Nesting is a method for arranging parts to minimize cutting time and material waste. Imagine using the outline of your hands to cut out parts. Hold them side by side and look at the space they fill. Now interlace your fingers and watch how the space shrinks. That’s nesting, and while the idea seems simple, the algorithms needed to figure it out have been around for around 80 years.

Nesting started with the “rucksack problem”: determining how to pack the most odd-sized objects into a fixed space. Think about packing for a long trip when you can only bring one piece of carry-on luggage, or a shipping clerk at Amazon trying to find the smallest box that holds your order.

Nesting algorithms can also solve the “best fit” problem. Imagine trying to figure out how to cut a group of random length pieces out of fixed-length boards, bars, or extrusions to minimize waste. Extend this to high-volume manufacturing, and the need for nesting tools becomes evident.

The main purpose of nesting is to work more efficiently by either decreasing the amount of waste material by filling the space in the best manner or by producing more parts per minute from reduced travel time between parts.

In this article, we’ll talk about the various ways to achieve this.

Greater Efficiency

Nesting can do more than just juggle objects on a 2D layout. Different tools allow you to minimize the travel of a hot end or CNC cutter, share a common cut line across multiple parts to eliminate skeletons, and cram multiple parts into the working volume of a 3D printer. Expensive tools and skilled laborers help make nesting critical to production efficiency and cost savings.

If you work with subtractive CNC (routers, milling machines, laser cutters, waterjet, or plasma cutters), you’ll benefit from 2D nesting, especially if your workflow supports SVG files. Additive manufacturing, such as 3D printing, can also benefit, but at the cost of a much higher learning curve and more complicated software.

How It Works

The simplest nesting packages draw an imaginary box around each object, juggling these rectangles to minimize waste. More elaborate solutions offer profile or shape nesting (working with the actual shapes rather than the overall rectangle where they fit), or embedding (where an empty space inside a shape is filled with another shape), taking into account odd shapes and subtle opportunities to fit them together.

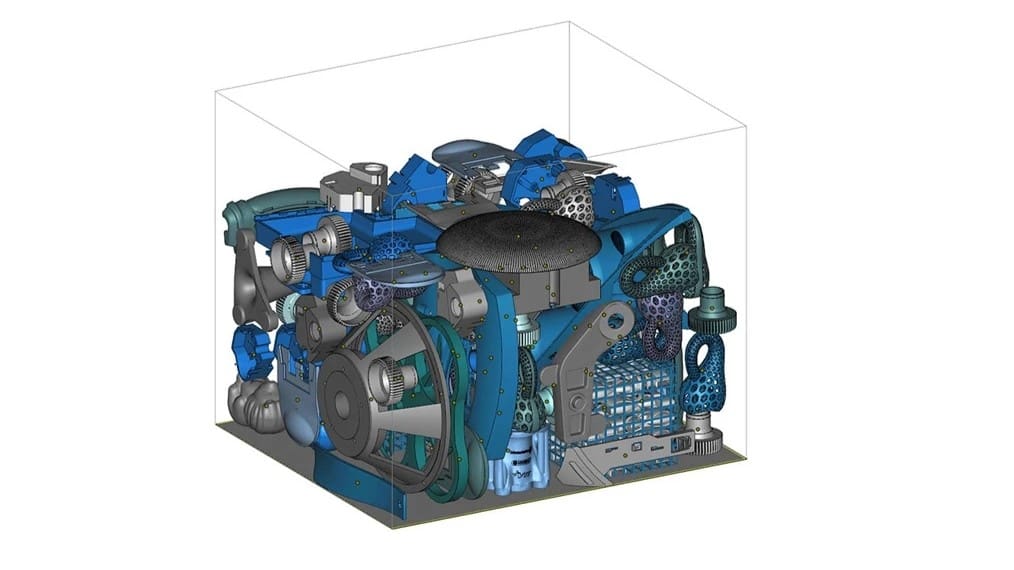

They may also work in 3D rather than 2D. Having the additional axis in place adds functionality for additive manufacturing, at the price of far more complexity.

The higher-end tools add priority (cut the most important parts first), shared edges (one cut line for multiple parts), and travel time minimization. After all, a cutter that isn’t cutting isn’t making you money.

Another important concept is static versus dynamic nesting. Static nesting software fits a specific set of objects into the smallest space. Dynamic nesting picks and chooses from a list of potential parts depending on the size and shape of the raw material.

When Does Nesting Happen

Nesting fits into the workflow between design and machining. Once you’re satisfied with your part diagrams, feed them to the nesting software, which rearranges everything into a tighter and tighter formation. You tell the software how long to optimize and the nesting algorithms arrange and rearrange, calculating the total material needed after each pass. The pass with the least material is saved and handed back to your workflow for CAM conversion to G-code.

Different nesting CNC tools may require SVG, DXF, DWG, IGES, or DSTV files. It’s wise to validate input and output formats with the software vendor.

Nesting Software

Below are a few common and popular nesting software options.

Deepnest

Deepnest is an open-source nesting product, in this case optimized for laser, plasma, and water jet cutters. It runs on Windows, Mac, and Linux. It reads DXF, SVG, and CDR files, and writes to DXF or SVG. It offers cut-line merging and part-in-part layouts to maximize material use and minimize cutting time.

Running Deepnest in the background while you work on designs or other projects is a possibility, however it will slow your computing power by using up some CPU resources.

SVGnest

SVGnest is free open-source software available for download from GitHub. Described as a browser-based vector nesting tool, the software claims to work as well as existing software already established in the industry. It’s worth noting that it’s limited to SVG inputs and outputs.

Sintratec

Sintratec is software designed for SLS lasers, which means that it has to operate on three axes. This adds another layer of processing, so a relatively powerful computer is needed to run this in a usable time frame. The results are worth it if you’re running SLS 3D printers for industrial or commercial reasons.

Sintratec has a cost associated (the single-user license that includes two nesting options is ∼$1,500), but depending on how much nesting you need to do, it can definitely be worth the expense.

Integrated Nesting

There are also some options for those who need more than nesting, although these carry the price tag to show it.

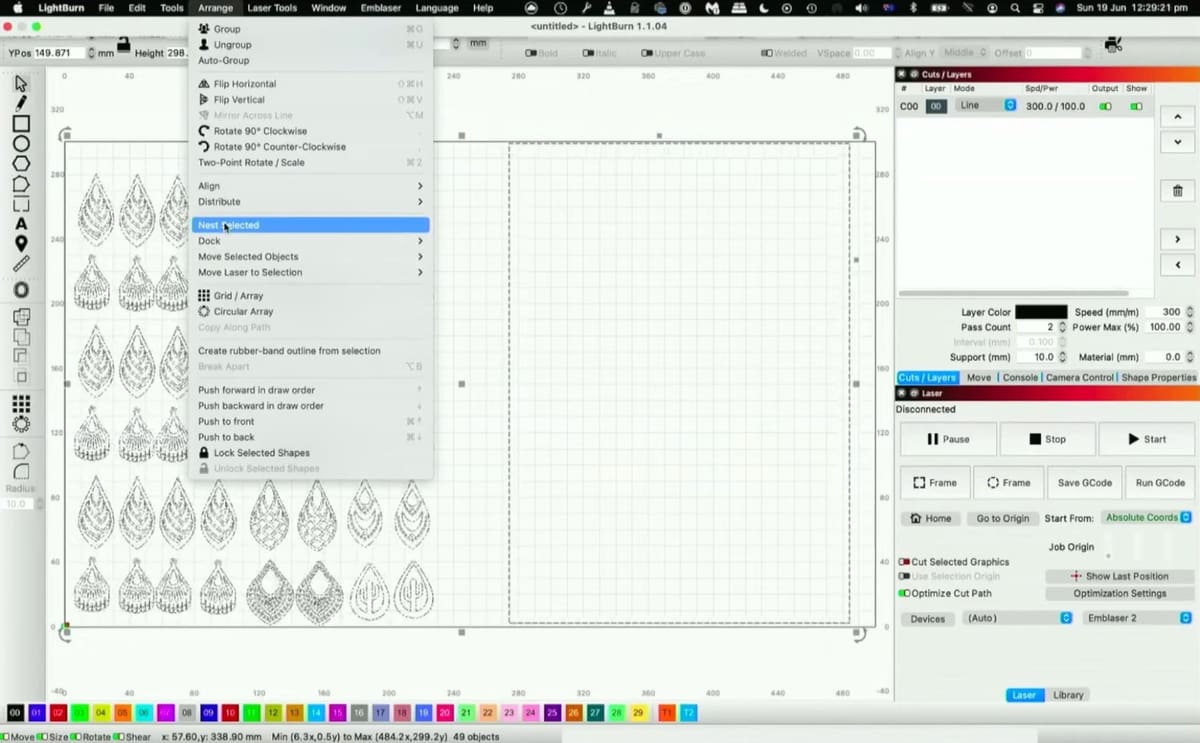

LightBurn

LightBurn is paid CAD software (ranging from ∼$60 to ∼$200, depending on your setup), specifically designed to control CO2 and fiber lasers. In recent versions, it has integrated a version of SVGnest. This allows you to complete your designs in the software, then a quick conversion allows you to set up the nesting properties.

VCarve Pro

VCarve Pro is one of the most popular CNC router software packages and it has a great nesting option built in.

Its ∼$700 tag reflects the software’s place in the industry, and the download can be big on your hard drive when you compare it to the web-based options that we previously mentioned, but once the designs are ready to go, a few button presses allow you to maximize the material usage based on things such as cutter width and angle.

In Closing

Nesting brings two important benefits to CNC operations: It reduces waste and saves time. Tools include simple open-source file import/export workflows to multi-user large-scale production tools.

Keep in mind that 3D nesting is a far more complex problem, especially when supports, sintering shrinkage, bridging limits, and other technical limitations are taken into account. There are many more 2D options, especially at the hobbyist and lower production levels.

We’ve explained how the tools work and a little about their workflow requirements. With open-source options at the cost of a download, there’s no risk in trying some nesting in your next project.

License: The text of "CNC Nesting (CNC Cutting Method) – Simply Explained" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.