes a wide variety of CNC machines that are quite popular among woodworkers. Next Wave claims that its machines, which are made in the US, are the world’s best, set apart for their reliability, accuracy, and durability.

The HD520 comes with a color touchscreen teach pendant, Vectric software, and an all-around workflow that’s a breeze to use. With the help of the many instructional videos, documents, and forum posts, plus personal customer support, you’re in good hands.

Next Wave’s CNCs have been used by companies like Tesla, Boeing, and GE. The three machines in the HD series are all ideal for wood carving, but the HD520 is the biggest, strongest, and fastest, which is why it’s made our list.

- Price: ~$5,000

- Cutting area: 25 x 50 x 7 in

- Materials: Plastic, woods, composites, and soft metals (aluminum, brass, etc.)

- Quality: 0.05-mm dimensional accuracy

Axiom Precision Iconic

The Axiom Precision Iconic series of CNC routers is indeed iconic. On their release, Axiom claimed that these machines would be “the new king of the entry-level CNC market,” and the user reviews actually seem to live up to the hype!

The company offers a CNC training program, which sets it apart from others on this list. Another perk is the USB port for file transfer, which eliminates the need for a tethered PC. A teach pendant controller also makes the CNC workflow even easier.

- Price: ~$5,000 (24 in), ~$6,000 (48 in)

- Cutting area: 24 x 24 x 4 in, 24 x 48 x 4 in

- Materials: Plastic, woods, and soft metals (aluminum, brass, etc.)

- Quality: 0.15-mm resolution

Sainsmart 3018 PROVer V2

Founded in 2011, Sainsmart’s mission is to provide innovative and accessible products for hobbyists, makers, and professionals. The company has surely made its mark in the DIY electronics and tools market with the Sainsmart 3018 PROVer V2, a newer upgrade to their best-selling line of desktop CNC machines, the 3018-PROVer.

This version cuts assembly time to 35 minutes, compared to 1 hour on its predecessor, the 3018-PROVer V1. It features an upgraded control board, an emergency stop button, and a silent spindle motor.

The PROVer V2 also includes an aluminum body and a Z-axis carriage for improved stability and accuracy. You can use it to engrave wood, plastic, acrylic, and soft metals for small to medium-sized projects.

Overall, the Sainsmart 3018 PROVer V2 is a robust machine, but many users have raised complaints over its unstable software. It reportedly runs itself into many system errors; hopefully, Sainsmart will fix this with future updates.

- Price: ~$270

- Cutting area: 11.8 x 7.1 x 1.8 in

- Materials: Wood, plastic, acrylic, soft metals

- Quality: ±0.1 mm dimensional accuracy

Sienci Labs Longmill MK2.5

Sienci Labs is a Canadian company founded in 2017 by Andy Lee and Chris Thorogood. High quality machines, community support, and continuous product improvement are at the heart of the company’s mission, and the Sienci Labs Longmill MK2.5 proves it.

This CNC router is robust and user-friendly with a rigid steel frame, high-torque stepper motors, and a modular design for easy upgrades. The machine comes in various sizes, catering to different project needs.

The Longmill MK2 is ideal for hobbyists and professionals working on woodworking, signage, and small-scale manufacturing projects.

The X motion produces a bit of noise, so beware of that if you’re working in an environment with close neighbors. During the first few runs, you’ll probably need to tweak a few things here and there, such as adjusting the router and tuning the gantry wheels. But if you run into any roadblocks, contact Sienci customer support, which many customers have described as helpful.

- Price: $1,360 to $1,900

- Cutting area: 12 x 30 in, 30 x 30 in, 48 x 30 in

- Materials: Wood, plastics, soft metals

- Quality: ±0.1 mm dimensional accuracy

Onefinity Woodworker

Onefinity might be new on the CNC scene, but its products are not to be disregarded. The company’s line of woodcutters is designed and tested in Canada and comes in two versions: Elite Woodworker and Woodworker Pro.

The Elite Woodworker is for users who need greater precision and advanced features. It has heavy-duty linear rails, ball screws on all axes, and a robust frame to ensure stability and accuracy while cutting.

To give you more bang for your buck, it comes with a high-resolution touchscreen controller, enhanced motor drivers, and connectivity options like Wi-Fi and Ethernet for easy integration with various software and accessories.

- Price: $3,500 to $4,200

- Cutting area: 32 x 32 in

- Materials: Wood, plastics, aluminum

- Quality (Dimensional Accuracy): ±0.02 mm

Woodworker Pro

For those who are not quite ready to go all out, the Woodworker Pro provides a more balanced mix of performance and affordability for demanding woodworking tasks. It features two possible spindle mounts to choose from, improved dust collection system, and reinforced frame for stability.

On the downside, because Onefinity doesn’t offer spindle support, you’ll need to contact a manufacturer if you want to add one to your machine. Also, it’s a good idea to keep pets and young children away from your setup as the unsupported round rails aren’t very effective.

- Price: $2,500 to $3,200

- Cutting Area: 32 x 32 in

- Materials: Wood, plastics, aluminum

- Quality: ±0.05 mm dimensional accuracy

Shaper Origin

Unlike other CNC routers on this list, the Shaper Origin stands out because it’s a handheld CNC router. Combining computer-guided precision with hand-held flexibility, it allows users to handle intricate designs and detailed cuts with ease.

The Shaper Origin features a touchscreen interface on which you can design a model directly. In only minutes, the device lets you scan your work surface, creating a map, which the Origin uses for precise positioning and tracking.

It continuously adjusts the router’s position within a defined tolerance to follow the design precisely, even if the user’s hand moves slightly off course.

One thing to keep in mind is that you can’t leave the Shaper Origin unattended to finish parts on its own. Cutting out parts requires a literal hands-on approach. Still, it’s perfect for items that are too big or just not practical to put on a traditional CNC router.

- Price: $3,200 to $4,000

- Cutting area: Only limited by the size of the workpiece and ShaperTape area

- Materials: Wood, plastics, aluminum

- Quality: ±0.1 mm dimensional accuracy

Maslow4

Although the original Maslow CNC machine was a hit, it was later discontinued. It’s now been redesigned from scratch through a successful Kickstater campaign, known as the Maslow4, and is now available.

This machine includes a chain-driven system that moves the router over a large work area, a new frame design for enhanced stability, and an upgraded control system that improves the accuracy and reliability of cuts. And the best part is it’s still open source, allowing for customization and modifications based on user needs.

It’s the go-to machine for large-scale projects, such as cutting full sheets of plywood for furniture. If you work in a small workshop or garage, the machine’s vertical orientation will also save you tons of floor space.

- Price: ~$525

- Cutting area: 1.2 x 2.4 m (4 x 8 feet)

- Materials: Wood, plywood, MDF

- Quality: ±0.5 mm dimensional accuracy

OpenBuilds Lead 1010

The OpenBuilds Lead 1010 enables makers to customize and improve an already impressively capable CNC mill. The Lead 1010 is constructed completely of regular V-slot extrusions and mounting components. You can even buy each component of this machine individually, including the motors, control system, and accessories.

Basically, this machine is built to be hacked and to fit in nearly every budget, so it’s an extremely versatile option. If you don’t want to buy a dust collection system or motors from the store, for example, you can build or source your own. OpenBuilds also offers a variety of upgrades such as a high-Z mod, a table, and an enclosure.

Your experience with this machine is what you make of it and which upgrades you buy. With all the bells and whistles, such as the dust shoe, leveling block, control system, and software package, this machine will help you create some impressive projects with ease.

Being open-source, the OpenBuilds community is enormous and always ready to help. All the part files and software are available for free, and customer support is also available via phone or email.

- Price: $1,400 to $4,000

- Cutting area: 29 x 32 x 4 in

- Materials: Plastic, woods, and soft metals (aluminum, brass, etc.)

- Quality: 0.05-mm dimensional accuracy

BobsCNC KL744

This next router stands out from the rest of the machines on this list. Instead of exhibiting an aluminum frame, the KL744 sports a frame composed entirely of 12-mm 9-ply Baltic birch plywood.

Despite its unusual appearance, the KL744 produces incredible wood carvings that rival traditional, higher-end CNC mills. While it may not be the best machine for milling precise parts, especially with hard materials, it’s perfect for making wooden engravings and carvings.

BobsCNC is renowned for helpful customer service and an enthusiastic user community. The simplicity of this machine’s design contributes to its being a wonderful beginner machine. However, do expect a tedious, involved assembly.

- Price: $3,500 to $5,900

- Cutting area: 48 x 48 x 5 in

- Materials: Plastics and woods

- Quality: 0.05-mm repeatability

License: The text of "10 CNC Wood Carving & Cutting Machines We Recommend" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.

CERTAIN CONTENT THAT APPEARS ON THIS SITE COMES FROM AMAZON. THIS CONTENT IS PROVIDED ‘AS IS’ AND IS SUBJECT TO CHANGE OR REMOVAL AT ANY TIME.