To anticipate any problems that may occur both with traditional machining tools and newer additive manufacturing machines, such as 3D printers, it’s useful to simulate machine operations prior to production. CAM software, like Autodesk’s Fusion 360, will often be able to simulate a CNC job prior to post-processing, but it often won’t read already-programmed G-code. This is where computer numerical control (CNC) simulation software comes into play.

CNC simulation tools are mathematical applications designed to predict the behavior, performance, and outcomes of certain manufacturing processes. They provide the means for testing and verifying the CNC program before the instructions are sent to the machine.

From verifying code integrity to preventing any issues that could damage physical components, CNC simulation tools offer insights into how the whole process can be optimized. With that said, there are several types of CNC simulation tools available that focus on different aspects.

In this list, we’ll focus on simulation tools capable of verifying post-processed G-code regardless of how it was created, making for a broader solution that can work virtually with any code generation method. We provide different alternatives that represent the diversity of this type of software. From multi-functional to streamlined, there’s a solution for everyone. Let’s dive in!

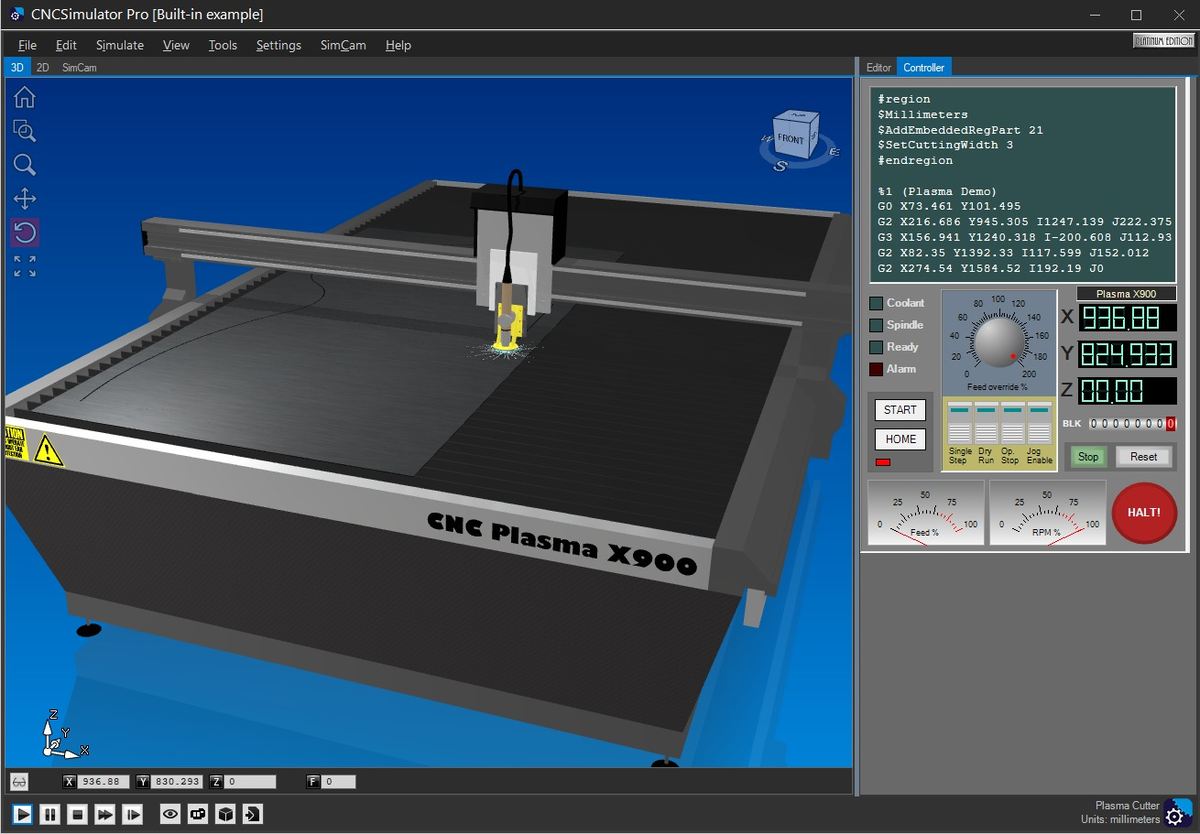

CNC Simulator Pro

CNC Simulator Pro is a popular program that’s been around since 2001. It’s a powerful – yet not overly complicated – tool with enhanced 3D visualization and support for different machines (turning, milling, routing) and processes (laser cutting and 3D printing).

In addition to editing and simulating G-code, the software includes CAD and CAM capabilities with its built-in SimCam package. Given CNC Simulator’s various features, it’s an all-in-one solution for most CNC user demands. That said, it does require an active internet connection to work.

A comprehensive online learning center offers extensive user support, including various tutorials and training programs. Upon registering for the first time, users will have access to a 30-day trial of the full version before needing to pay for a license.

- Operating system: Windows

- Type: Online

- Price: 30-day free trial, ~$100 per year subscription, ~$535 for a perpetual license

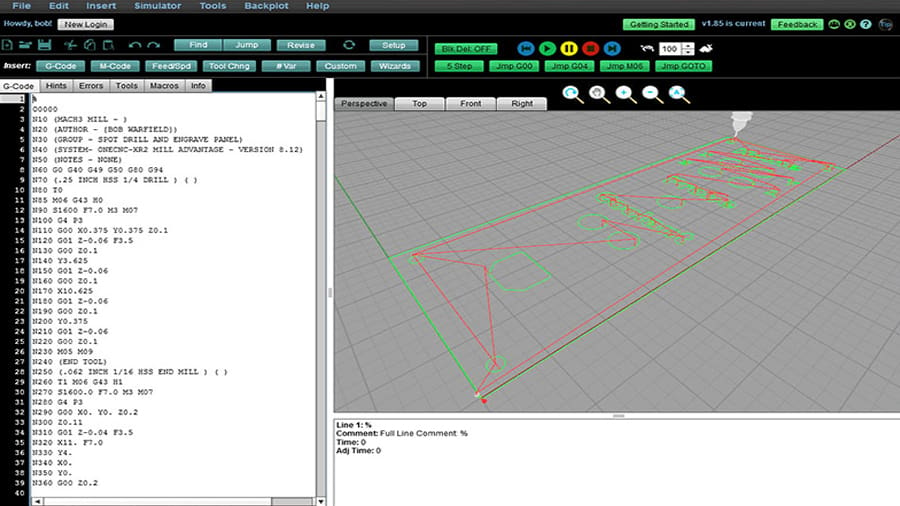

G-Wizard Editor

G-Wizard Editor is a G-code simulator and editing tool that’s primarily used for checking, modifying, and writing CAM-generated code. The so-called “conversational programming” feature is an interactive way to write G-code with descriptive images in a fill-in-the-blanks manner. It also features rich code error-checking tools that clarify glitches instead of just pointing them out.

The software is both a useful learning tool for beginners and a flexible light solution for more experienced users. An internet connection is required during installation and only once every 28 days thereafter. Though G-Wizard Editor is a paid program, a 30-day free trial is available.

- Operating systems: Windows, MacOS

- Type: Offline

- Price: 30-day free trial, ~$100 per year subscription, ~$300 for a lifetime license

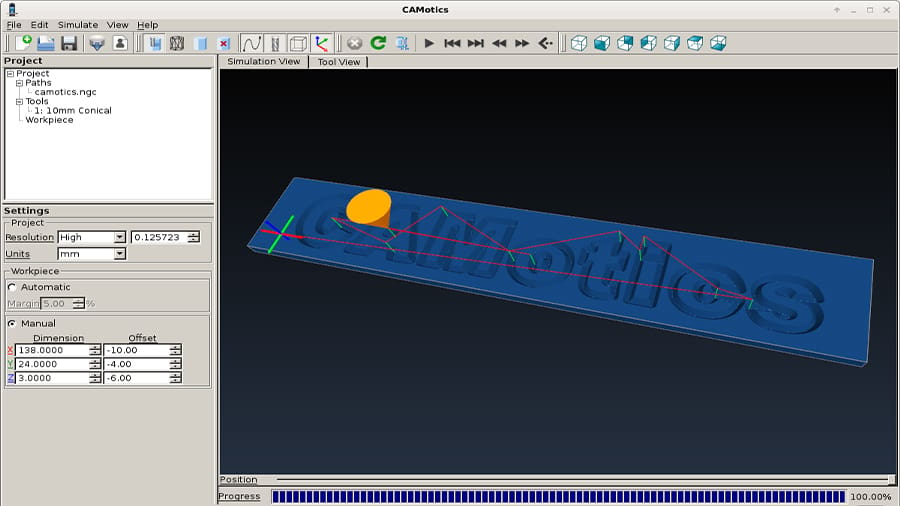

CAMotics

CAMotics is an open-source G-code and toolpath simulator aimed at the maker community. Since its release in 2011, the software has amassed a broad, active user community. Running on Windows, MacOS, and Linux, it’s one of the few complete cross-platform simulation tools out there.

The program supports up to 3-axis simulation in a 3D environment and offers special functionality for certain tasks, like engraving and PCB board cutting. Overall, CAMotics is a straightforward and efficient simulator that gets the job done. It’s user-friendly, suitable for everyone regardless of previous experience, and – the best part – it’s completely free (though donations are welcome)!

- Operating systems: Windows, MacOS, Linux

- Type: Offline

- Price: Free

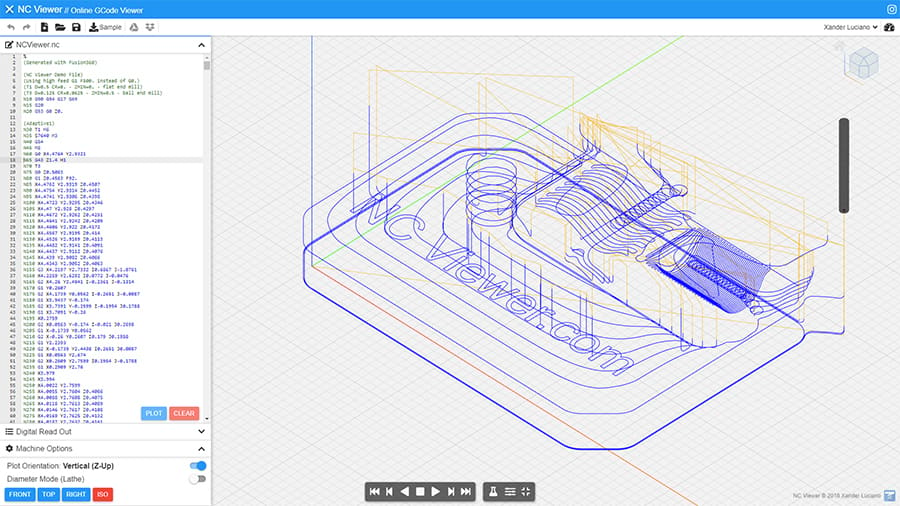

NC Viewer

NC Viewer is the only browser-based CNC simulator on this list. It’s essentially a toolpath simulator with a clean interactive 3D environment. Although it doesn’t offer as many features as other simulation tools, it’s useful for verifying, viewing, and back-plotting CNC G-code.

It goes without saying that the program requires an internet connection at all times. For those using Fusion 360, there’s a plug-in that embeds the NC Viewer and facilitates the live viewing of external NC files. Both the web-based and plug-in programs are completely free.

- Operating system: Browser-based

- Type: Online

- Price: Free

Eureka G-Code

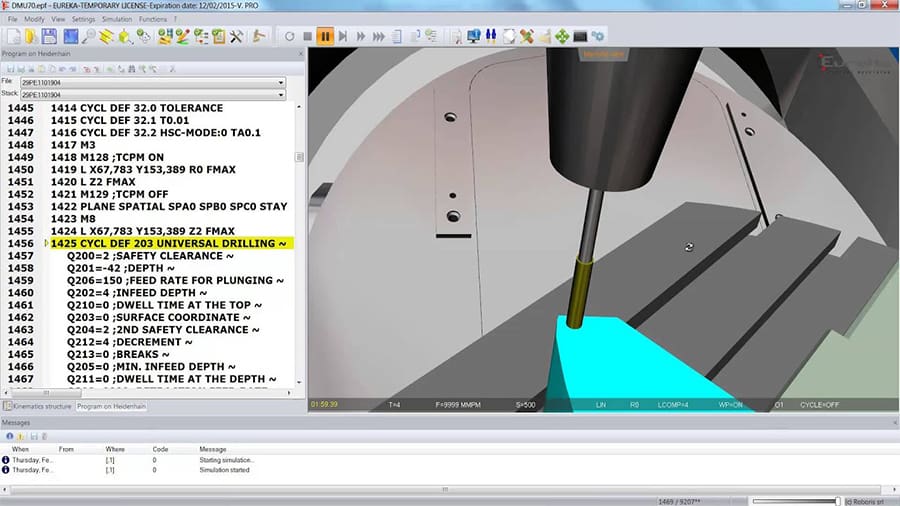

Last, but definitely not least, Eureka G-Code is a realistic machine simulation program by the Italian company Roboris. The company specializes in machine simulation, where Eureka G-Code is part of a broader software suite that includes other powerful tools, including a multi-axis simulator for additive manufacturing and a module that optimizes G-code via AI.

As advertised, Eureka G-Code not only verifies G-code commands and other CNC controls, it also analyzes the machining results to reduce production time and remove potential mistakes. It can simulate any number of axes and heads as well as allow for tool head changes. Additionally, the program integrates with most CAD tools, which facilitates simulation workflow.

- Operating system: Windows

- Types: Online (cloud-based) and offline

- Price: Price on consultation

License: The text of "The Best CNC Simulators (Online & Offline)" by All3DP is licensed under a Creative Commons Attribution 4.0 International License.