What It Is

A CNC water jet is an industrial tool that uses a high-pressure water jet to cut various materials. It can use water alone to cut soft materials like wood and rubber, or the water can be mixed with an abrasive substance (like garnet or aluminum oxide) to cut harder materials.

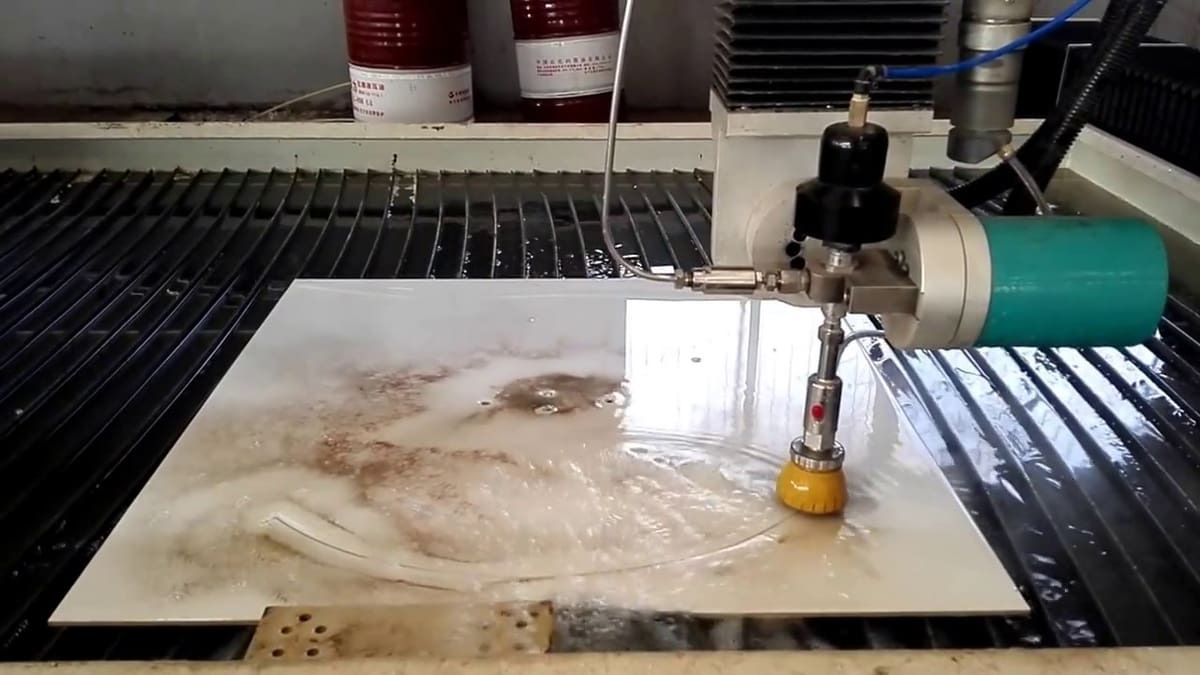

To reduce noise and splash, the actual cutting is typically done underwater, and the water pressure is usually between 20,000 to 55,000 PSI (pounds per square inch), or 50,000 to 60,000 PSI. Think of a CNC water jet as having around 30 times more pressure than a power washer yet channeling the spray through a narrower jewel nozzle (usually around 0.010” to 0.015” in diameter) to keep it consistent. This jewel nozzle is selected specifically for its corrosion resistance.

Water is normally introduced into the CNC water jet unit using a pump and filter. The filtering process is crucial because only clean water can attain the ultra-high pressure needed to create a consistent cutting stream. Filtering also protects the high-pressure parts; though in some cases, a water treatment system may be required if the water contains harmful minerals.

Having compounds in the water can lead to premature corrosion, which can cause damage to the pressurized components. Also, having minerals like magnesium salts, calcium, chlorides, and sulphates result in decreased high-pressure seal, which means you may have to use a water softener.

Each water jet system has specifications for the size of particles that it can handle, and most manufacturers will point out the filtration required to protect components. To know the suitability of your water supply, look at the TDS (total dissolved solids) content of the water. TDS is simply the sum of all material – organic and inorganic – dissolved in your water supply. Some water jet manufacturers suggest using Reverse Osmosis where the TDS exceeds a certain level.

Note: Water pre-treatment is not always required if the TDS is within manageable levels (normally at or below 250 ppm). As long as the water is within the allowable TDS levels, it is okay to use the water – whether in a water-only or abrasive waterjet.

How It Works

Think of a CNC water jet as a tool that accelerates “erosion”. It’s more of a non-thermal mechanical sawing process that works like a bandsaw to cut materials. The nozzle directs a thin stream of high-speed water – sometimes containing sharp pieces of rock – to bombard the material being cut. This nozzle is usually connected to a high-pressure water pump that supplies it with sufficient pressure.

The rock pieces, if present, are usually pieces of garnet, which is a type of hard rock commonly used in sandpaper. Other materials may be used, but garnet has always been a favorite choice for cutting metal plates in particular.

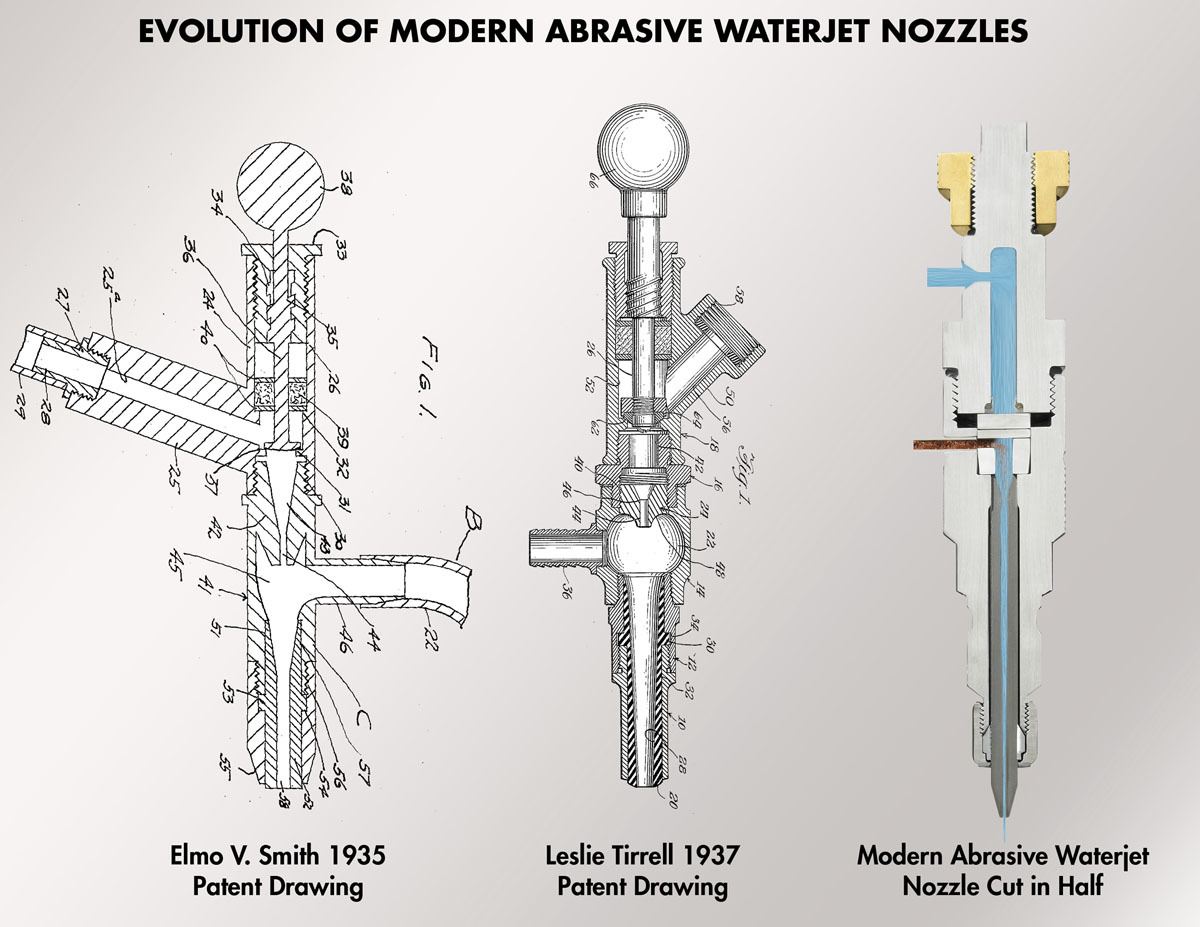

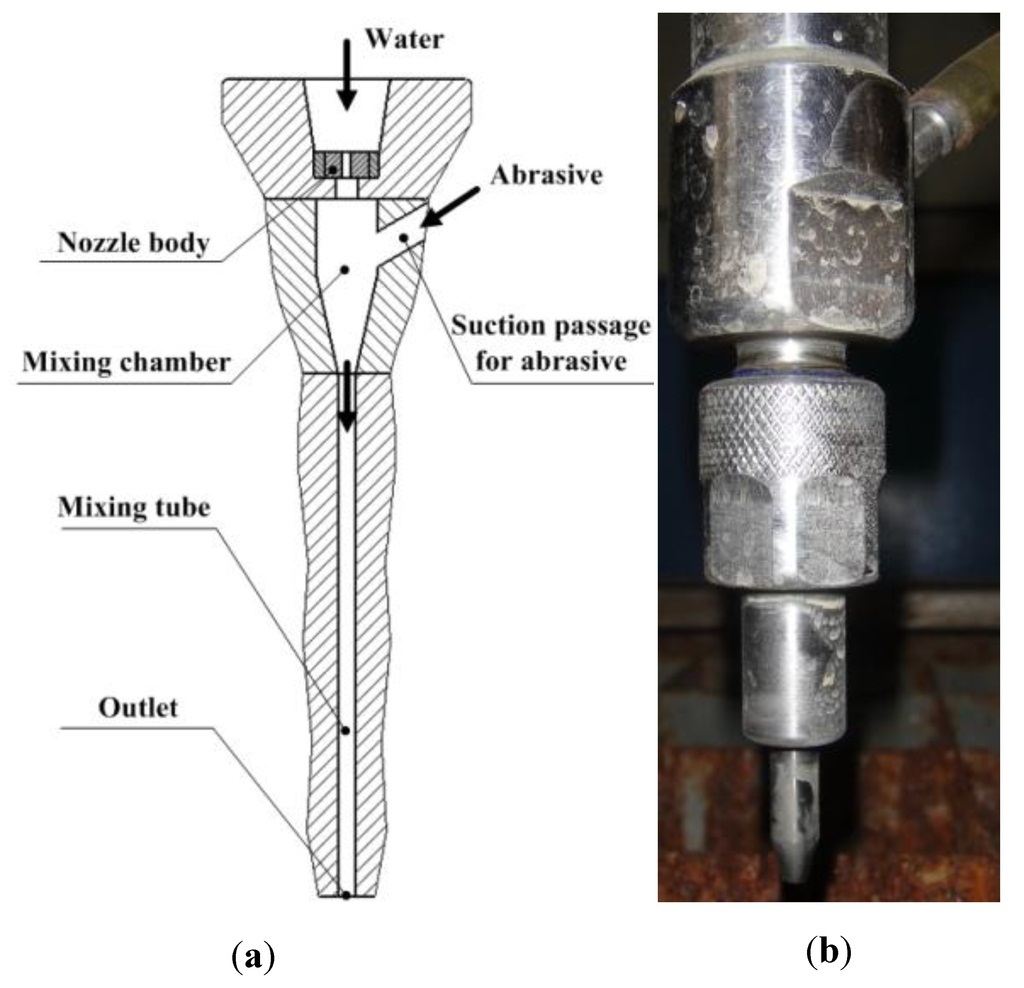

At the nozzle, the stream is directed through a tiny jeweled opening, resistant to abrasion, which focuses it into a fine “needle”, thus creating a highly efficient and powerful cutting tool operating at 2 to 3 times the speed of sound.

Put Simply

The first step is to generate pressure with the help of a high pressure pump that can go beyond 6,000 bar. The second step is to convert this pressure into velocity via a small-diameter orifice. The last step (optional) is the introduction of garnet, which increases the cutting power by 1,000 times.

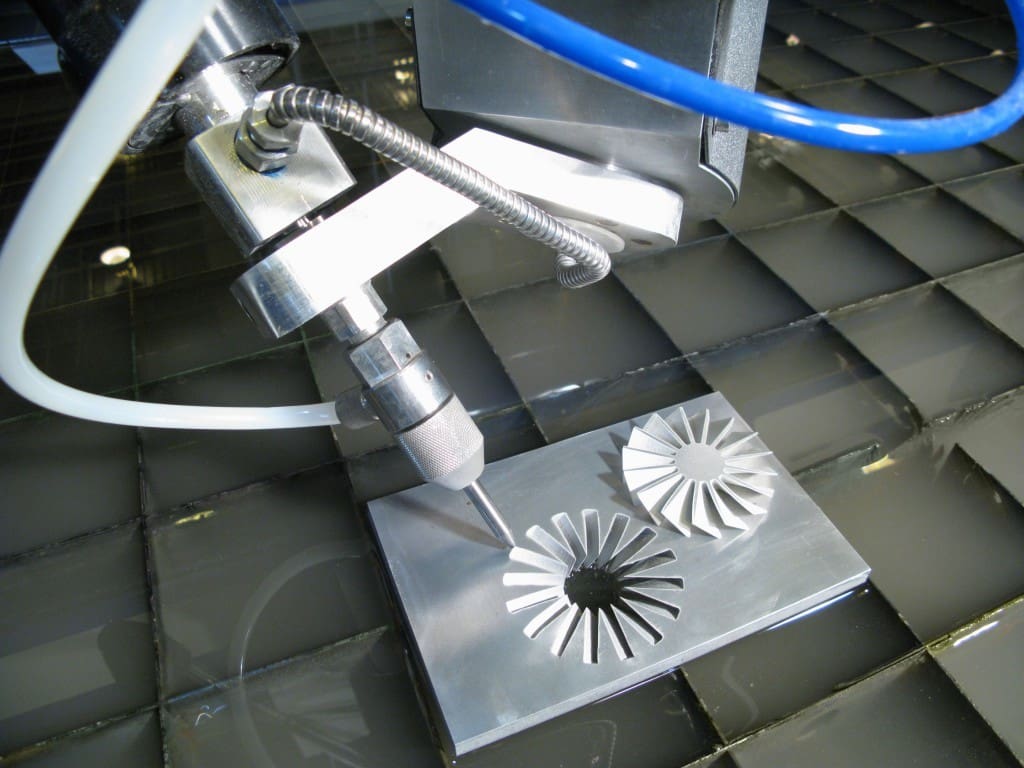

Interestingly, the nozzle can also be integrated into multi-axis motion equipment where the cutting head is typically mounted on a robotic arm. For instance, a 5-axis water jet is capable of cutting bezels and contours by controlling the angle of the cut. Such results can, of course, be produced using traditional methods like angle grinding, but using a water jet significantly reduces the noise created in the process, among other benefits.

Adding Abrasive

A CNC water jet can also operate with the help of additives and abrasives like aluminum oxide or garnet, which are known to enhance the cutting process.

The mixing of abrasive into the stream happens inside the water jet cutting head. Typically, the high-velocity water stream creates a vacuum that draws a metered amount of abrasive into a mixing chamber to produce a powerful jet stream. Once abrasive has been added, the water jet – now carrying abrasive particles – will exit the focusing tube as a supersonic water stream carrying with it the abrasive that wears through materials like glass, steel, and granite.

Any heat resulting from this process will be “quenched” by the stream of water before it gets to heat the surrounding. Besides the lack of heat, the momentum of the stream ensures the particles are moving in a straight line after exiting the nozzle, and this results in a super straight and accurate cutting edge for several materials.

Abrasive water jet cutting is meant for hard materials that cannot be cut using pure water – like stone, metal, synthetic ceramics, and composites. However, some materials cannot be cut successfully using a CNC water jet at all. One of them is tempered glass, which shatters when any cutting attempt is made.

Pros and Cons

One of the main benefits of using a CNC water jet is that it has the capability of cutting materials without interfering with their inherent structure, and this is mainly because there is no “heat affected zone” (HAZ). This feature makes it easier to cut metals without altering their intrinsic properties and is helpful when the materials being cut are sensitive to the high temperature associated with other cutting methods.

Other benefits:

- Can cut complex shapes

- Can cut heterogenous materials

- Cuts hard materials like stainless steel and hardened steel

- Provides high precision cutting

- Dust-free, odorless, and relatively heat-free

Cons:

- Longer cutting time than with traditional cutting systems

- Expensive process, being out of reach for the regular DIYer

- Not effective for cutting very thick materials as it will present many problems in maintaining dimensional accuracy

Availability

Abrasive water jets are fairly new and are a means of replacing traditional processes like slitting, gear cutting, drilling, profile milling, broaching, and sawing in the automotive mining, and aerospace industries. The ballpark price for a 2-axis abrasive system should be somewhere between $100,000 and $200,000, while a water-only CNC water jet should be in the $50,000 and $100,000 range.

Some well-known CNC water jets include:

- Kimla Streamcut waterjet

- ACCURL 3D waterjet cutting machine

- WAZER (The First Desktop Waterjet Cutting Machine)

- Aqua Hornet 1000 CNC

- TECHNI waterjet

- LiSEC MRX-B

Feature image source: ant-ag.com